34 BR24 35

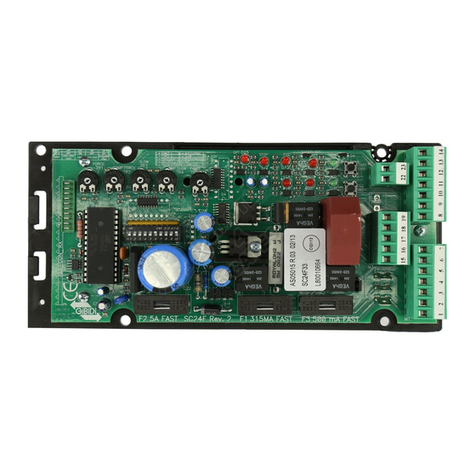

BR24

UK

READ CAREFULLY THESE INSTRUCTIONS BEFORE PROCEEDING WITH INSTALLATION.

Thank you for choosing GI.BI.DI.

WARNING: IMPORTANT SAFETY INSTRUCTIONS.

It is important for the safety of persons to follow these instructions.

Keep this instructions manual.

WARNINGS:

This product has been tested by GI.BI.DI. for full compliance with the requirements of the directives in force. GI.BI.DI. S.r.l. reserves

the right to change the technical data without prior notice in relation to product development.

DISPOSAL: GI.BI.DI. advises recycling the plastic components and to dispose of them at special

authorised centres for electronic components thus protecting the environment from polluting substances.

UK

TECHNICAL SPECIFICATIONS / FUNCTIONS

• Red leds of NC contacts. There is not the safety devices led. See “SIGNALLING LEDS” table.

• Green / yellow leds of NO contacts. See “SIGNALLING LEDS” table.

• Management of 2 control units synchronized between them.

• Management of 1 electric lock or electromagnet.

• Management of courtesy light.

• Management of 230 Vac boom lights

• Management of traffic light.

• Enabling the photocell test done before the opening and closing movement.

• Enabling the test of the amperometric circuit and conductive edge 8k2 done before the opening and closinG

movement.

• Stop and motion inversion for 1 s after safety devices intervention . At the next START pulse, the motion

restarts in the obstacle freeing direction.

• Separate safety devices power supply. Connect to this terminals the safety devices that will be tested.

• Double reading of the limit switch always active, except in dead man operating logic.

• Decelerations always active except in dead man operating logic.

• Working time in opening and closing fixed at 10 sec.

• Deceleration time in opening and closing fixed at 10 sec.

• Motor power fixed at 10 level.

• Digital programming of all functions.

• Adjustable pause time.

• Deceleration speed that can be selected between adjustable mode on 10 levels (with terminal block JP13

open) or fixed mode by secondary transformer (green or red cable on faston CF1).

• Control of current absorption (anti-crushing) adjustable on 100 levels both in thrust phase and in deceleration

phase.

• 4 operating logics: step by step with stop, step by step, condominium or automatic, dead man.

• Anti-crushing enabling only in closing (motion inversion for 1 second and locking) or amperometric detection for

limit switch active both in opening and closing.

• Programming of: automatic closing, fast closing, preflashing, fixed or intermittent flashing light, management of

an external clock with 3 different modes, cycles number for planned maintenance, installer code, number of

cycles done, number of powered days.

INSTALLATION WARNINGS

• Before proceeding with the installation, fit a magneto-thermal or differential switch with a maximum capacity of

10A upstream of the system. The switch must guarantee omnipolar separation of the contacts, with an opening

distance of at least 3 mm.

• To prevent possible interferences, differentiate and always keep the power cables (minimum cross-section

1,5mm²) separate from the signal cables (minimum cross-section 0,5mm²).

• Make the connections referring to the following tables and to the attached screen-print. Be extremely careful to

connect in series all the devices that must be connected to the same N.C. (normally closed) input and in

parallel all the devices that share the same N.O. (normally open) input. Incorrect installation or improper use of

the product may compromise system safety.

• Keep all the materials contained in the packaging away from children, since they pose a potential risk.

• The manufacturer declines all responsibility for improper functioning of the automated device, if the original

components and accessories suitable for the specific automation are not used.

• At the end of the installation, always check carefully the proper functioning of the system and devices used.

• This instruction manual addresses people qualified for the installation of “live equipment”. Therefore good

technical knowledge and professional practice in compliance with the regulations in force are required.

• Maintenance must be carry out by qualified personnel.

• Before carrying out any cleaning or maintenance operation, disconnect the control unit from the mains.

• This control unit may only be used for the purpose for which it was designed. Check the aim of the final use

and be sure to take all the necessary safeties.

• Use of the products for purposes different from the intended use has not been tested by the manufacturer,

therefore any work is carried out on full responsibility of the installer.

• Mark the automated gate with visible warning plates.

• Warn the user that children and animals may not play or stand around near the gate.

• Appropriately protect the dangerous points (for example, use a conductive edge).

• The control unit does not assure by it self the safety against crushing. Be sure that the safety devices

connected to the control unit are fit for purpose.

WARNINGS FOR THE USER

• In the event of an operating fault or failure, cut the power upstream of the control unit and call the Technical

Service.

• Periodically check the functioning of the safety devices. Any repairs must be carry out by specialised personnel

using original and certified materials.

• The appliance is not to be used by children or people with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given supervision or instruction.

• Do not touch the card for adjustments and/or maintenance.