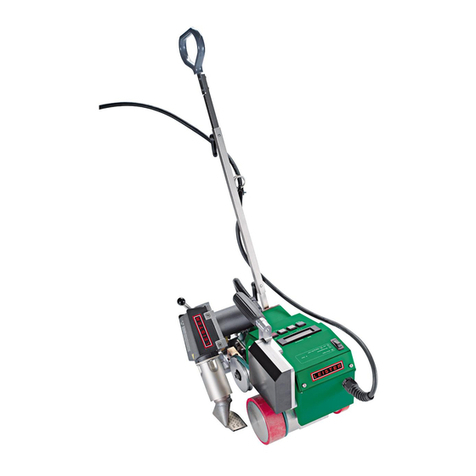

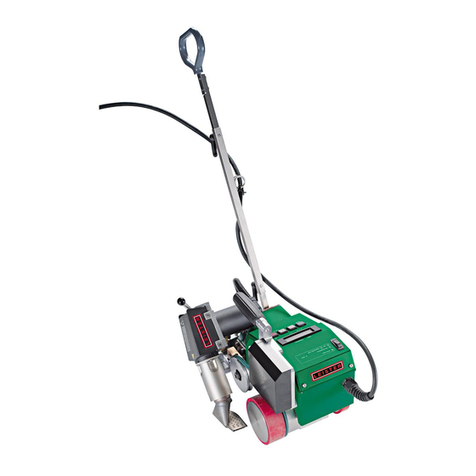

Leister TWINMAT User manual

Other Leister Welding System manuals

Leister

Leister NOVOLAS Basic AT User guide

Leister

Leister TAPEMAT User manual

Leister

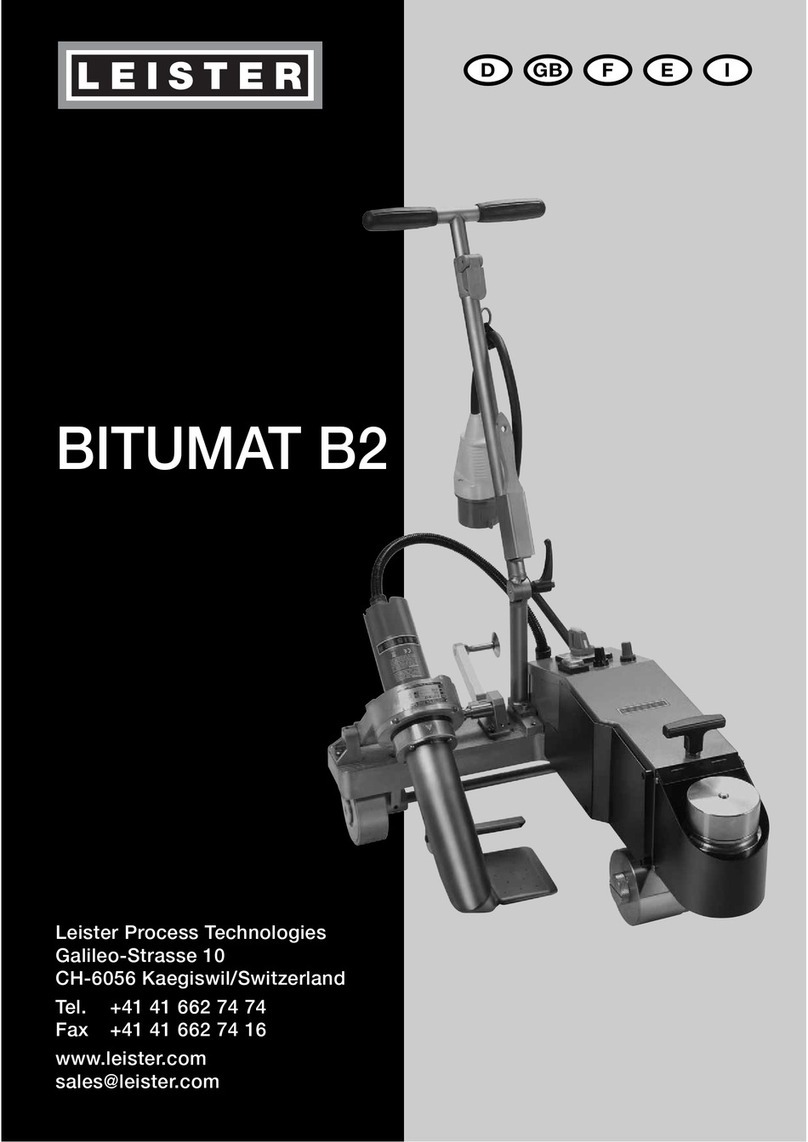

Leister BITUMAT B2 User manual

Leister

Leister BITUMAT B2 User manual

Leister

Leister VARIANT T1 User manual

Leister

Leister Uniroof E User manual

Leister

Leister WELDPLAST S2 User manual

Leister

Leister VARIMAT V2 User manual

Leister

Leister UNIROOF E 40 mm User manual

Leister

Leister WELDPLAST 600 User manual

Leister

Leister WELDPLAST S2 User manual

Leister

Leister TRIAC ST User manual

Leister

Leister LQS GEOSTAR User manual

Leister

Leister UNIFLOOR 500 User manual

Leister

Leister Uniplan E User manual

Leister

Leister TRIAC BT User manual

Leister

Leister UNIPLAN 300 User manual

Leister

Leister Uniplan E User manual

Leister

Leister SEAMTEK 36 User manual

Leister

Leister FUSION 2 User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual