Introduction

Operating Instructions MSA 2

6

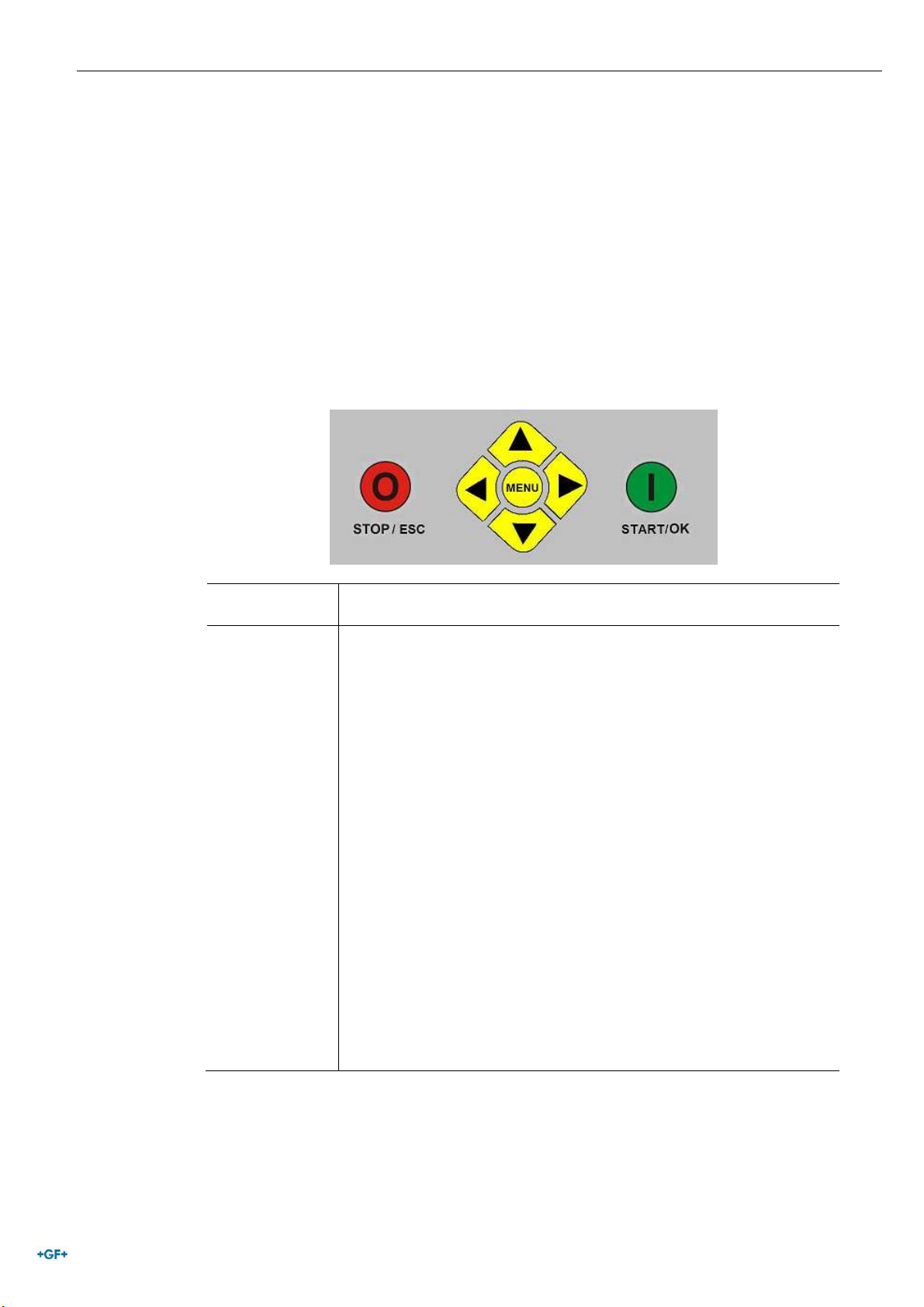

1.2.2 Display

The graphical display is the main user interface of the welding

machine. It shows the steps to be executed in sequence, the

fusion data, possible errors and alarm messages.

It is possible to change its brightness using the andbuttons

and then save permanently the new value pressing the

button, in case of limited visibility due to weather conditions. The

operation can be done only when the display shows the fitting

icon

1.2.3 Ambient Temperature Sensor

The outside sensor measures the ambient temperature, to check

the temperature is in the permitted range (between -20° C and

50° C) and adjust the fusion time according to the external

conditions.

1.2.4 USB Interface

The USB type-A interface available on the rear of the machine is

the interface used to upgrade the software version, perform the

calibration of the unit and (MSA 2.1 only) export the protocols.

The connector is protected against dust and water by a cap,

which ensures an IP67 protection factor when properly fixed.

1.2.5 Power Cable

The power cable is delivered with an earthed plug for being

connected to power supply at 230V/50Hz.

The power source can be either the mains or a generator. In the

latter case there are no deterministic rules to select the right

generator output power. Requirements will vary depending on

the efficiency of the generator as well as other factors, like the

power needed by the fitting.