CONTENTS

1. SPECIFICATIONS .......................................................................................................... 1

(1) Main unit................................................................................................................................................ 1

(2) Button sewing machine ......................................................................................................................... 1

(3) Button feeder......................................................................................................................................... 2

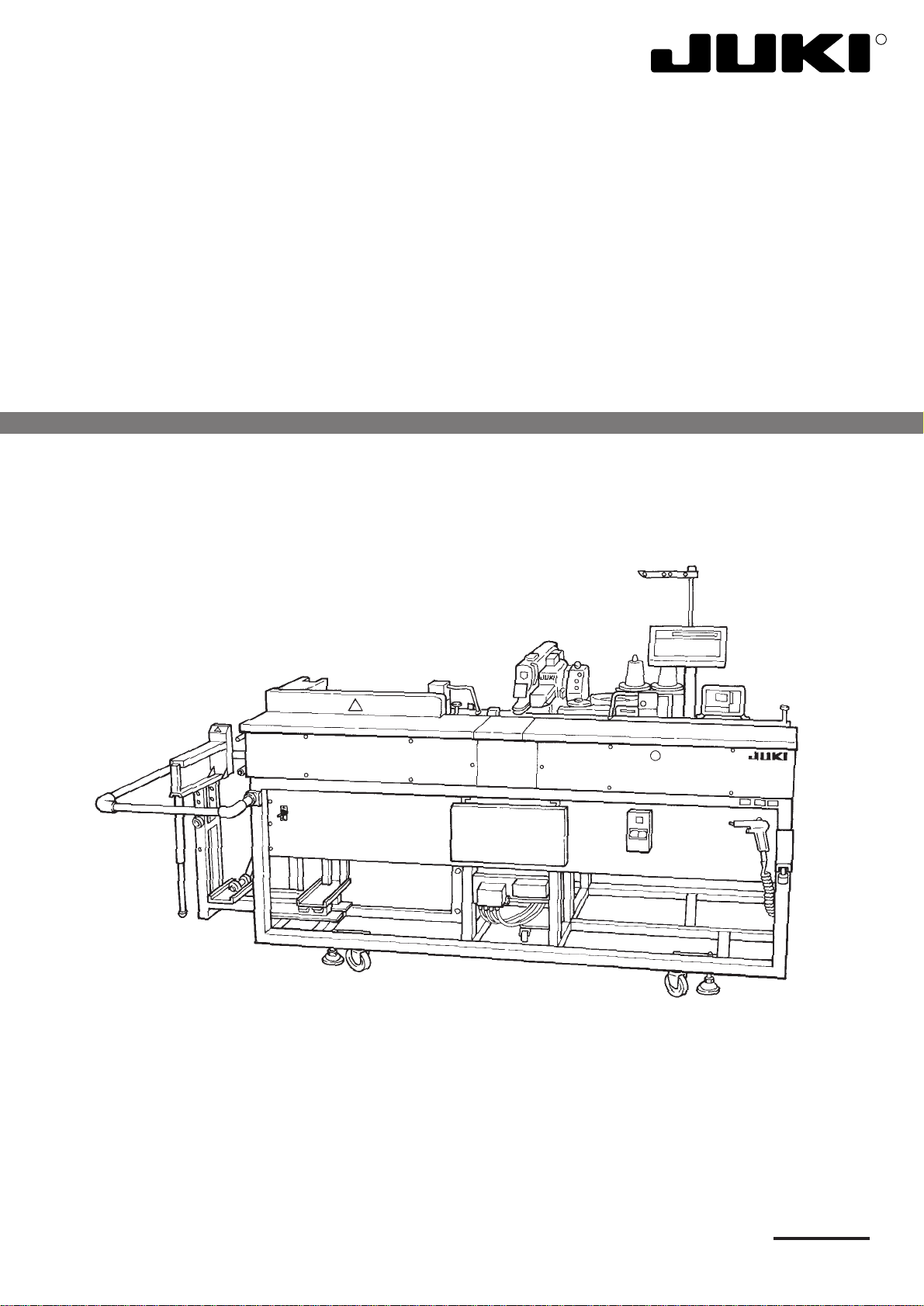

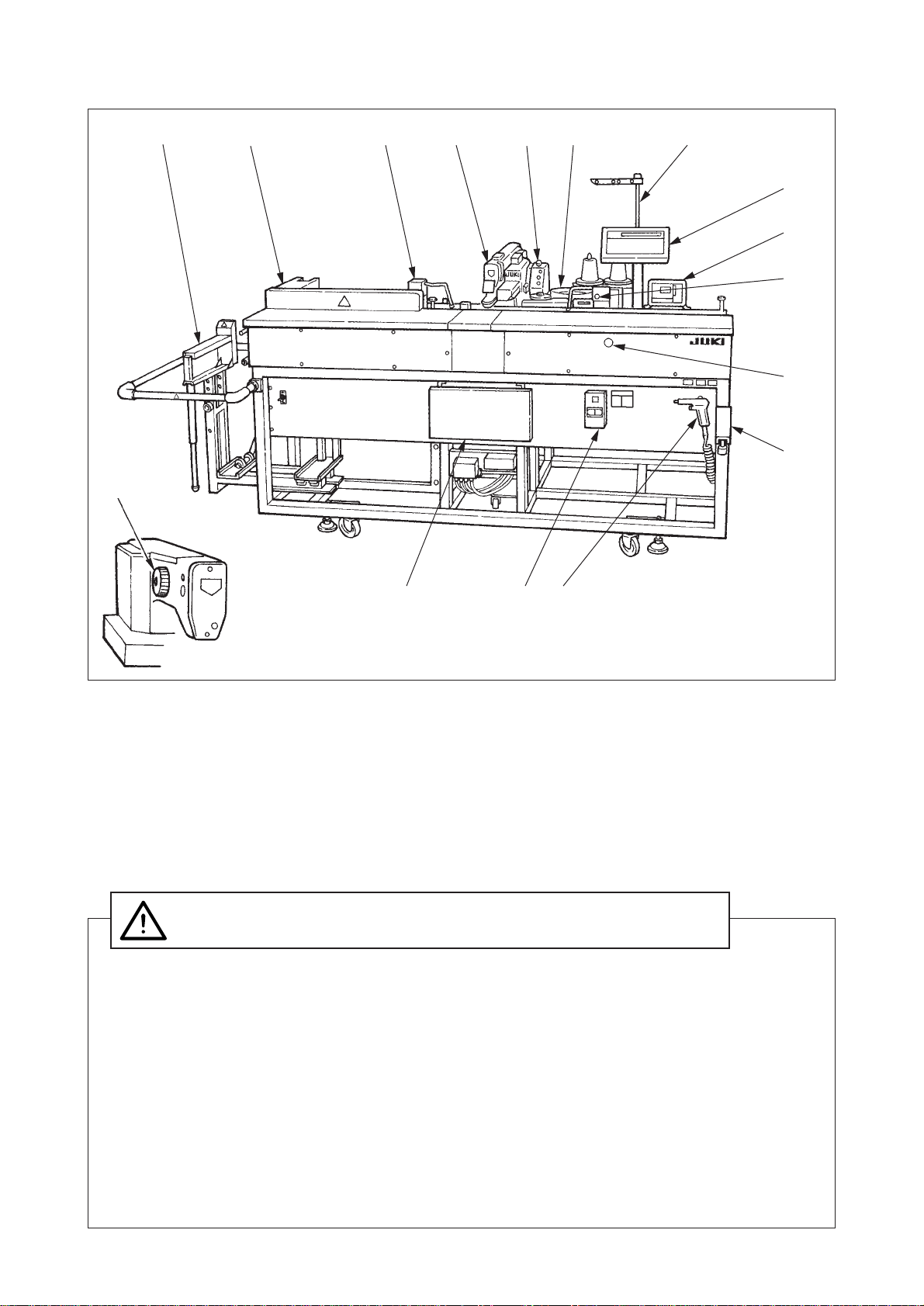

2. CONFIGURATION OF THE MAIN PARTS .................................................................... 3

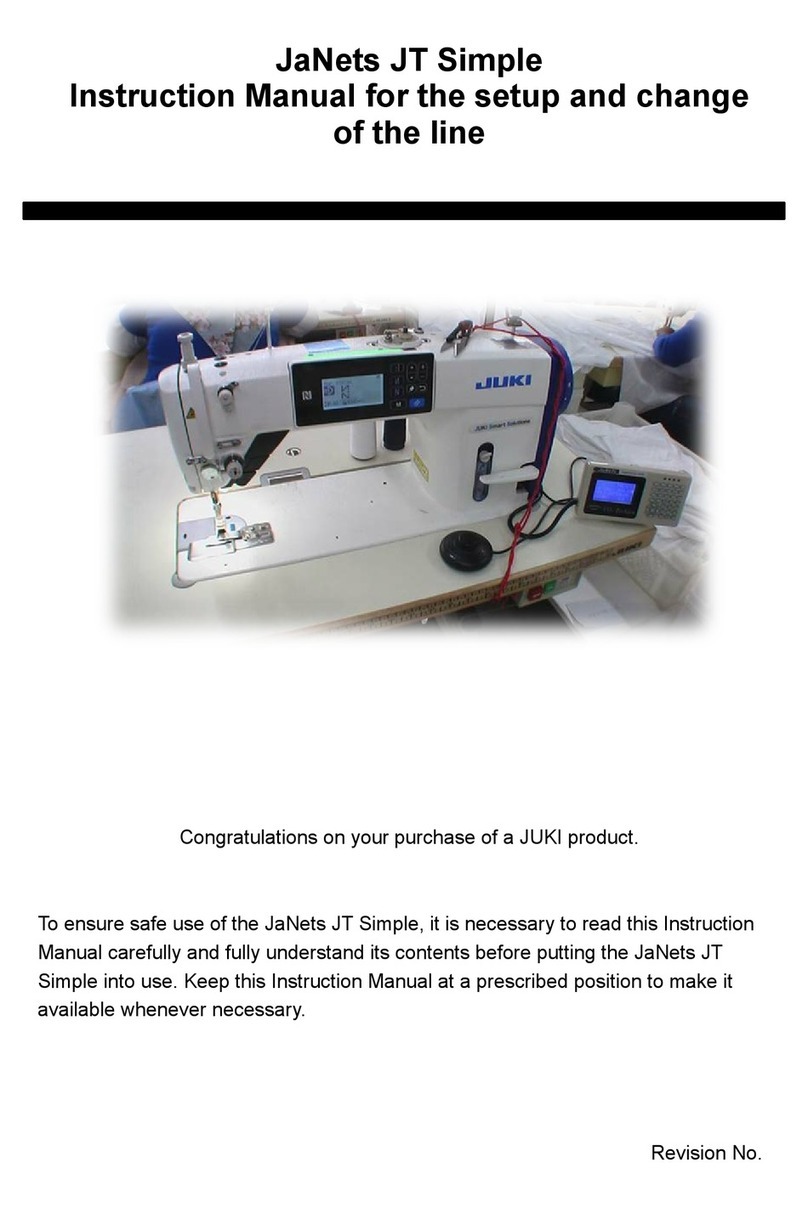

3. NAME OF EACH PART AND PREPARATION FOR TRIAL RUN................................. 4

(1) Operating switches................................................................................................................................ 4

(2) Adjusting the seam allowance............................................................................................................... 6

(3) Adjusting the position of the work clamp............................................................................................... 8

(4) Adjusting the stacker............................................................................................................................. 9

(5) Adjusting the knee switch...................................................................................................................... 9

4. OPERATION OF LK ..................................................................................................... 10

(1) NAMES ON THE operation BOX OF LK............................................................................................. 10

(2) HOW TO OPERATE THE operation BOX OF LK ............................................................................... 10

1) Setting the item data.................................................................................................................... 10

2) Changing to the other sewing pattern........................................................................................... 13

3) Performing sewing using the function keys (

P1

,

P2

and

P3

keys) ........................................ 13

4) Adjusting the position of the button clamps ..................................................................................14

5) Checking the contour of a sewing pattern .................................................................................... 15

(3) Winding the bobbin thread .................................................................................................................. 16

1) To wind a bobbin while the sewing machine is performing sewing .............................................. 16

2) To wind a bobbin independently................................................................................................... 16

5. ADJUSTMENT OF COMPONENTS OF LK ................................................................. 17

(1) Adjusting the feed plate....................................................................................................................... 17

(2) Adjusting the button clamp jaw lever................................................................................................... 17

(3) Adjusting the lifting amount of the button clamp ................................................................................. 18

(4) Adjustment of the pressure of the button clamp unit........................................................................... 18

(5) Adjustment of the wiper....................................................................................................................... 19

(6) Adjustment of the wiper spring............................................................................................................ 19

(7) Adjusting the rising amount of the thread tension disk........................................................................ 20

(8) The moving knife and counter knife .................................................................................................... 20

(9) Cleaning the filter ................................................................................................................................ 21

(10) Adjusting the height of the needle bar............................................................................................... 21

(11) Adjusting thre needle-to-hook relation .............................................................................................. 21

(12) How to use the memory switch ......................................................................................................... 22

1) Starting the memory switch .......................................................................................................... 22

2) Example of the memory switch setting .........................................................................................23

3) Setting the counter operation ....................................................................................................... 24

4) Table of functions of the memory switch ......................................................................................25

6. OPERATION OF ACF .................................................................................................. 26

(1) Explanation of the operation panel of ACF ......................................................................................... 26

(2) Preparation before operation .............................................................................................................. 27

(3) Inputting and confirming data.............................................................................................................. 27

1) Memory number selection ............................................................................................................ 27

2) Input of the sewing data ............................................................................................................... 28

3) Checking the sewing data ............................................................................................................ 31

4) Counter settings ........................................................................................................................... 33

(4) Operation ............................................................................................................................................ 34

1) Automatic operation...................................................................................................................... 34

2) Manual operation.......................................................................................................................... 35

3) Independent operation.................................................................................................................. 35

4) Emergency stop............................................................................................................................ 36

5) Error message and the reset procedure....................................................................................... 36