2

ENGLISH

INTRODUCTION

ABOUT THIS OPERATING MANUAL

This operang manual includes introducon about the symbols and safety in-

strucons. You can see the descripon, instrucon and maintenance about our

product in the followed pages. And some technical data and informaon about the

product.

In case of any queson, we therefore kindly ask you to contact aer-sales service

personnel or distributor.

This operang manual is to be read and observed by any person using or handle this

operang table.

In addion to some accident, we obtest users to be familiar with the usage and the

points of aenon.

Intended Purpose

The electric operang table is used for maternity, childbirth and diagnosis, and for

carrying paents during surgery.

SYMBOLS USED IN THE TEXT

Danger!

This symbol will appear whenever safety instrucon are designed to pro-

tect people from physical harm. The symbol stands for imminent danger

of death or of serious injury.

Cauon!

This symbol will appear where situaons are described which might be

dangerous ,and which might inict slight injuries.

Aenon!

This symbol will appear in front of such hints which shall prevent the

table or other equipment from being damaged

Advice!

This symbol will appear in front of addional helpful pieces of advice.

●A dot in front of the text means:

Please pay aenon and you have to do.

SUMMARY OF THE INSTRUCTIONS

Danger!

Paents may be exposed to danger by electrostac tension.By means of the

potenal equalizaon device electrostac tension are conducted to earth.

Always connect the potenal equalizaon device of the operang table to earth be-

fore use.

Danger!

The paent may get hurt if the operang table is displaced while he or she is

lying on the top in the knee-elbow-posion. Do not displace the table with

the paent in knee-elbow-posion.

Danger!

The paent may get hurt if the operang table is displaced with an aached

extension device, due to its reduced stability against lng.Do not displace the

operang table with an aached extension device when a paent is lying on the top.

Danger!

Do not press two buons at the same me!

Aenon!

never press one buon over 2min!

Aenon!

The cushion will deform if exposed to heat. The operang table, including

its cushion ,must not be sterilized bu super heated steam.

Aenon!

Agents for disinfecon of the paent’s skin may cause discoloraons on

the cushions.Remove such disinfecng agents from the cushion in order to

avoid such discoloraons.

Aenon!

Disinfecng sprays may cause corrosion on mechanical parts,or create

explosive mixtures inside the table components.For this reason,do not use

disinfecng sprays!

advice:

The posion of the castors will inuence the stability of the operang

table.

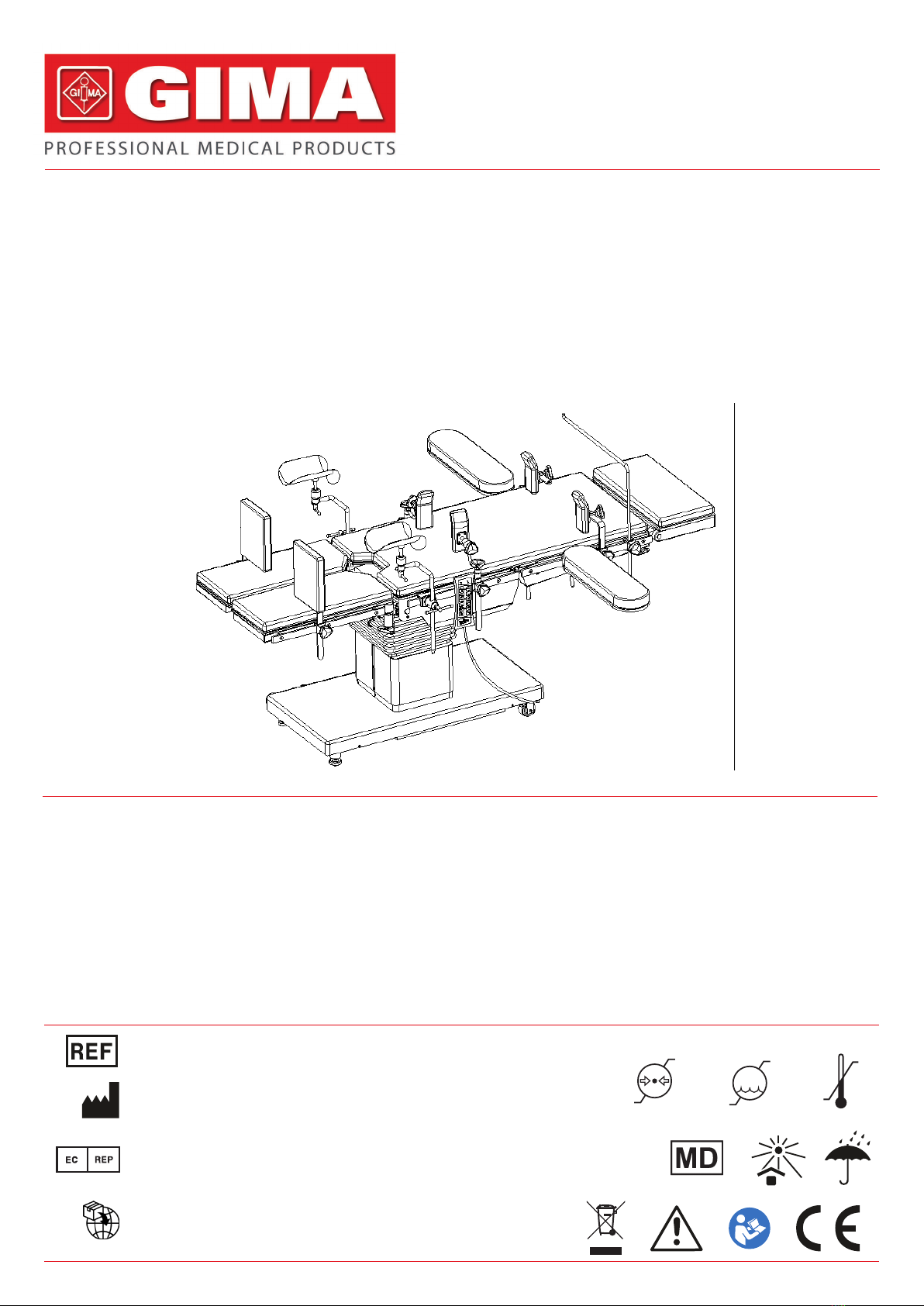

DESCRIPTION

USE AND BRIEF INTRODUCTION

The product belongs to class I, type B. Non AP or APG device, connuous device.

And possesses applicaon part.

SUMMARY

INTRODUCTION ................................................................................. 2

About this operating manual............................................................... 2

Symbols used in the text ...................................................................... 2

Summary of the instructions................................................................ 2

DESCRIPTION ..................................................................................... 2

Use and brief introduction................................................................... 2

GENERAL CONTENT ........................................................................... 3

Basic data............................................................................................ 3

Product information and feature ......................................................... 3

COMMISSIONING .............................................................................. 3

keeping ............................................................................................... 3

Transportation .................................................................................... 3

Unpacking........................................................................................... 3

Power requirements ............................................................................ 3

Using................................................................................................... 3

Attention before using......................................................................... 3

Attention after using............................................................................ 3

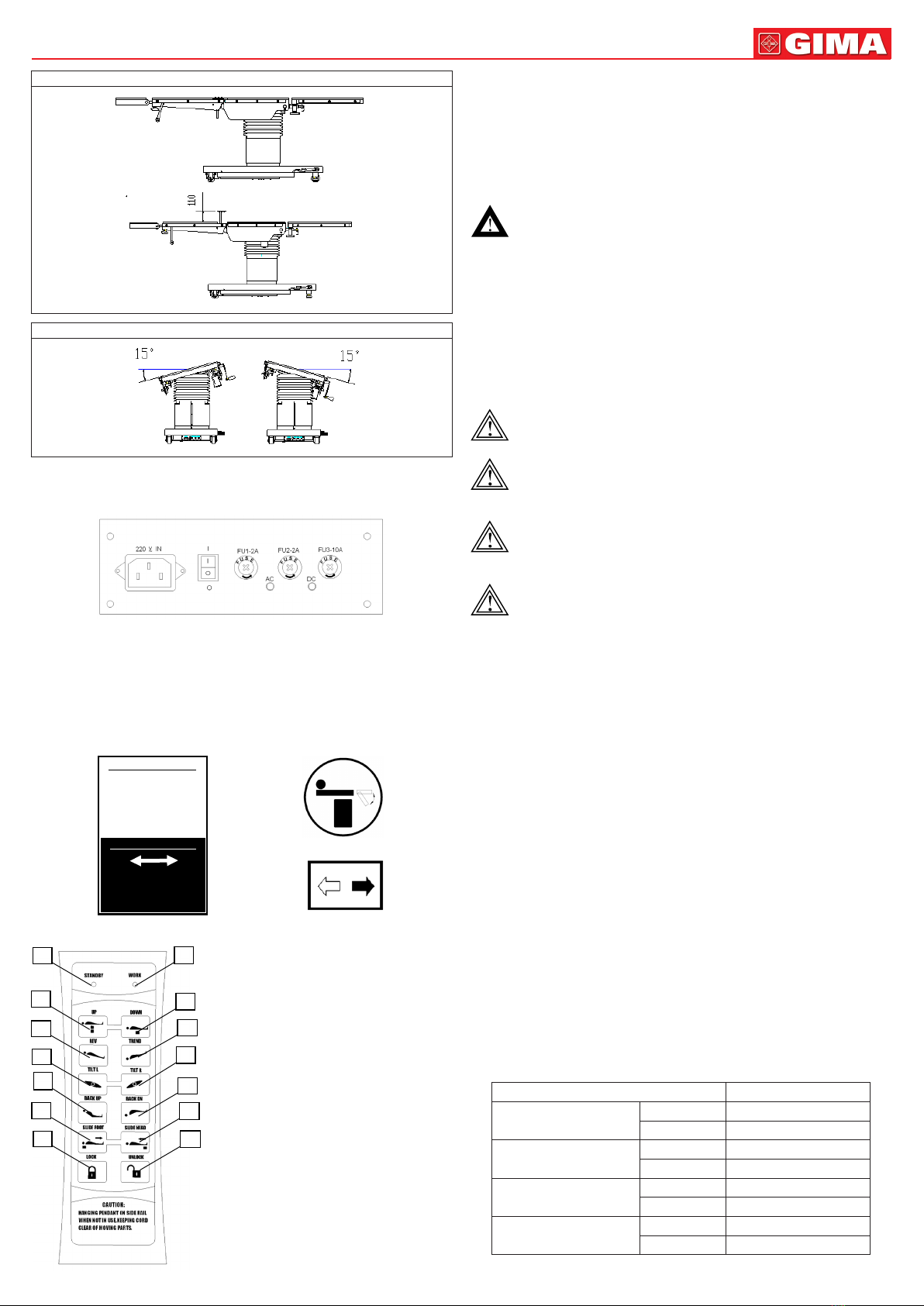

METHOD OF USING OPERATION TABLE ............................................ 4

Preparation before using..................................................................... 4

Displacement ...................................................................................... 4

Using adjust ........................................................................................ 4

MOVEMENTS DIAGRAM OF A100-4................................................... 4

PICTURE OF CONTROL PANEL............................................................ 5

LABEL ON THE TABLE.........................................................................5

FUNCTION OF TELECONTROLLER ......................................................5

CLEAN OUT AND DISINFECTION........................................................ 5

MAINTENANCE .................................................................................. 5

COMMON PROBLEMS AND SOLUTIONS ........................................... 6

MAIN TECHNICAL DATA..................................................................... 6

PACKING LIST..................................................................................... 7

A100-4 WITH ALL STANDARD ACCESSORIES...................................... 7

SYMBOL EXPLANATION: .................................................................... 7