FRENCH FITNESS FF-FSR70 User manual

Other FRENCH FITNESS Fitness Equipment manuals

FRENCH FITNESS

FRENCH FITNESS FFB-ESM User manual

FRENCH FITNESS

FRENCH FITNESS FSR10 User manual

FRENCH FITNESS

FRENCH FITNESS FF-SS20 User manual

FRENCH FITNESS

FRENCH FITNESS FF-GHD20 User manual

FRENCH FITNESS

FRENCH FITNESS FFN-SM User manual

FRENCH FITNESS

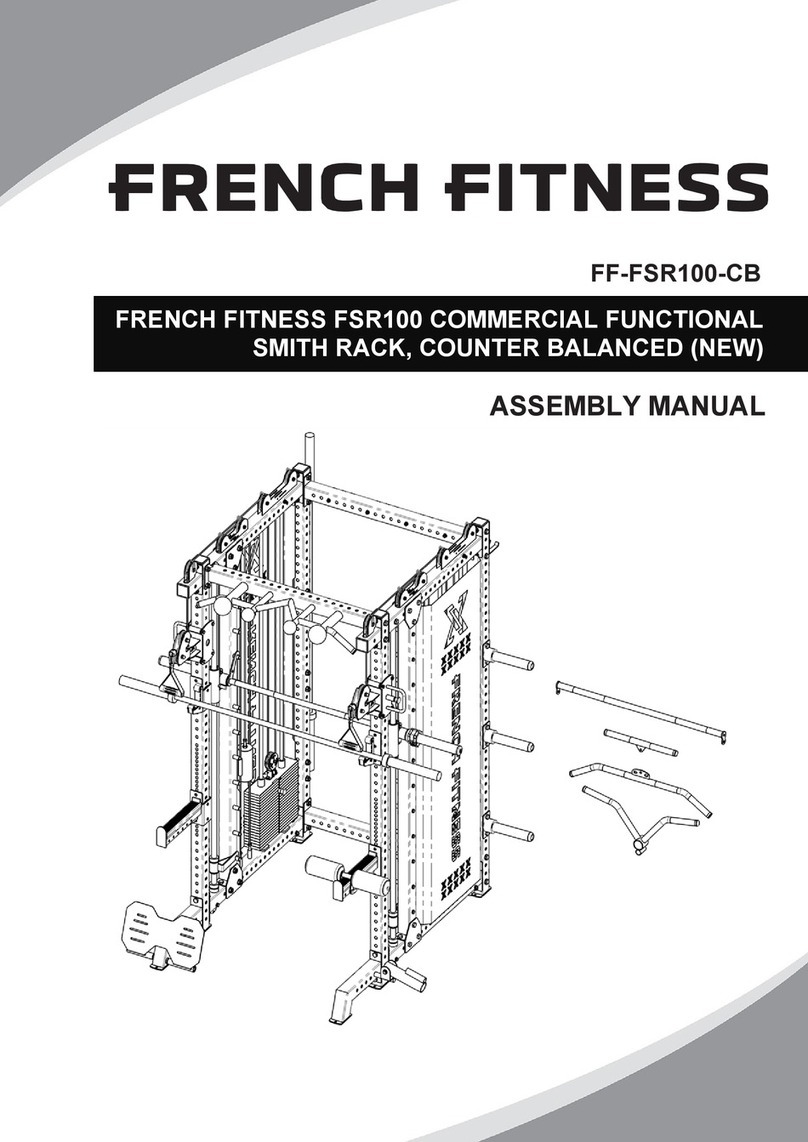

FRENCH FITNESS FF-FSR100-CB User manual

FRENCH FITNESS

FRENCH FITNESS FFM-CLPS User manual

FRENCH FITNESS

FRENCH FITNESS FF-FL30 User manual

FRENCH FITNESS

FRENCH FITNESS FF-AR User manual

FRENCH FITNESS

FRENCH FITNESS FFN-ASP User manual

FRENCH FITNESS

FRENCH FITNESS FFS-5SMJG User manual

FRENCH FITNESS

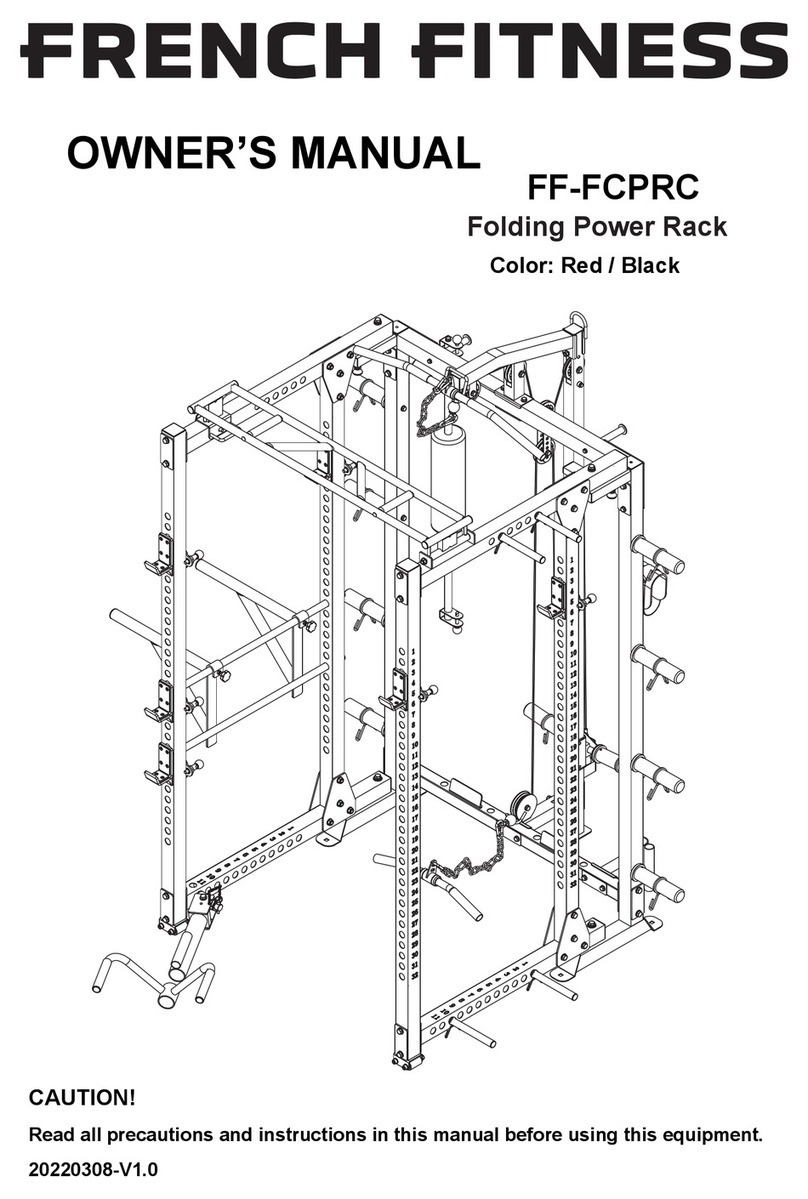

FRENCH FITNESS FF-FCPRC User manual

FRENCH FITNESS

FRENCH FITNESS SM200 User manual

FRENCH FITNESS

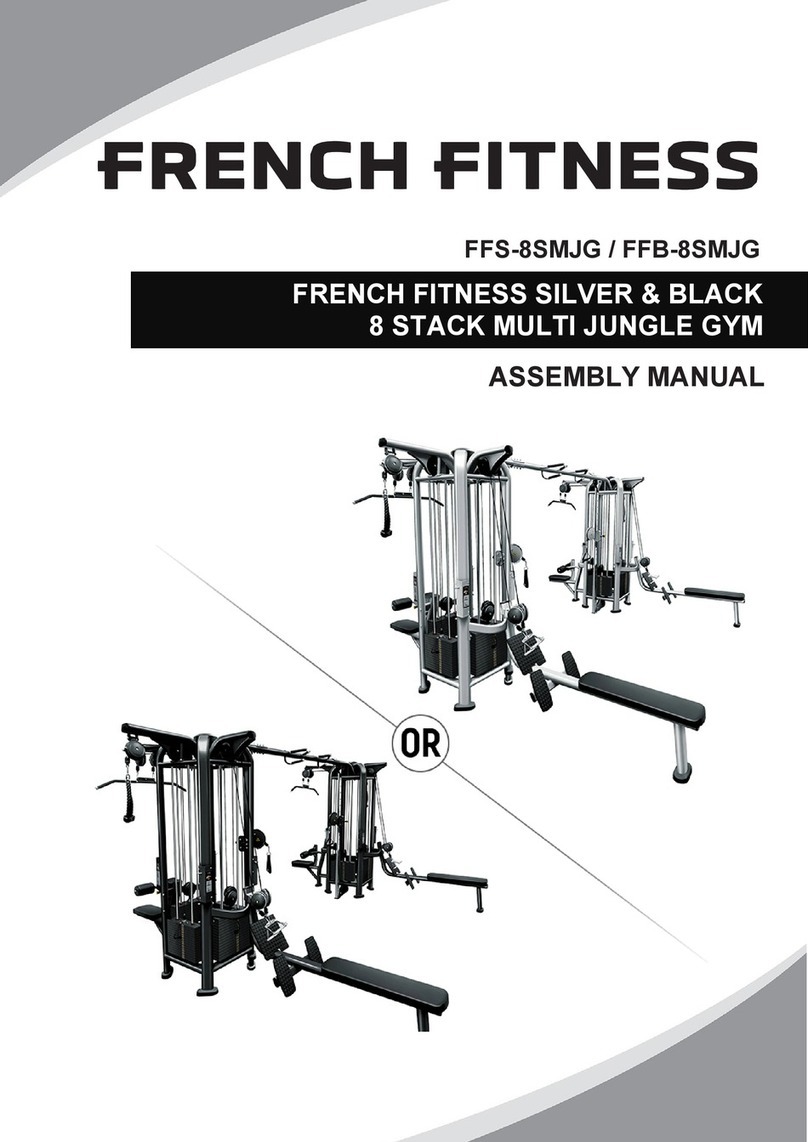

FRENCH FITNESS FFS-8SMJG User manual

FRENCH FITNESS

FRENCH FITNESS FF-FSR80 User manual

FRENCH FITNESS

FRENCH FITNESS Strength Pendulum Squat User manual

FRENCH FITNESS

FRENCH FITNESS X9 User manual

FRENCH FITNESS

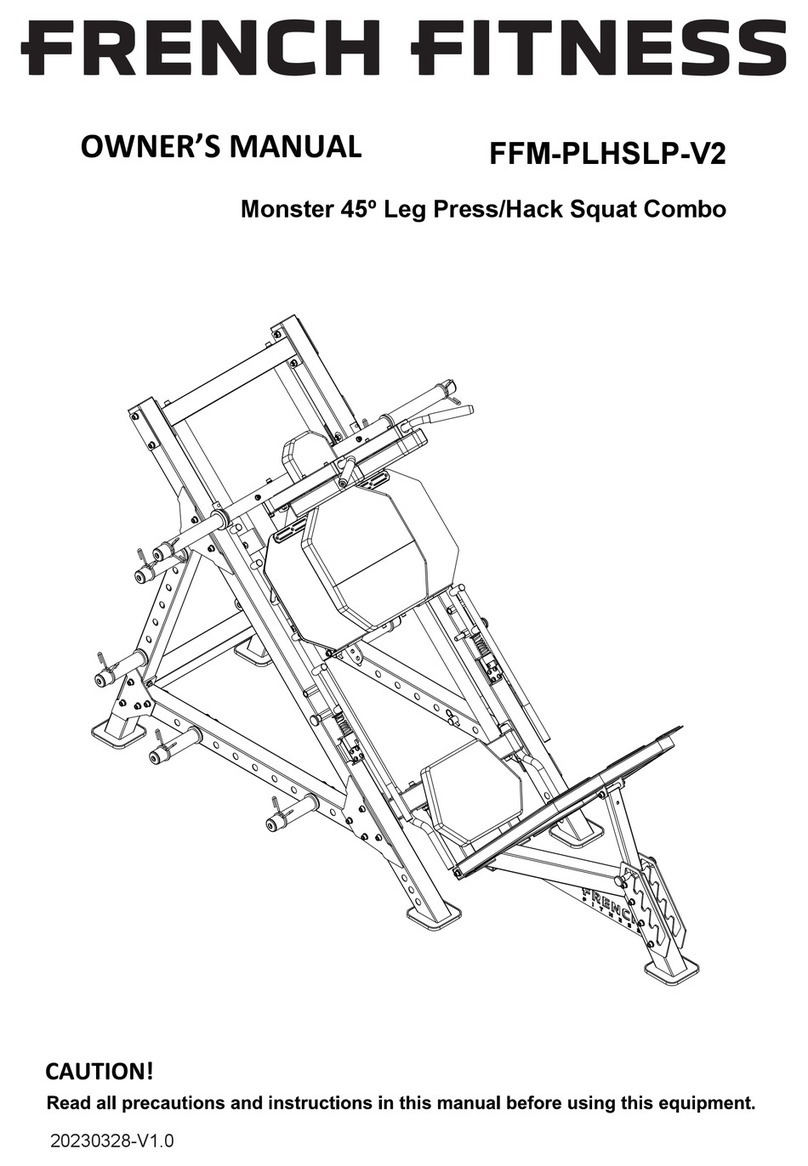

FRENCH FITNESS FFM-PLHSLP-V2 User manual

FRENCH FITNESS

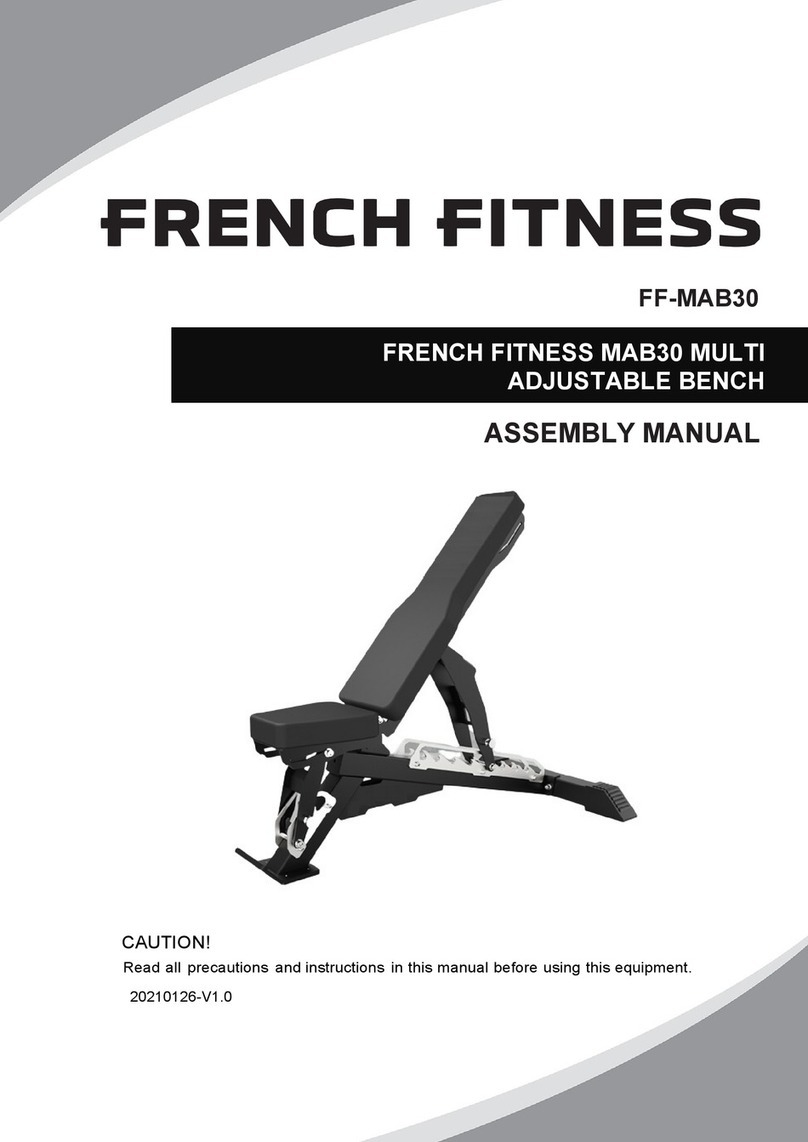

FRENCH FITNESS MAB30 MULTI User manual

FRENCH FITNESS

FRENCH FITNESS FFS User manual