JABLOTRON ALARMS a.s.

Pod Skalkou 4567/33 46601 Jablonec n. Nisou

Czech Republic www.jablotron.com

||

|

The JA-114E Bus access module with LCD, keypad and RFID

The access module is a component of the JABLOTRON JA-100 system.

Its modular architecture enables users to create a combination whose size of

installation perfectly meets their needs. The device should be installed by a

trained technician with a valid certificate issued by authorized distributor.

The module comprises first a control segment (1), an LCD display (4), an

RFID chip card / tag reader and keypad (5) . The JA-192E segments can be

used to extend the JA-114E unit by the required number of segments (the

max. allowed amount is 20 on one unit). The tilting keypad cover (7) can be

removed if the user prefers permanent access. It also works as an RFID

card / tag reader.

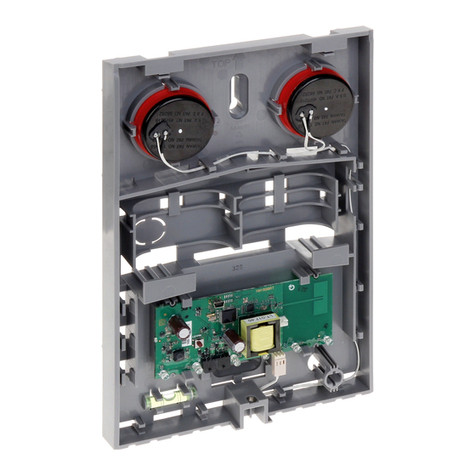

Figure 2: 8 – Connector for control

segments; 9 – production code;

10 – BUS terminals; 11 – tamper

contact

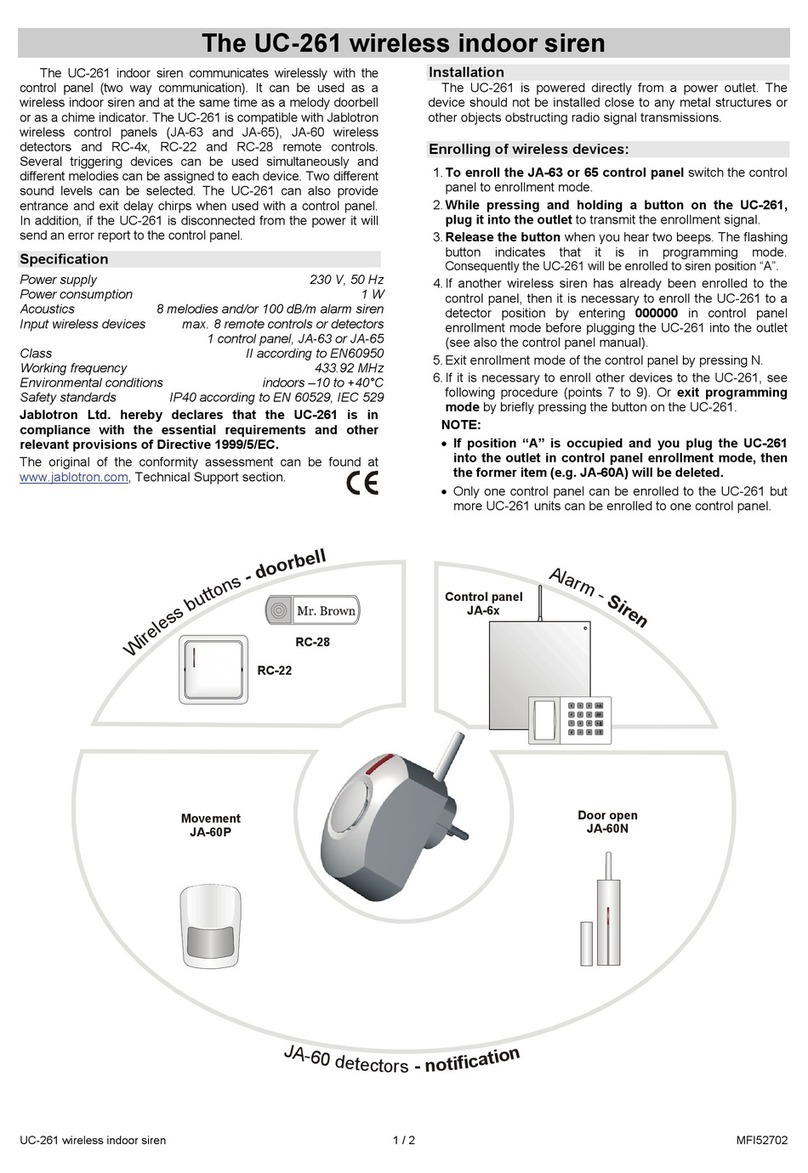

Figure 1 : 1 – control segment; 2 – segment buttons; 3 – backlit activation

button; 4 – LCD; 5 – access module with RFID reader; 6 – tabs for module

opening; 7 - cover screws Installation

1. Press the four tabs (6) on the sides and release the keypad from the

plastic base.

2. When installing more control segments, first remove the socket cover on

the 1st segment.

3. Remove the transparent plastic cover from the segments (by levering on

both sides of the segments near the buttons).

4. Always connect the segment wires to the connector of the previous

segment and click them into each other (we recommend coiling the wires

by turning the segment by 360° – this will prevent any possible damage to

the wires between the plastic parts). Use this method to install all the

required segments. Finally, push the socket cover in.

5. Push the cable through the plastic base and attach it to the selected

place together with the segments using screws. If more segments are

required, fix them onto the wall using screws as well.

6. Connect the BUS cable to the BUS terminals (10).

When connecting the module to the BUS,

always switch the power off.

7. Insert the module into the base.

8. Proceed according to the control panel installation manual. Basic

procedure:

a. When the device is switched on, the yellow backlit activation button

(3) starts flashing repeatedly to indicate that the module has not

been enrolled into the system.

b. Go to the F-Link software, select the required position in the

Devices window and launch the enrollment mode by clicking on

the Enroll option.

c. Press the backlit activation button (3) above the screen – the

module is thus enrolled and the yellow LED indicator goes off.

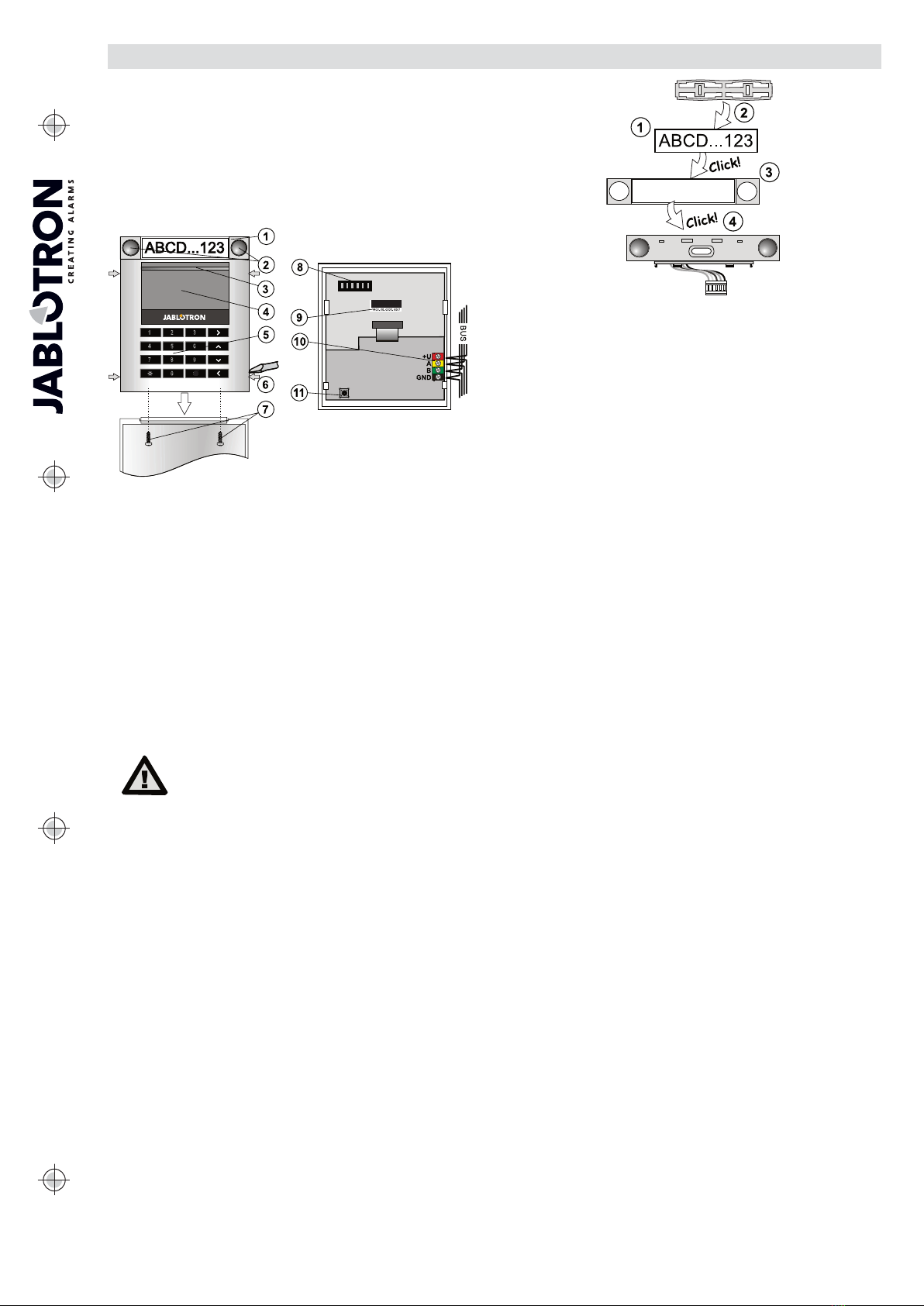

9. When you have completed the installation, insert descriptive labels onto

the segment transparent covers and close them, see figure 3. Label

printing is a part of the F-Link software (Devices window, at the module

position – Internal settings).

Notes:

The module can also be enrolled to the system by entering its

production code (9) in the F-Link software or using a bar code scanner.

All numbers stated under the bar code shall be entered (1400-00-0000-

0001).

To comply with the EN 50131-3 norm it is necessary to fix the cover

tabs (6) by the screws from the accessories. In picture no 1 the cover

tabs are displayed and marked by the arrows.

Figure 3: Inserting a label into a control segment

Unit modifications

If you need to change the unit’s individual segments, it is possible to

separate them by levering the corresponding separating gaps from one side

(sideways from the buttons). Make sure the system BUS is disconnected.

Setting the properties

Go to the Devices window in the F-Link software. When you are at the

module position, use the Internal settings option. The particular unit is

displayed and it is possible to set its properties. Internal settings is separated

into 2 basic tabs: Segments and Settings.

It is possible to set the required functions for individual segments (control

of sections, section status signalling, alarm triggering, PG output control, PG

output status signalling, etc.). More details are available in the F-Link

software.

3rd optional setting tab Common segment – settings and function

description

A common segment (up to 2 of them allowed on one module unit)

simulates the simultaneous pressing of several segments which are placed

on this module and which control sections. In the Segments tab and select

the specific segment function called Common segment A (B). Then in the

new tab Common segment select the segments which will be operated en

bloc.

Note: A module has to be equipped with a minimum of 3 segments otherwise

this function can not be used.

The selected sections will all be set / unset after pressing a button on the

common segment.

If the states of the segments which are operated by the common segment

are mixed, then only the segments that need changing will be set / unset.

If partial setting is enabled for some segments, then the common segment

respects this: 1st press = partially setting, 2nd press = full setting. It is not

suitable to combine a common segment with a common section

The indication of the common segment is: all segments unset = green,

some set (partially set) = yellow, all sections fully set = red.

In the Settings tab you can set all other module functions like acoustic

signalling, backlight intensity, RFID reader mode, optical and acoustic

indication, LCD display settings, etc. Details related to settings can be found

in the installation manual of the control panel and of course in the tooltips

displayed by the F-Link software.

Optical indication

Activation button – indicates the system status. No light – sleep mode,

green light – everything OK, green flashes – authorisation performed, red

flashes – alarm, yellow light – fault, yellow flashes – not enrolled to the

system, yellow double flash – Service mode.

Note: The activation button doesn´t indicate module tamper activation in

Service mode.

Segments – don´t indicate a thing when Service mode is entered or when

the segment has the function None. The optical indication of a PG segment

can be inverted. The only exception for segment indication is when a mains

fault has been detected, then this setting is automatically disabled.

Module can be preset to the following 6 indication levels:

1. Indicates permanently – BUS modules indicate permanently only if

an external power supply is connected. Without an external power

supply it indicates the same as option 2. When the mains is restored

the module indicates permanently again.

2. Section / PG status change on keypad – the module indicates

when the section / PG status has been changed. The status change

is indicated on the specific segment. Entrance delays and alarms are

indicated by the whole module.

3. Section / PG status change on segment – the module indicates

when a section / PG output status has been changed. A segment

status change, an entrance delay and an alarm is indicated on a

specific segment.

4. Segment status change on keypad – The module indicates when

the status of a segment has been changed (setting, unsetting, PG

ON, PG OFF). The change of the status is indicated only on the

specific segment.

The JA-114E Bus access module with LCD, keypad and RFID MLU51108