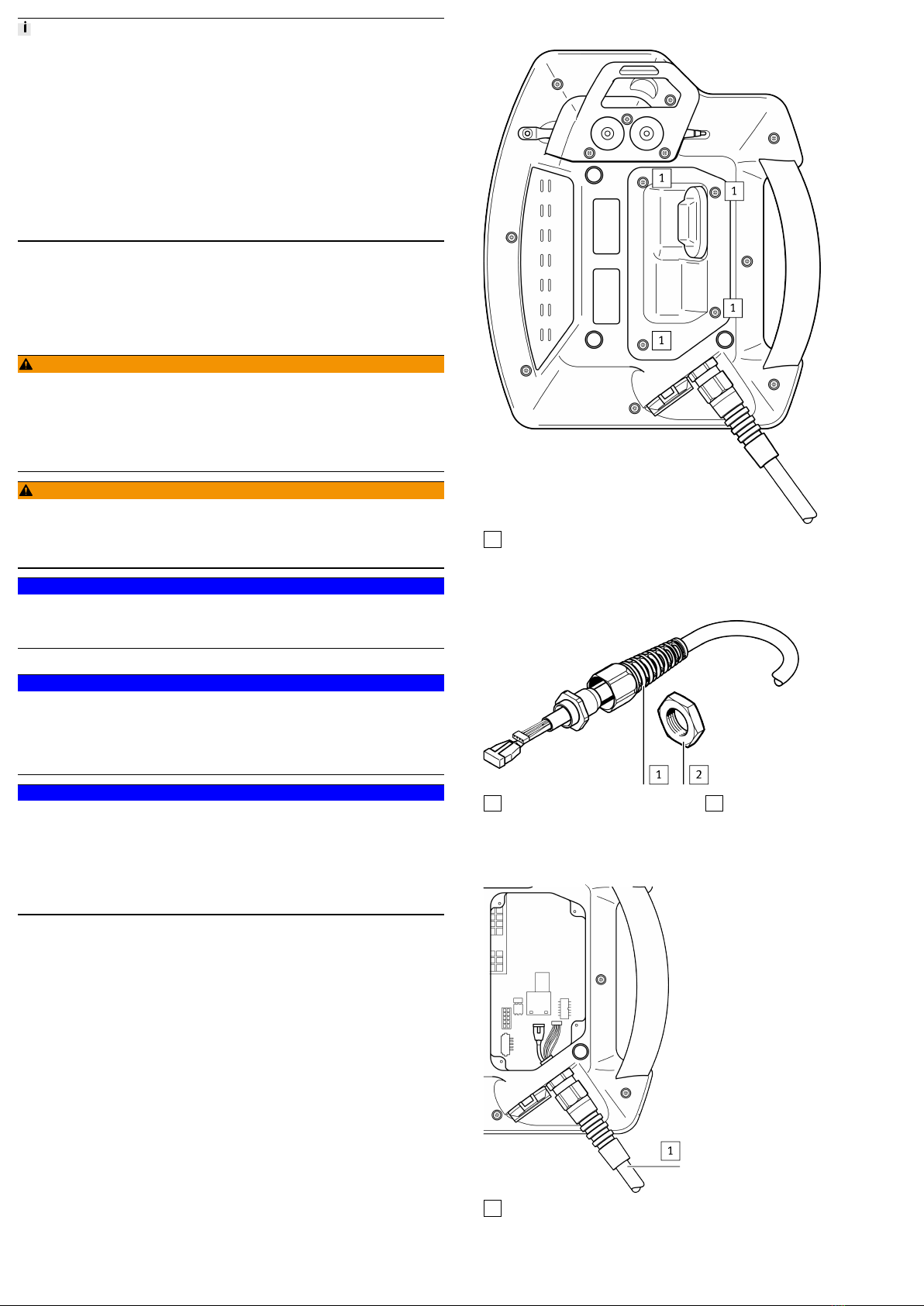

5. Fix the grommet with a size 19 spanner (torque: 3 Nm).

6. Insert the main plug and the RJ45 plug into the sockets provided for this pur

pose.

7. Tighten the strain relief with the spanner. Part of the cable sheath should be

located inside the housing. Make sure that the rubber ring for the strain relief

is correctly under the grommet.

8. Attach cover and screw in the TORX screws (torque: 0.8…1.0 Nm).

Unplug cable

1. Pull the cable with your fingers to unplug the main plug.

2. To RJ45plug, actuate the locking lever.

7.2 Cable installation in the connection shaft

WARNING!

Failure of the emergency stop or the enabling function.

Failure of the emergency stop or enabling functions can result in personal injury

and material damage.

• When plugging in, make sure that the main plug engages correctly.

• Check the emergency stop and enabling functions before recommissioning

the handheld terminal CDSAD3RV.

• Check the emergency stop and enabling functions before commissioning the

machine or system.

NOTICE!

Incorrect handling when closing the connection shaft.

Incorrect handling can damage the cables and the connection shaft.

• The seal must be clean, undamaged and in the correct position.

• Do not pinch the cable.

• Screw on the cover of the connection shaft with all screws and tighten to a

torque of 0.8 to 1.0Nm.

NOTICE!

Incorrect handling of the plug when working in the connection shaft.

Incorrect handling can damage the plugs and the socket.

• Do not use sharp objects to remove the plugs.

• Disconnect the main plug by pulling its wires with fingers.

• Press the locking lever to disconnect the RJ45 plug.

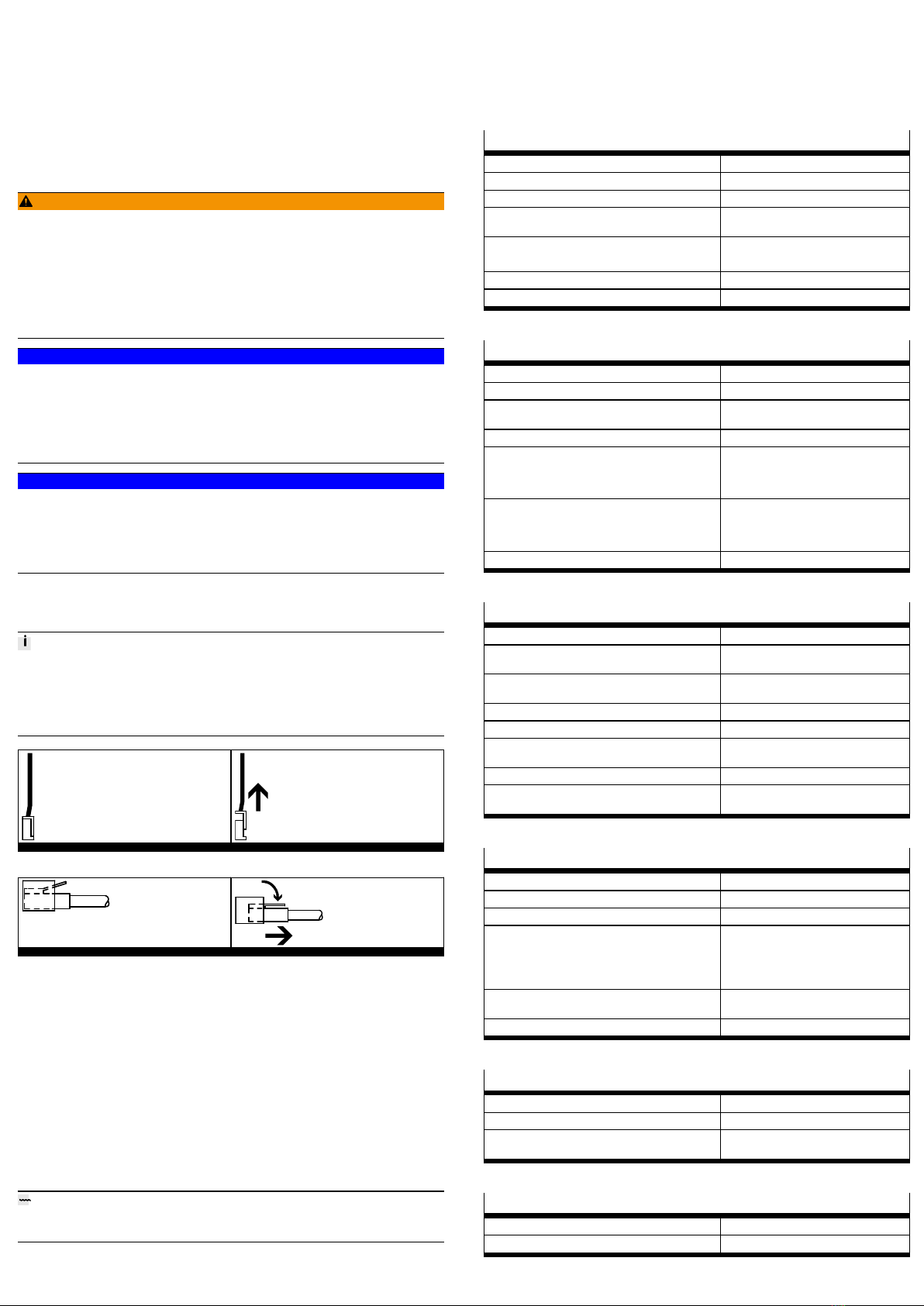

When the connection shaft is opened, the connecting cables can be positioned as

shown in the following sections. Before opening the handheld terminal

CDSAD3RV observe the following instructions:

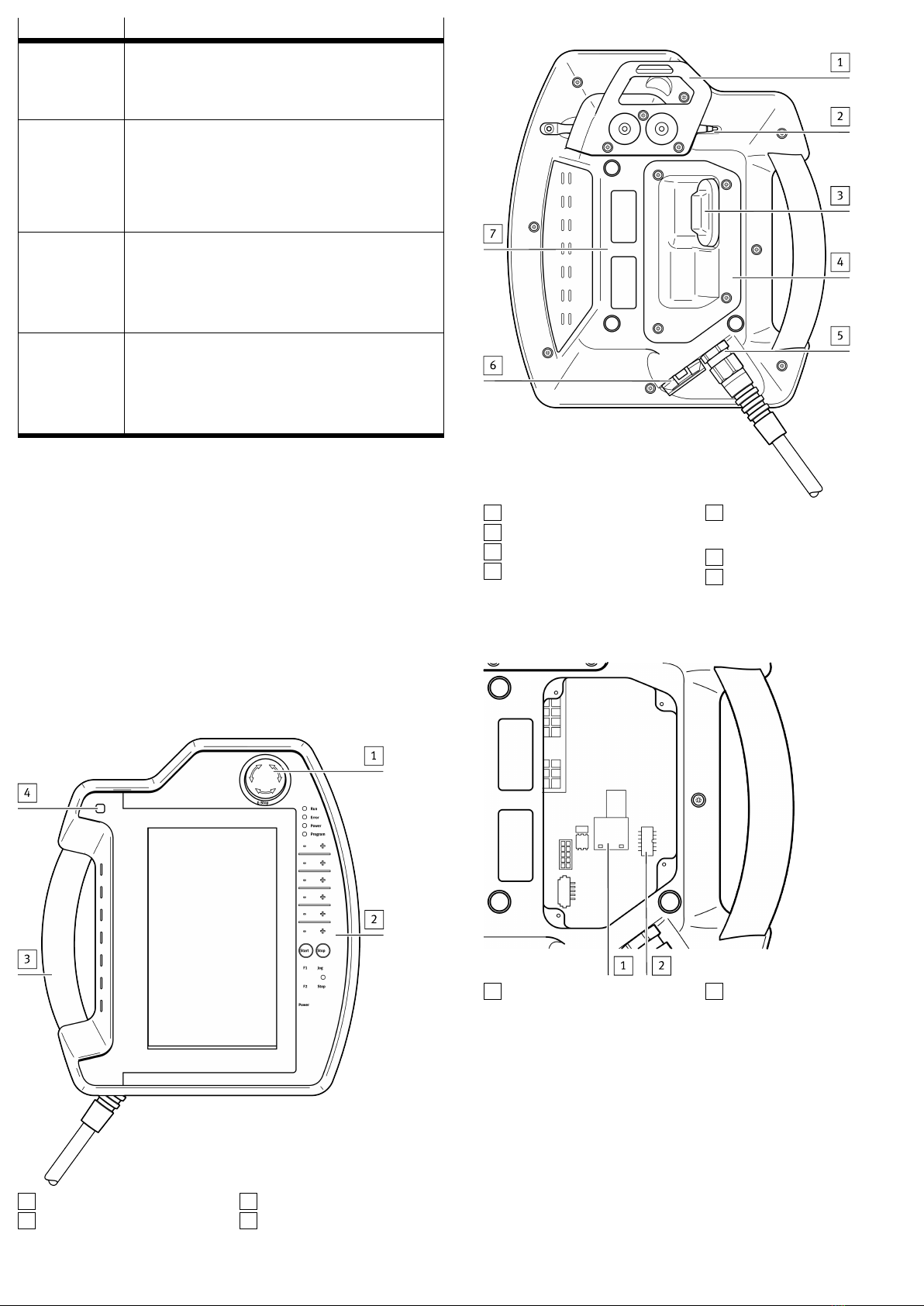

Information for opening the connection shaft

• Place the handheld terminal CDSAD3RV with the display facing downwards

on a flat, clean and soft base so that the handheld terminal CDSAD3RV or its

operating elements are not damaged (e.g. ESD mat).

• To open and close the connection shaft, use a "TORX size 10" screwdriver.

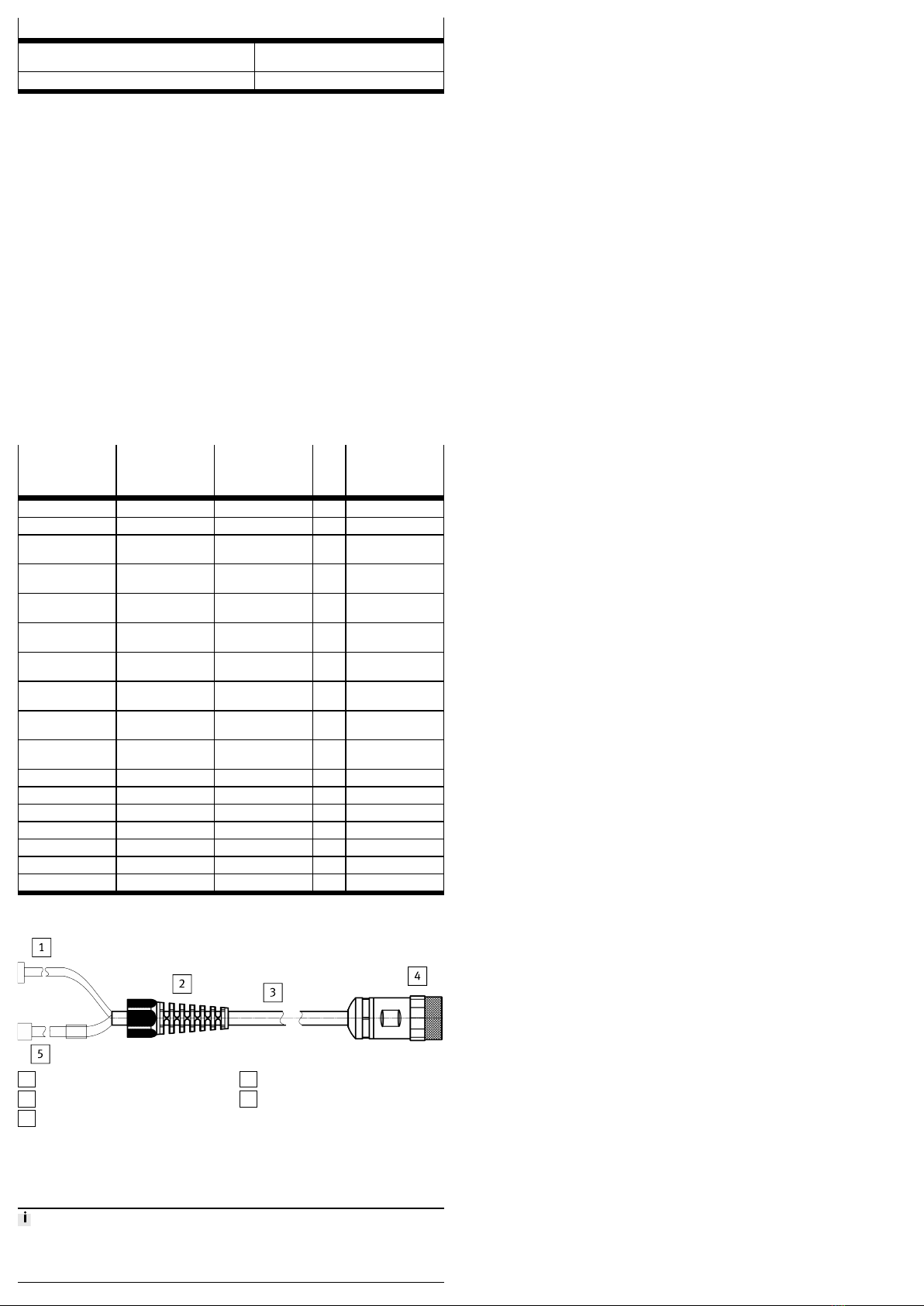

Tab. 7 Unplugging the main plug

Tab. 8 Unplugging the RJ45 plug

8 Maintenance

9 Repair

Repair or maintenance of the product by unauthorised persons is not permitted;

this may invalidate the conformity of the product.

If necessary, replace the complete product.

– If a safety device is defective, the product must be replaced.

– In this case, send the defective product unchanged with a description of the

fault and application to Festo for analysis.

– Check with your regional Festo contact person to clarify the conditions for the

return shipment.

10 Disposal

ENVIRONMENT!

Dispose of the product and packaging according to the applicable provisions of

environmentally sound recycling.

10.1 Safety-related control elements

After expiry of the service life T10D, but no later than after 20 years, the safety

related control elements "Emergency stop device" and "3position enabling

switch" must be permanently disabled.

11 Technical data

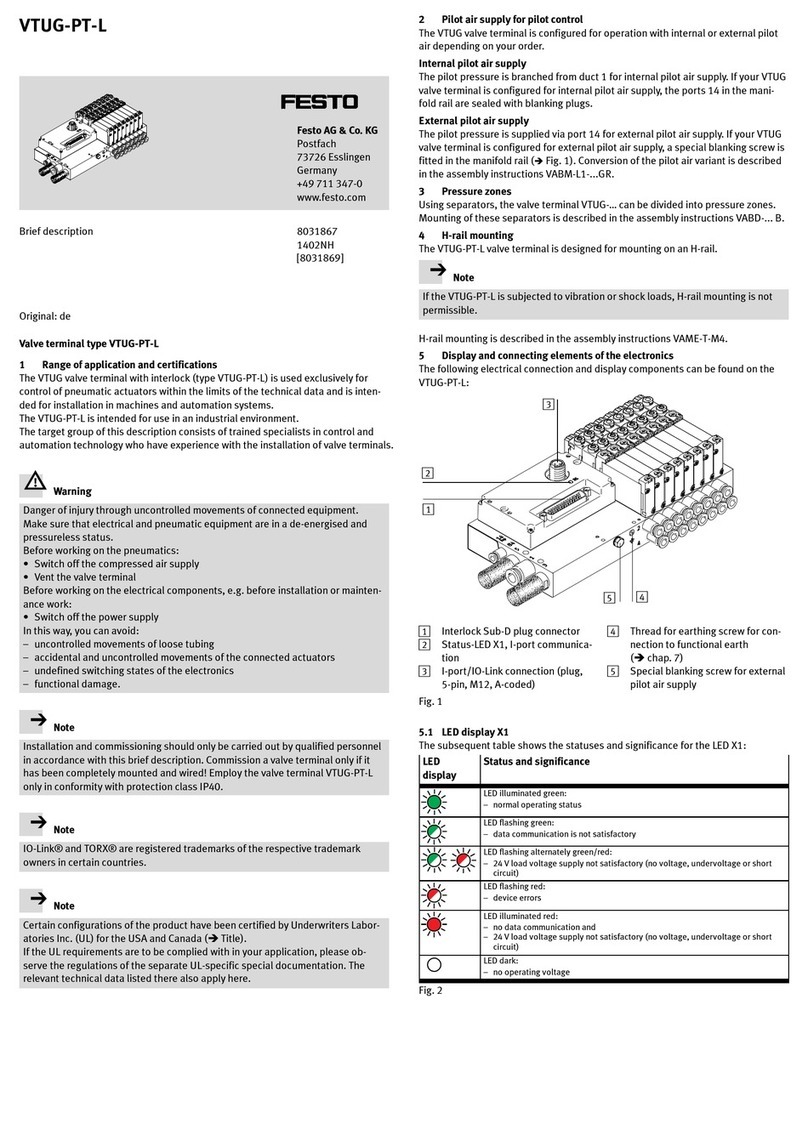

11.1 Handheld terminal CDSA-D3-RV

Emergency stop device

Nominal voltage (Ue) [VDC] 24

Minimum current (Ie) [mA] 10 (per contact)

Max. current rating [mA] 1,000 (per contact)

Utilisation category (in accordance with

IEC 6094751)

DC13

Schlegel FRVKOO

– B10D 250,000

Design twocircuit, external wiring

Electrical isolation [VAC] 500 to all other networks

Tab. 9 Emergency stop device

3-position enabling switch

Output type Electromechanical switching contact

Switchable nominal voltage (Ue) [VDC] 24

Nominal voltage tolerance range (in

accordance with EN 611312)

[VDC] 19.2…30

Max. nominal current (Ie) [mA] 500

B10D

– Switch setting 2 106

– Switch setting 3 106

Actuating forces

– From switch position 1 to 2 Typically 3 N

– From switch position 2 to 3 Typically 17 N

Electrical isolation [VAC] 500 to all other networks

Tab. 10 3position enabling switch

Technical data, general

Nominal voltage [VDC] 24

Nominal voltage tolerance range (in

accordance with EN 611312)

[VDC] 19.2…30

Max. interruption duration of the supply

voltage (in accordance with EN 611312)

[ms] £ 10

Max. starting current [A] 5.6 (current limitation available)

Power consumption [W] 12 (500mA at 24 V DC)

Protection class (in accordance with

EN 611312 and/or EN 50178)

III

Degree of protection IP65

CE certification See declaration of conformity

èwww.festo.com

Tab. 11 Technical data, general

Ambient conditions

Operating temperature [°C] 0…40

Storage temperature [°C] –25…70

Relative humidity (noncondensing) [%] 5…95

Vibration resistance (in accordance with

IEC 6006826)

– With 3.5 mm [Hz] 5 £ f < 8.4

– With 1g [Hz] 8.4 £ f < 150

Shock resistance (in accordance with

EN 611312)

[g/ms] 15/11

Max. operating altitude (sea level) [m] 2,000

Tab. 12 Ambient conditions

Mechanical characteristics

Design Housing made of ABS

Flammability UL94V0

Fallproof suitability [m] 1.5 (on industrial floor), then at least

degree of protectionIP54

Tab. 13 Mechanical characteristics

Dimensions, weight

Height [mm] 251

Width [mm] 212