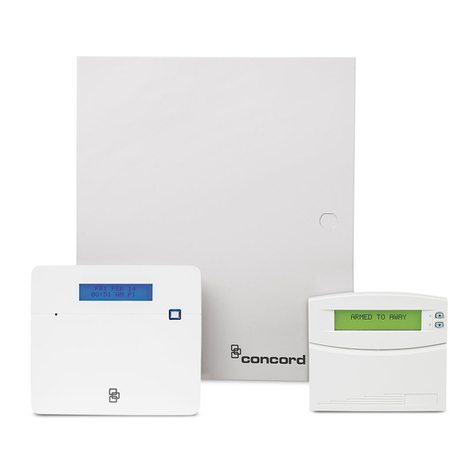

Chapter 1: Introduction

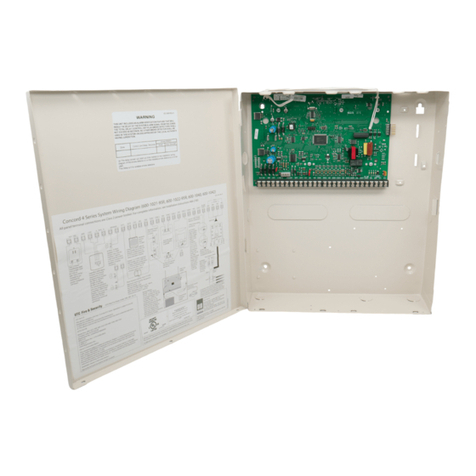

Concord 4 Installation Manual 3

SuperBus 2000 bus devices

The following components can be used with the Concord 4 panel:

Table 3: SuperBus devices

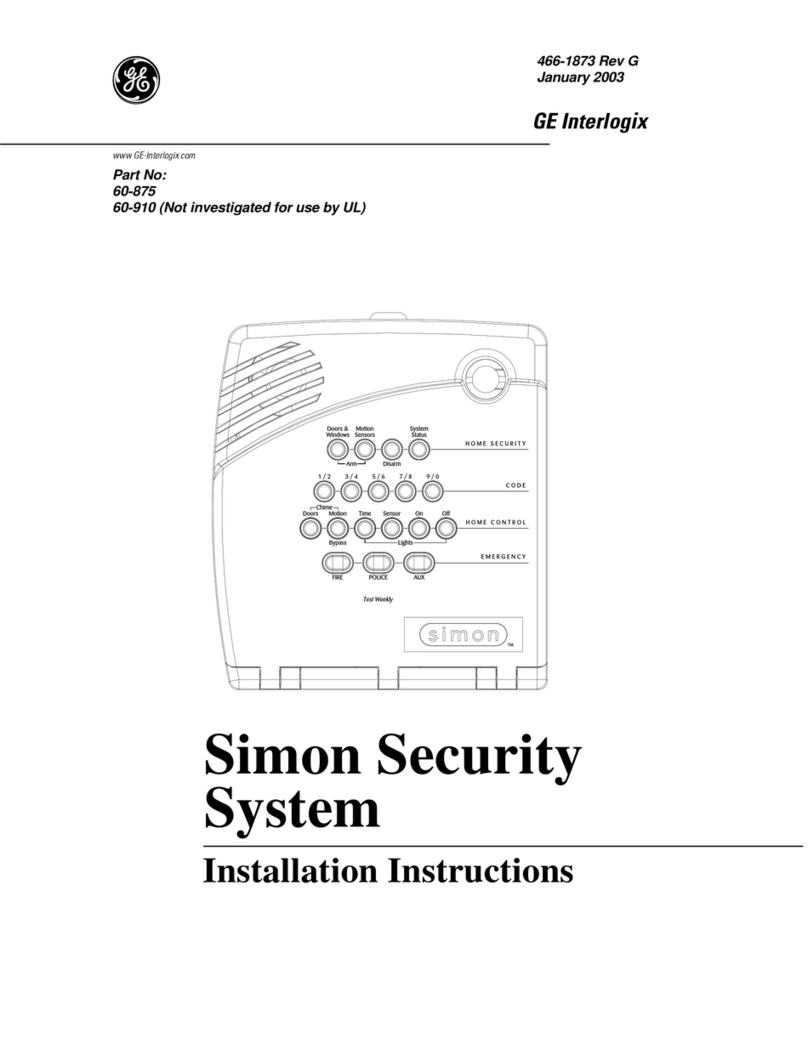

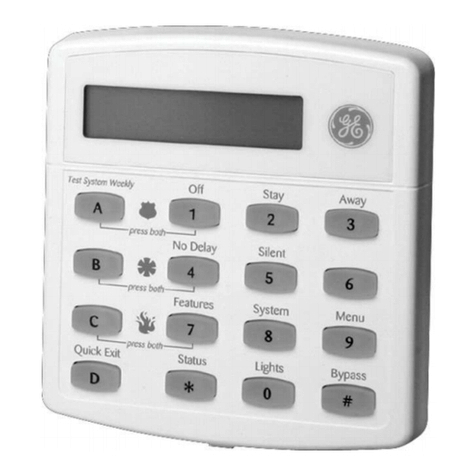

Touchpads Use the following touchpads for installer/user programming and

system operation.

• SuperBus 2000 2x16 LCD touchpad

• SuperBus 2000 2x20 LCD touchpad

• SuperBus 2000 2x20 VFD touchpad

• SuperBus 2000 ATP 1000 touchpad

• SuperBus 2000 ATP 2100 touchpad

• SuperBus 2000 ATP 2600 touchpad

Use the following touchpads for installer quick programming,

system operation and user programming:

• SuperBus 2000 fixed display touchpad

• SuperBus 2000 FTP 1000 touchpad

SuperBus 2000 RF transceiver Use the transceiver to receive signals from sensors and touchpad

that may be on the fringe of panel reception. The transceiver is

compatible with all 319.5 MHz crystal and SAW learn mode

wireless sensors and touchpads.

Power line carrier transformer Allows the use of X10 powerhouse lamp modules for light control

and light activation during alarms.

SuperBus 2000 voice only

module

Provides an output for a speaker that sounds system status and

alarm voice messages.

SuperBus 2000 phone

interface/voice module

Allows system access and control using touchtone telephones,

onsite or offsite. The module includes an output for a speaker

that sounds system status and alarm voice messages

SnapCards The following SnapCards expand the system as described:

8Z input Snapcard: Provides eight additional hardwired zone

inputs, of which two are dedicated for using two-wire smoke

detectors.

4 output SnapCard: Provides four form C relay outputs that can

be set up to activate other signaling devices, based on system

events, schedules, or direct control.

4Z

input/output combo SnapCard: Provides three hardwired zone

inputs, one two-wire smoke detector loop, and two outputs that

can be set up to activate other signaling devices, based on

system events, schedules, or direct control.

SuperBus 2000 8Z input module

(HIM)

Provides eight additional hardwire zone inputs.

SuperBus 2000 four-relay output

module (HOM)

Provides four form C relay outputs that can be set up to activate

other signaling devices, based on system events.