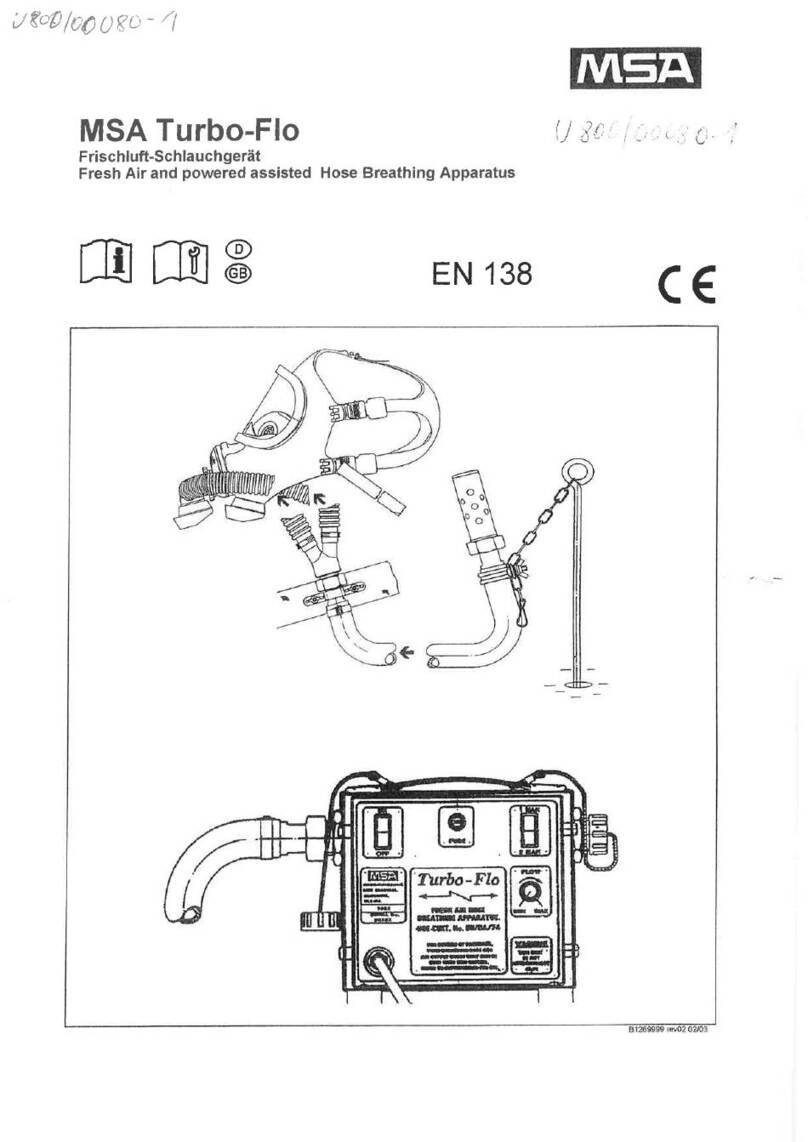

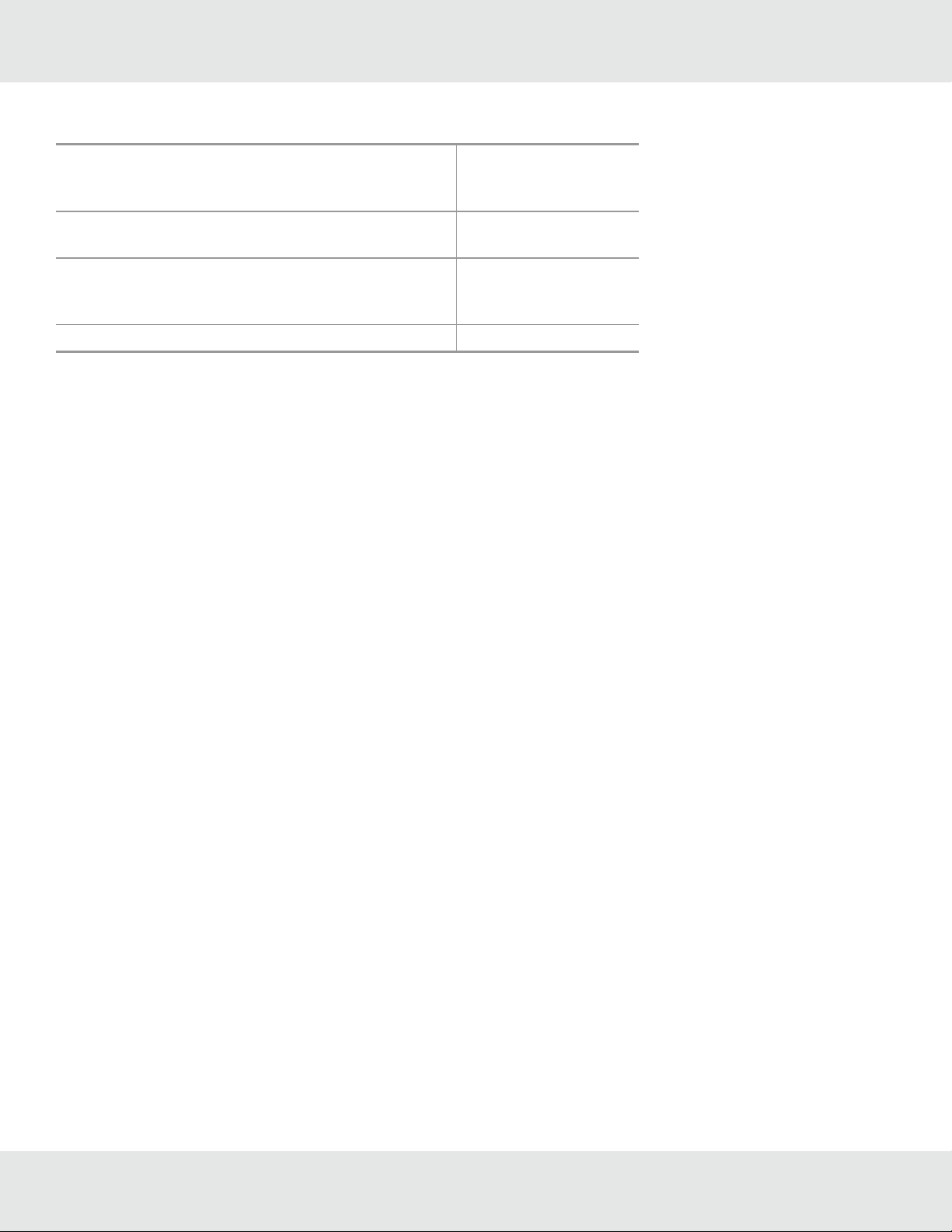

6. This approval applies only when the device is supplied with respirable air through 8 to 300 feet of air supply hose within

the pressure range stated within this user's manual.

7. A maximum of 12 sections, straight or uncoiled, of air supply hose may be used in making up the maximum working

length of hose. Each section of coiled hose, regardless of length, is considered 50 feet in length (max.: 6 sections).

8. Below 32° F, add the following nosecups to the Ultravue® Facepiece: 471539, 471540, or 471541.

9. NIOSH approval information is included as a supplement (P/N 10122516) to these instructions for Abrasi-Blast

Respirators.

1.2 Important Notice for Respiratory Protection Program Administrators

1. Before occupational use of this respirator, a written respiratory protection program must be implemented meeting all the

local government requirements. In the United States, employer must comply with OSHA 29 CFR 1910.134 which

includes medical evaluation, training, and fit testing.

2. An adequate respiratory protection program must include knowledge of hazards, hazard assessment, selection of proper

respiratory protective equipment instruction and training in the use of equipment, inspection and maintenance of

equipment, and medical surveillance. [See OSHA regulations, Title 29 CFR, Part 1910.134, Subpart I, Par. 1910.134

(c).]

3. This respirator may be used only after proper instruction and training in its use as specified in OSHA regulations Title 29

CFR, Part 1910.134, Subpart 1, Par. 1910.134 (b) (3).

4. Do not mark the respirator, i.e., with stamps, labels, paint or other method. Use of such markings may interfere with

apparatus use or may constitute a flammability hazard.

5. Be sure that no other equipment interferes with the respirator facial seal, the user’s ability to operate the respirator, or

other necessary means of mobility.

For more information on the SCBA use and performance standards, consult the following publications:

• ASTM F3387, Latest edition, Standard Practices for Respiratory Protection, ASTM International

https://www.astm.org/Standards/F3387.htm? (ASTM F3387 formerly known as ANSI Z88.2)

• Title 29 CFR Part 1910, Occupational Safety and Health Standards, https://www.osha.gov/law-regs.html

• Title 29 CFR Part 1910.134, Respiratory Protection Standard, https://www.osha.gov/law-regs.html

• Compressed Gas Association, Inc., https://www.cganet.com/

WARNING!

1. Read and observe all NIOSH and other approval limitations as they apply to using the breathing apparatus.

2. DO NOT use the respirator as an underwater device.

3. This system must be supplied with respirable [Quality Verification Level (Grade) D, see ANSI/CGA G-7.1] or higher

quality air; and a dew point not to exceed -65°F (24ppm v/v) [Compressed Gas Association Specification G-7.1 for

Quality Verification Level (Grade) D Gaseous Air].

4. This device may not seal properly with your face if you have a beard, gross sideburns or similar physical characteristics

(see NFPA-1500 and ASTM F3387 - latest edition). An improper facial seal may allow contaminants to leak into the

facepiece, reducing or eliminating respiratory protection. Do not use this device if such conditions exist. The face-to-

facepiece seal must be tested before each use. Never remove the facepiece except in a safe, nonhazardous non-toxic

atmosphere.

5. Return to a safe atmosphere immediately if discoloration, crazing, blistering, cracking or other deterioration of the lens

material is observed.

US Abrasi-Blast Respirator 6

1 Introduction