2

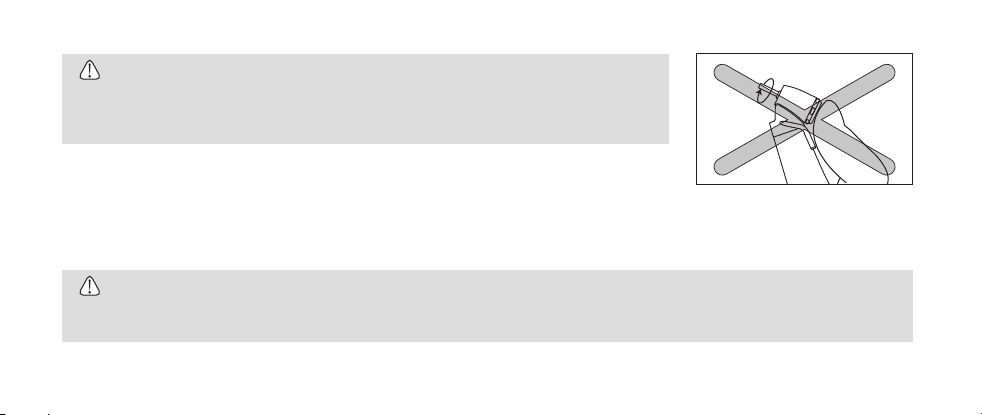

CAUTION

•Read this Operation Manual before use to fully understand the product functions and file for future reference.

•When operating the product always consider the safety of the patient.

•Users are responsible for the operational control, maintenance and continual inspection of this product.

•Do not attempt to disassemble the product nor tamper with the mechanism except as recommended by NSK in this Operation Manual.

•Do not allow any impact on to the product. Do not drop the product.

•Operators and all others in the area must wear eye protection and a mask when operating this handpiece.

•Always operate with coolant water. Without coolant water, the handpiece may overheat causing a burn injury.

•If overheating and/or an unusual noise are observed even in use with coolant water, the bearings may be worn. Contact your Authorized NSK

Dealer to repair whenever any abnormalities are found.

•Entry of debris into the gear, or inside the handpiece, may result in overheating which could cause a burn injury.

•Should the product function abnormally, cease operation immediately and contact your Authorized NSK Dealer.

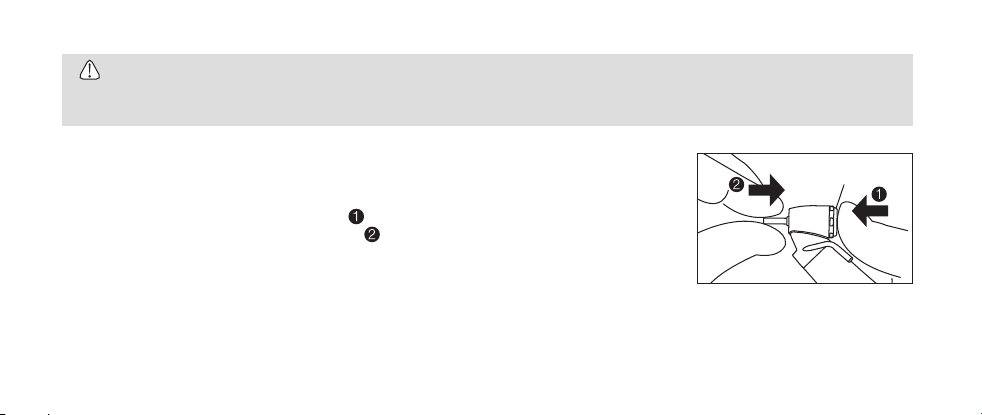

•Depressing the Push Button while the handpiece is in operation may cause overheating, serious technical damage and possible premature

handpiece failure. During operation avoid contact with any oral tissue that may cause the Push Button to be depressed while the handpiece is

in operation.

•Do not use high acid water or sterilizing solutions to wipe, immerse or clean the product.