Bracket Locking Nuts finger-tight. Wrap Locking Nut with a strip of

paper before final tightening with a 3/4” wrench, to avoid scratches or

scuff marks (See Diagram #6). Tighten Locking Nuts securely.

9. CHECK ALL FASTENERS FOR TIGHTNESS: When the desired

height and rake of your Deflector Screen DX is achieved, check and

tighten (a) the four Hex Cap Screws in the Pivot Mounts, (b) the four

Hex Screws in the Rod Clamps, (c) the two Locking Nuts on the

Telescope Brackets, (d) the two QuickSet Knobs on the Telescope

Brackets, and (e) the two Wing Knobs on the Rake Adjustment Arms.

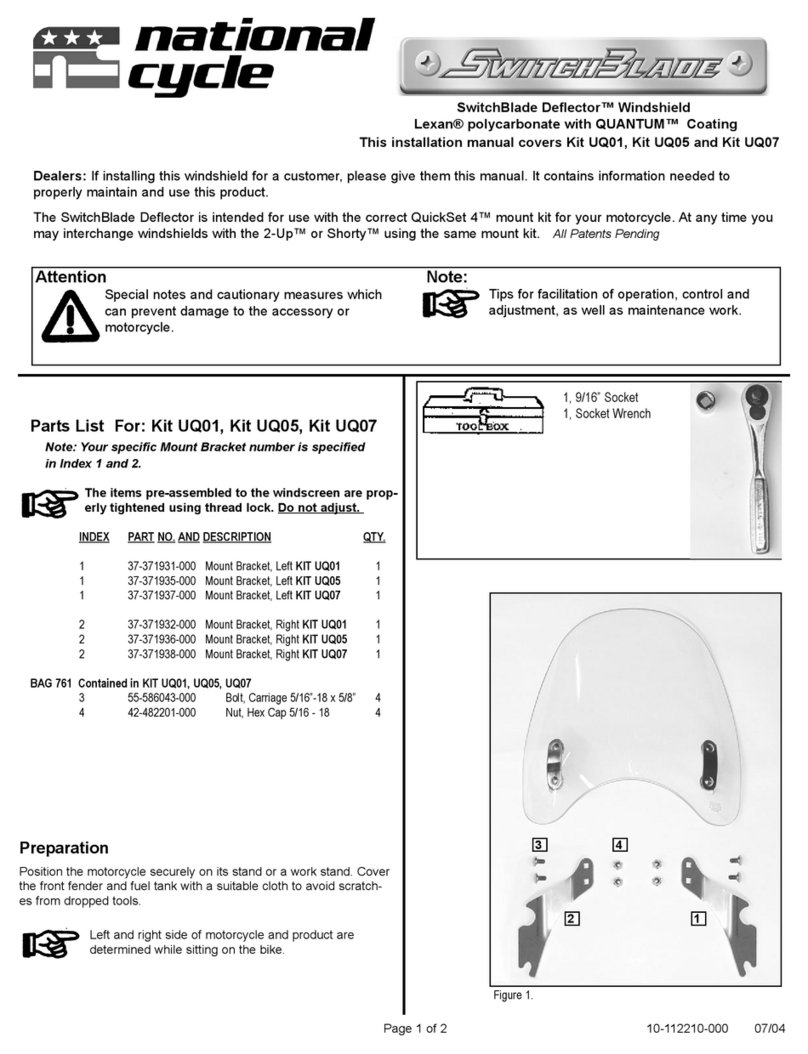

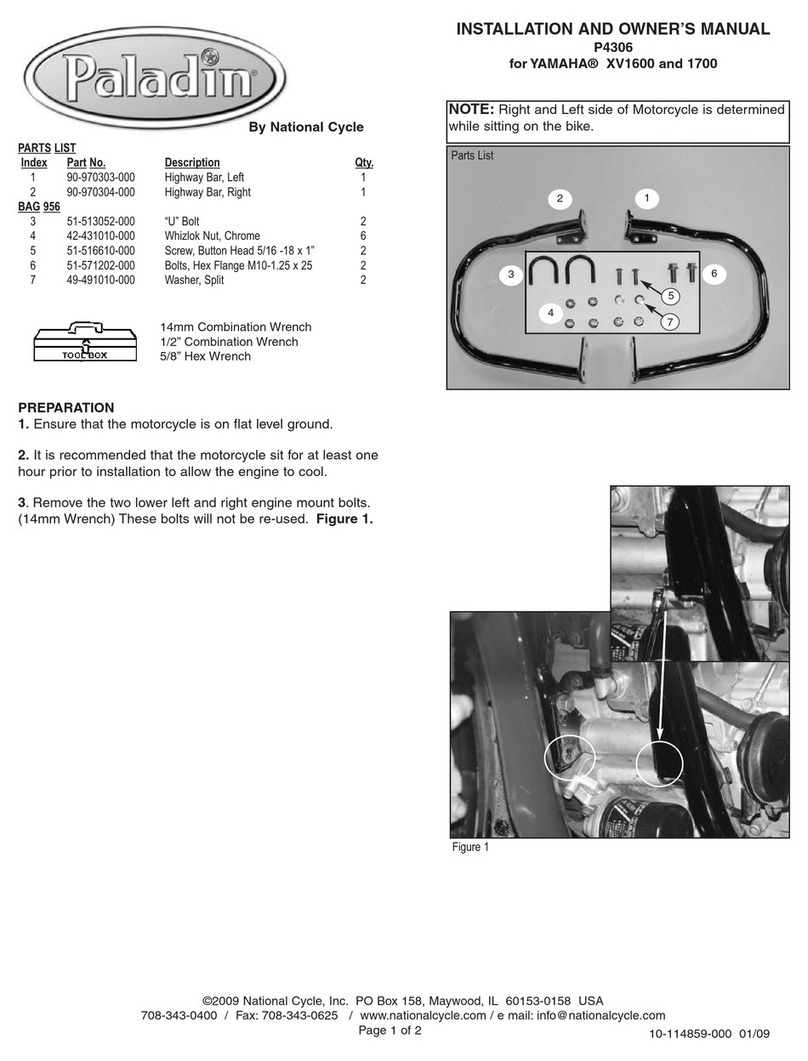

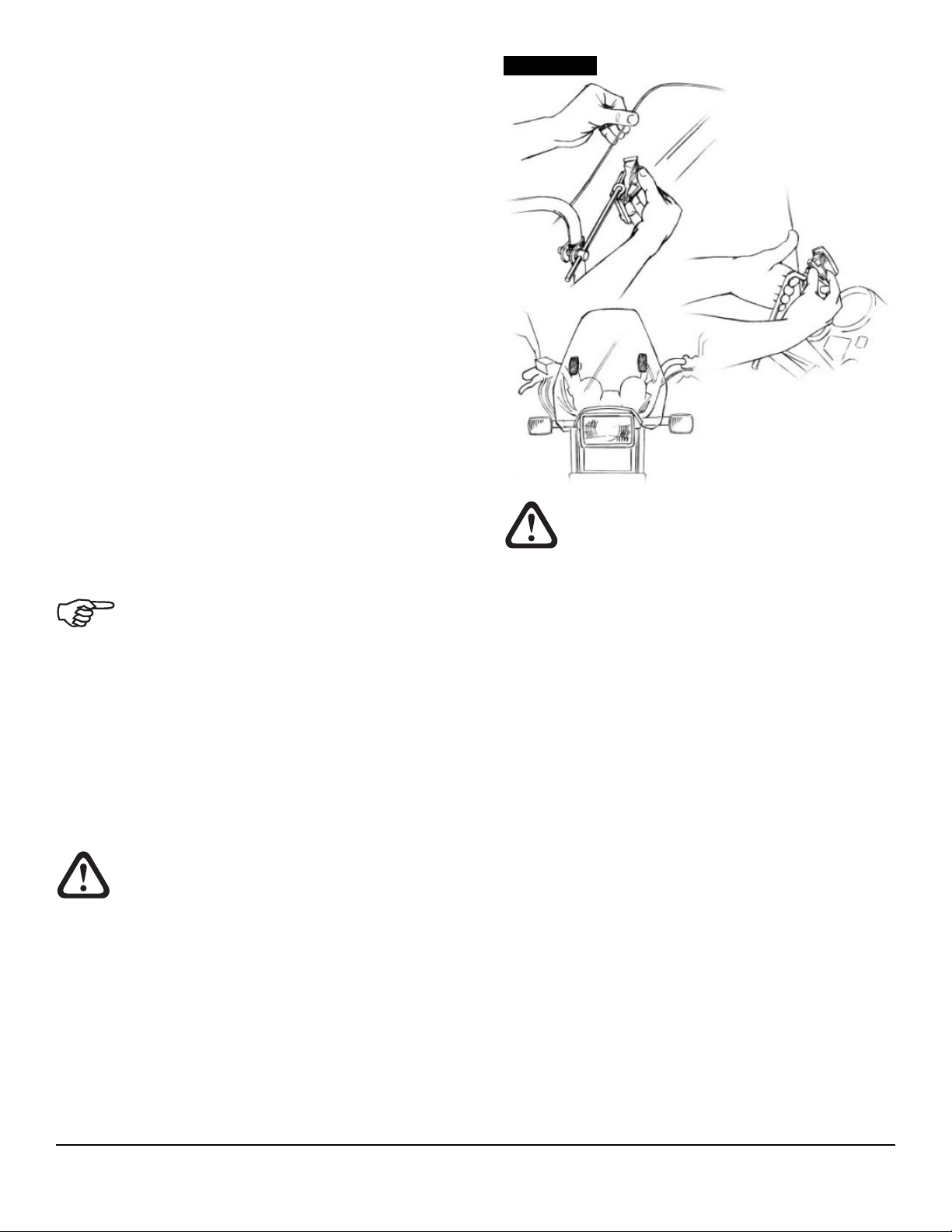

10. FURTHER ADJUSTMENTS: (See Diagram #7). The rake of your

Deflector Screen DX can now be changed at any time by simply loos-

ening the two Wing Knobs, pivoting the screen on its mounts, and

retightening the Wing Knobs.

To maintain absolute rigidity, the screen should be “preloaded”

against some point of the headlight shell. With both Wing Knobs

loose, lift on the left Upright with your left hand, and use your thumb to

push the screen more vertical at the Rake Adjustment Arm, one notch

at a time. This will force the gasket on the screen’s lower lip into con-

tact with the headlight shell. Tighten the left Wing Knob. Repeat this

procedure on the right side to balance the preload adjustment.

If the degree of rake is too great after preloading, repositioning of the

Uprights in the Telescope Brackets will realign the screen to your

desired angle. Loosen the Telescope Bracket Locking Nuts, move the

Uprights higher or lower, and then re-tighten the Locking Nuts.

SCREEN REMOVAL

To remove the screen, spin the QuickSet Knobs to release the

T

elescope Brackets and lift the windscreen assembly free from the

motorcycle. No tools are required! The Pivot Mounts stay secured to

your handlebars and in alignment for fast, tool-free reinstallation.

NOTE: The double Ball End Rake Adjustment Arms are not to be used

as a removal point, and should not be disassembled repeatedly. If you

need to remove the Uprights from the screen, detach at the Wing

Knobs.

CLEANING

Pre-rinse your screen with water to remove surface grit. Use mild, non-

abrasive liquid soap, warm water, and a clean, soft cloth/sponge or wet

chamois to wash the screen. Rinse again, as all residue must be

removed. Wipe dry with a chamois or soft sponge to prevent water

spots.

PAINT, GLUE OR GREASE REMOVAL

Moisten a ball of cotton or soft cloth with naphtha or turpentine and gen-

tly scrub to remove paint, glue or grease. Follow with a soap and water

wash as described above.

HAIRLINE SCRATCHES AND ABRASIONS

Small scratches can be removed or minimized with a mild automotive

glazing compound or a high quality plastic polisher. NOTE: Test on a

small sample area first. Recommended polishing products include

Novus 2 Fine Scratch Remover, McGuiar’s Mirror Glaze MGH-17, and

The Wax Shop’s Safe Cut Swirl & Haze Remover. Flannel or chamois

make good polishing cloths. We recommend hand buffing for best

results.Keep moving across the scratch while buffing. Try not to concen-

trate on a small area, which can distort the windscreen’s optics.

Today’s motorcycles are built with enough frame rigidity to withstand the

moderate loads placed on them by the foreseeable addition of a windshield.

National Cycle, Inc. Maywood, IL 601533-0158 USA 708-343-0400 Fax: 708-343-0625

Page 3 of 3 10-119950-000 05/06 Rev.B

CAUTION

Never ride your motorcycle with loose windshield mount-

ing hardware. Check the hardware for tightness regularly.

WARNING

DO NOT USE ALCOHOL SOLUTIONS OR GLASS

CLEANERS to clean your screen. DO NOT use rain pro-

tective products on this screen. Alcohol solutions, brake

fluids, and strong solvents will permanently damage the

screen.

NOTE

The double Ball End Rake Adjustment Arms are not to be

used as a removal point, and should not be disassembled

repeatedly. If you need to remove the Uprights from the

screen, detach at the Wing Knobs.

DIAGRAM 7

T

o change the screen’s rake angle,

loosen Wing Knobs.

Tighten

Wing Knob.

“Preload” screen to contact headlight.

Push with thumb...

...and lift upright.

It is not necessary for the preloaded

screen to contact the headlight at all

points.

If the addition of an accessory(ies) adversely affects your motorcycle’s

stability, immediately remove the accessory(ies). Do not ride a motor-

cycle that exhibits unsafe handling characteristics. Have experi-

enced service personnel correct any problems before riding with the

accessory(ies) installed. For further questions concerning handling

problems associated with an accessory(ies), contact your dealer, motor-

cycle manufacturer, or accessory manufacturer.

Sunlight reflected off the inside curvature of a windshield can, at certain

times of the day, cause extreme heat buildup on the motorcycle’s instru-

ments and possibly even melt them. Exercise care in parking to avoid

this. Park facing the sun or place an opaque object over this area.

National Cycle windshields and fairings are designed to provide wind

protection and enhanced comfort, but not protection in the event of a

collision with another vehicle, the road, or any other object.

Some of our products use certain features, patented and otherwise, that

may minimize injury in certain accidents, but the possibility of injury

exists if the windscreen is broken.

The acrylic sheet that is used in our Deflector Screen™ is almost 30X

more impact resistant than glass. If it is subject to impact beyond its

resistance, it breaks into comparatively large pieces, and does not nor-

mally shatter into small slivers.

All of our products are made in conformance and exceed the require-

ments of D.O.T. SS205,Z26.1, classifications AS6 and AS7, which cover

all safety glazing for motorcycle applications.

Plexifairing GT, Plexifairing 3, Plexistar 2, Deflector Screen, Deflector

Screen DX, Streetshield, Streetshield EX, FlyScreen, QuickSet3, Rake

Adjust, and No-Hole Ballsocket are covered by one or more of the fol-

lowing patents: 4082345, 4168098, 4379584, 4489973, 5732965,

578833, 6254166, 6484914.

©2006 National Cycle, Inc., Maywood, IL U.S.A.