NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

4

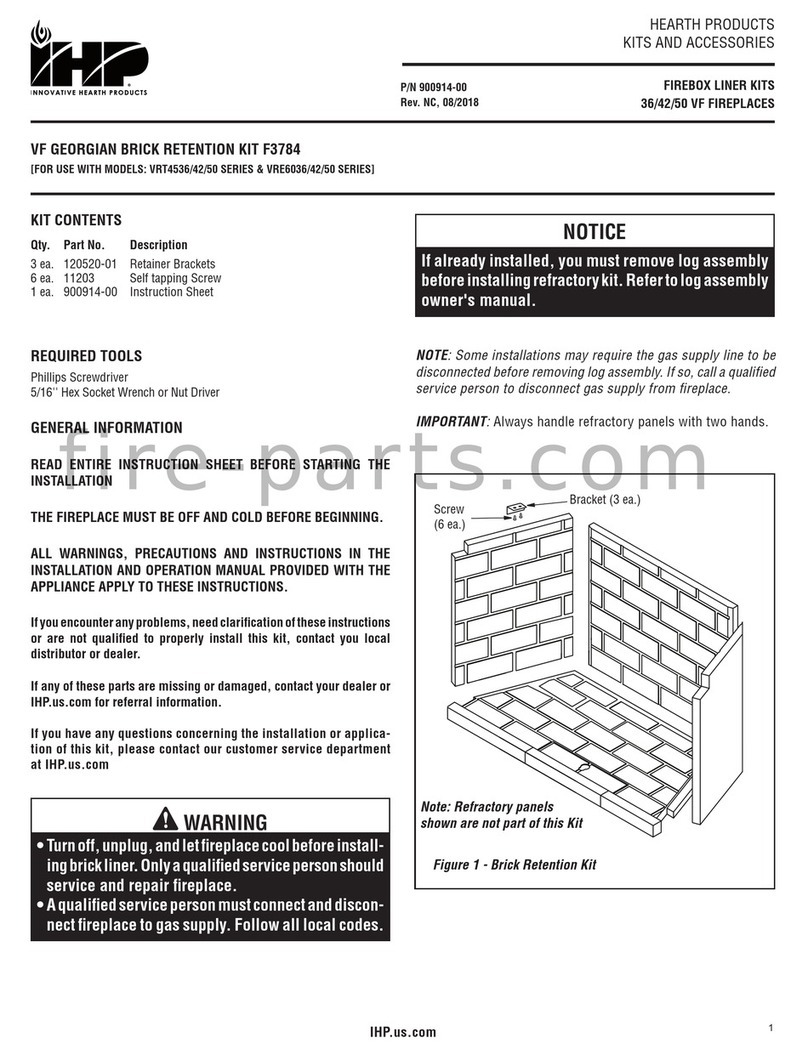

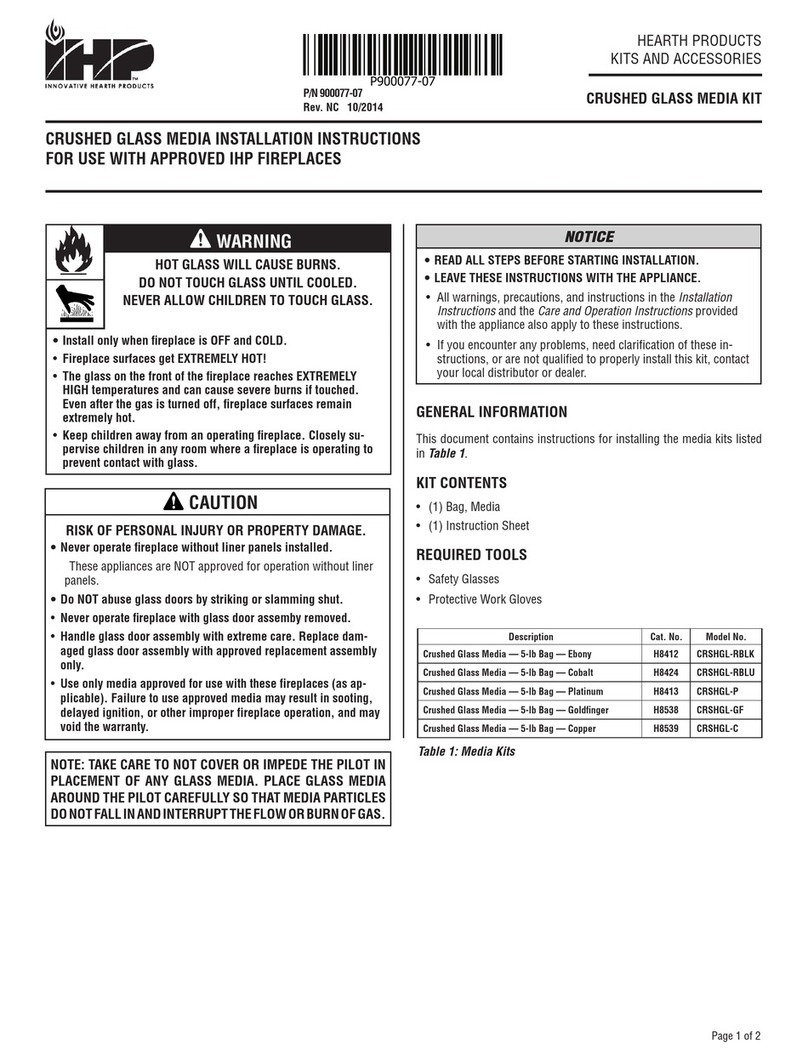

NOTICE

This kit must be installed by a qualified installer,

service agency, or gas supplier at the time of the

fireplace installation. These instructions must

be used in conjunction with the installation and

operation manual provided with the fireplace.

WARNING

DO NOT cover or place objects in front of the heat

register opening. AVOID locating heat register

opening within 76 inches above floor level as

discharge temperatures are hot!

WARNING

Minimum clearances below the ceiling is 4”. Note

that staining or streaking may occur on light colored

ceilings due to any dust, etc. in air flow.

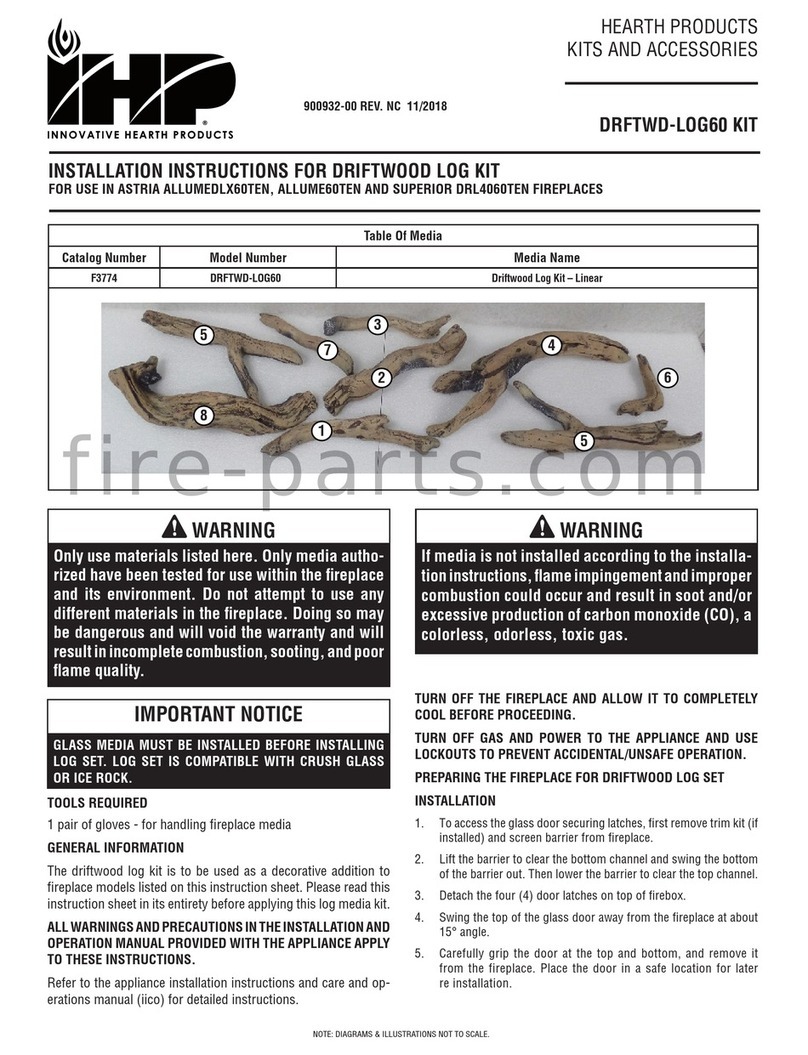

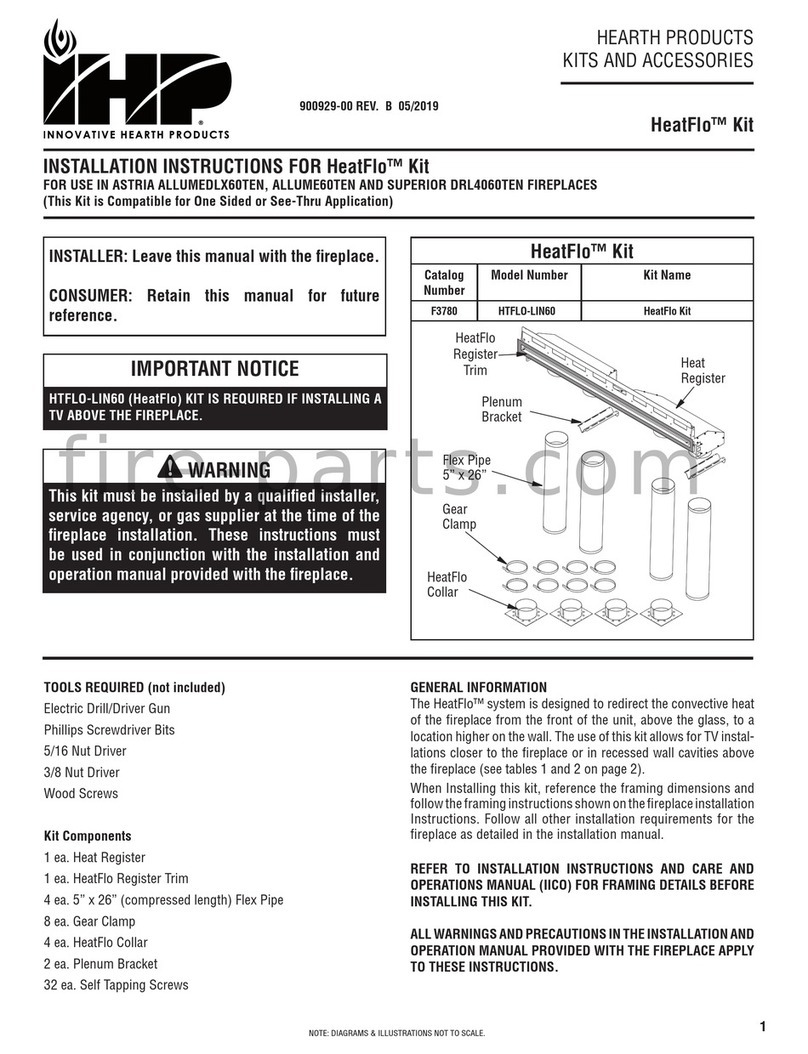

HEATFLO™ KIT INSTALLATION

FIREPLACE PREPARATION

NOTE: The installation of this HeatFlo system must be done at the

framing stage. Some work can be performed before the fireplace

is placed in the framing, though installing the collars onto the

fireplace must be done after to prevent interference with framing

header when placing fireplace.

NOTE: Before the following steps are performed, it is recommended

to prepare the fireplace top spacers, install the non-combustible

fireboard standoffs, and install the header shield. Refer to fireplace

installation instructions.

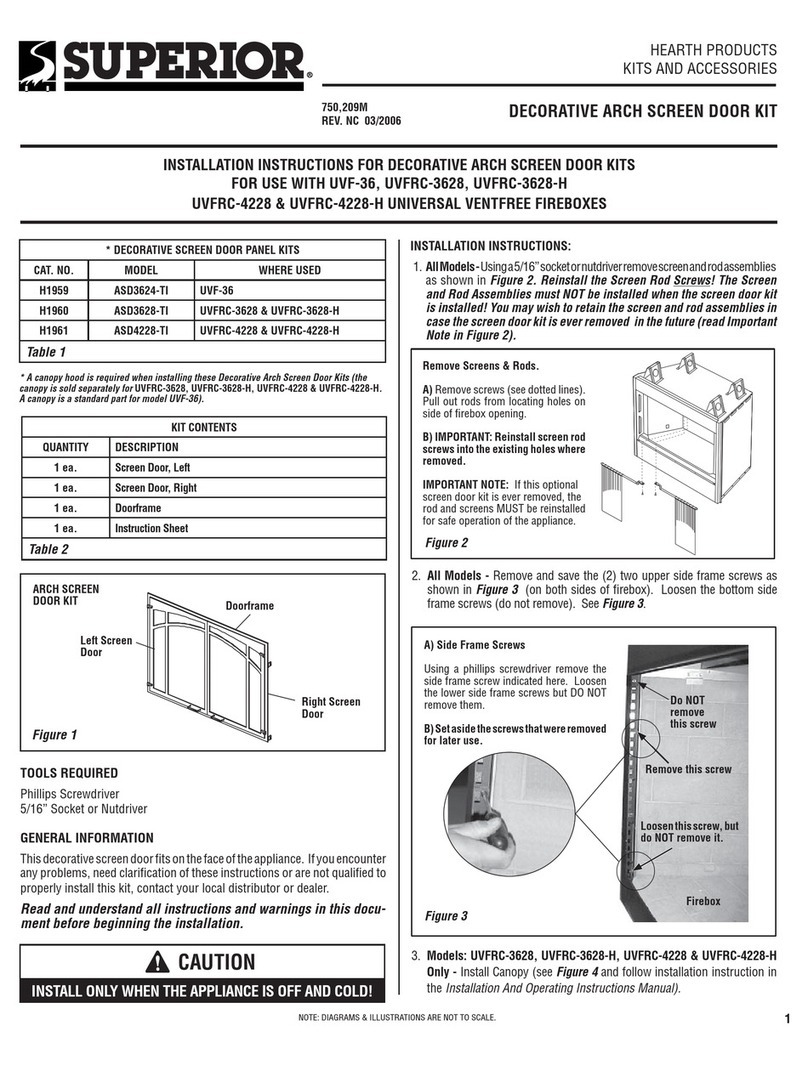

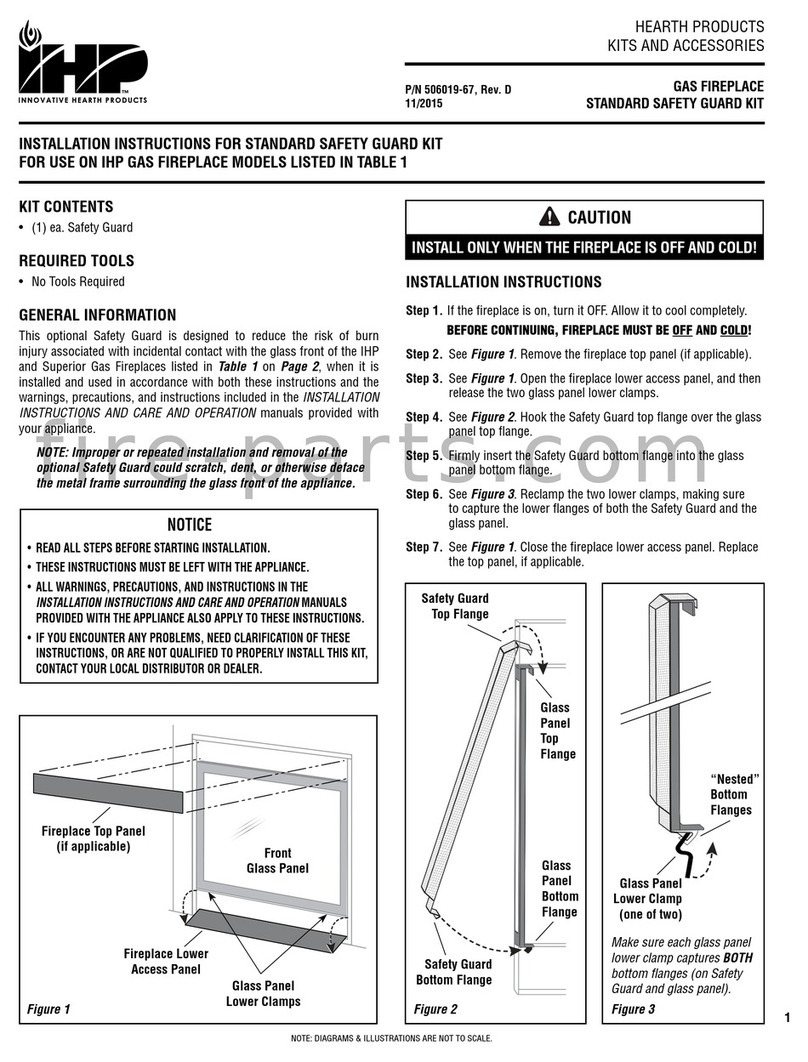

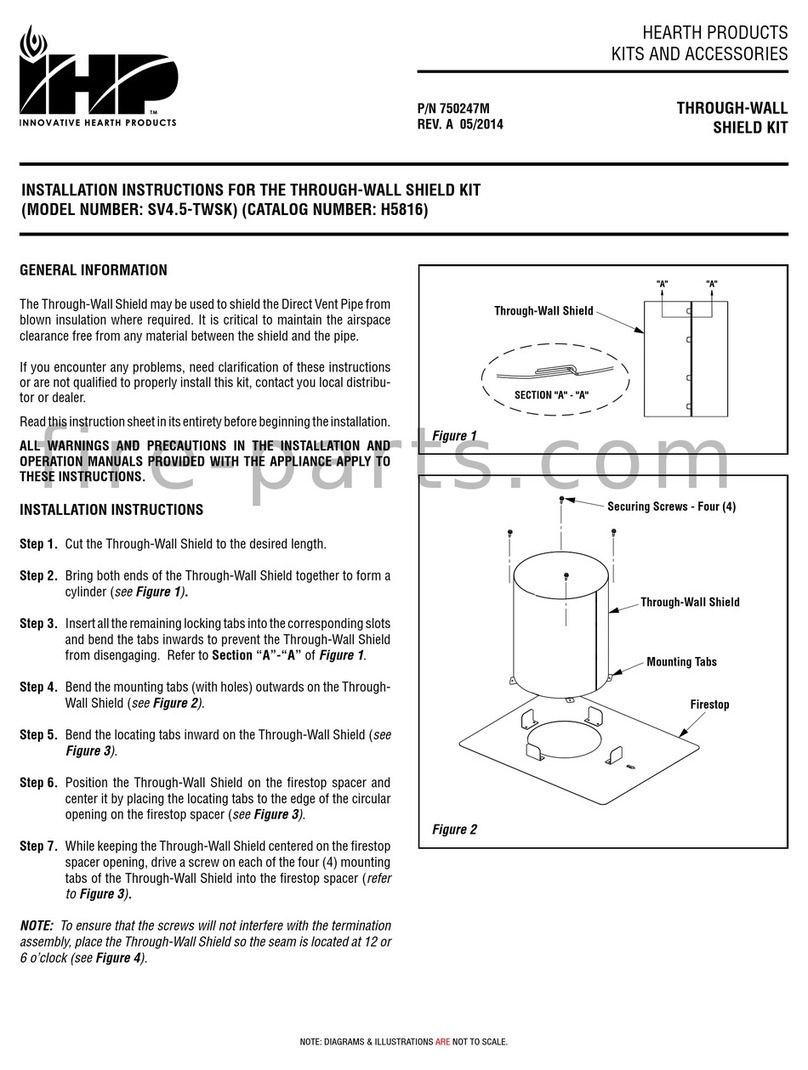

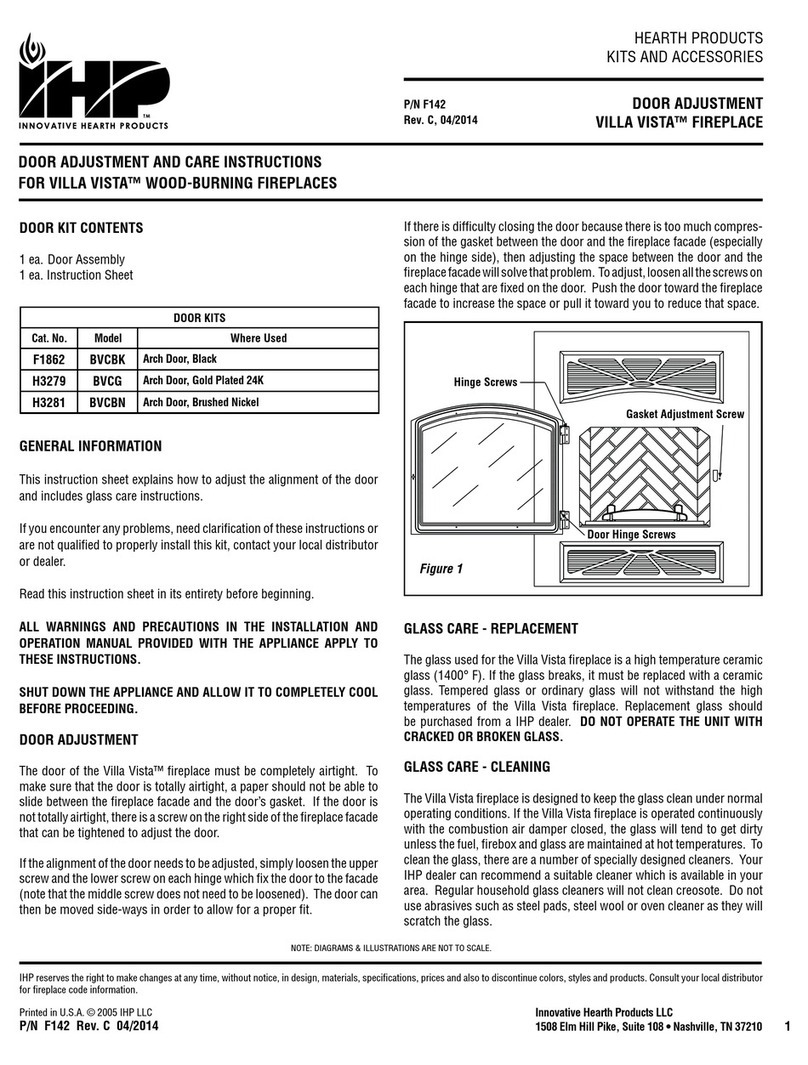

1. Remove four knockouts in fireplace top and discard (Figure 4).

2. Remove four precut plugs in insulation between fireplace top

and inner heat deflector (Figure 4).

3. Remove four knockouts from inner heat deflector (Figure 4).

4. Installfireplaceintoframingaccordingtothefireplaceinstallation

instructions.

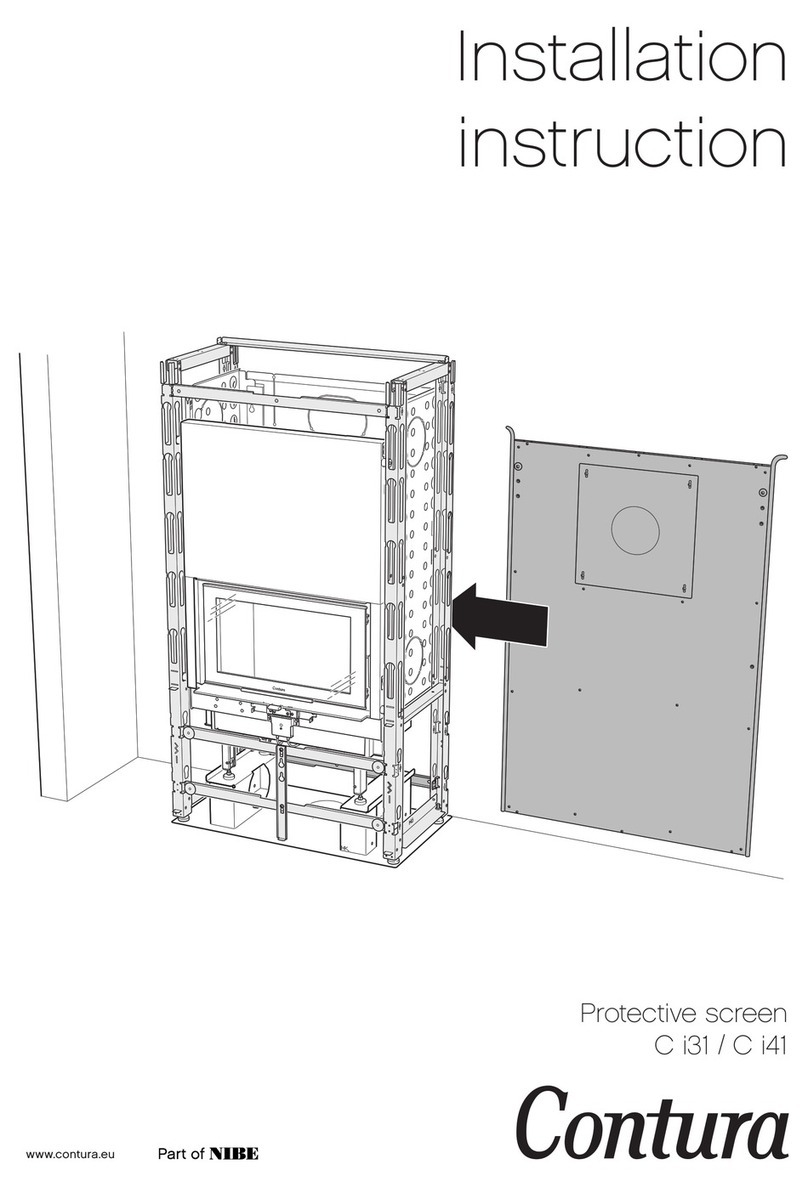

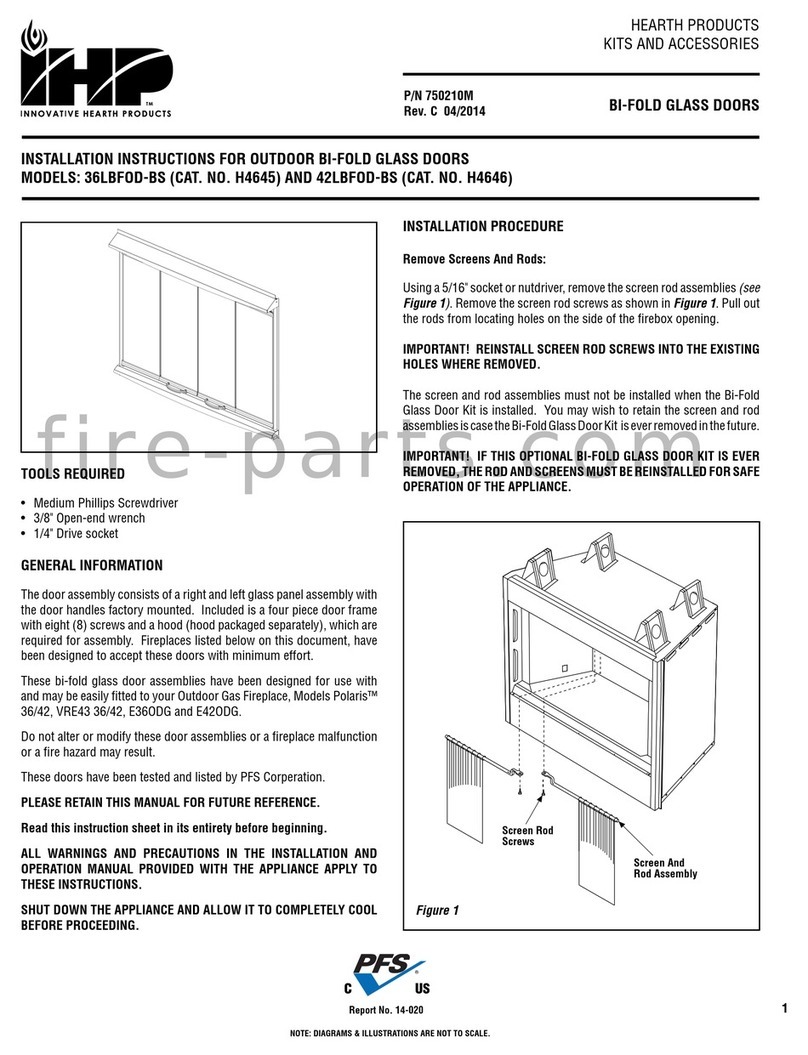

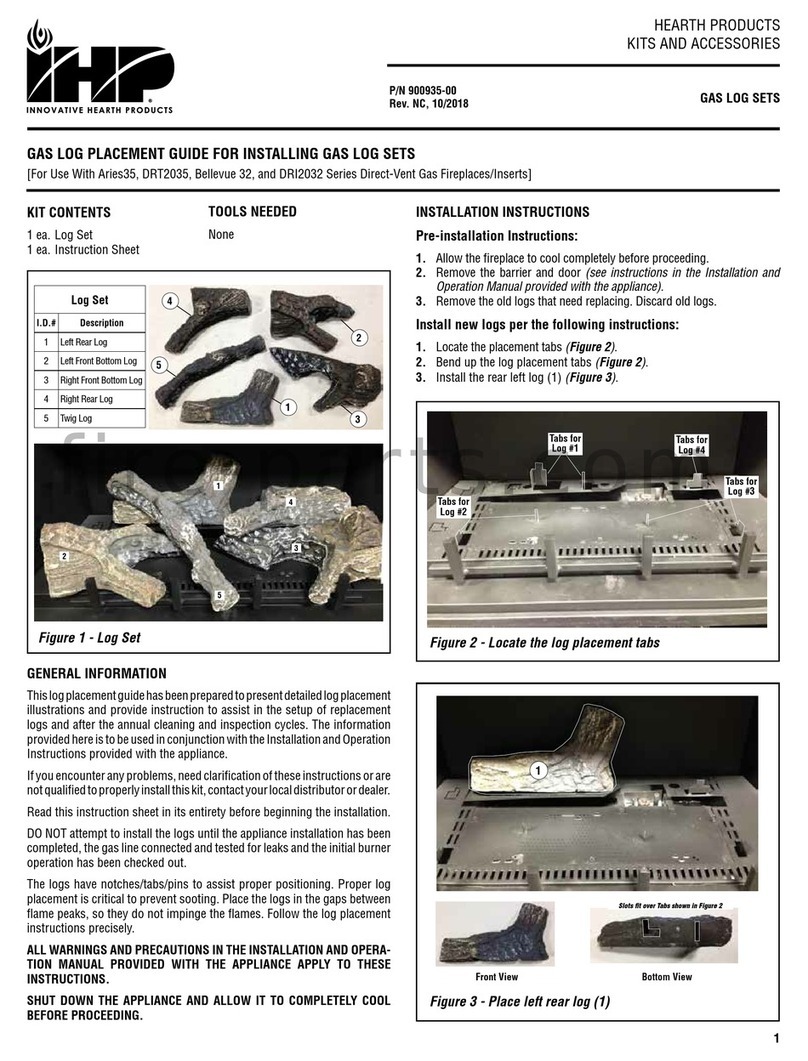

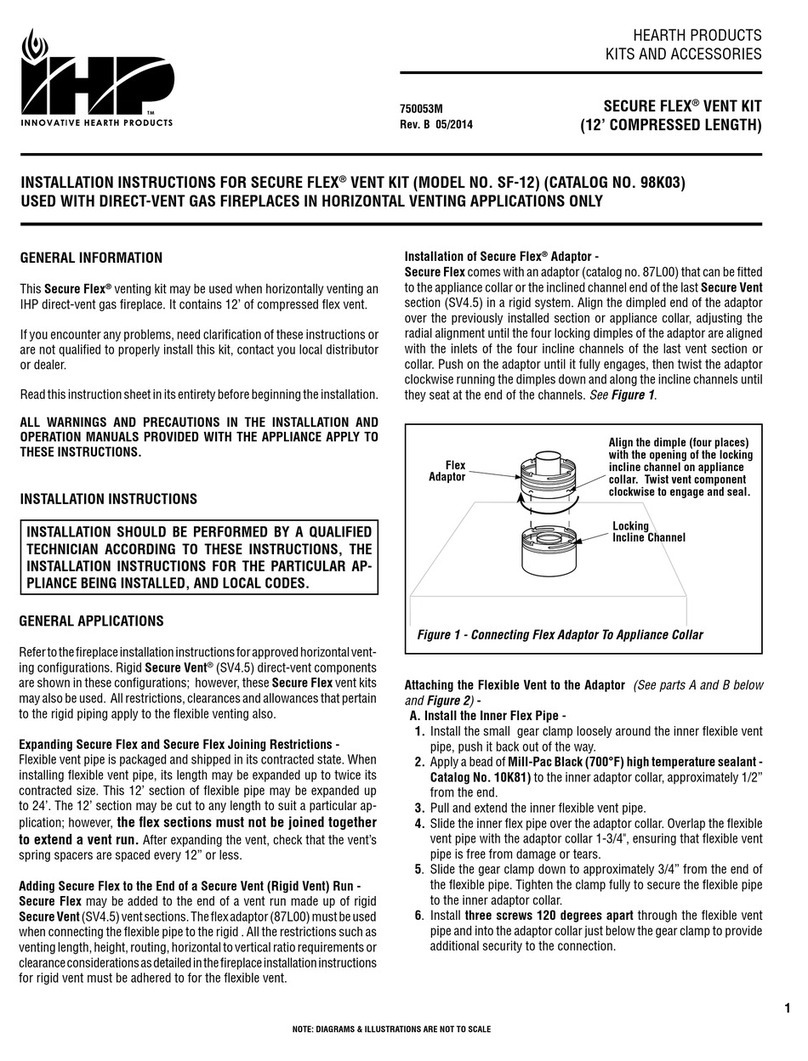

5. Insert four small collars into knockout openings in fireplace top

with tabs up (Figure 5). Tabs should be resting on fireplace top.

6. Place four large collars with flange down on fireplace top aligned

with small collars (Figure 5).

7. Place four collar mounting plates over large collars and attach

with screws provided (Figure 5).

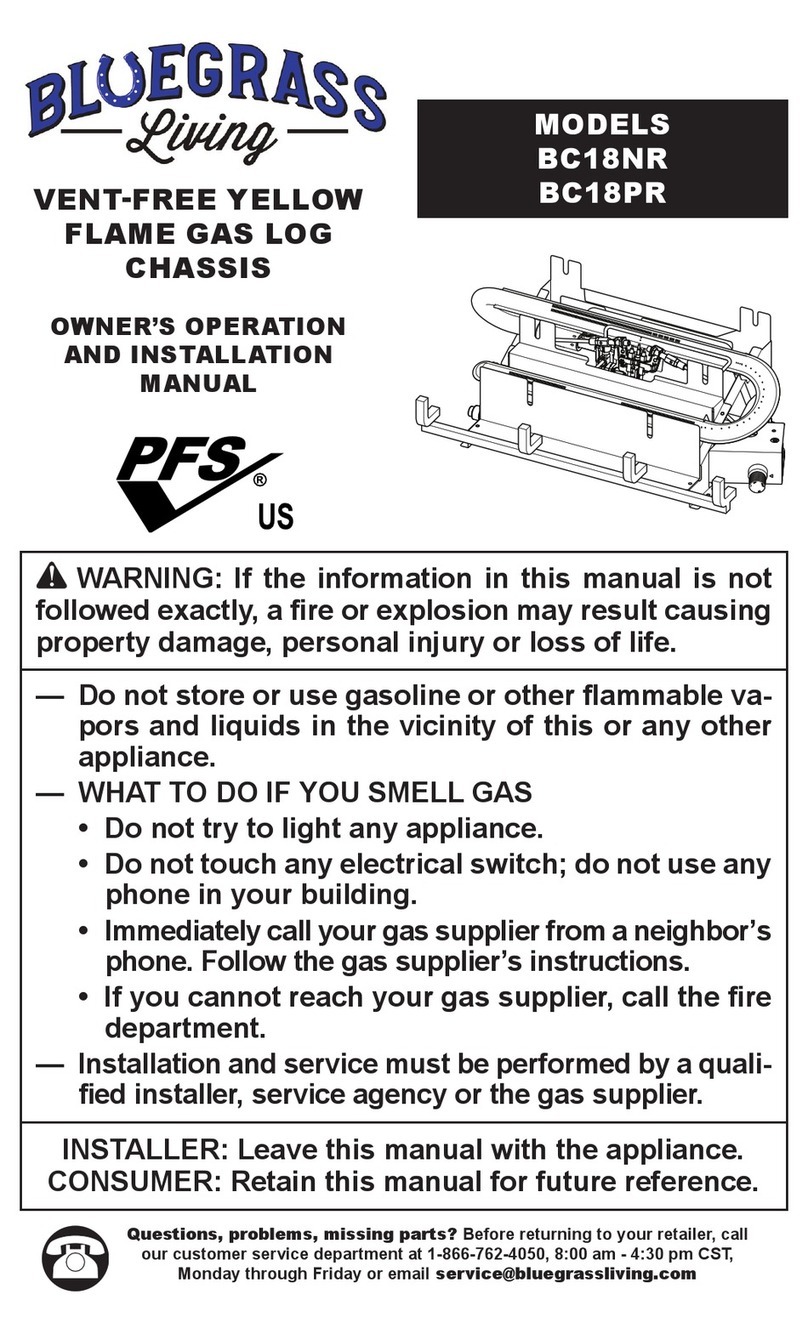

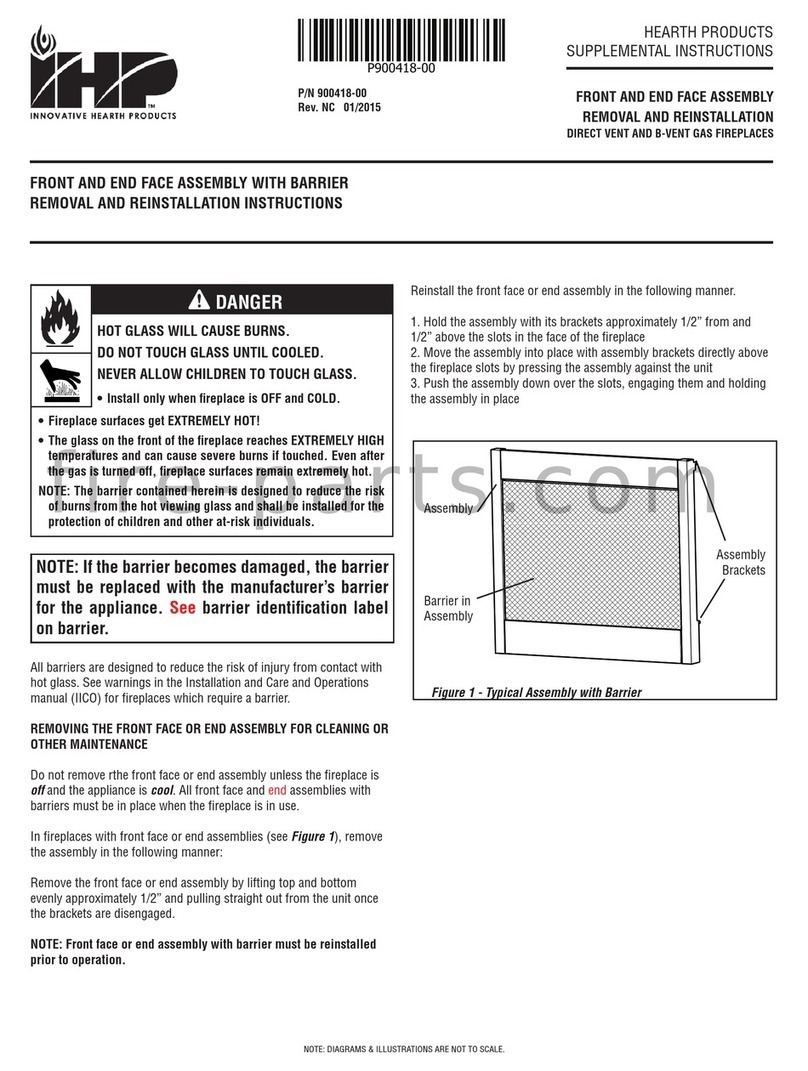

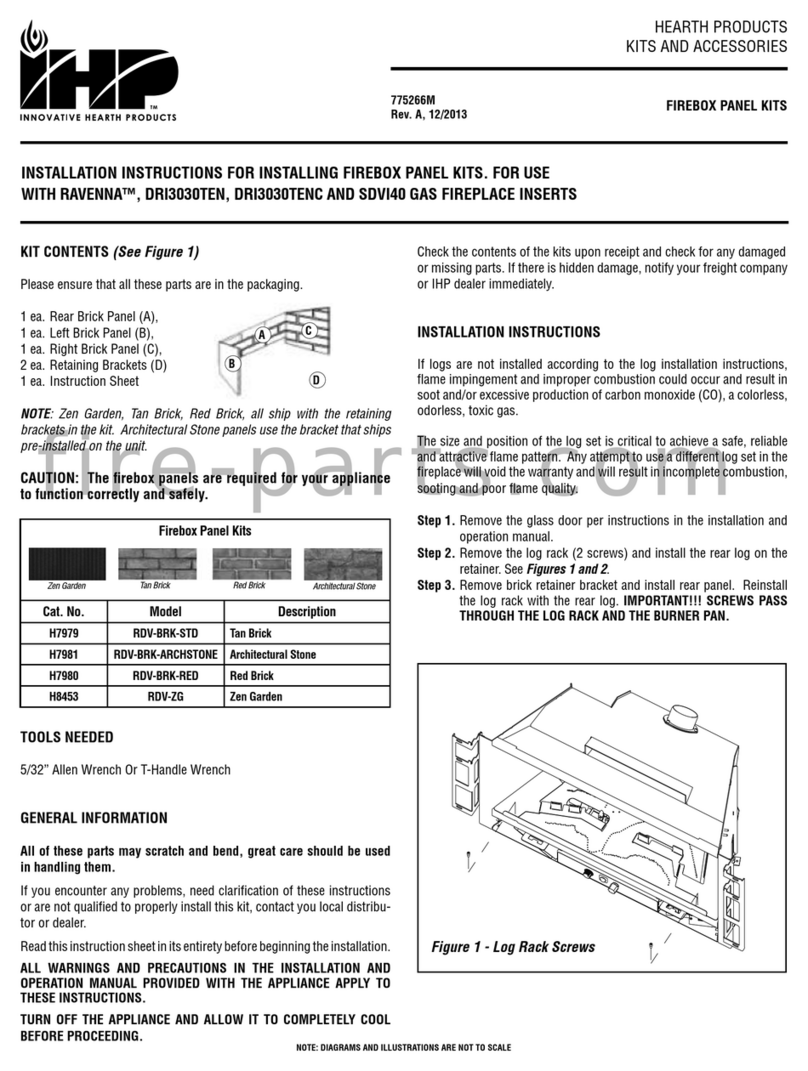

8. Complete fireplace preparation by removing flat hood from

convection opening and replace with angled hood provided

(Figure 6).

Fireplace Top

Metal Knockout

Insulation Plug

Heat Deflector

Metal Knockout

Collar Mounting

Plate

Large Collar

Small Collar

Figure 4 Figure 5

Fireplace Top

Metal Knockout

Insulation Plug

Heat Deflector

Metal Knockout

Collar Mounting

Plate

Large Collar

Small Collar

Figure 4 - Knockout Removal

Figure 6 - Hood Removal / Installation

Figure 5 - Collar Installation

NOTE: Flat hood (shown) must be replaced with angled hood provided in kit.