Tool in the stand

Actual Temp. 180

o

C

Sleep

Tool in the stand after sleep

No heat

Actual Temp. 20

o

C

Hibernation

0

c

Selected temp.

350

o

C

Power 10%

350

6

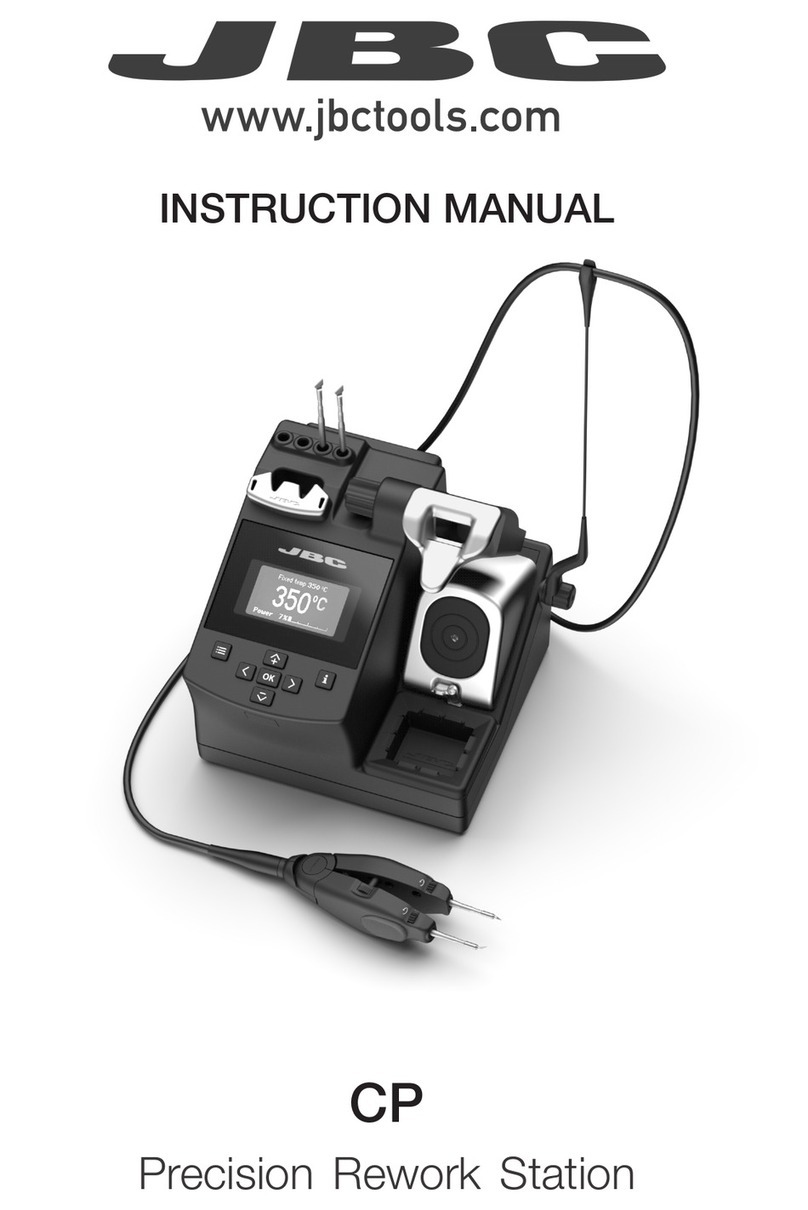

3. Hibernation

Operation

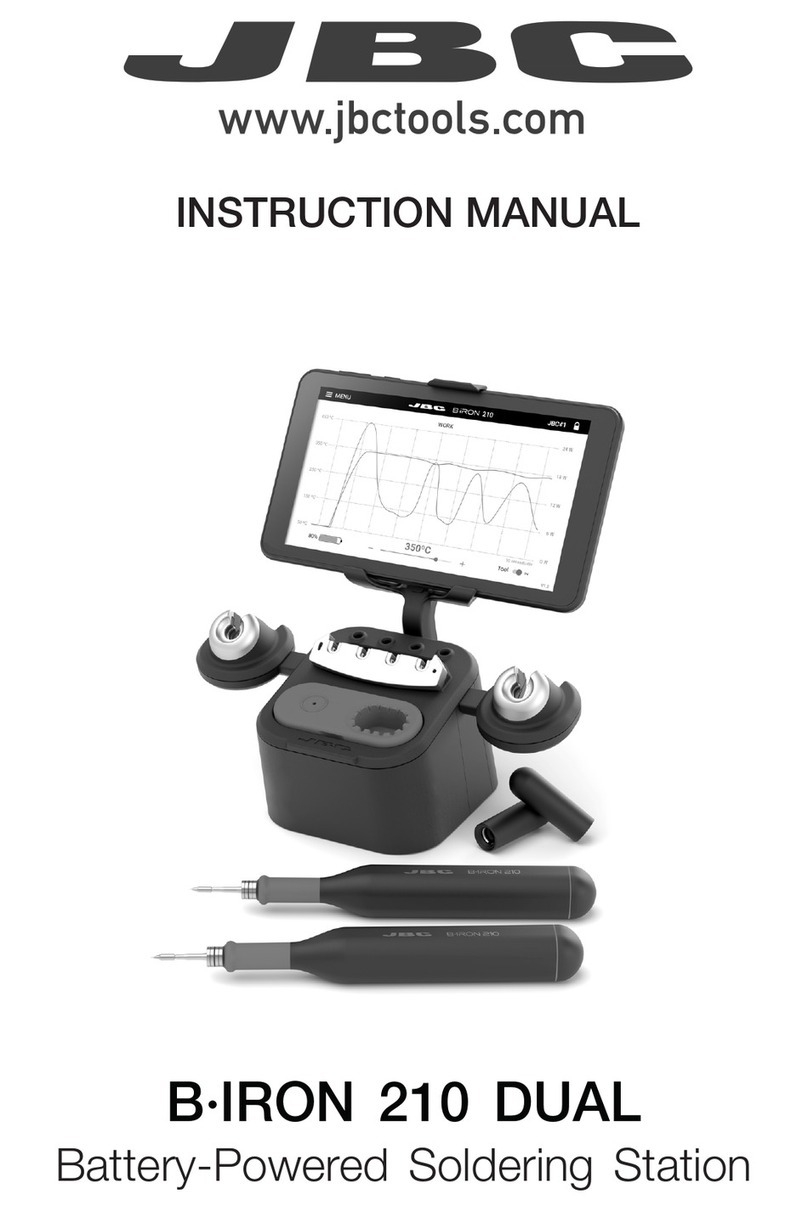

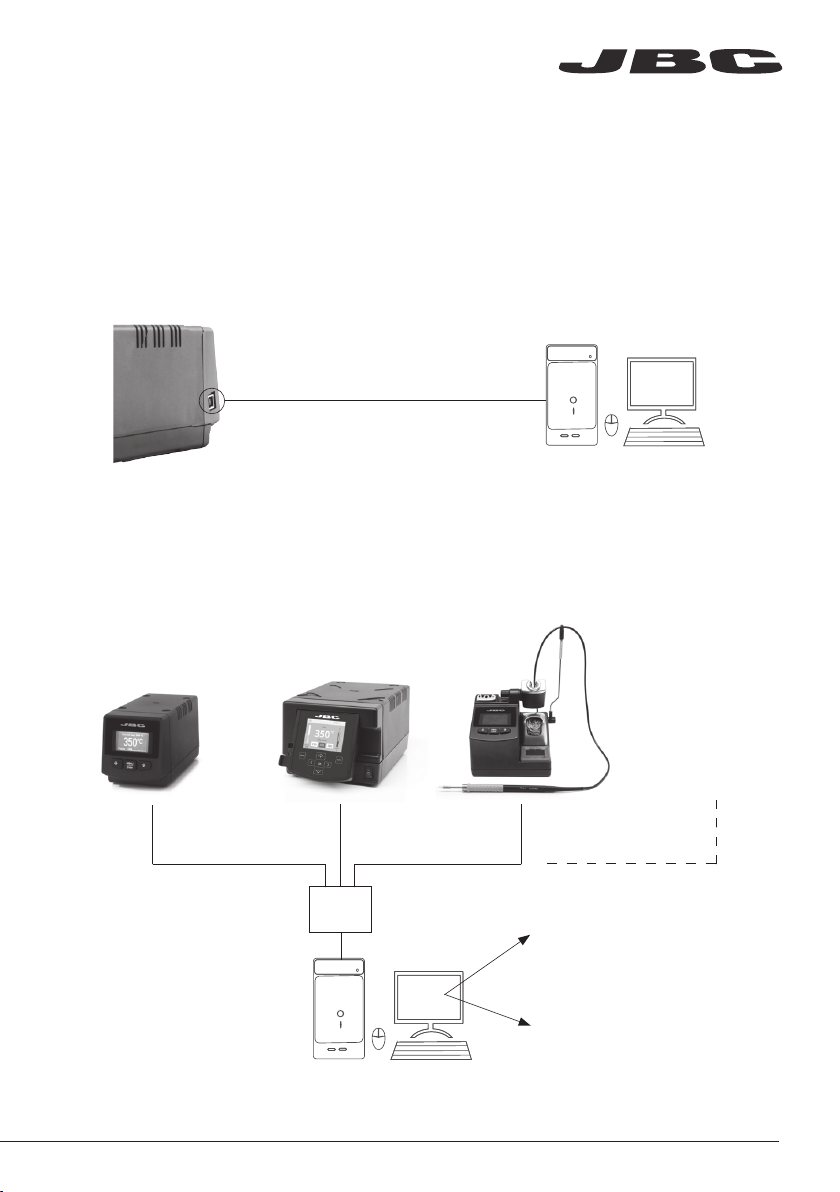

The JBC Exclusive Heating System

This revolutionary technology is able to recover tip temperature extremely quickly.

This allows the user to work at a lower temperature.

As a result, tip life increases x5 times.

1. Work 2. Sleep

After

30’

Lift tool from the stand and

the tool tip will heat up to the

selected temperature.

When the tool is in the stand,

the temperature reduces to

180ºC / 360ºF (preset sleep

temperature).

After longer periods of

inactivity (pre-set to 30 min.),

the power is cut and the

tool cools down to room

temperature.

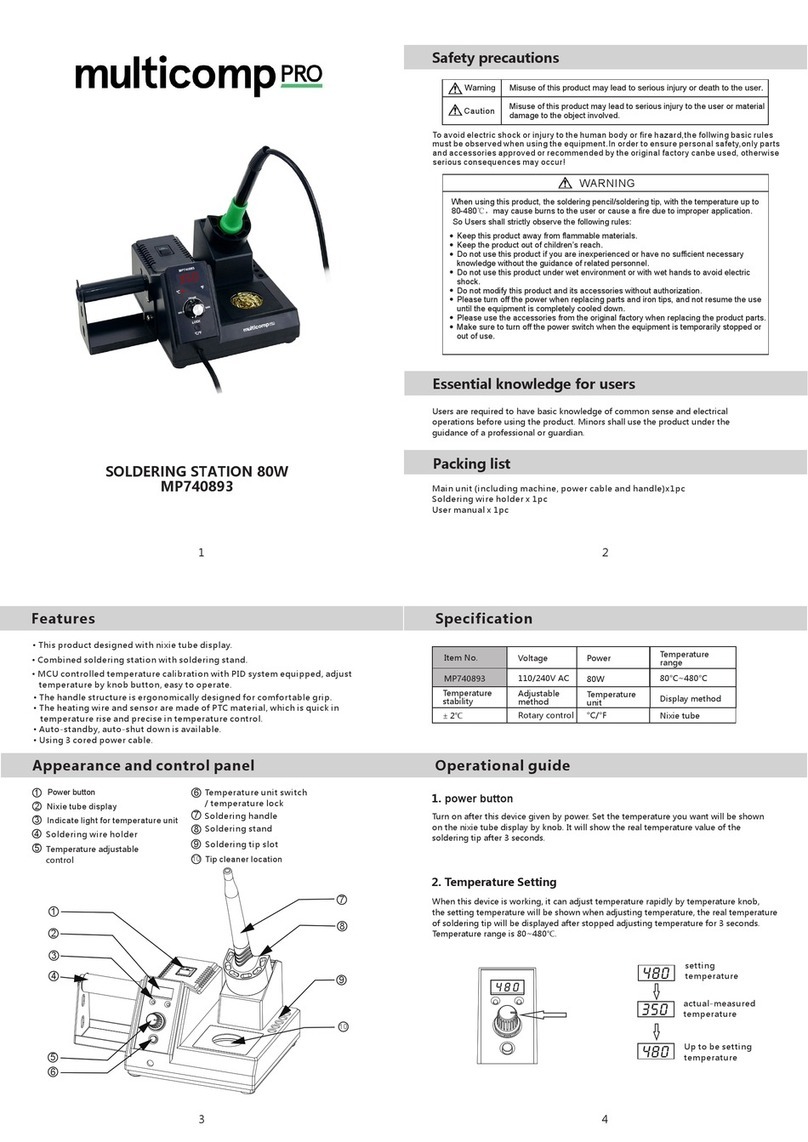

· Change temperature

(from 90 to 450ºC)

Menu:

· Select temperature levels

· Fix one temperature

· Set temperature limits

Menu:

· Change Sleep temperature

· Set Sleep delay

(from 0 to 9 min or no Sleep)

Menu:

· Set Hibernation delay

(from 0 to 60 min or no

hibernation)