1

IK 5000 QUADRA-CHEK Deutsch

Bedienung

Eine genaue Beschreibung finden Sie unter www.heidenhain.de

Vor der Inbetriebnahme

Achtung

Die Montage und Inbetriebnahme• ist von einer Fachkraft für Elektrik

und Feinmechanik unter Beachtung

der örtlichen Sicherheitsvorschriften

vorzunehmen.

Die Steckverbindung darf nur• spannungsfrei verbunden oder gelöst

werden!

Der Antrieb darf während der• Montage nicht in Betrieb gesetzt

werden.

Stromschlaggefahr!

Niemals bei angeschlossener• Stromversorgung am geöffneten

Gerät arbeiten! Vor Öffnen des

Gerätes Netzstecker ziehen!

Schutzleiter darf nie unterbrochen• sein, auch nicht bei Anschluss über

Adapter.

Achtung

Keine Messgeräte oder anderen Geräte

anschließen, während die IK 5000

eingeschaltet ist.

Sicherheitsvorkehrungen

Für den Betrieb der IK 5000

gelten die allgemein anerkannten

Sicherheitsvorschriften. Nichtbeachtung

dieser Sicherheitsvorschriften kann zu

Sach- oder Personenschäden führen.

Die Sicherheitsvorschriften können je

nach Unternehmen variieren. Im Falle

eines Konflikts zwischen dem Inhalt

dieser Kurzanleitung und den internen

Regelungen eines Unternehmens, in

dem dieses Gerät verwendet wird,

sollten die strengeren Regelungen

gelten.

Anschlüsse an der IK 5000

MancheVerbindungen werden direkt mit

dem Anschluss an der IK 5000 PC-Karte

hergestellt, andere über Erweiterungs-

anschlüsse, die zur Karte hinzugefügt

werden können (sog. Flyouts). Die vor-

hergehende Seite bietet einen Über-

blick über die Anschlüsse an der Karte

und die zusätzlichen Anschlüsse an

der Rückseite eines IK-5000-Systems.

Die Anschlusskonfigurationen für alle

standardmäßigen IK-5000-Systeme sind

ebenfalls dargestellt. Einige Anschlüsse

gibt es an mehreren IK-5000-Produkten,

andere gibt es nur an bestimmten

Systemen der IK-5000-Produktfamilie.

Die Pinbelegung der Anschlüsse ist am

Ende dieser Kurzanleitung beschrieben.

Messmethoden mit der

IK 5000

IK 5294 Fadenkreuz

IK 5293 ManuellesTastsystem

IK 5394-EG Manueller optischer

Kantensensor

IK 5394-3D ManuellesTastsystem

undVideo

IK 5493 Optischer Kantensen-

sor und CNC

IK 5494-2D Video und CNC

IK 5494-3D Tastsystem,Video

und CNC

IK 5594-3D TastsystemTP200,

Video und CNC

Anschlüsse an der IK 5000

A Eingänge für Messgeräte, X-,Y-,

Z-Achse, und Fußschalter

B Ausgänge für CNC-Steuerung,

X-,Y- und Z-Achse

H Eingang für Messgerät,

Q-Achse

J Ausgang für CNC-Steuerung,

Q-Achse

K Ausgänge für

Beleuchtungssteuerung

(Video) und Zoom

M Eingang fürTastsystem

N Ausgang für Kamera-Zoom-

Steuerung

P Eingang für Profilprojektor-

Lichtquelle für optische

Kantenerkennung

R Eingang für Profilprojektor-

Bildschirmsensor für optische

Kantenerkennung

Verwendung dieser

Kurzanleitung

Diese Kurzanleitung können Sie

verwenden, wenn Ihr System bereits

für die Durchführung von Messungen

konfiguriert ist. Ist Ihr System noch

nicht konfiguriert, lesen Sie bitte die

Kurzanleitung IK 5000 für Hersteller

und Händler und konfigurieren Sie Ihr

System zuerst.

Diese Kurzanleitung beinhaltet eine ge-

kürzte Fassung der Benutzer-Anleitung

für alle standardmäßigen IK-5000-

Produkte. Für das jeweils verwendete

System gelten nur bestimmte Anweisun-

gen. Befolgen Sie die Anweisungen in

der dargestellten Reihenfolge und lassen

Sie diejenigen Schritte aus, die für Ihr

spezielles System nicht relevant sind.

Hinweis

Die vollständige Benutzer-

Anleitung finden Sie online im

Benutzer-Handbuch IK 5000 unter

www.heidenhain.de.

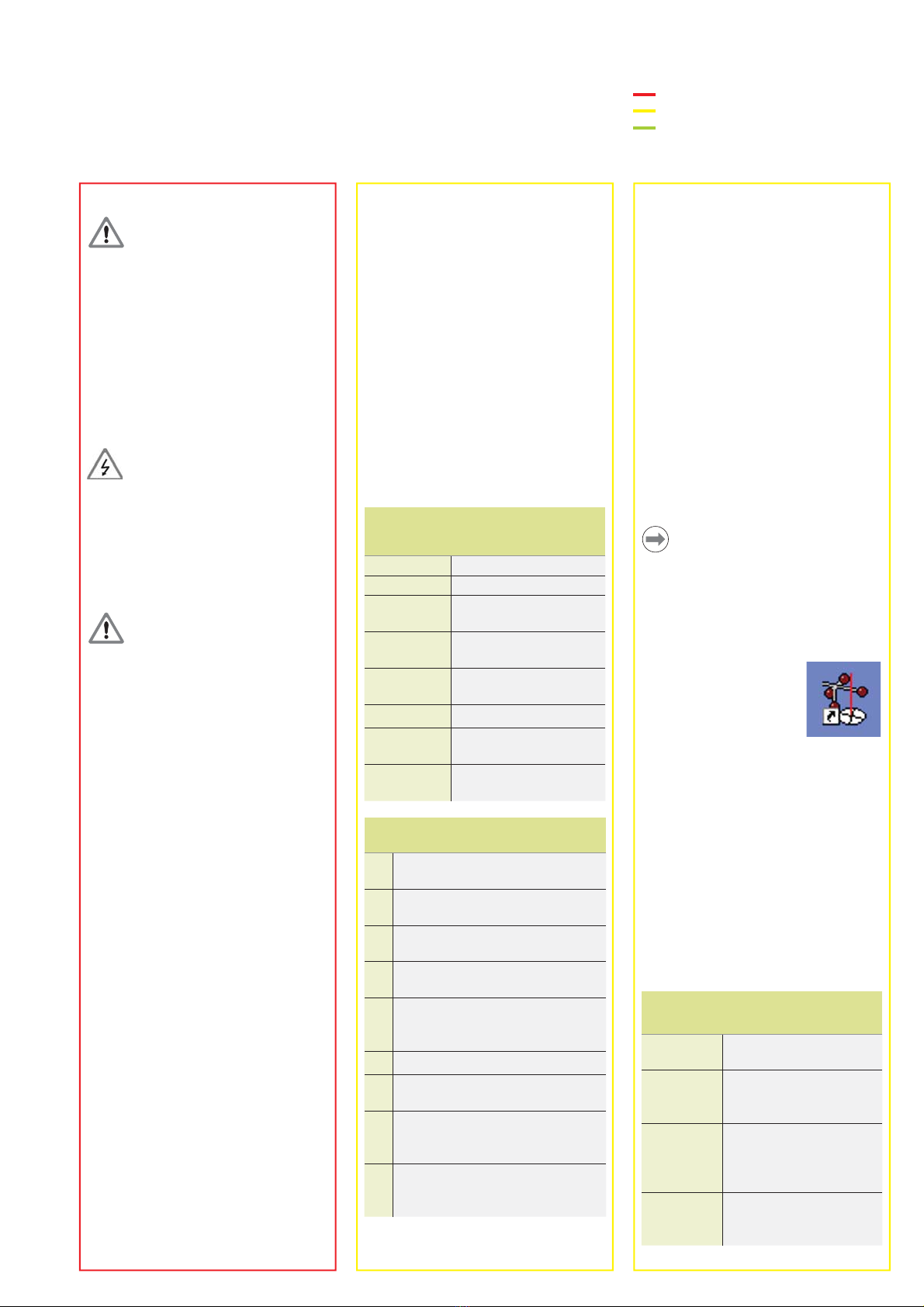

IK-5000-Programm starten

Klicken Sie zum Starten

des Programms auf

das QC-5000-SYMBOL

auf derWindows®-

Benutzeroberfläche.

Benutzer-Oberfläche

Die Benutzeroberfläche entspricht

den üblichenWindows-Konventionen

bezüglich Menüführung, Auswahl von

Optionen, Click-and-Drag-Funktionen

sowie der grundsätzlichen Datei- und

Bearbeitungsoptionen.

Anwender-Oberflächen

(Arbeitsbereiche)

Die Benutzeroberfläche der IK 5000

ist ein Arbeitsbereich, bestehend aus

Fenstern, Menüs,Werkzeugboxen und

einer Statusleiste.

IK 5000 Anwender-

Oberfläche

Fenster Zeigen Zahlen,Text

und Grafiken

Menüs Enthalten Optionen für

Dateien, Bearbeitungs-

und Messfunktionen

Werkzeug-

boxen Enthalten

Schaltflächen für den

Schnellzugriff auf

Menüfunktionen

Status-

leiste Enthält Informationen

zum Systemstatus der

IK 5000

unbedingt beachten

wichtig

informativ