4

SUGATSUNE KOGYO CO.,LTD

Tokyo, JAPAN

SUGATSUNE KOGYO (UK) LTD

Reading, UK

Phone: +44 118 9272 955

SUGATSUNE EUROPE GmbH

Dusseldorf, GERMANY

Phone: +49 211 53812900

SUGATSUNE SHANGHAI Co., LTD

Shanghai, CHINA

Guangzhou, CHINA

SUGATSUNE KOGYO INDIA PRIVATE LIMITED

Mumbai, INDIA

SUGATSUNE AMERICA, INC

California, USA

Chicago, USA

Phone: +1 312 461 1081

SUGATSUNE CANADA, INC.

Phone: +1 514 312 5267

2018.10 0755-6

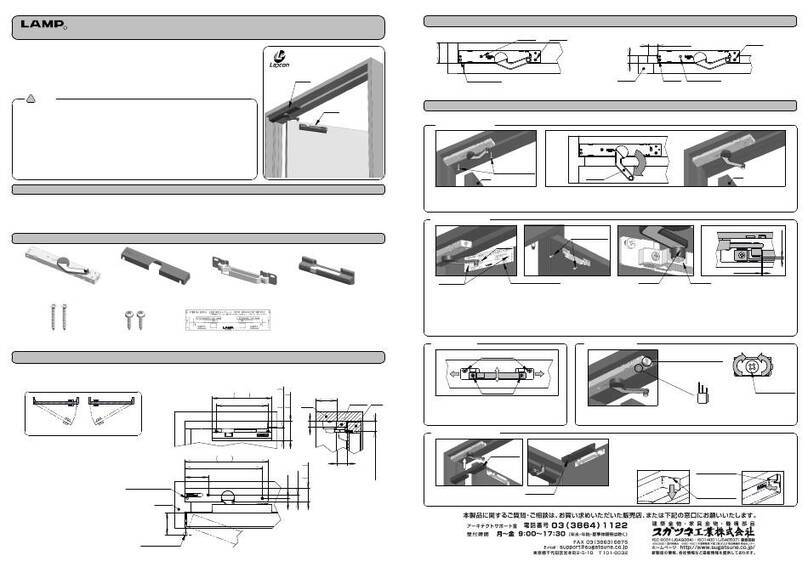

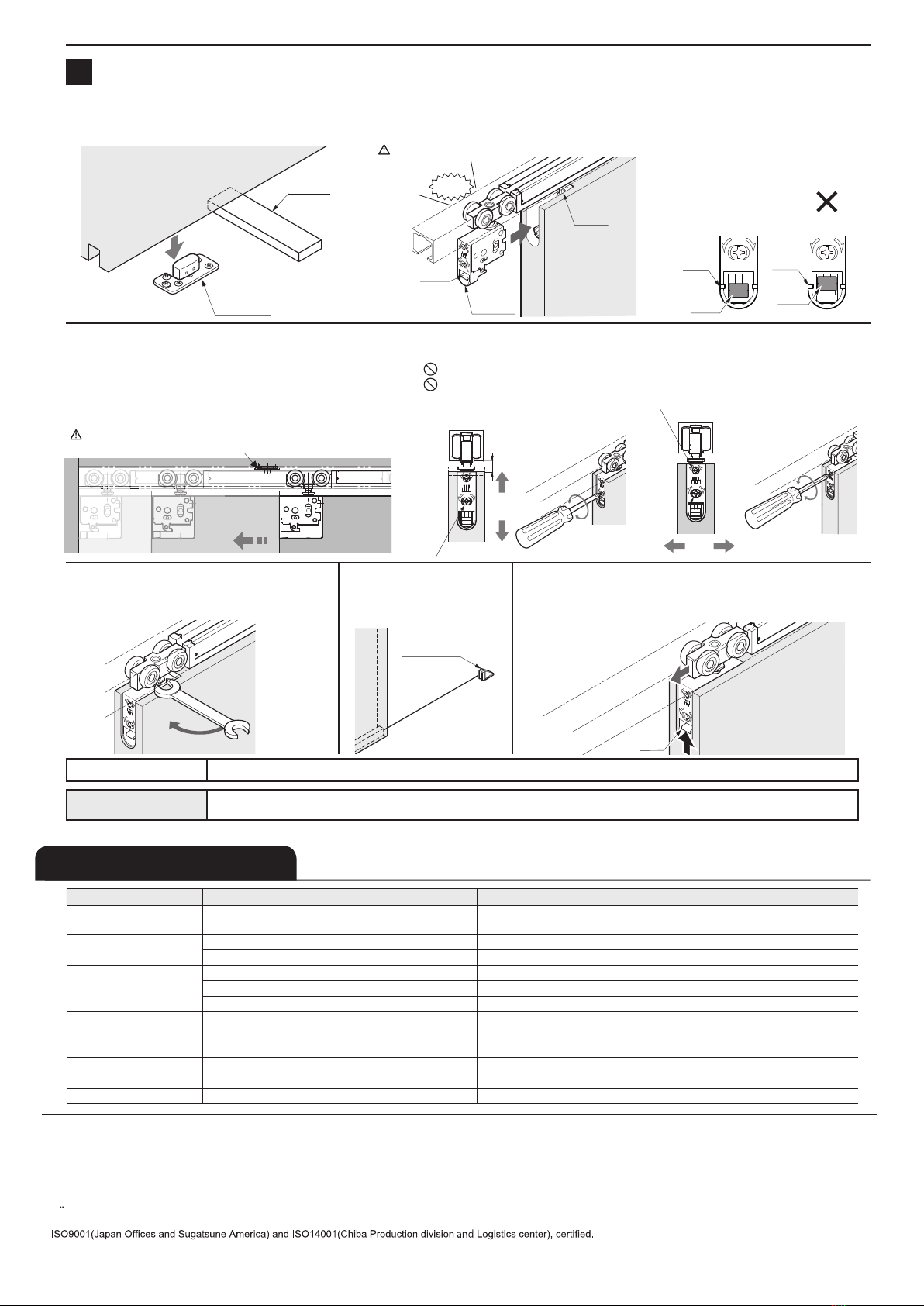

9HUL¿FDWLRQRIVOLGLQJGRRUFORVHURSHUDWLRQ

Slowly move the door toward the door head, and confirm that the

VOLGLQJGRRUFORVHUVWDUWVLWVIXQFWLRQDWDSSUR[PPEHIRUHWKHIXOO

FORVHSRVLWLRQ&DUU\RXWVLPLODUYHUL¿FDWLRQIRUWKHGRRUWDLOGLUHFWLRQ

:KHQWKHFORVHULVQRWZRUNLQJFRUUHFWO\UHIHUWRWKH³7URXEOHVKRRWLQJ´

section.

'RQRWFORVHWKHGRRUZLWKH[FHVVLYHIRUFH,WPD\FDXVHGDPDJHRUPDOIXQFWLRQ

of soft close mechanism.

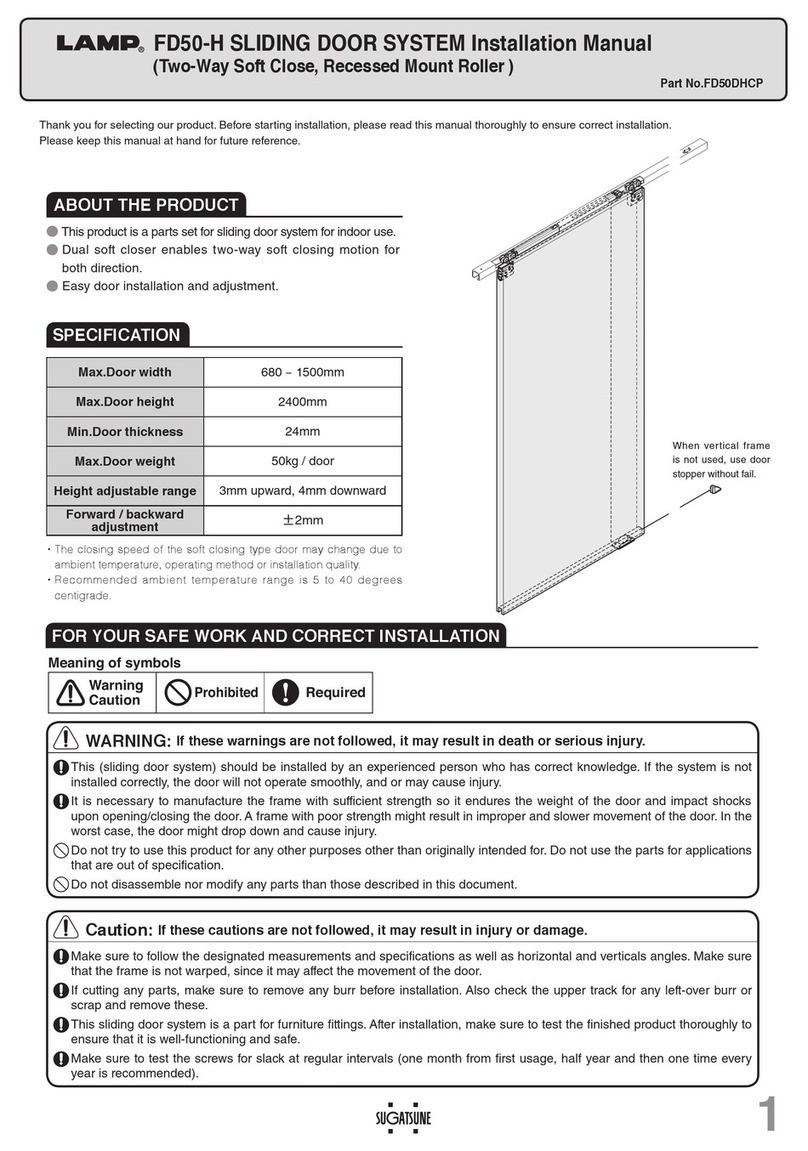

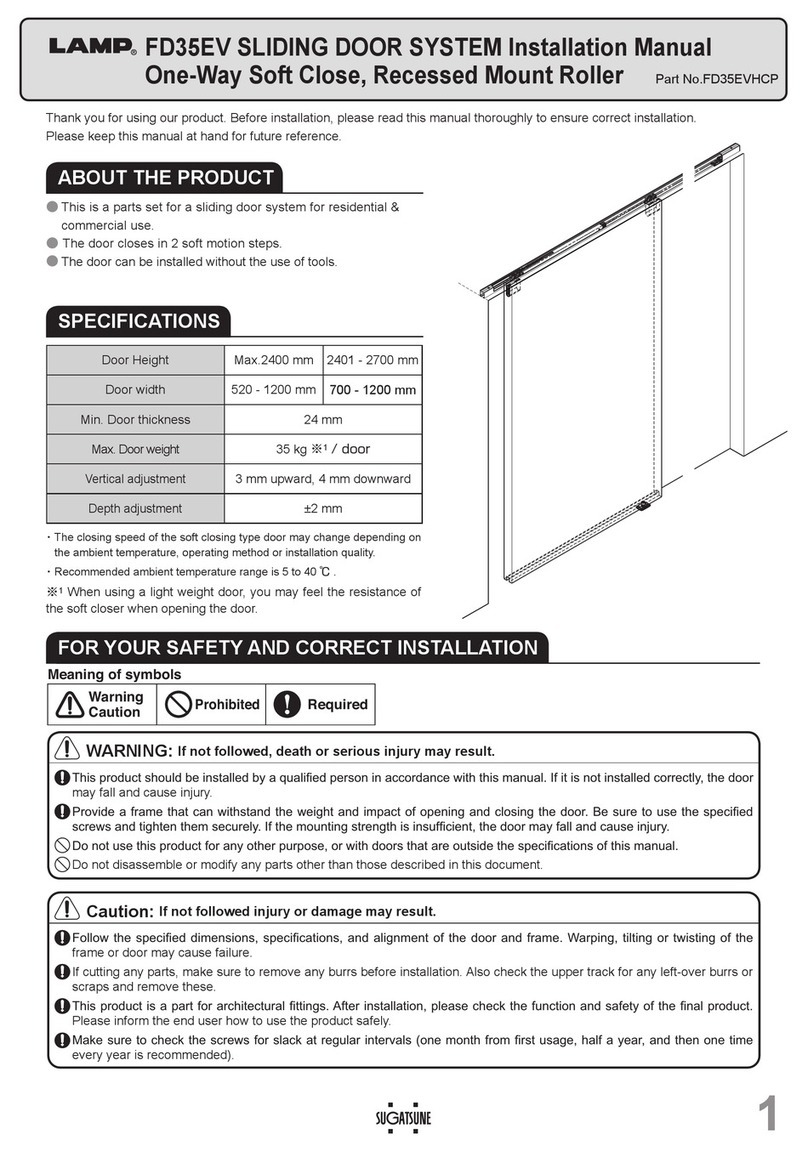

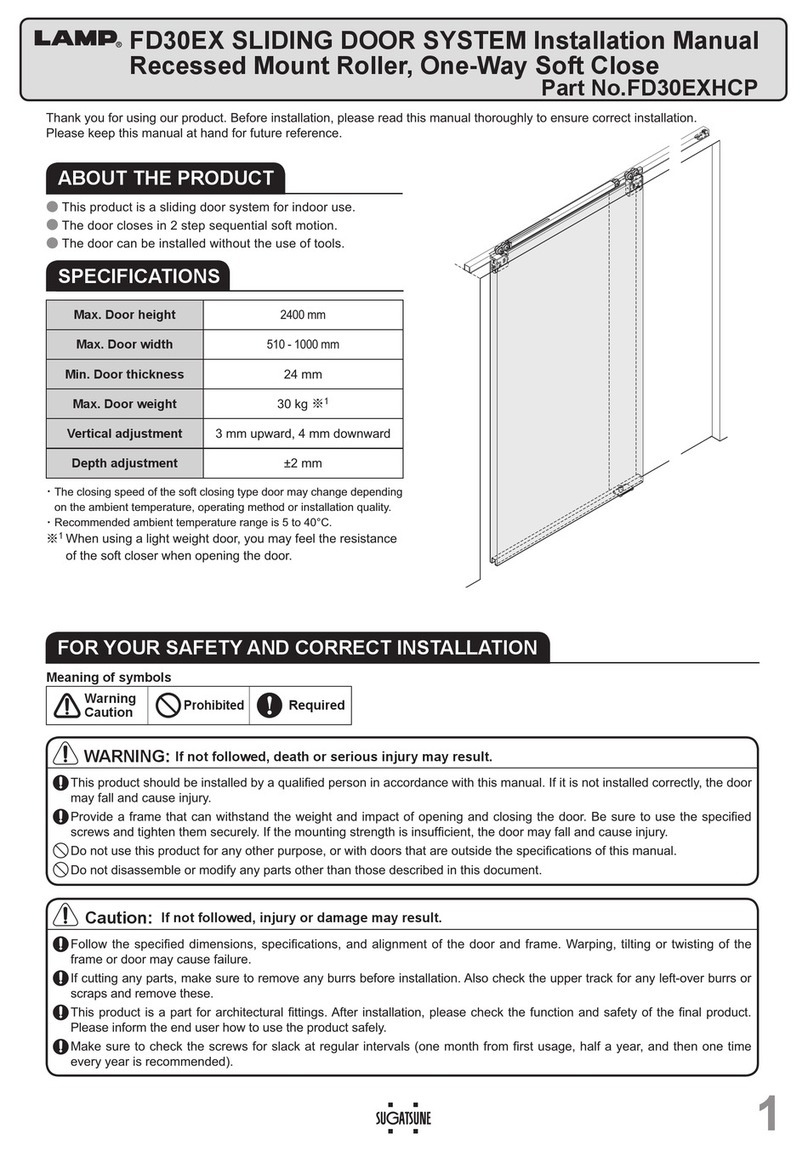

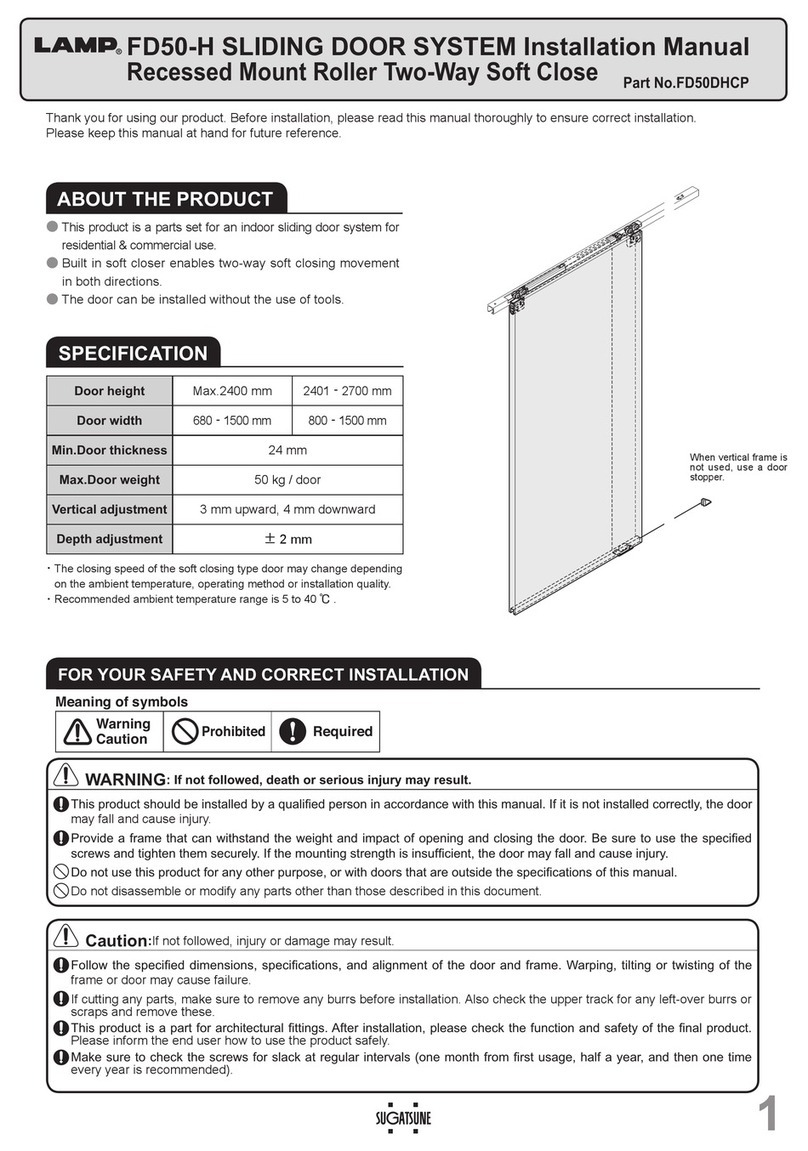

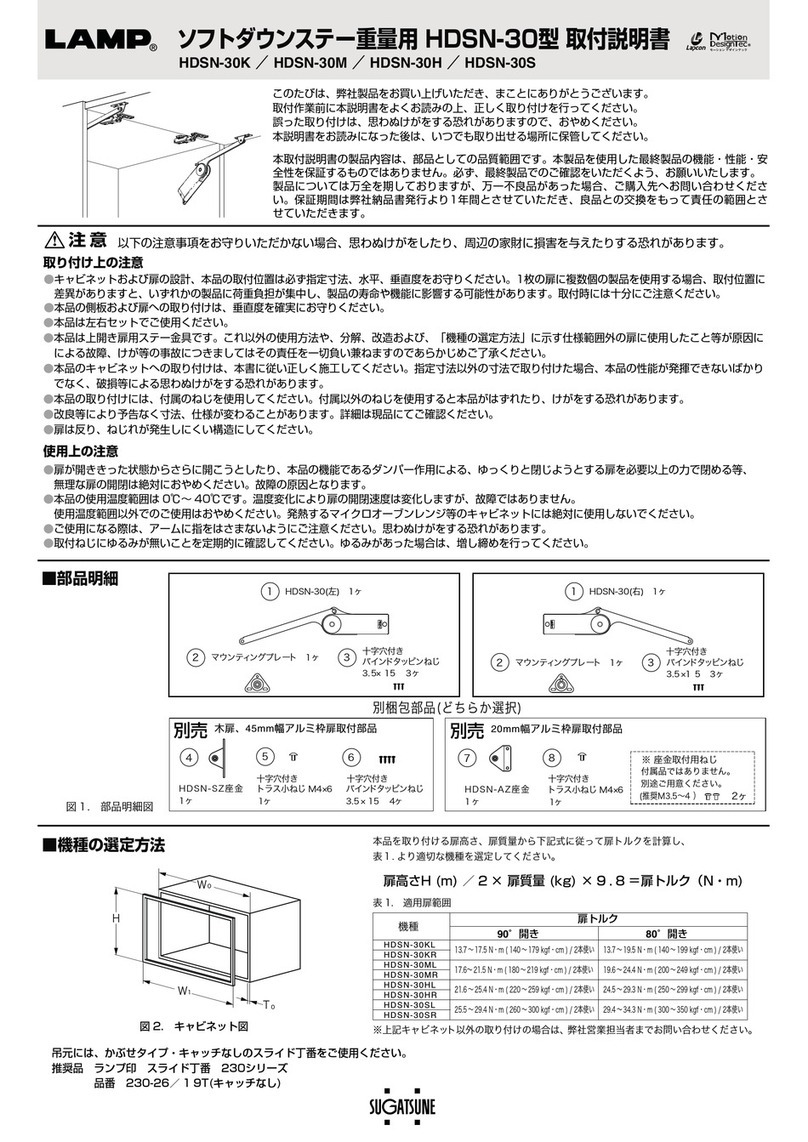

HANGING THE DOOR AND ADJUSTMENT

2

2. Door installation (top)

,QVHUWUHFHVVHGUROOHUPDLQXQLWLQWRGRRUVLGHFDVLQJDQGSXVKLQWKHORZHUHQGRIWKHUHFHVVHGUROOHUXQWLOD³FOLFN´VRXQGLVKHDUG

&RQ¿UPWKDWWKHOHYHULVSRVLWLRQHGDWWKHPDUNRQWKHUHFHVVHGUROOHUPDLQXQLWDVVKRZQ

Ensure that the roller main unit is securely attached to the casing.

1. Door installation (bottom)

3XWDPP VXSSRUWXQGHUWKHGRRU,QVHUWWKHIORRU

guide in the groove, and then hang the door.

右左

上

下

Vertical position adjustment screw

9

3

4

When removing the door

Use a 10 mm support under the door. Then pull out the

recessed roller main unit from the door while raising the lever.

4. Adjusting door position

AGMXVWWKHGRRUVXFKWKDWWKHGRRULVSDUDOOHOWRWKHXSSHUWUDFNZLWKPPFOHDUDQFHEHWZHHQWKHGRRUDQGÀRRU

Do not turn the adjustment screw more than the adjustment range.

To avoid damage of the adjustment screw, do not use electric screwdriver.

5. Fixing the jump prevention nut

With spanner 12, tighten the jump protect nuts until

they will contact to main unit.

When a vertical frame is not used,

install a door stopper.

Use door stopper of option.

22

右左

上

下

Forward / backward adjustment screw

Clockwise =Raise

&RXQWHUFORFNZLVH /RZHU

Trigger

Tighten

Vertical

DGMXVWPHQWUDQJHPP

Forward / backward

DGMXVWPHQWUDQJHPP

PERIODICAL INSPECTION

・Clean inside of track.

・&KHFNXSSHUVSDFHDQGORZHUVSDFHRIWKHGRRU,IQHFHVVDU\FRUUHFWWKHVSDFH

Trouble Check Solution

Door stops during soft

closing

&KHFNLIGRRUERWWRPFRQWDFWVZLWKÀRRU &RQ¿UPWKDWWKHWUDFN¿[LQJVFUHZVDUHQRWORRVHQHG7KHQDGMXVWGRRUKHLJKW

VXFKWKDWFOHDUDQFHEHWZHHQWKHGRRUERWWRPDQGÀRRULVPP

No soft closing Check if trigger is installed. ,QVWDOOWKHWULJJHUWRFRUUHFWSRVLWLRQ

Check if hook lock is used. Soft closer may not be able to close the door. Please contact Sugatsune.

$EQRUPDOQRLVHGXULQJ

operation

Check if door touches other parts. Provide necessary space between the door and adjacent objects.

Check track rollers for aluminum dust. Remove the track and pull out the roller. Then, clean the roller.

Check for loose screws retaining the upper track. Tighten the screw.

+HDY\GRRURSHUDWLRQ Check if door touches adjacent parts. Correct door position to avoid contact with other objects.

$GMXVWSRVLWLRQRIÀRRUJXLGHRUVWRSSHU

Check if the door is warped. Replace door with one that is not warped.

Door does not move. Check the track retaining screws for looseness. Roller touches the screw.

Retighten screws to free the roller.

Door starts to move. &KHFNLIWKHXSSHUWUDFNLVVHWKRUL]RQWDOO\ 8VLQJDOHYHOJDXJHUHVHWXSSHUUDLOKRUL]RQWDOO\

TROUBLESHOOTING

)LQDOYHUL¿FDWLRQ &RQ¿UPWKDWDOOVFUHZVDUHVHFXUHO\WLJKWHQHG$QGFRQ¿UPWKDWDOOVFUHZVKDYHEHHQXVHG

Floor guide

Support

Click

Lever

Main unit

Casing

右左

上

下

右左

上

下

Mark Mark

Lever Lever

OK

Correct lever position Incorrect lever position

Door stopper

(floor mount)

(option)

Lever