ENGLISH

3

1 Introduction

This manual mainly explains how to attach or detach a tape reel for EF08HD.

For detailed functions, refer to"Instruction Manual" in "Instruction Manual CD version" attached to a mounter and also "EF08HD

Instruction Manual. "

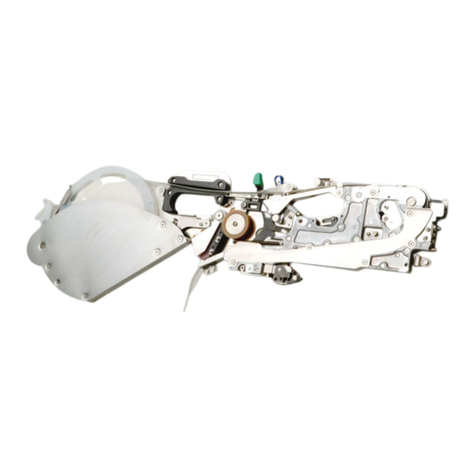

2 Name of each part

25

23 24

28

27

1 432 5

6

7

8

9

10

11

12 13 14 15 16

17 18 19 20 21 22 26

3 Operation panel section

Name of operation LED

display Button operation Explanation of operation

Feed pitch setting 02 / 04

Press ■switch button twice

Press ▲switch button or ▼switch button to

change a feed pitch

Press ■switch button twice

To switch a feed pitch to 2 mm and 4 mm

Initialization 0H Press ■switch and ▼switch at the same time To put it into states that can be produced

Initialization completion state

cancellation Press and hold ■switch button long To cancel initialization state

Normal rotation pitch feed Press and hold ▲switch button long To feed a tape by a pitch

Reverse rotation pitch feed Press and hold ▼switch button long To reverselyfeed a tape by a pitch

Operation stop Press ■switch button short To stop feed operation and initialization operation

Error reset E Press ■switch button short To cancel error display

Operation lane change Press switch button alone To be able to change operation effective lane

(between Land R)

Buttonoperation Pressa switch button short:: for less than one second

Pressaswitchbutton long: for one second or more

Pressabuttontwice:thesame switch button for less than one second and two times in sequence

Pressabuttonatthe same time: two switch buttons at the same time

4 Specification

Product code EF08HD/EF08HD (IS) Feed pitch 2 and 4 mm

Color of lever Blue Number of occupied positions 1

Outside dimensions Entire length: 911 mm, height: 455 mm,

and width: 17 mm(Areel support is attached.) Mass 3.0kg

Power supply Supplied from a mounter Component transportingmethod Motor-driven

Power-supply voltage DC 24V Allowable current 2.1A

Tape size Available two 8 mm tapes

(0603 or bigger component) Tape types Paper and embossed tapes

Emboss tape conditions Applicable component emboss width : 4.3 mm or less Applicable component emboss depth : 3.5 mm or less

Operation environmental

conditions during operation Temperature: 10℃to 35℃, humidity: 30 to 80% RH (No condensation), altitude: 1,000 m or less

Accuracy guarantee

temperature Temperature: 20℃to 25℃

Noise 57.7dB(A)

Excessive voltage class Class 1 (IEC60664-1): Excessive voltage is supplied from the circuit whose voltage is limited to a low level (such as a secondary low

voltage circuit)

Environmental pollution level Level 3: Environment whose pollutionis worse than that of the normal environment (such as a manufacturing plant)

* Use componentswhose size and tape specifications conform to JIS C0806-3:1999 and IEC 60286-3:2007.

No. Description No. Description No. Description

1 Upper cover (L/R) 11 Lock release lever 21 Tape loading slot (L lane)

2 Sprocket wheel (L/R) 12 Front liner block assy 22 Reel support guide

3 Cover tape U guide 13 RFID tag (for the IS specification only) 23 Reel support Lassy

4 Tensioner arm (L/R) 14 Slide rail 24 Reel support arm

5 Idler arm (L/R) 15 X guide pin R 25 Tail guide

6 Grip chamber frame 16 Lock section (Bank clamp section) 26 Reel hook

7 Operationpanel 17 Connector 27 PP cap

8 Storage space for PP cap and Tape support 18 Bottom guide block 28 Tape support

9 Chamber lid 19 Rating plate

10 Tape loading slot (R lane) 20 Revision label