1. Safety precautions prior to use

Read Handpiece’s Operation manual carefully before use.

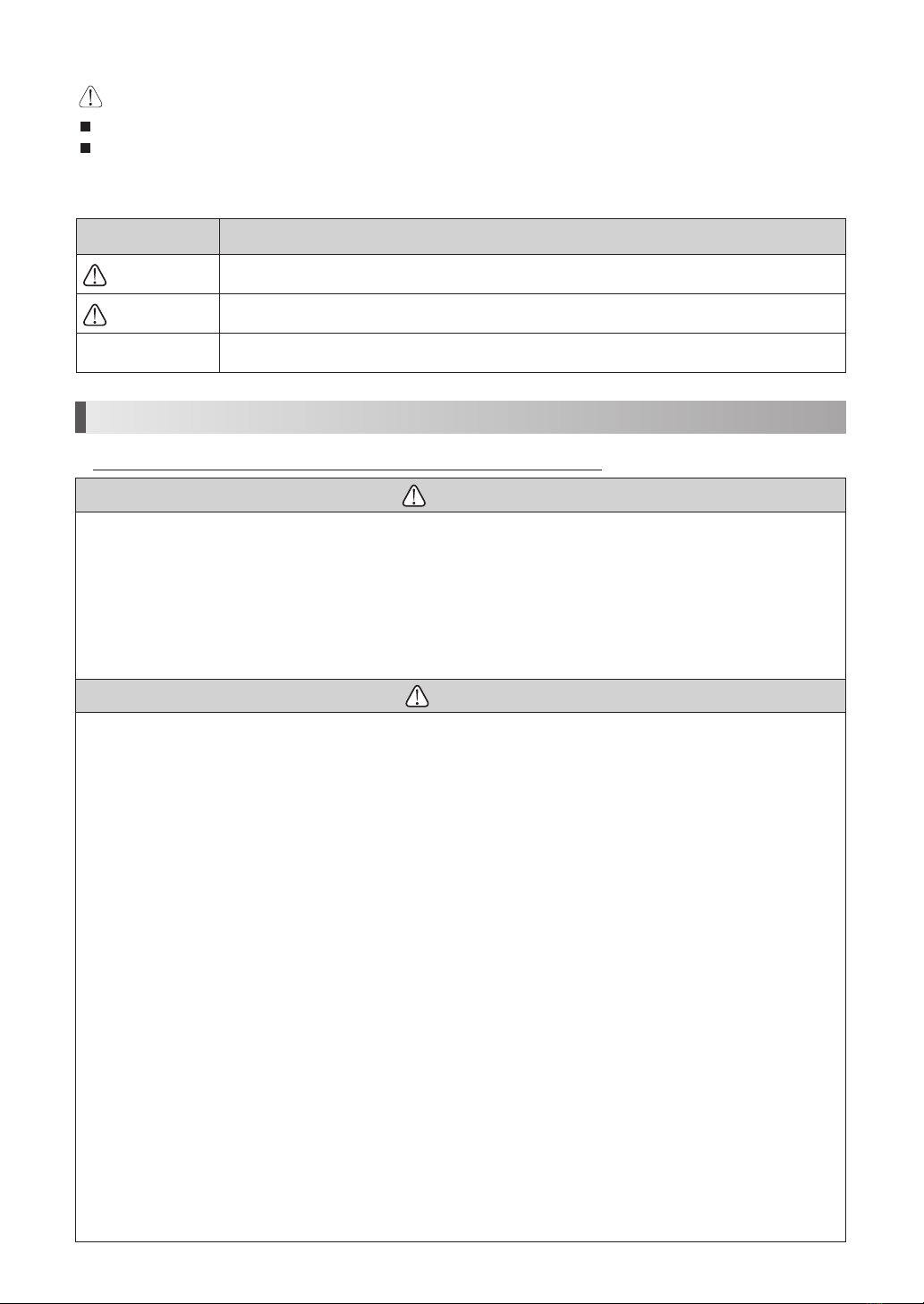

Classification Degree of Danger or Damage and Seriousness

WARNING Explains an instruction where personal injury or physical damage may occur.

CAUTION Explains an instruction where minor to medium injury or physical damage may occur.

NOTICE Explains an instruction that should be observed for safety reasons.

• The accuracy of the Torque Monitor depends on the high precision performance of the handpiece attached to the

micromotor. Real torque value may not otherwise be correctly displayed. To guarantee handpiece torque accuracy,

that matches the monitor display system, USE ONLY the NSK contra angle handpieces listed on “12. Contra Angle

Handpieces and Accessories”. When other handpice had connected, it may not output accurate torque which

indicated on handpiece.

• Surgic Pro series needs special precautions regarding EMC and needs to be installed and put into service according

to the EMC information. (Refer to 16. EMC Information)

• Portable and mobile RF (Radio Frequency) communications equipment can affect Surgic Pro series. Do not use RF

equipment outskirts for the product.

• The use of accessories, Motors and cables other than those specified, with the exception of Motors and cables sold

by the manufacturer of Surgic Pro series as replacement parts for internal components, may result in increased

EMISSIONS or decreased IMMUNITY of the Control Unit.

• Surgic Pro series should not be used adjacent to or stacked with other equipment and that if adjacent or stacked use

is necessary, the Control Unit should be observed to verify normal operation in the configuration in which it will be

used.

• When operating this system always consider the safety of the patient.

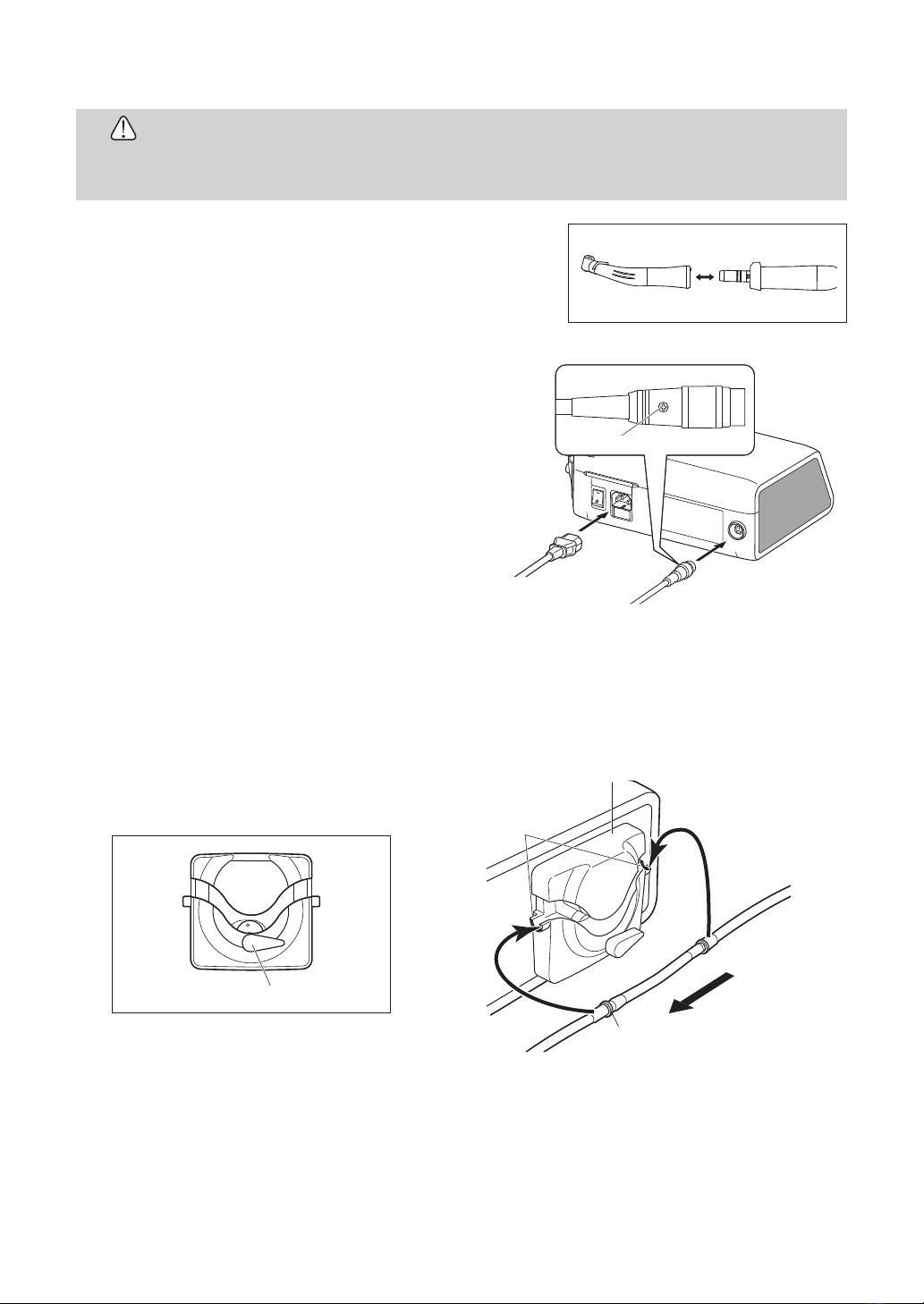

• Do not attempt to disassemble the Control Unit /Foot Control / Micromotor nor temper with the mechanism.

• Check for vibration, noise and overheating before use and if any abnormalities are found in use, stop using

immediately and contact dealer.

• Use an electrical outlet that is grounded.

• Do not drop, hit, or subject to excessive shock.

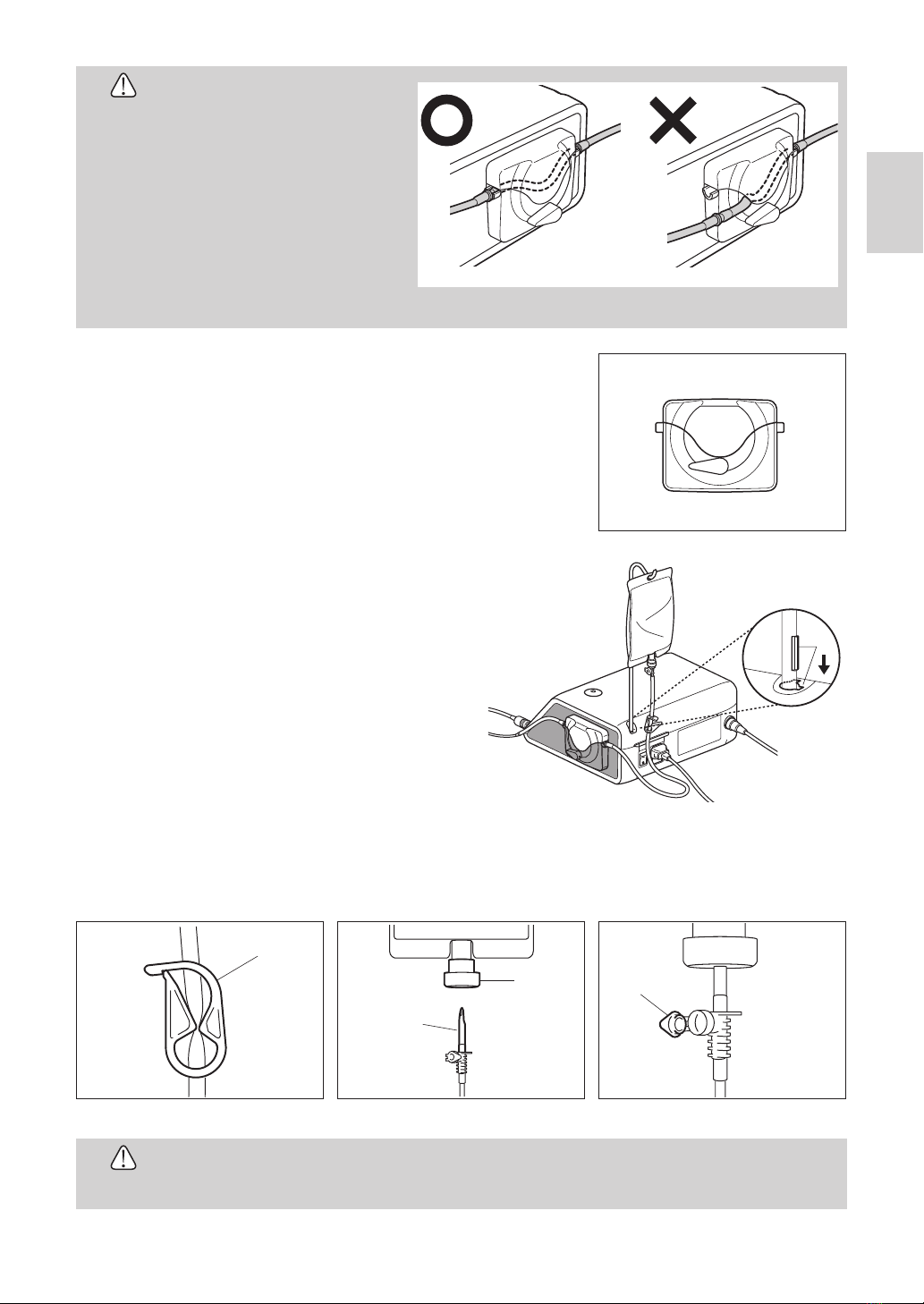

• Do not bend the Irrigation Tube while the irrigation pump is operating. It could cause tube breakage.

• Do not use bent, damaged or sub-standard burs or drill. The Shank could bend or brake.

• Do not exceed the recommended speed and torque.

• TO PREVENT ELECTRIC SHOCK Do not unplug the AC Power cord with wet hands.

• TO PREVENT ELECTRIC SHOCK Be sure to prevent water on the Control Unit.

• TO PREVENT ELECTRIC SHOCK Use an electrical outlet that is grounded.

• The system may present a possibility of malfunction when used in the presence of an electromagnetic interference

wave. Do not install the system in the vicinity of the device which emits magnetic waves. Turn off the Main Power

Switch of the Control Unit of this system when an ultrasonic oscillation device or an electrode knife is located in the

vicinity is used.

CAUTION

WARNING

2

Read these safety cautions thoroughly before use and operate the product properly.

These indicators are to allow you to use the product safely, prevent danger and harm to you and others. These are

classified by degree of danger, damage and seriousness. All indicators concern safety, be sure to follow them.

Cautions for handling and operation