OVEM-... -05-...-

GN

-07-...-

GN

-10-...-

GN

-14-...-

GN

-20-...-

GN

-30-...-

GN

-05-...-

GO

-07-...-

GO

-10-...-

GO

-14-...-

GO

-20-...-

GO

-30-...-

GO

- Exhaust port 2 3 3 4 4 5 5.5 6 6 7 9 11

Tab. 11 Minimum inside diameter of the connection tubes for connections with G-

female thread

Notes on the pneumatic connection

– Maximum permissible tube length 2 m

– OVEM-...-GN/-GO: minimum inside diameter of the connection tubes

è Tab. 11 Minimum inside diameter of the connection tubes for connections

with G-female thread.

– Do not seal exhaust port.

– OVEM-...-07/-10/-14/-20/-30: If necessary, lengthen silencers with a silencer

extension èwww.festo.com/catalogue.

– Recommendation: Use type PUN tubes èwww.festo.com/catalogue.

7.2 Electrical installation

WARNING!

Risk of injury due to electric shock.

• For the electrical power supply, use only PELV circuits in accordance with IEC

60204-1/EN 60204-1 (Protective Extra-Low Voltage, PELV).

• Observe the general requirements of IEC 60204-1/EN60204-1 for PELV cir-

cuits.

• Only use voltage sources that ensure a reliable electric separation from the

mains network in accordance with IEC 60204-1/EN 60204-1.

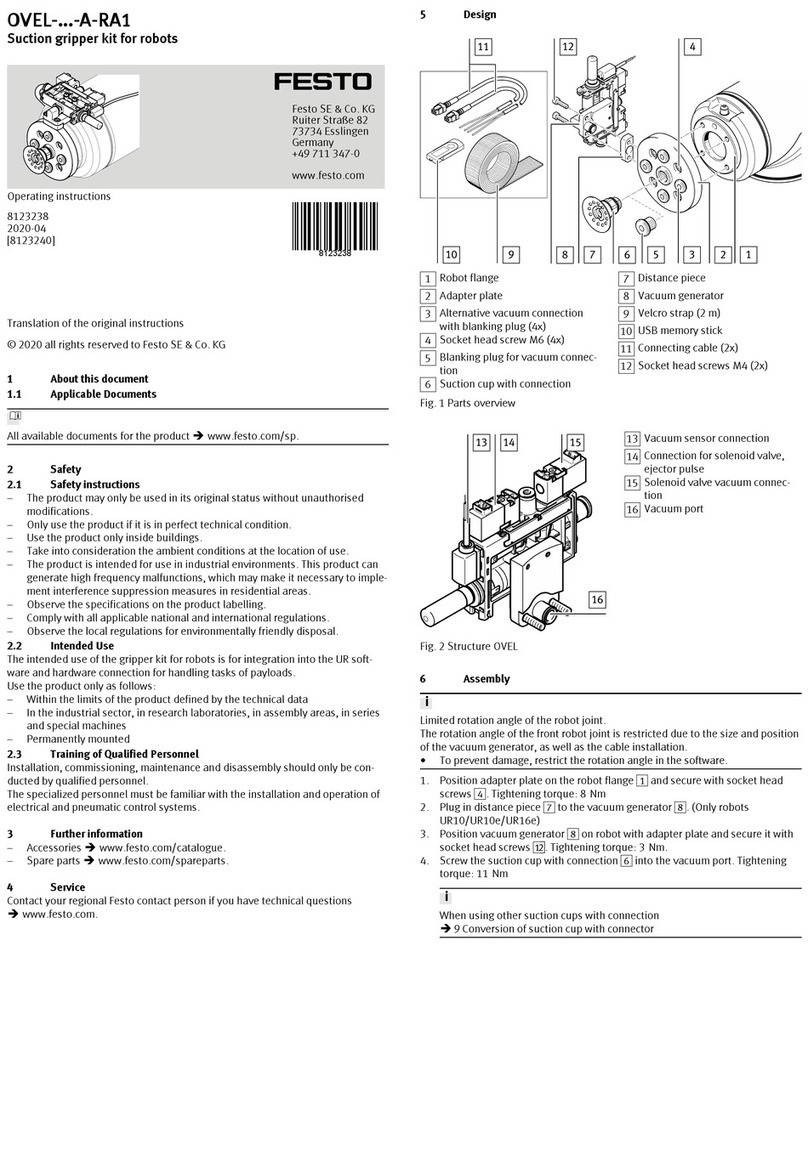

• Connect the vacuum generator to the electrical connection.

– 5-pin plug, M12x1

– Maximum tightening torque of M12 plug: 0.5Nm

– Maximum permissible cable length: 20m

Plug Pin Wire

colour1)

Function

1 brown (BN) +24V

2 white (WH) Vacuum switching input

3 blue (BU) 0V

4 black (BK) Switching output (Out)2)

5 grey (GY) Switching input ejector pulse/power ejector pulse

1) When using the connecting cable as per Accessories

2) Pin 4 not assigned for types without vacuum sensor

Tab. 12 Pin allocation OVEM-...-1PD

Circuit Diagrams

OVEM-...-1P OVEM-...-1N

OVEM without vacuum sensor

Tab. 13 Circuit diagrams for vacuum generator

8 Commissioning

Commissioning by qualified personnel.

8.1 Quick commissioning

Factory settings:

– Switching characteristics of the electrical output: threshold value comparator

– Switching function of the electrical output: N/O contact (normally open)

– Switching point (SP): -0.4bar. Alternatively, teach-in switching point

è 9.1 Teach-in switching point.

– Fixed hysteresis (HYS): 20mbar

1. Mount the vacuum generator è 6 Assembly.

2. Connect the pneumatics for the vacuum generator

è 7.1 Pneumatic installation.

3. Connect the electrics for the vacuum generator è 7.2 Electrical installation.

The factory settings cannot be restored.

8.2 Commissioning the vacuum generator

At initial commissioning, the vacuum generator is placed in operation with the

factory settings .

Requirement

Vacuum generator is fully mounted and connected è 6 Assembly.

Checking operating conditions

• Check operating conditions and critical limits è 14 Technical data.

Commissioning the vacuum generator OVEM-...-OE/-OPE

1. Apply operating pressure to supply port (1).

ÄNegative pressure is generated at the vacuum port (2).

2. Switch on the operating voltage.

ÄThe current pressure is displayed and the vacuum generator is ready for

operation.

Commissioning the vacuum generator OVEM-...-CE/-CPE

1. Apply operating pressure to supply port (1).

2. Switch on the operating voltage.

3. Activate suction: apply input signal to pin 5.

ÄNegative pressure is generated at the vacuum port (2). The current pres-

sure is displayed and the vacuum generator is ready for operation.

Changing the operating pressure changes the power of the negative pressure at

the vacuum port. This allows the vacuum to be adjusted.

Functions and parameters can be specified:

– manually at the device

– by teach-in

8.3 Setting the intensity of the ejector pulse

Requirement

– Vacuum generator is in operation

Procedure

1. Screw in the flow control screw aJ completely

ÄThe channel for the ejector pulse is closed. An ejector pulse is not gener-

ated.

2. Switch off vacuum generation.

3. Screw the flow control screw out or in to adjust the ejector pulse to the

required intensity.

4. Test the settings before commissioning.

8.4 Reducing the vacuum

OVEM-...-CN/-ON

• Cut off the compressed air supply by switching the input voltage off (-CN) or

on (-ON).

ÄThe vacuum port5 is pressurised. The workpiece is released from the

suction gripper.

OVEM-...-CE/-OE/-CPE/-OPE

• Switching on the solenoid valve for ejector pulse1 generates an ejector

pulse.

ÄThe vacuum port5 is pressurised. The workpiece is released from the

suction gripper.

The use of large suction cups with connectors can create a device-independent

vacuum due to the interference resistance when the suction cup with connector is

detached from the workpiece.

Set up the ejector pulse accordingly.

9 Operation and use

9.1 Teach-in switching point

Change in switching pressure if the EDIT key is accidentally pressed (£2s).

• Do not press the EDIT key accidentally.

The vacuum generator is preset at the factory (è 8.1 Quick commissioning).

These settings can be quickly adapted to the application by teach-in of a switch-

ing point.

1. Apply operating voltage.

2. Set the desired teach pressure (e.g. object gripped).

3. Press and hold the EDIT key aA>2s.

ÄLED Out aB flashes.

4. Release the EDIT button aA.

ÄThe current teach point (TP) minus the functional reserve is saved as the

switching point (SP) and is applied for the switching output.

9.2 Mechanical manual override

Both solenoid valves can be manually switched with the manual override.