28 29

ENGLISH ENGLISH

Do not use smoking sterilizers, autoclaves, and do not use methyl (phenol) to clean the headboard and

foot of the bed. It may cause corrosion, discoloration and deterioration. Note: When cleaning the bed or

changing the bedclothes, please pay attention to the corners, edges and screws of the frame to prevent

scratches.

MATTRESS-CLEANING AND MAINTENANCE

1. When using it, avoid scratching the fabric with sharp-angled tools or knives, cover it with sheets or cleaning

pads, and clean it frequently to protect it from dryness.

2. Clean the mattress regularly with a vacuum cleaner, Mattress cover can be washed in 100°C.

3. Expose the mattress often to keep the sleep fresh and comfortable, but be careful not to expose the

mattress to too long.

4. If the fabric is accidentally stained, please refer to the corresponding recommended cleaning methods in

the instructions, do not use corrosive chemicals to clean the fabric.

5. If accidentally the chewing gum or other jellies get on the fabric, do not wipe it forcibly. Use an ice pack to

allow it harden and gently peel it off.

6. If the thread is found to be loose due to wear and tear, do not pull it off by hand, use scissors to cut it

together.

* If your order does not have a mattress, please refer to the contract configuration.

CASTER-DETECTION AND MAINTENANCE

1. Regularly check the casters to avoid hitting or overloading, which will cause damage to the casters.

2. Grease the casters or wheels on a regularly, and the frequency of addition should be determined according

to the specific actual use conditions. In general, lubricating grease is added every six months.

3. After cleaning the caster equipment, pay attention to adding grease.The selection of lubricating grease should

be based on the actual use environment, special high temperature and special low temperature environment,

and the corresponding lubricating grease should be selected.

4. It is forbidden to force the casters to brake when braking, which will cause damage to the brake system.

5. The wear of the tire surface of the wheel can be detected by visual inspection. Some thread spun yarn and

other accumulations may be wrapped around the wheel, remove the bolts and nuts of the wheel, clean up

the debris, and check whether the bearing of the wheel is damaged. If the parts are not damaged, can be

reassembled and used.

6. Judging whether the caster is replaced according to the time used, wear and tear, you can replace the wheels

and make sure that the axles bolt and nuts are well put together and connected. If possible, use a lock

washers or locknuts to help you with this process.

7. For the casters equipped with brakes, it is necessary to regularly check whether the brakes are working

properly. Check the brakes once a day or before each use. For a hospital bed equipped with multiple brake

casters, only one brake caster can be locked at a time which will allow you to try and push the bed also check

whether one of the brake performance of each caster is good. If the function of the brake fails due to wear or

damage to the wheels, immediately replace the wheels and then retest the brake system.

8. If the mechanism of the brake system of the caster is damaged, and the brake needs to be repaired or

replaced, please contact our after-sales service department or authorized dealer provide by our company.

Every time the brakes are replaced, the brake performance of the casters must be retested.

GUARDRAIL-MAINTENANCE

1. Please check whether the side rails are installed correctly to prevent the lying patient from shifting and rolling

down.

2. Please always check the screws of the total position of the guardrail and the wire to prevent loosening and

falling off.

3. Please use the red plastic parts of the guardrail switch correctly, and do not use brute force prevent it from

damaging the guardrail.

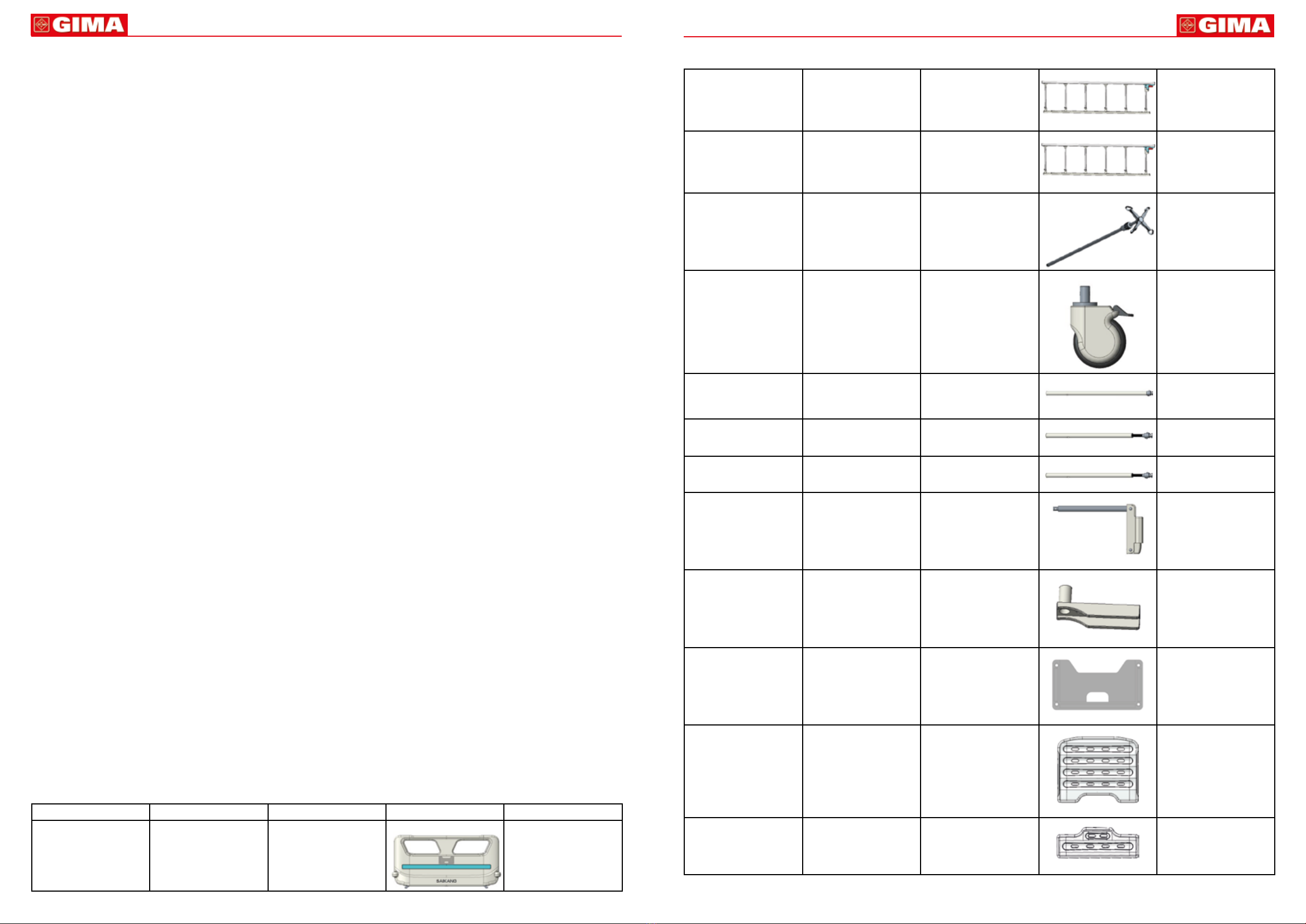

SPARE PART LIST

N. Name Model n. Picture Specification

1 V21Head foot board GPSL101TS648 Hook distance:

990*460

2Aluminum alloy

side rail BKLLGH105943 10*1170

3Aluminum alloy

side rail BKLLGH105944 10*1170

4 IV pole S0FJSY010003 Ø16-19/off-white

5 5 inch caster LGPLU101TS122 M8

6 Back telescopic crank LGPSG10101002 950-150

7 Leg telescopic crank LGPSG10101001 650-95

8 Leg telescopic crank LGPSG10101003 600-200

10 T elescopic crank

handle GPSL1012524S Off-white/250*220 mm

11 Crank handle base GPSL1012525S Off-white/p2142c

12 Name card GPSL101TS184 /

13 First platform GPSL101TS610 733*903

14 Second platform GPSL101TS611 333*903