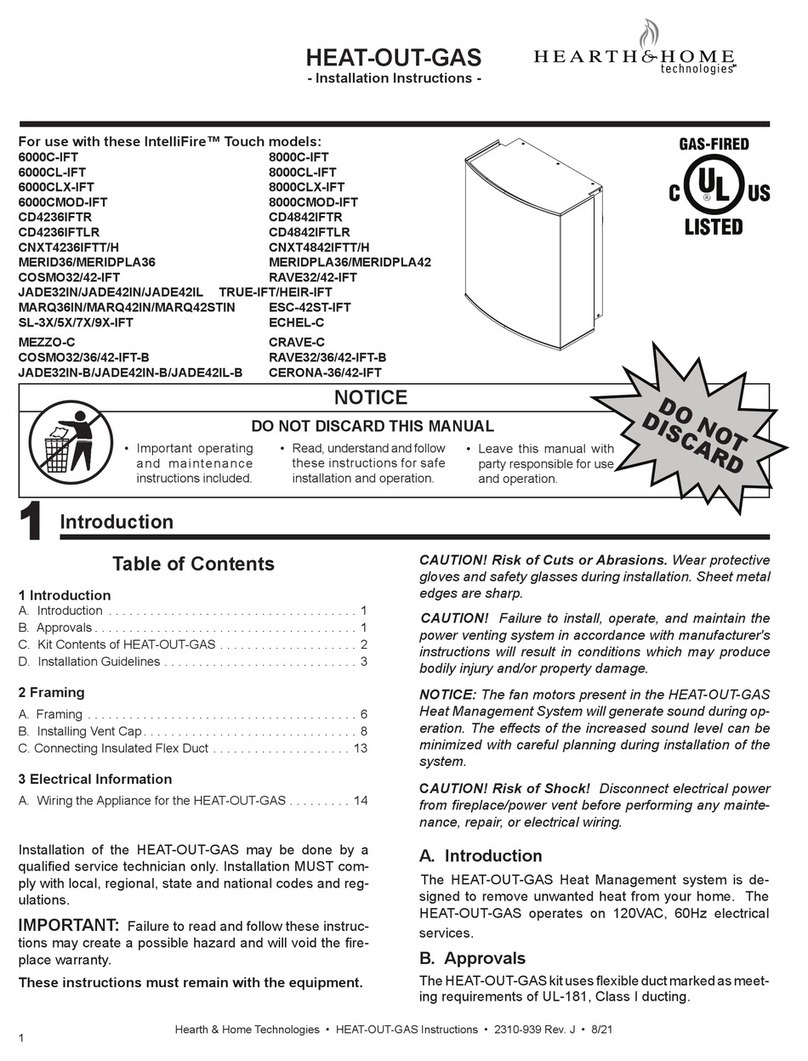

Hearth & Home PVLP-SLP-AU User manual

Other Hearth & Home Fireplace Accessories manuals

Hearth & Home

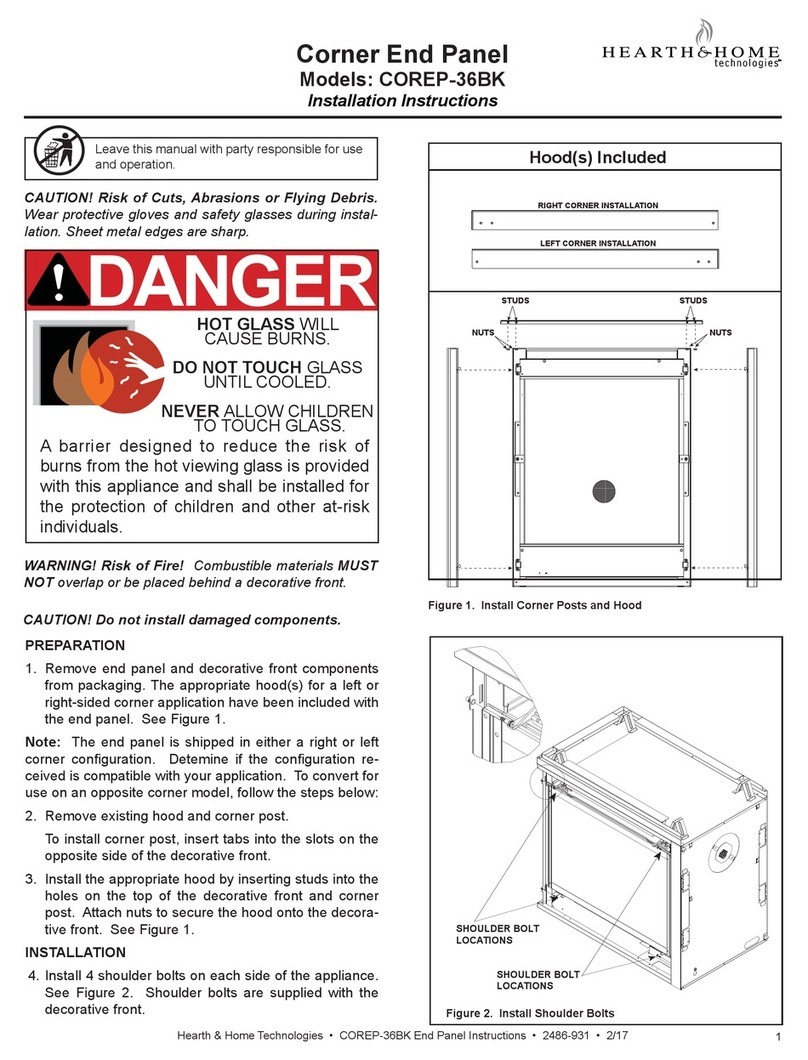

Hearth & Home COREP-36BK User manual

Hearth & Home

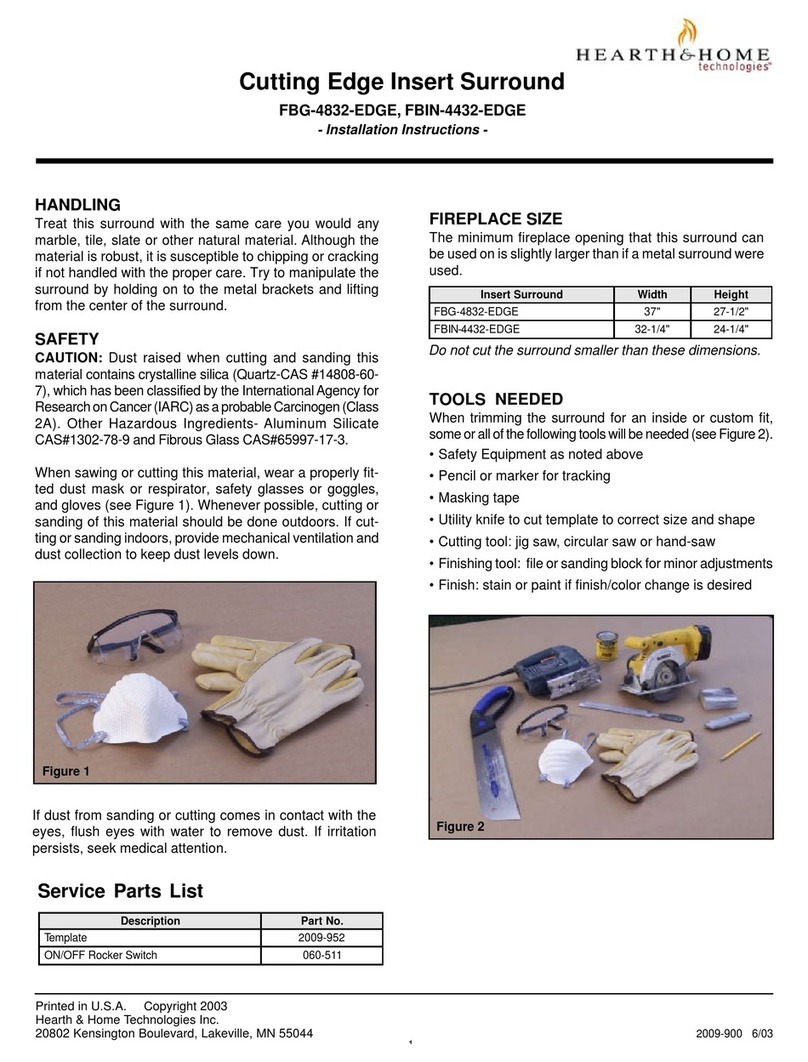

Hearth & Home FBG-4832-EDGE User manual

Hearth & Home

Hearth & Home LEGACY42-IFT User manual

Hearth & Home

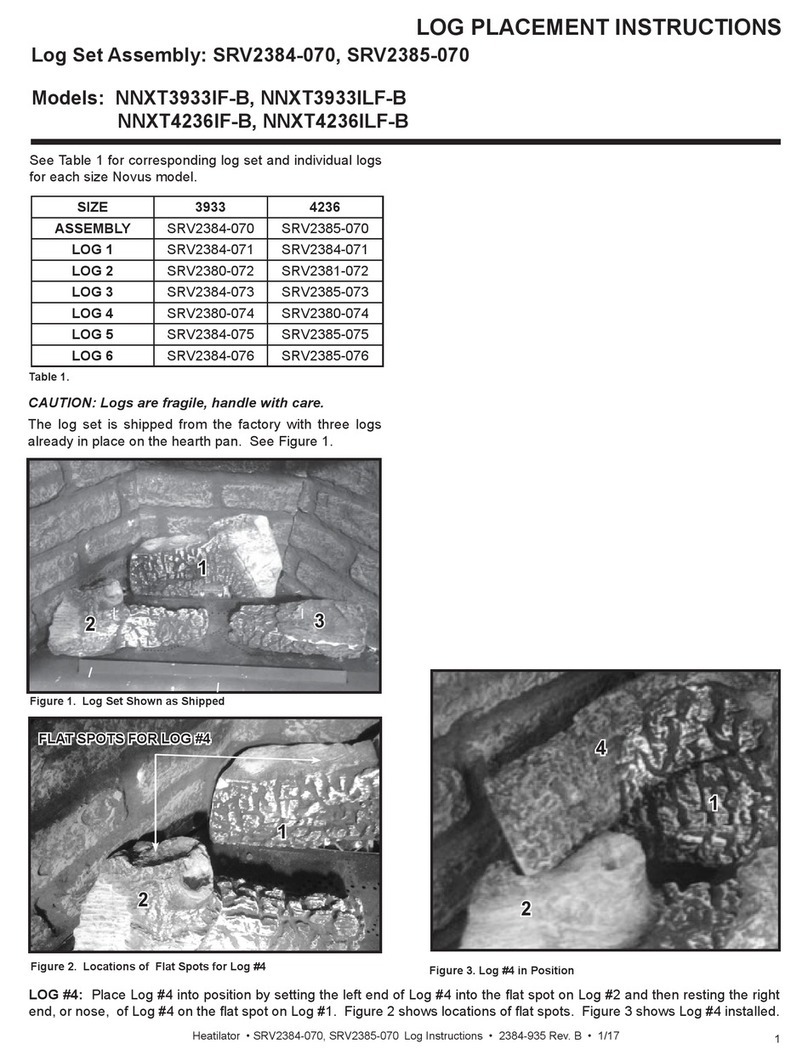

Hearth & Home SRV2384-070 User manual

Hearth & Home

Hearth & Home IntelliFire Plus User manual

Hearth & Home

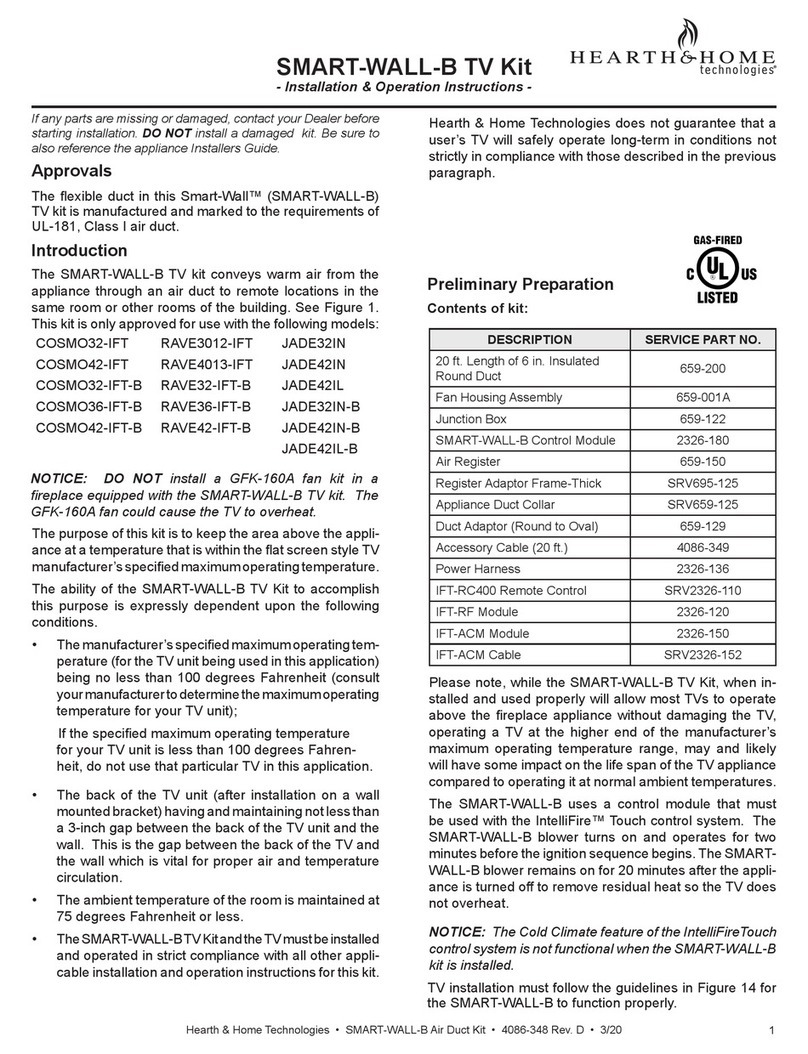

Hearth & Home SMART WALL B Installation instructions

Hearth & Home

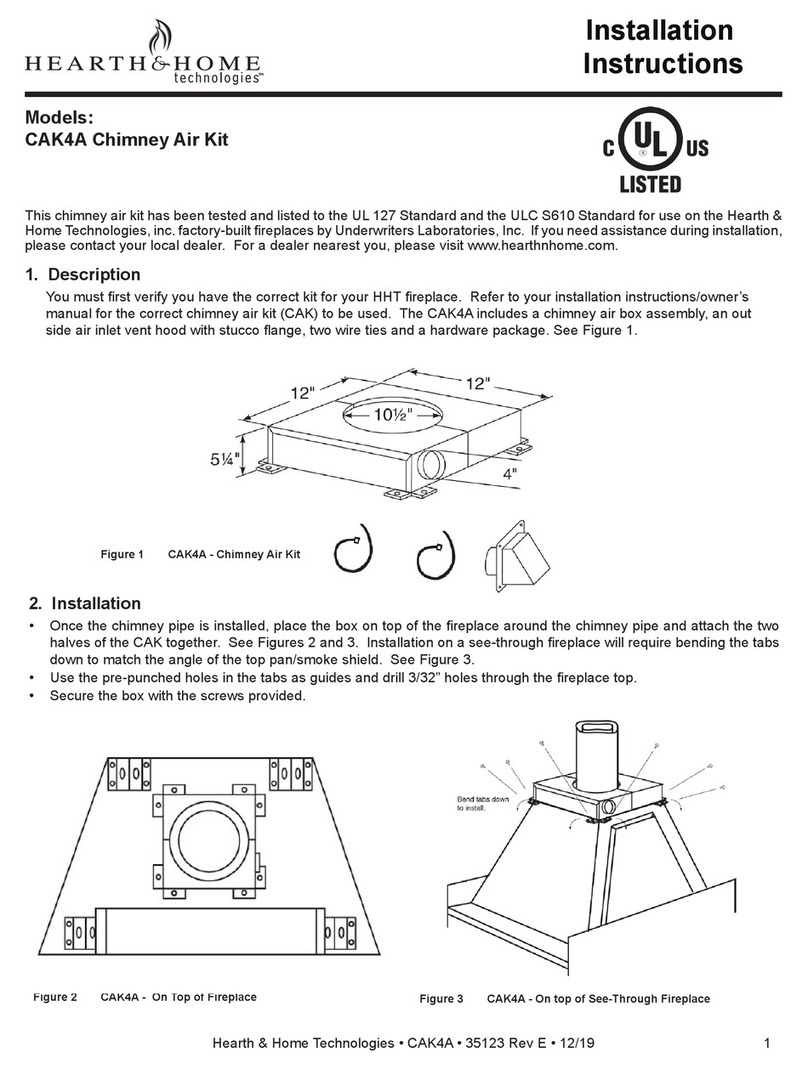

Hearth & Home CAK4A User manual

Hearth & Home

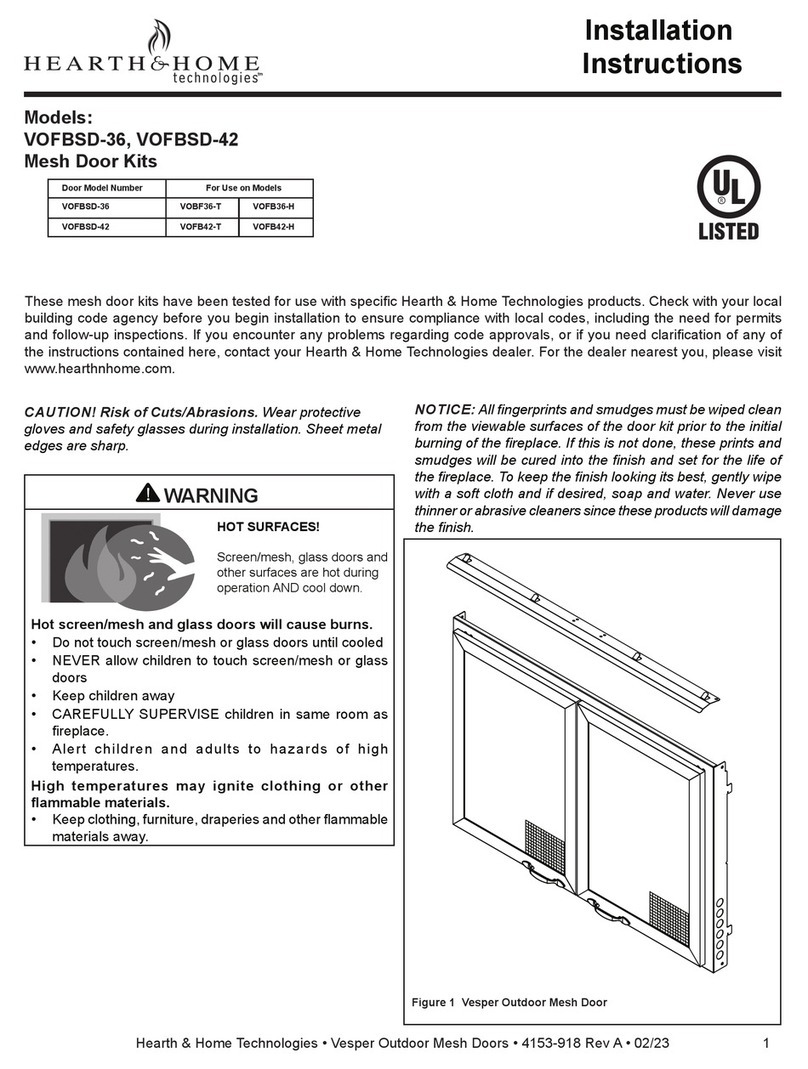

Hearth & Home VOFBSD-36 User manual

Hearth & Home

Hearth & Home 6000C-IFT User manual

Hearth & Home

Hearth & Home AVFLST48SSODK User manual

Hearth & Home

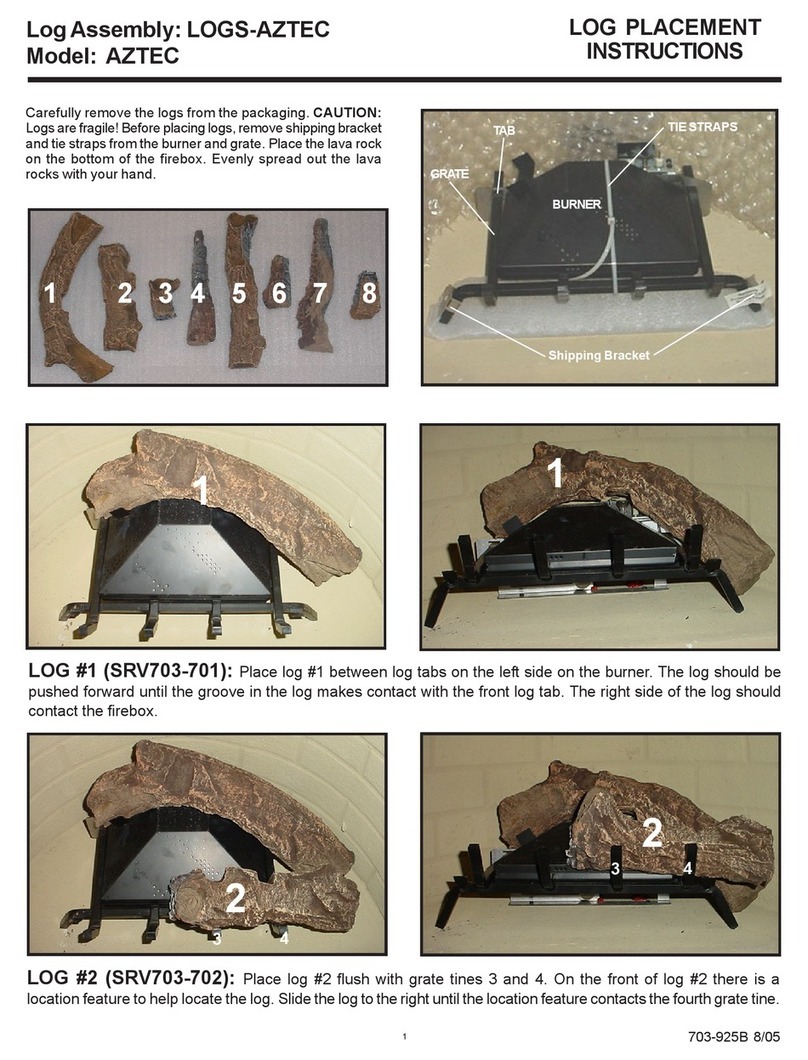

Hearth & Home LOGS-AZTEC User manual

Hearth & Home

Hearth & Home LOGS-2129 User manual

Hearth & Home

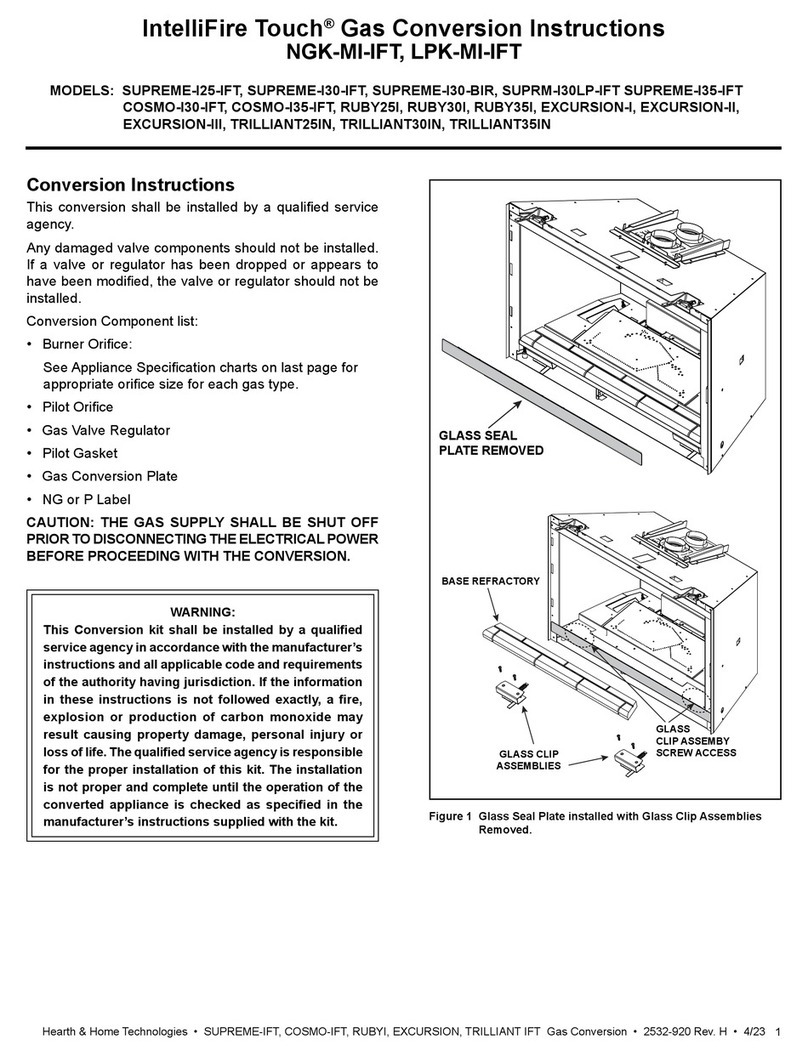

Hearth & Home IntelliFire Touch NGK-MI-IFT User manual

Hearth & Home

Hearth & Home MANOR36 User manual

Hearth & Home

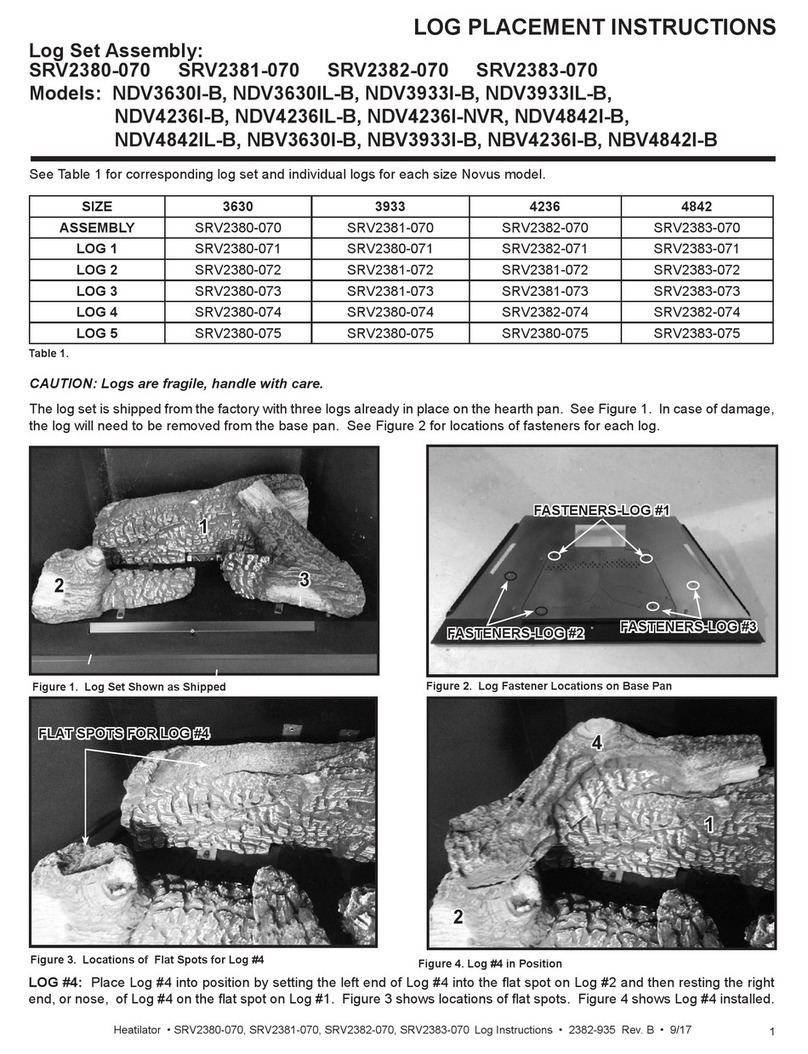

Hearth & Home SRV2380-070 User manual

Hearth & Home

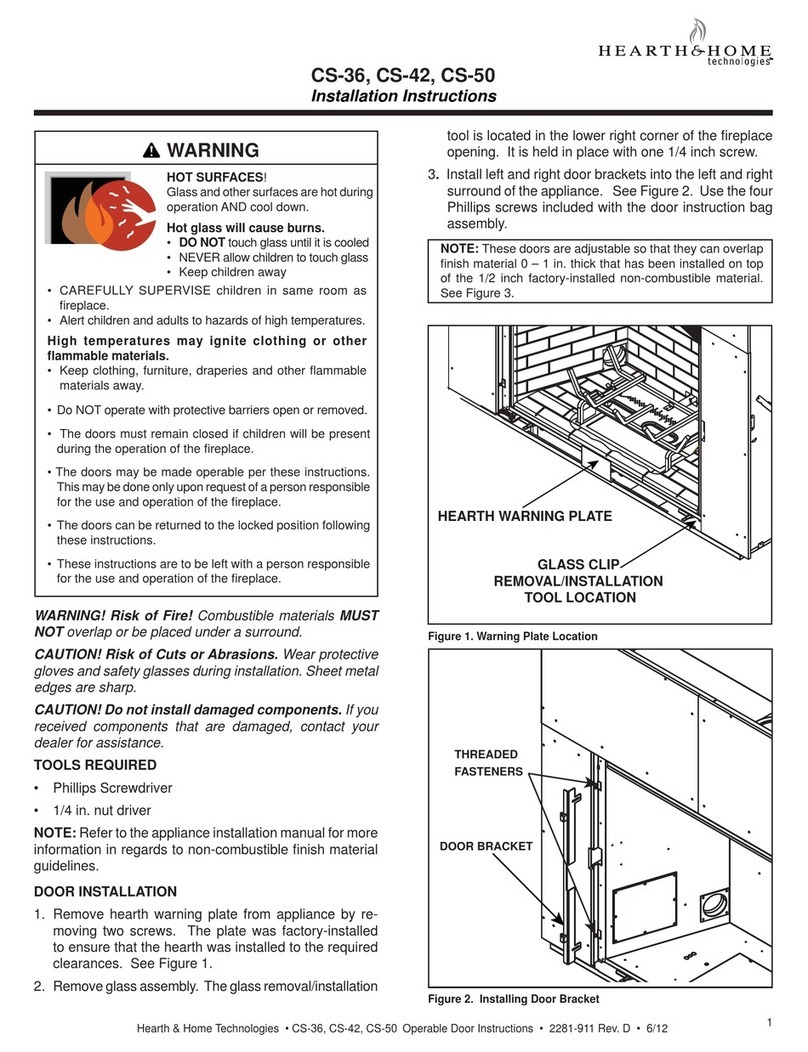

Hearth & Home CS-36 User manual

Hearth & Home

Hearth & Home Outdoor Lifestyles ODCOUG-36NR User manual

Hearth & Home

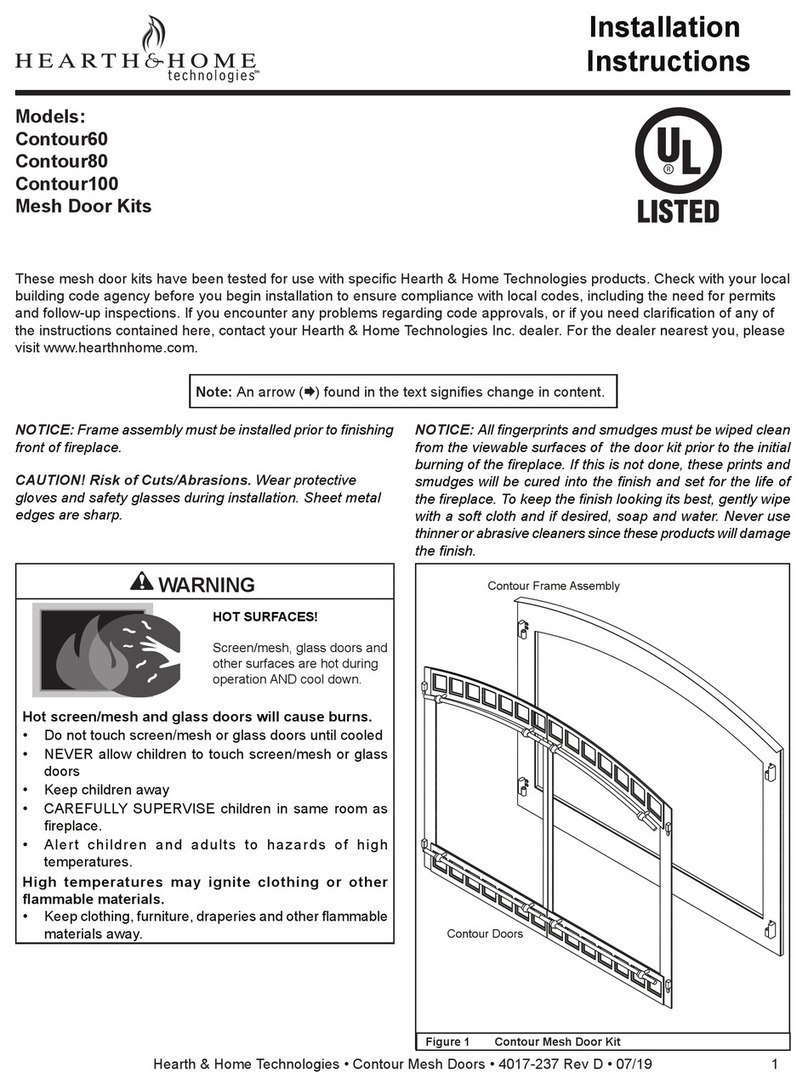

Hearth & Home Contour60 User manual

Hearth & Home

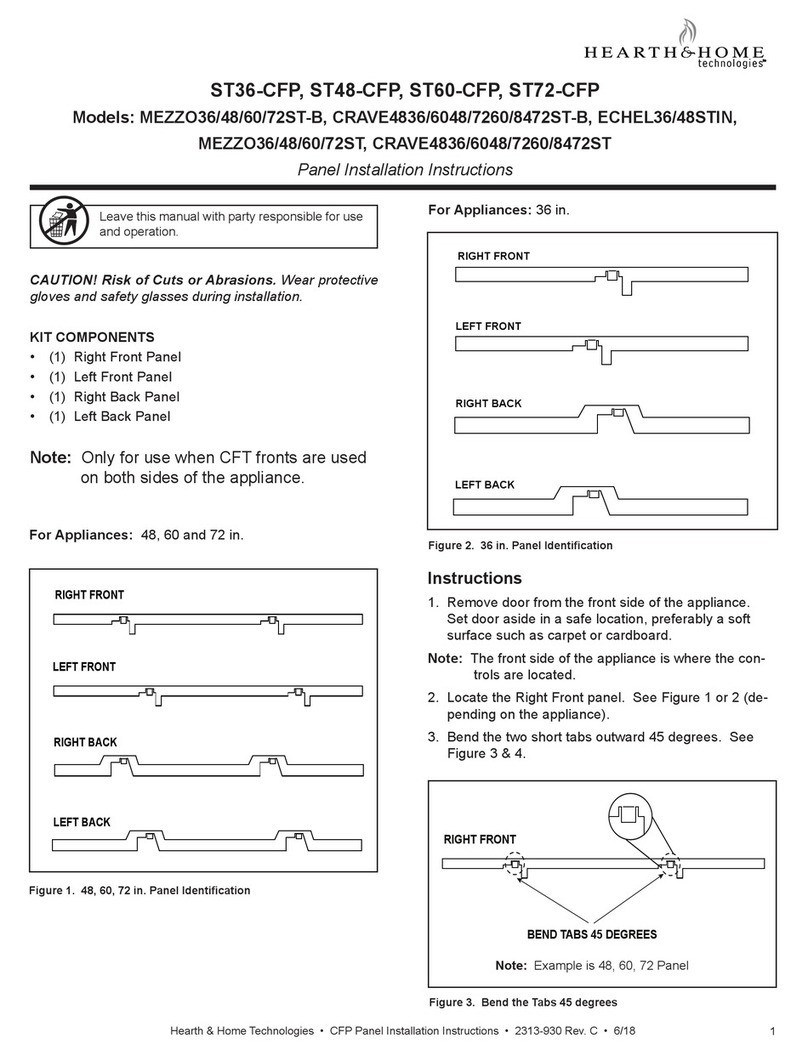

Hearth & Home ST36-CFP User manual

Hearth & Home

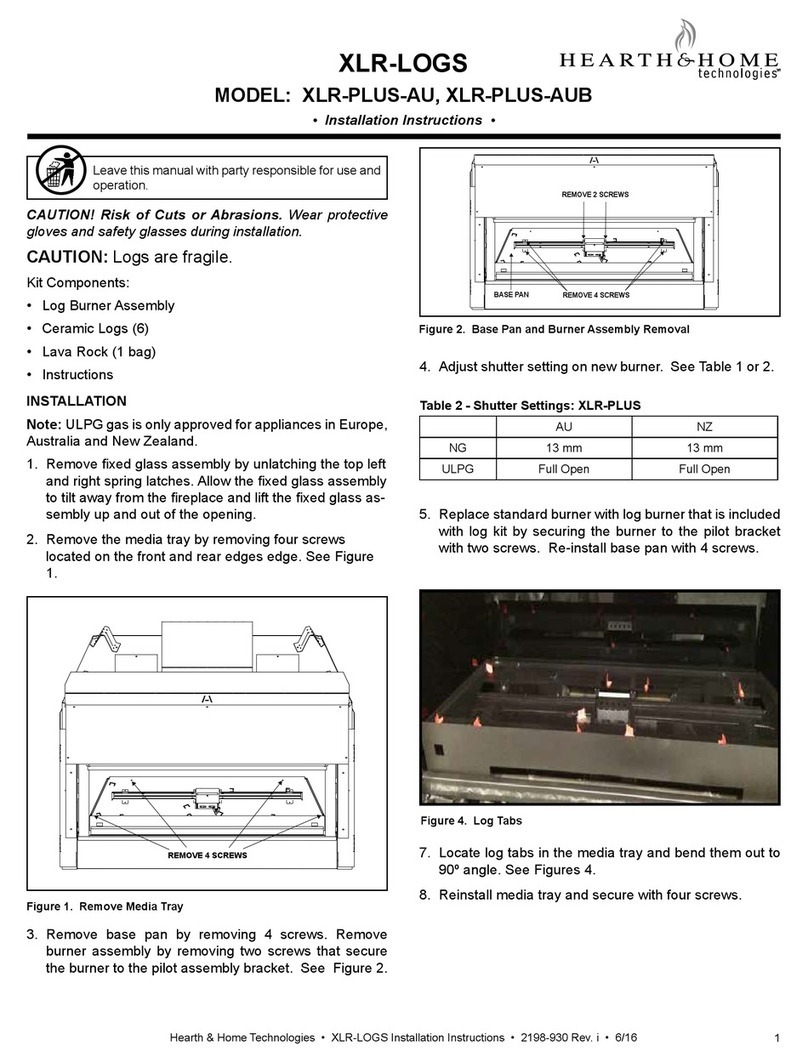

Hearth & Home XLR-LOGS User manual

Popular Fireplace Accessories manuals by other brands

Town & Country Fireplaces

Town & Country Fireplaces 22150051 instructions

Travis Industries

Travis Industries 33 DVI installation instructions

Lopi

Lopi Hearthview 864 user manual

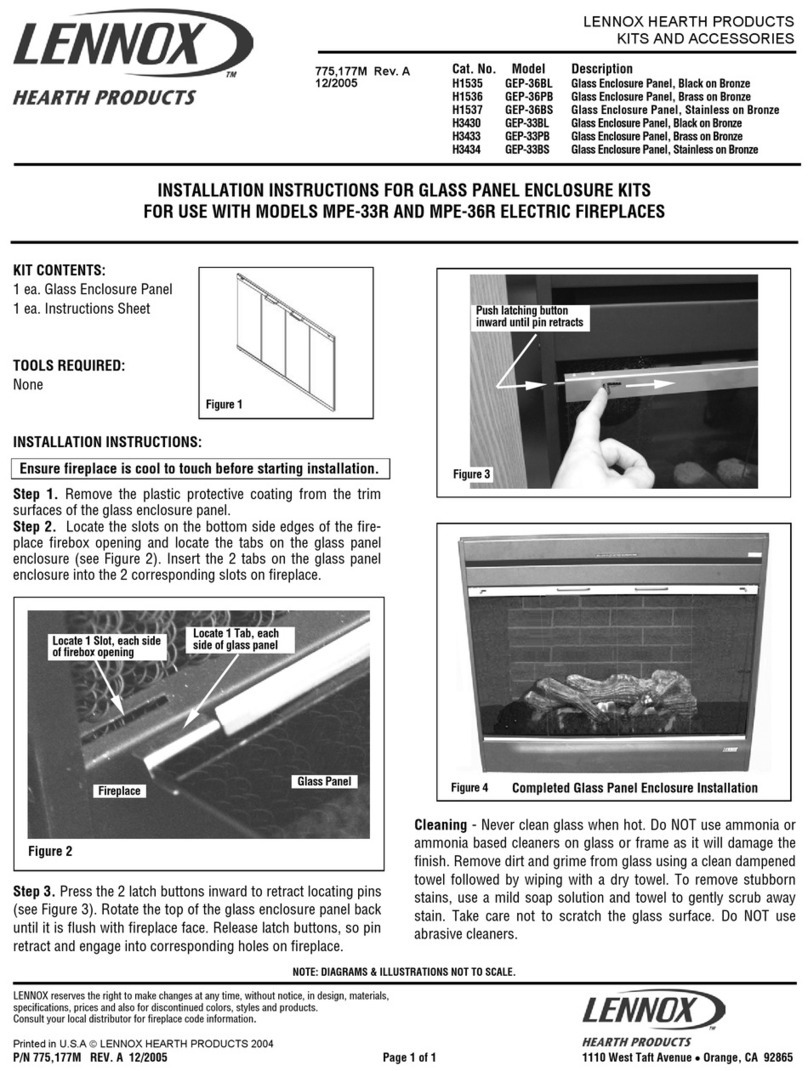

Lennox Hearth Products

Lennox Hearth Products LENNOX MPE-33R installation instructions

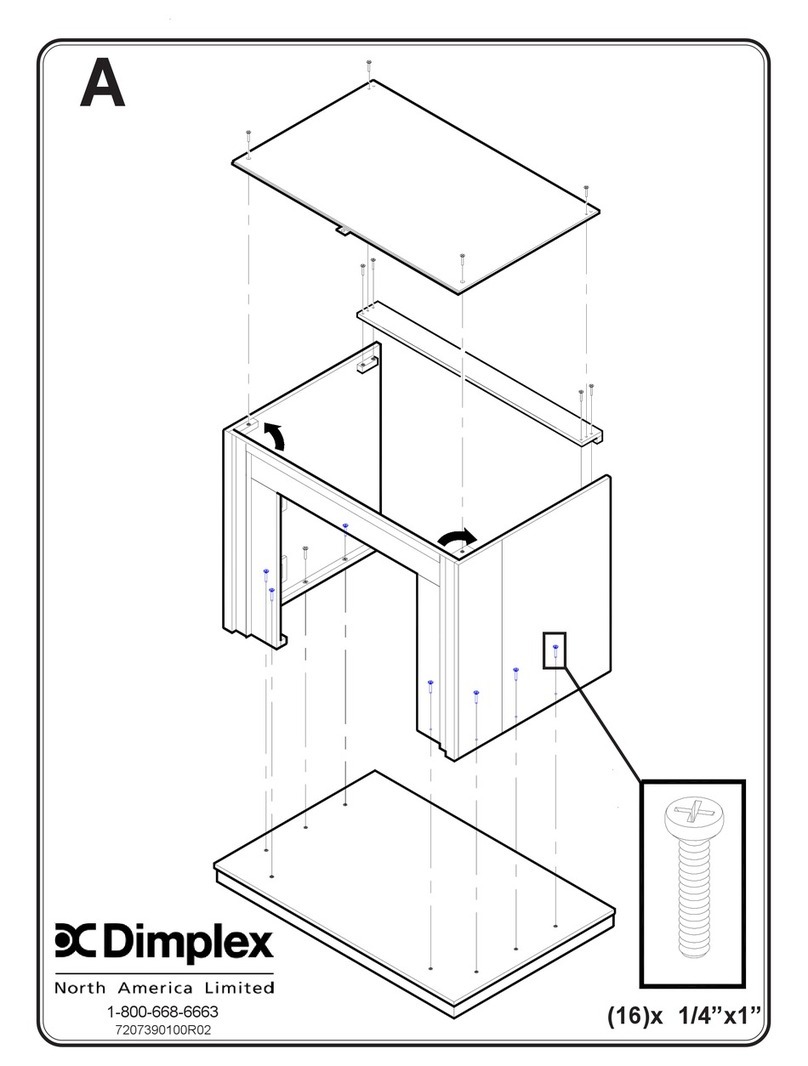

Dimplex

Dimplex DFP6776C install guide

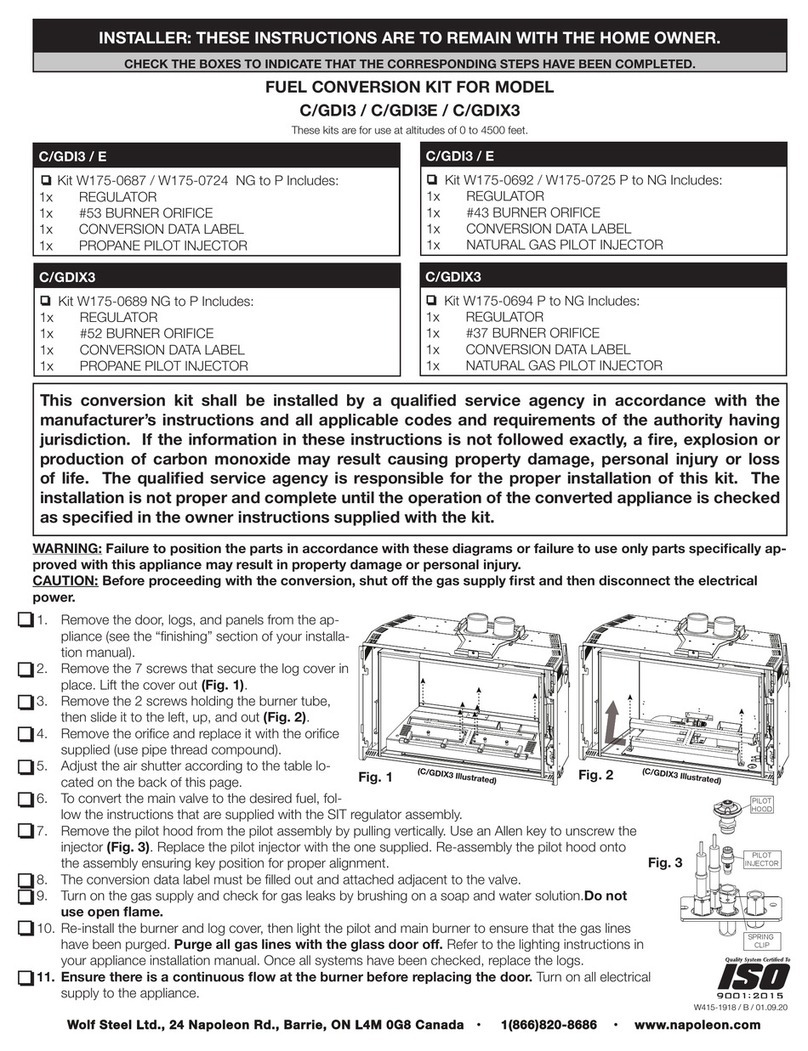

Napoleon

Napoleon W175-0689 instruction manual

Travis Industries

Travis Industries 95400424 installation instructions

Osburn

Osburn ZERO CLEARANCE KIT installation instructions

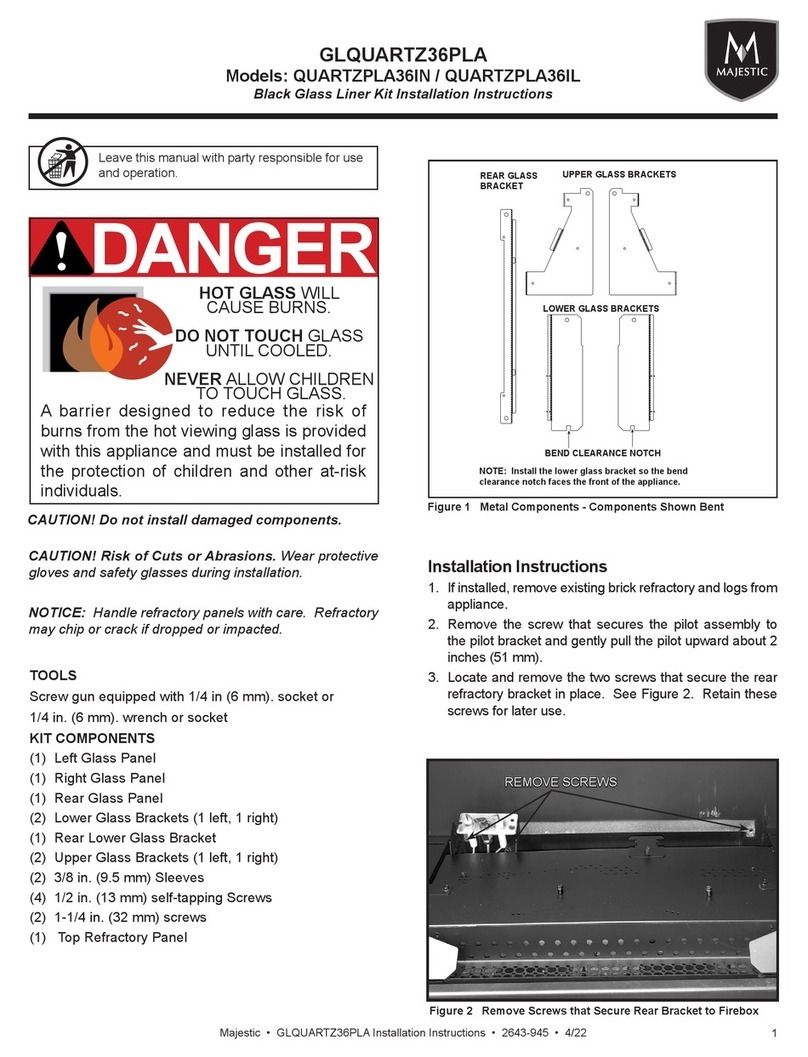

Majestic

Majestic QUARTZPLA36IN installation instructions

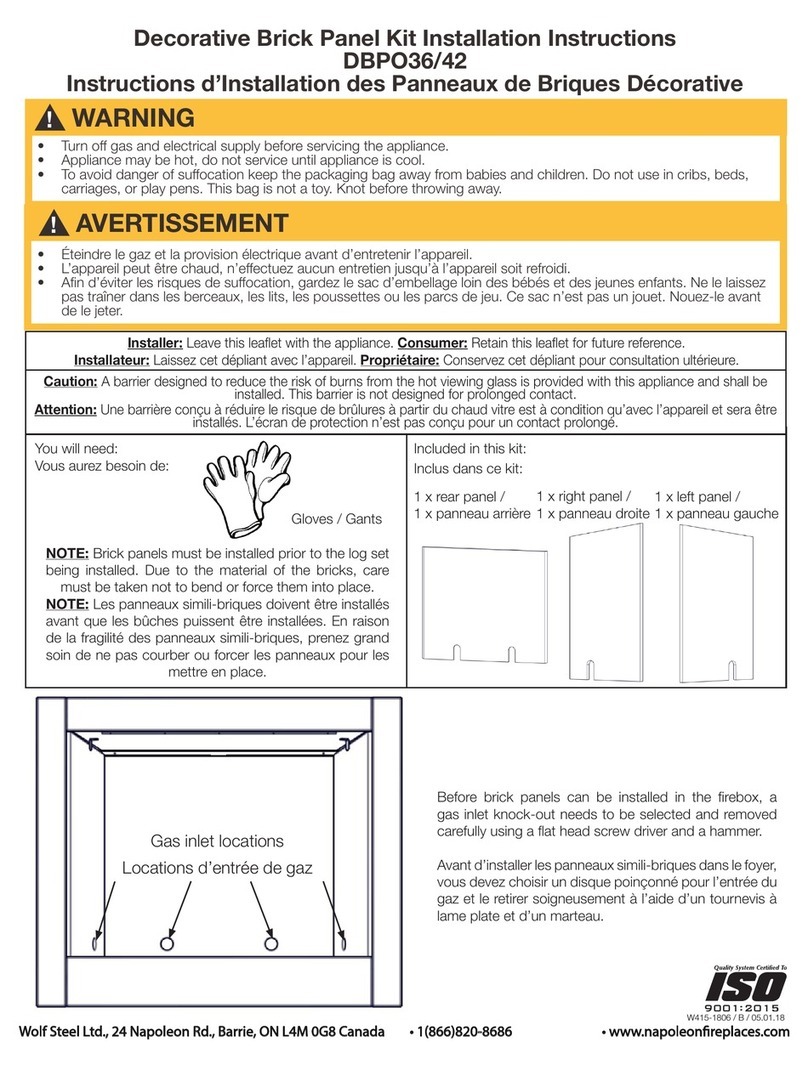

Napoleon

Napoleon DBPO36 installation instructions

Dimplex

Dimplex SMP-130-E install guide

Empire Comfort Systems

Empire Comfort Systems LS50TINF installation instructions