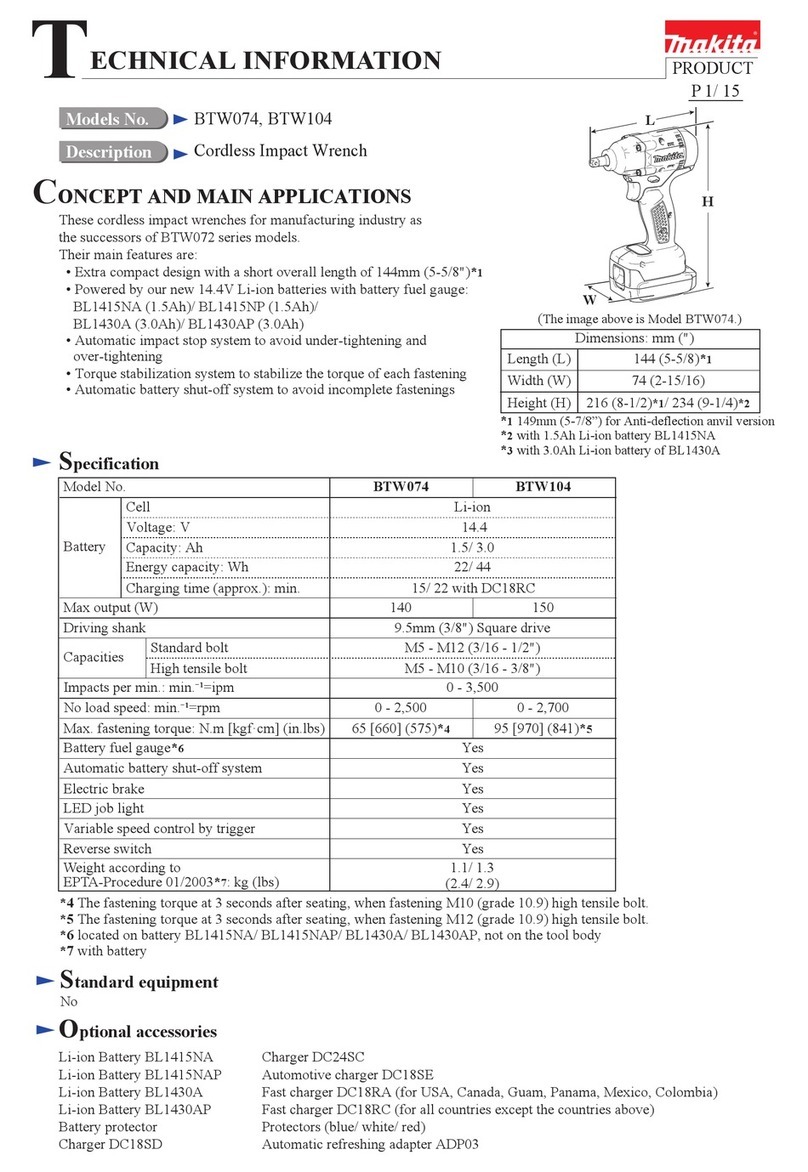

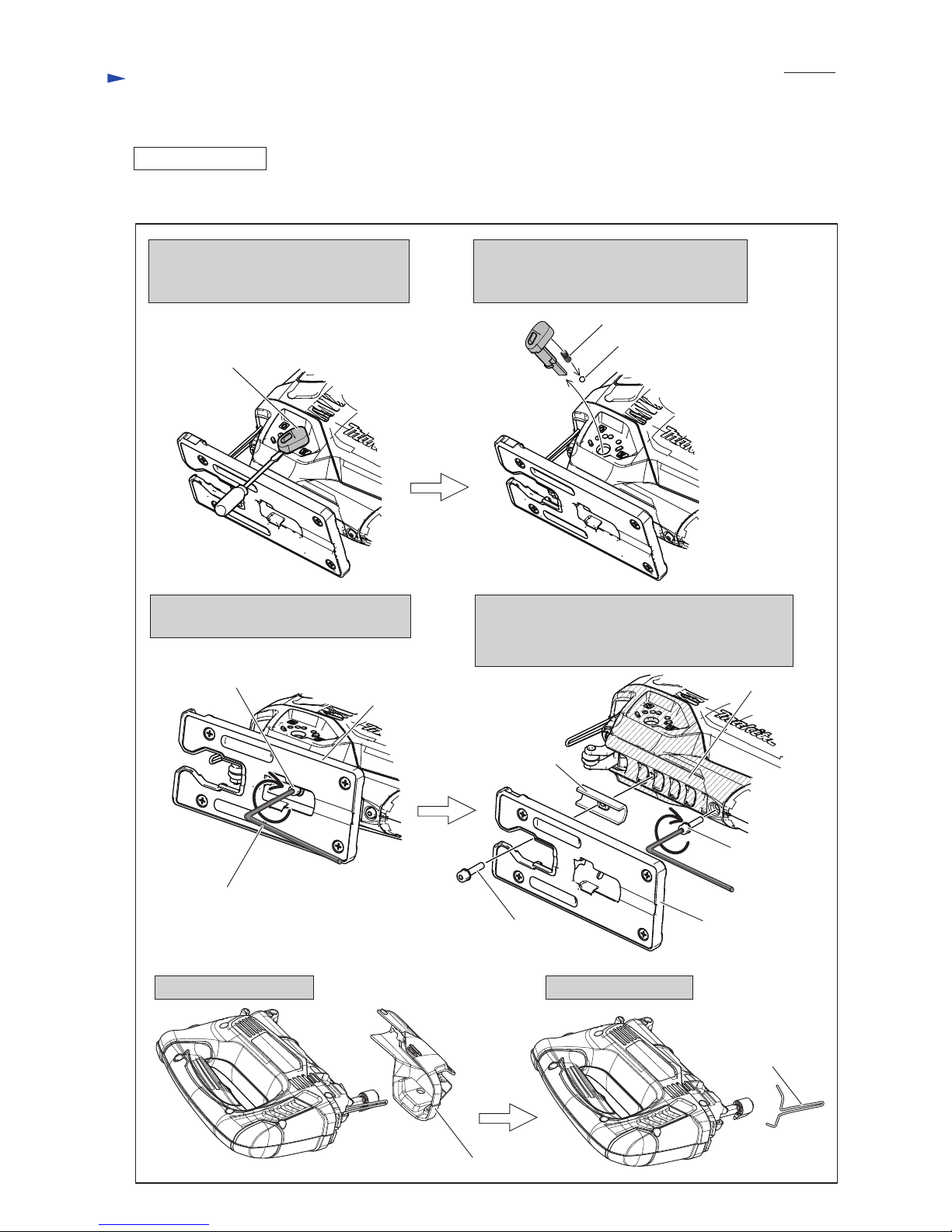

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 12

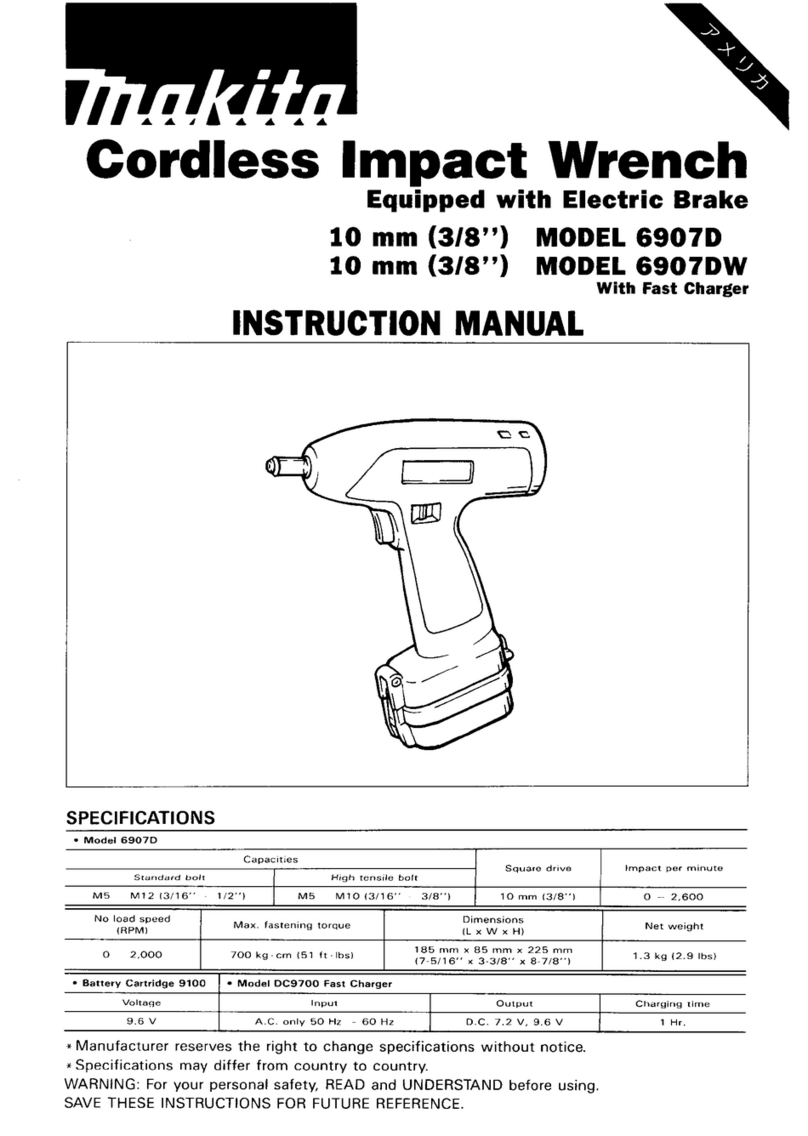

Specification

Standard equipment

Note: The standard equipment for the tool shown above may differ by country.

Description Jig Saw

Model No. JV0600

Model JV0600 has been developed as a jig saw to cover

the midrange class that had not been in our range.

Its main features are:

• Compact and lightweight design has been achieved

without losing strong power nor high maneuverability

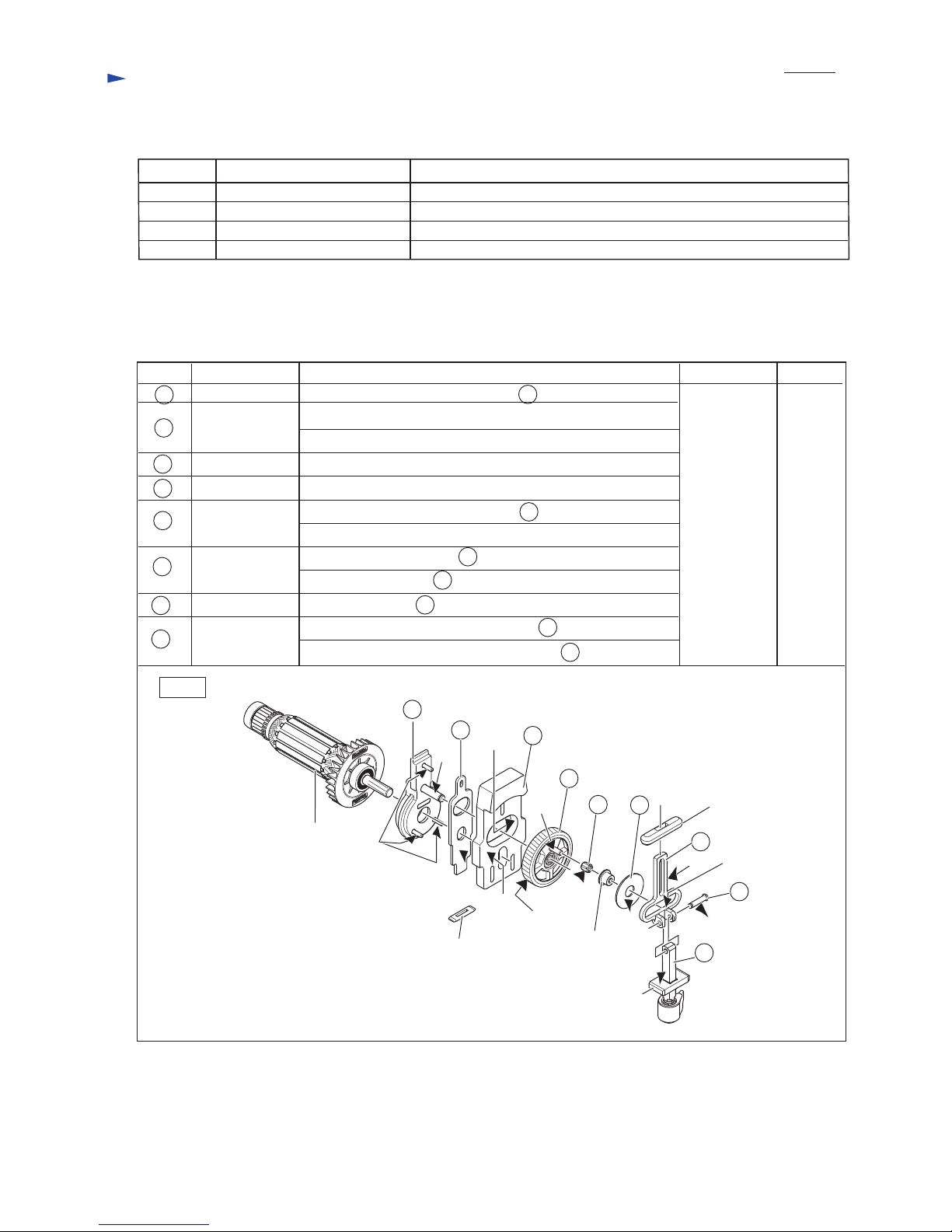

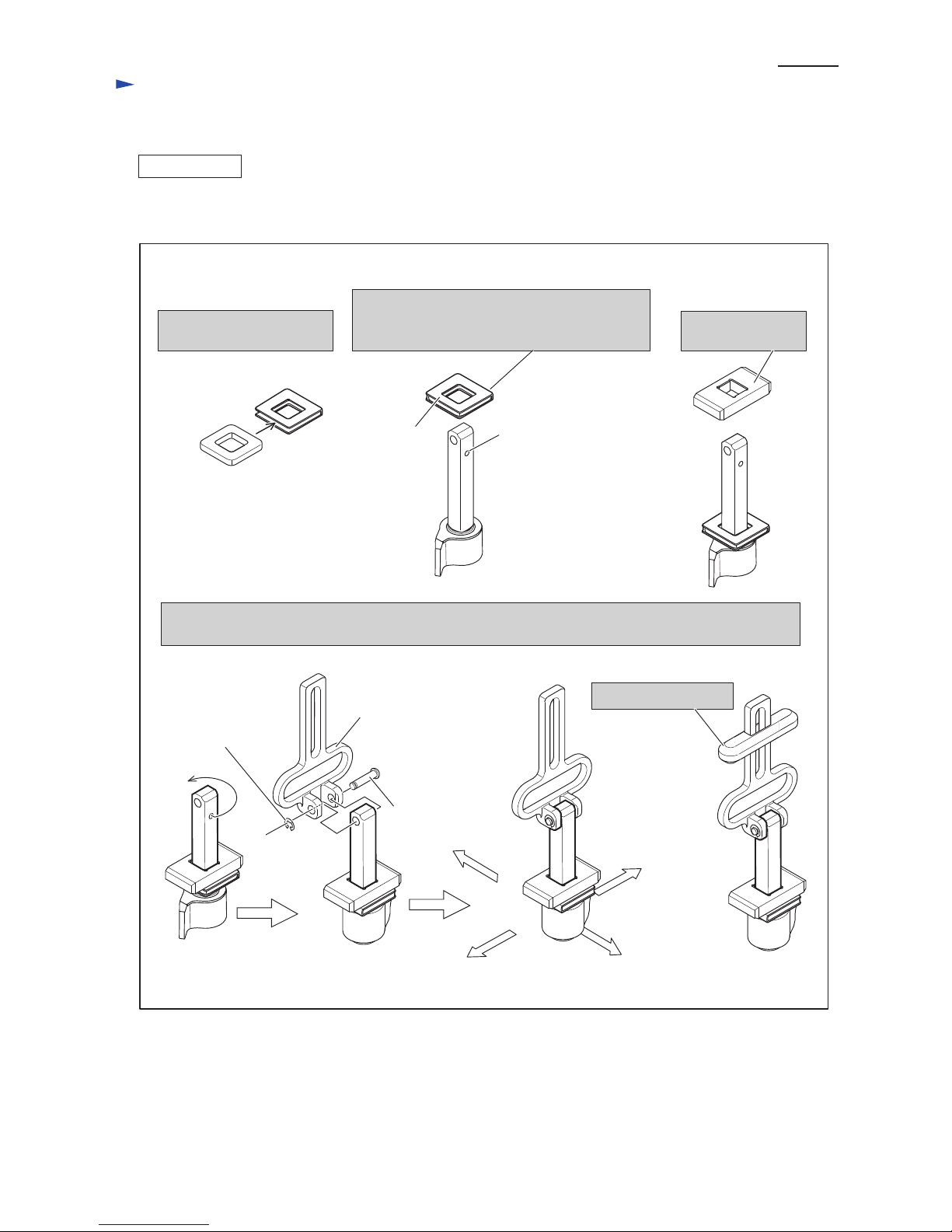

• New toolless blade clamp for quick blade changes

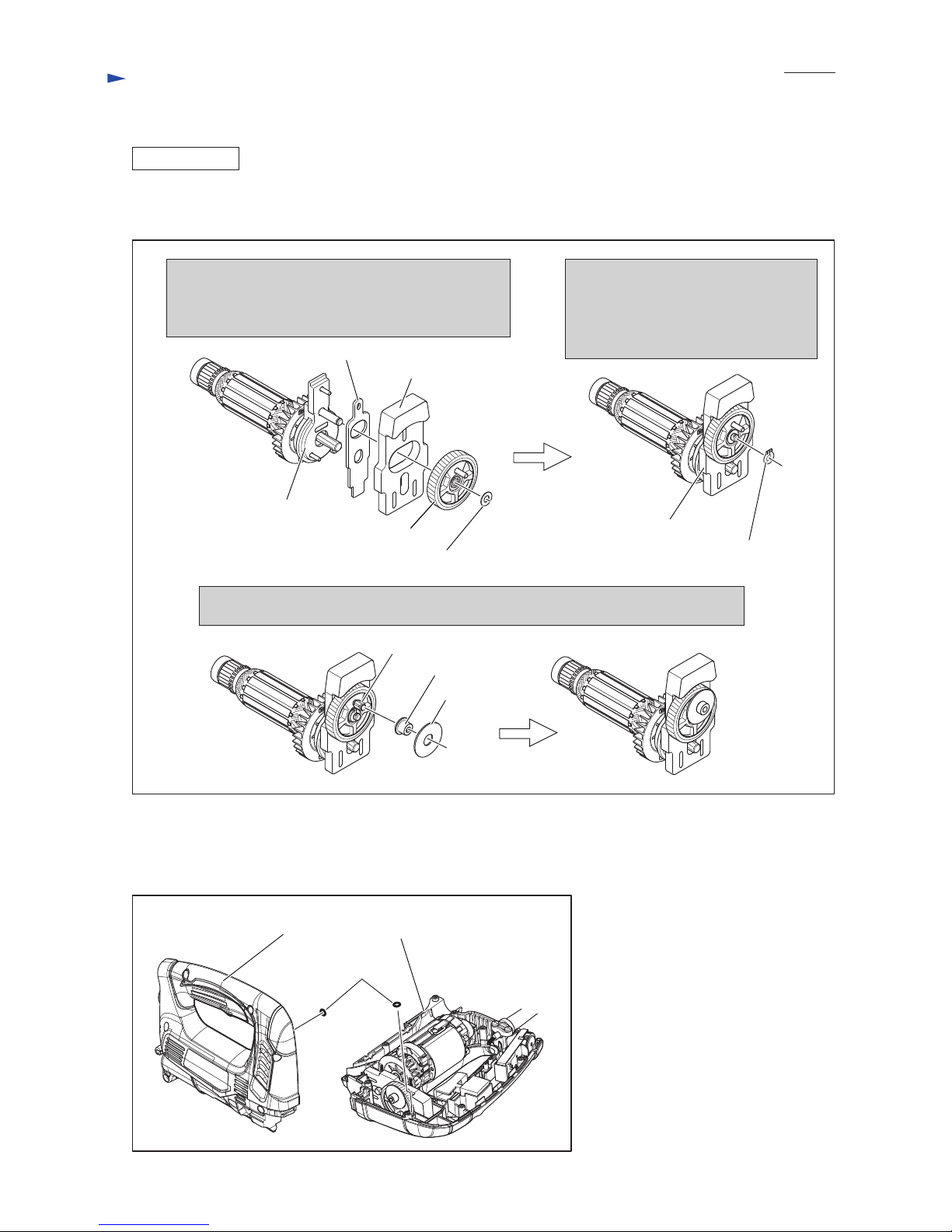

• Rigid aluminum support housing with blow-off device

added to protect the rod portion from saw dust for

enhanced performance against dust.

Jig saw blade No. B-10 ......... 1

Hex wrench 3 ........................ 1

Guide rule set ........................ 1 (for some countries only)

Plastic carrying case ............. 1

Optional accessories

Guide rule set

Kerf board set

Hose 28-1.5

Hose 28-3.0

Jig saw blades

Cover plate

120

110

220

230

240

6.2 650

---

380 60050/60

3.1 650 380 60050/60

3.0 650 380 60050/60

2.9 650 380 60050/60

6.5 380 60050/60

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output (W)

Current (A)

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 236 (9-1/4)

77 (3)

199 (7-7/8)

L

H

W

* When cutting with optional blade No. B-16L

Weight according to

EPTA-Procedure 01/2003: kg (lbs) 2.4 (5.2)

No load speed: strokes per min.

Aluminum

Capacities: mm (")

Wood*

20 (25/32)

Steel 10 (3/8)

Stroke length: mm (") 23 (7/8)

Shank type

Protection against electric shock

Power supply cord: m (ft) Europe: 4.0 (13.1), Australia, Brazil: 2.0 (6.6),

Other countries: 2.5 (8.2)

Double insulation

Variable speed control by dial Yes

10.5

Housing type

Cut settings

Vibration measured according to

EN60745-2-11: m/s²

3 Orbital settings + Straight cutting

Yes

Material of base

Toolless blade change

500 - 3,100

B-type

90 (3-1/2)

Clamshell type

Aluminum

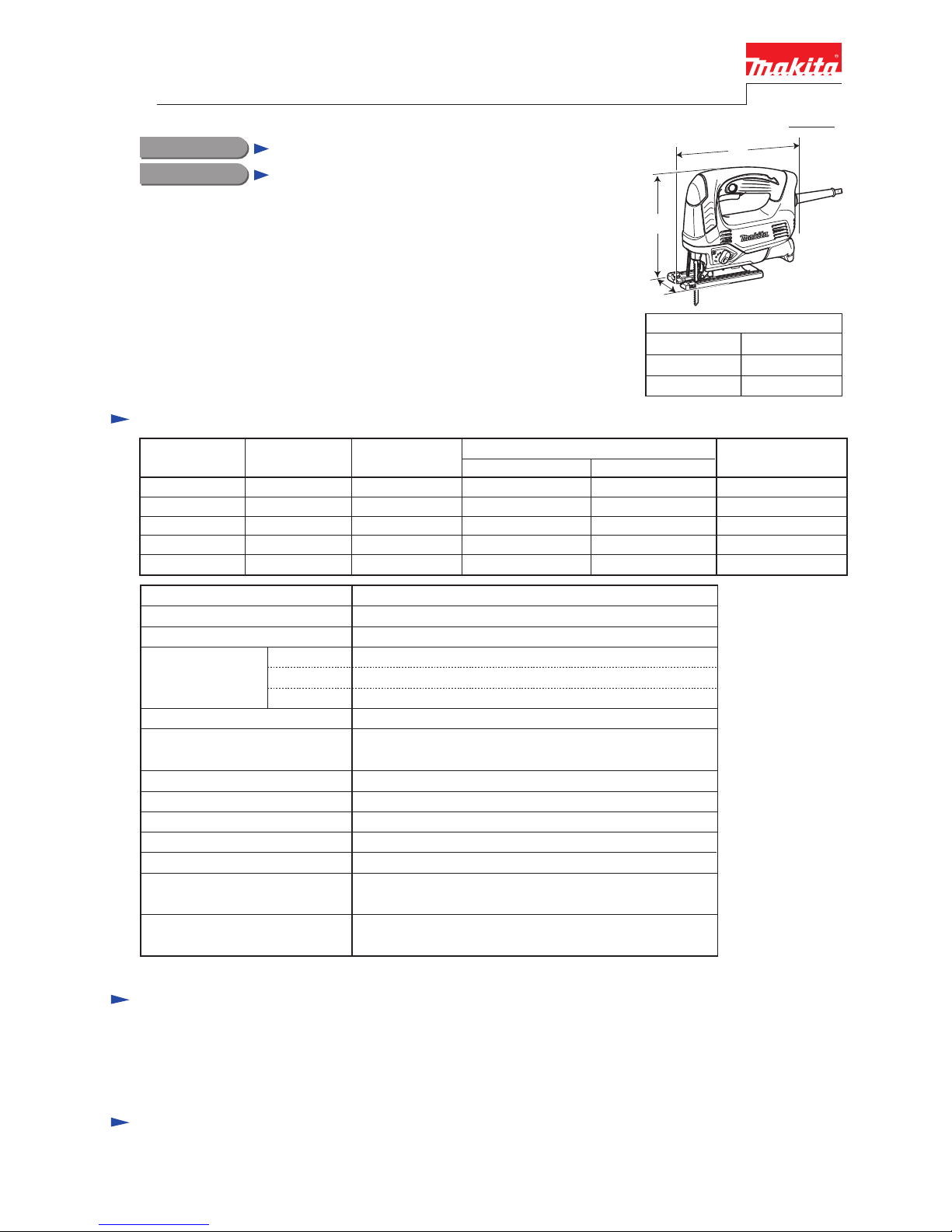

TECHNICAL INFORMATION