8

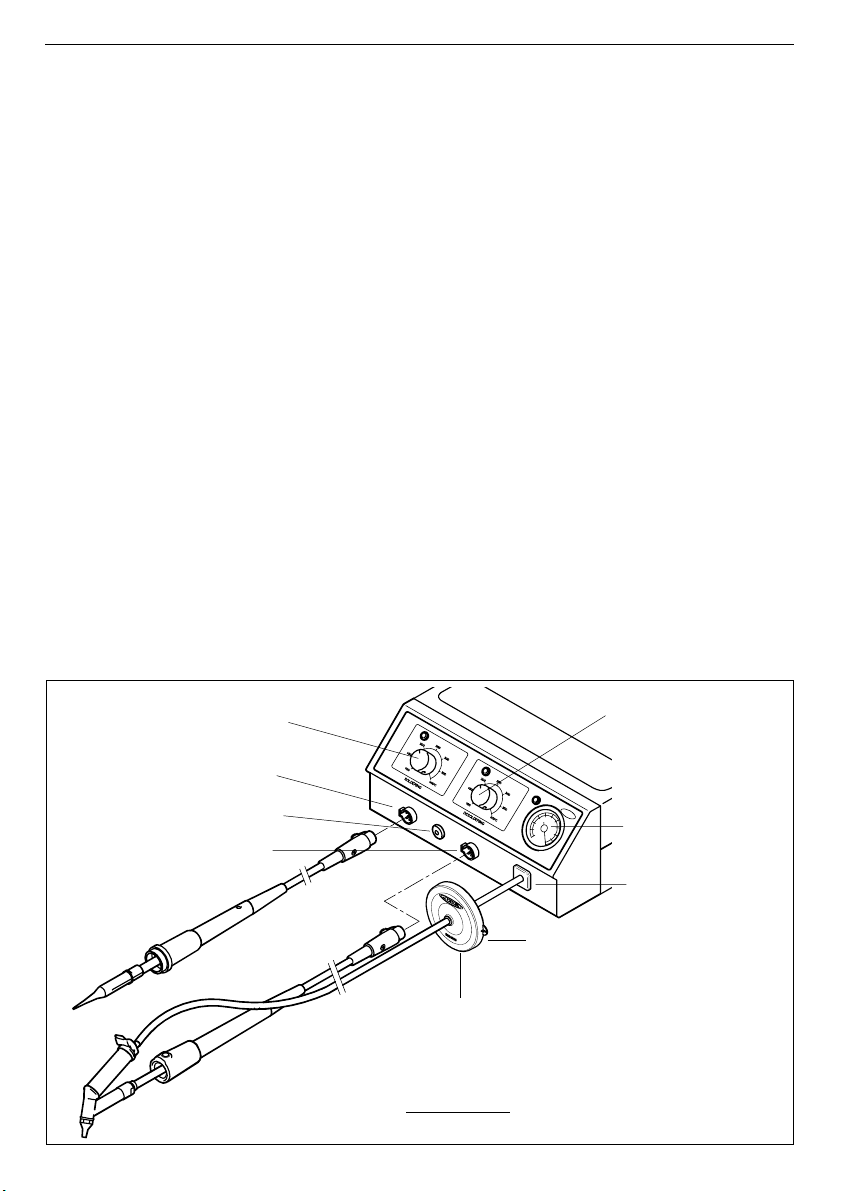

1 2 3

ESPAÑOL

ab

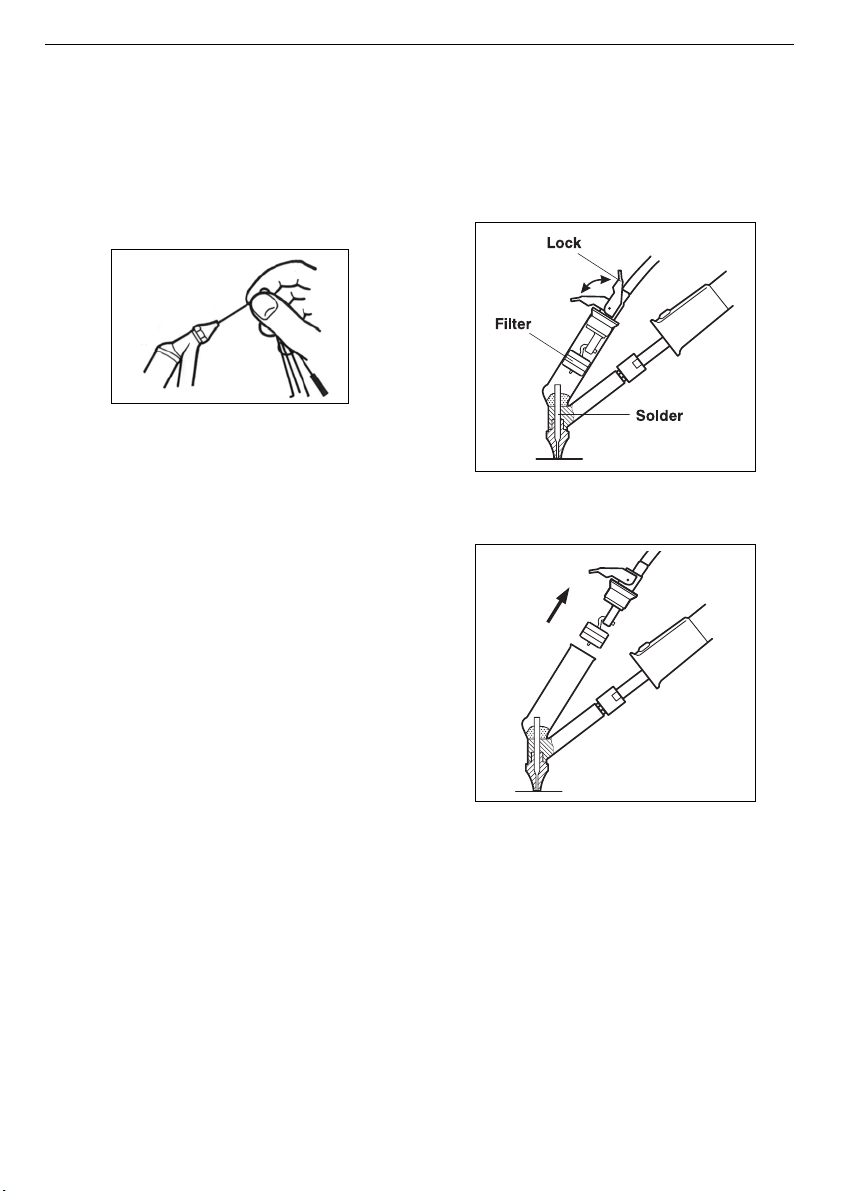

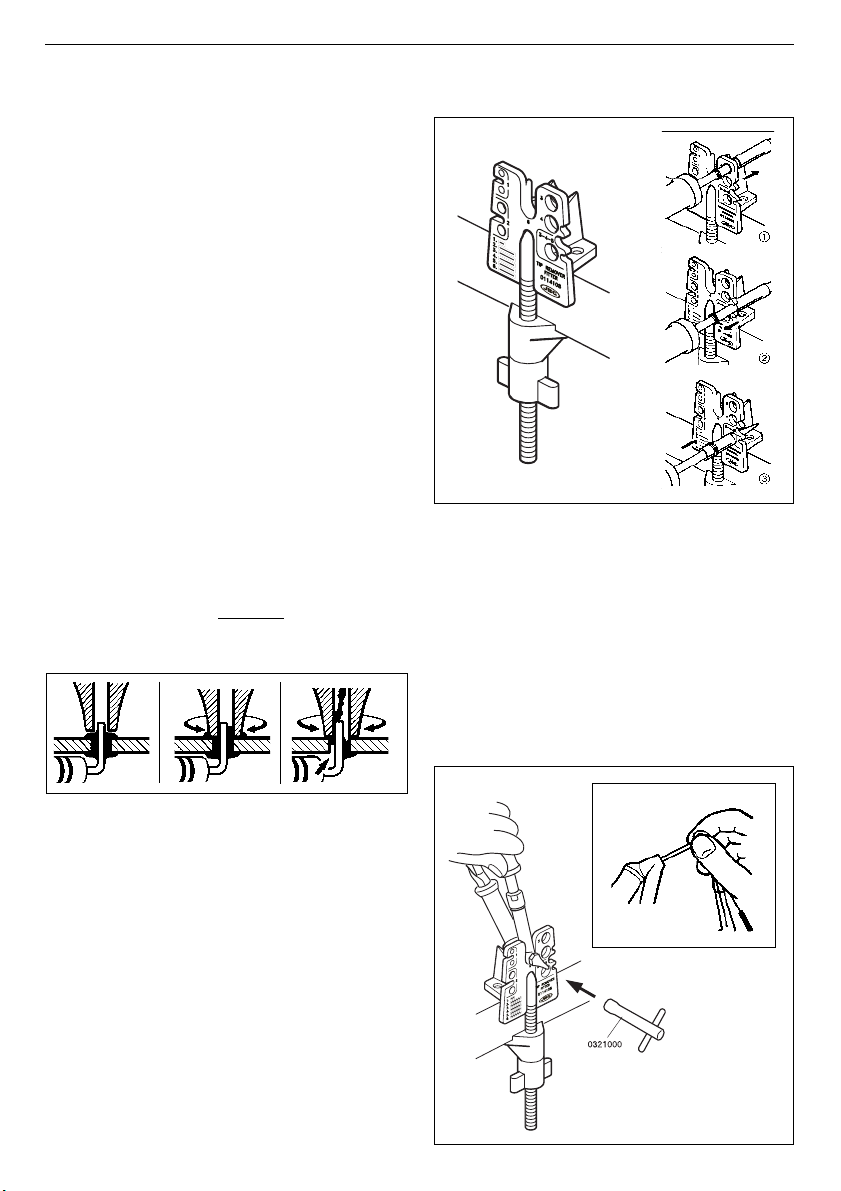

Cambio de punta del desoldador

Esta operación debe realizarse en caliente a una

temperatura mínima de 250°C, para que los

residuos de estaño que hayan quedado en el

interior estén fundidos.

- Apoye el cuerpo del desoldador en el

extractor de puntas y desenrosque la punta

a sustituir, con la ayuda de la llave que se

suministra (Fig. a).

- Pase la baqueta más gruesa por el interior del

conducto del cuerpo desoldador (Fig. b).

➂Introduzca la nueva punta y asegúrese de

que ha penetrado a fondo.

RECOMENDACIONES DE USO

Para soldar y desoldar

- Los componentes y el circuito deben estar

limpios y desengrasados.

- Con preferencia seleccione una temperatura

inferior a 375°C. El exceso de temperatura

puede provocar el desprendimiento de las

pistas del circuito impreso.

- La punta debe estar bien estañada para

conducir bien el calor. Si permanece mucho

tiempo en reposo, estáñela de nuevo.

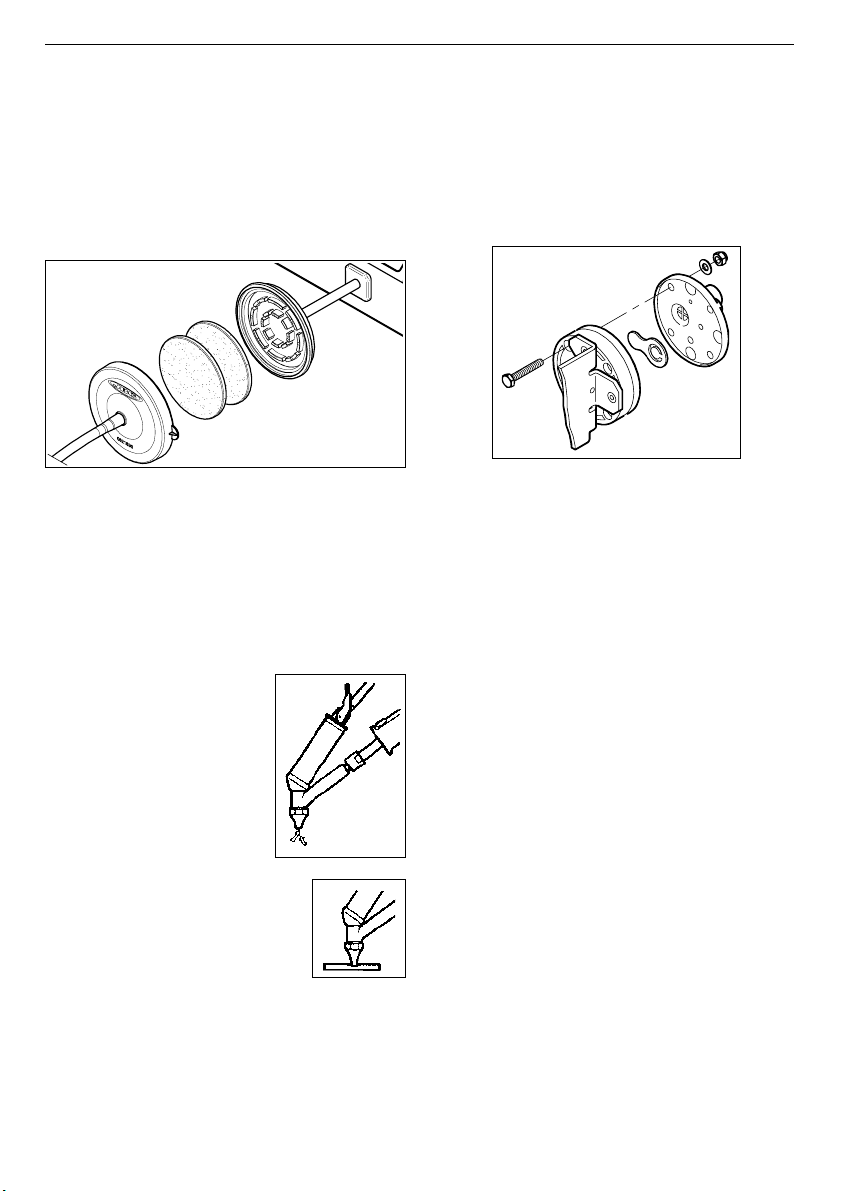

Proceso para desoldar

Utilice un modelo de punta de mayor diámetro

interior que el pin a desoldar, con el fin de

conseguir el máximo de aspiración y de

transmisión térmica.

1Apoye la punta del desoldador, de forma

que el terminal del componente penetre dentro

del orificio de la punta.

2Cuando la soldadura se licúe, imprima a la

punta del desoldador un movimiento de

rotación que permita desprender de los

laterales el terminal del componente.

3Accione entonces, no antes, el pulsador de

la bomba de vacío el tiempo necesario para

succionar la soldadura.

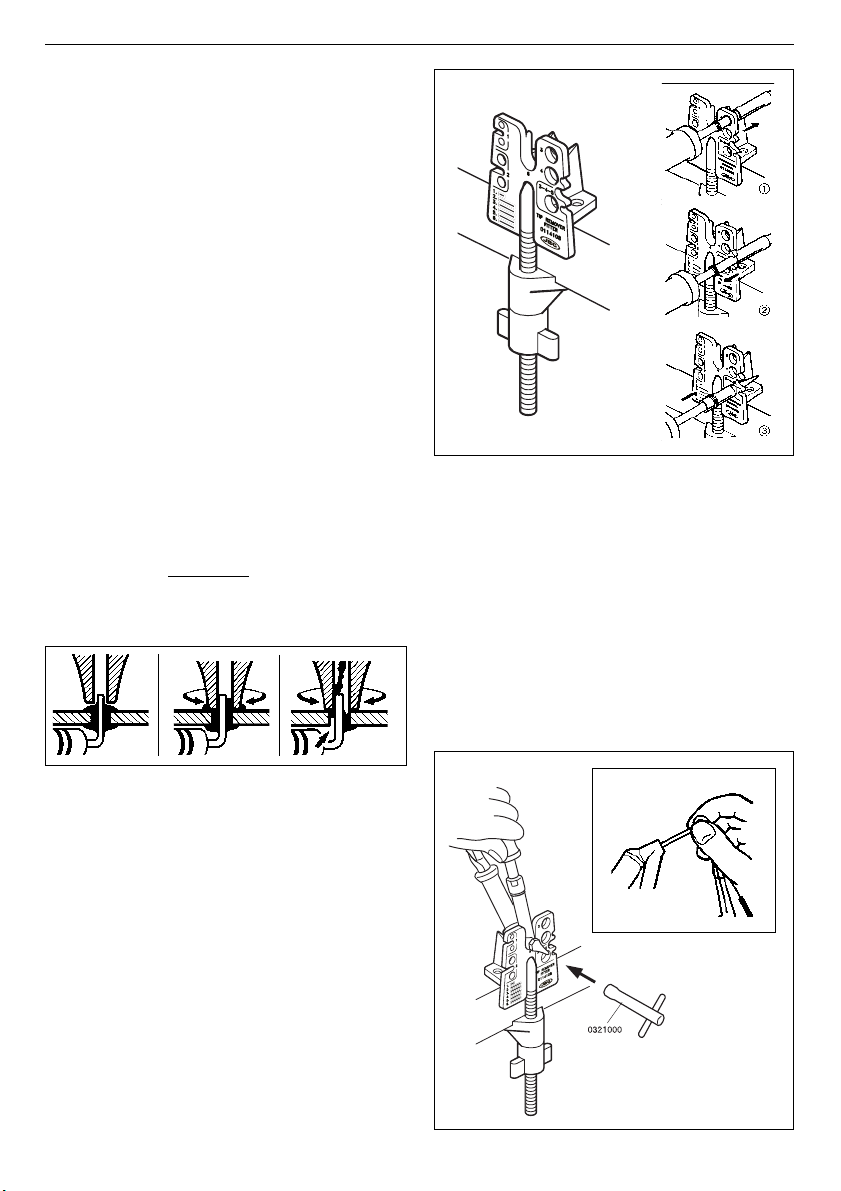

Cambio de punta del soldador

Utilice el extractor de puntas Ref. 0114108.

➀Retire la anilla para liberar la punta.

➁Extraiga la punta tirando del soldador, en

sentido longitudinal y sin forzar la resistencia.

Después de cada pulsación del botón del

desoldador hay un breve retardo hasta el paro de

la bomba de aspiración, con la finalidad de

asegurar que se vacía completamente el circuito

de aspiración.

Si algún terminal ha quedado con restos de

soldadura, después de intentar desoldarlo,

suéldelo nuevamente aportando estaño y repita

la operación de desoldar.