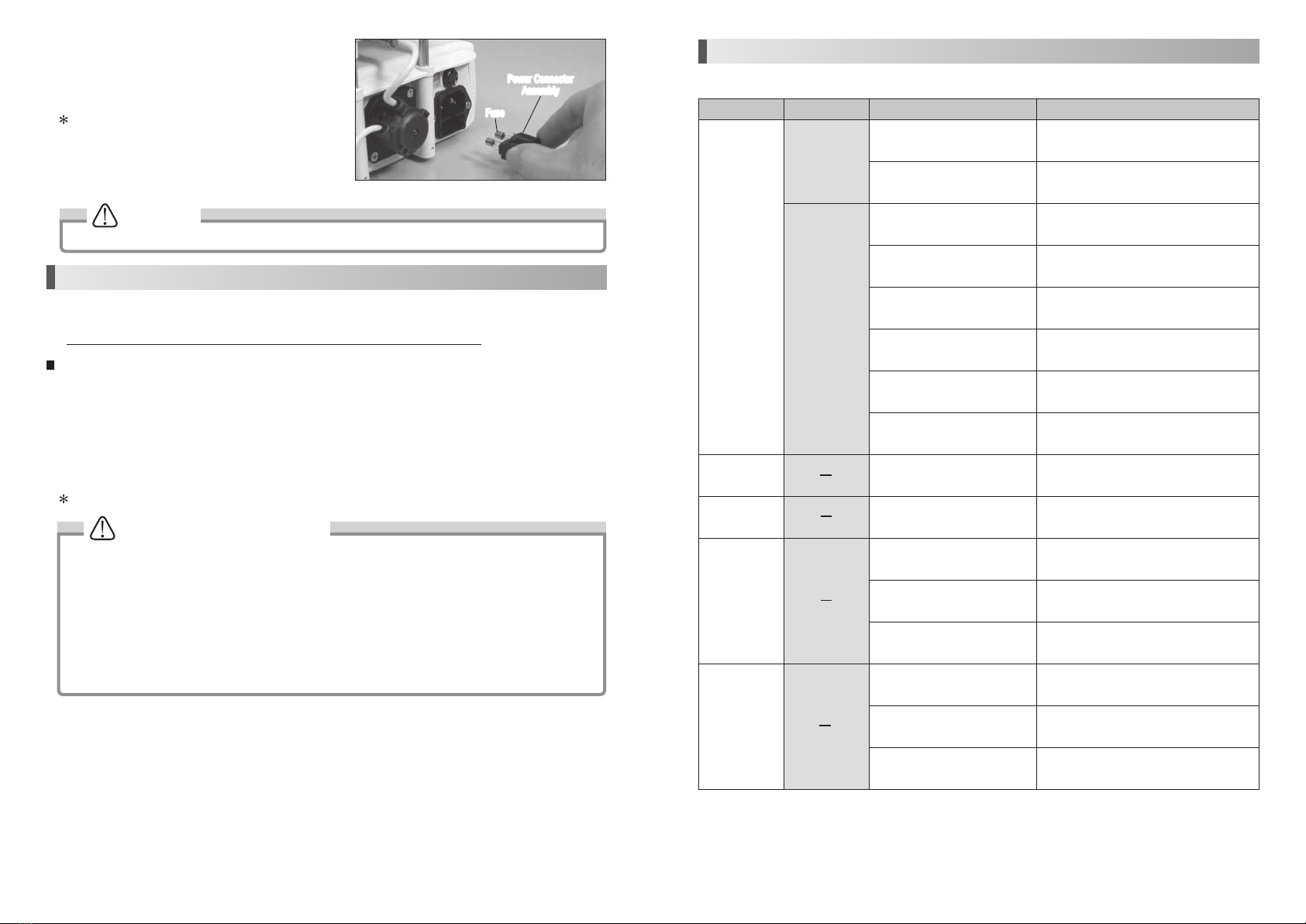

Fig. 1

2 3

· This product needs special precautions regarding EMC and needs to be installed and put into service according to the

EMC information.

· Portable and mobile RF communications equipment can affect this product.

· The use of ACCESSORIES, transducers and cables other than those specified, with the exception of transducers and

cables sold by the manufacturer of the product as replacement parts for internal components, may result in increased

EMISSIONS or decreased IMMUNITY of it.

· This product should not be used adjacent to or stacked with other equipment and that if adjacent or stacked use is

necessary, it should be observed to verify normal operation in the configuration in which it will be used.

· Use an electrical outlet that is grounded. It may cause electrical shock, if it may not use it.

· When operating the handpiece always consider the safety of the patient.

· The handpiece is designed only for dental clinical use.

· Check the vibration outside the patient´s oral cavity before use. If any abnormalities are found, stop using immediately

and contact your dealer.

· Should this product function abnormally, cease operation immediately and returen it to the dealer for repair.

· Do not force or pull on Power Cord and/or Handpiece Cord. It could cause disconnection.

· Do not exceed Maximum Power Level for Tips. It could damage tooth structure and Tips.

· Check if the Tip has no flush, damages, bending and rust before use. Use new one.

· Always use with pouring enough water, or it may damage tooth plane and overheat the handpiece.

· Do not hit metal or prosthetic crown etc., except for removing them. Tips could break and fall into mouth.

· Do not sharpen and/or bend the Tip. Tips may damage and not generate enough vibration during scaling.

· Do not hit gingiva, mucosa and/or skin directly. It could cause damage and burn.

· During cutting, Tip will gradually wear away, as the Tip wears the stroke will get smaller and cutting power level will

decrease. When level drops too far, change the Tip.

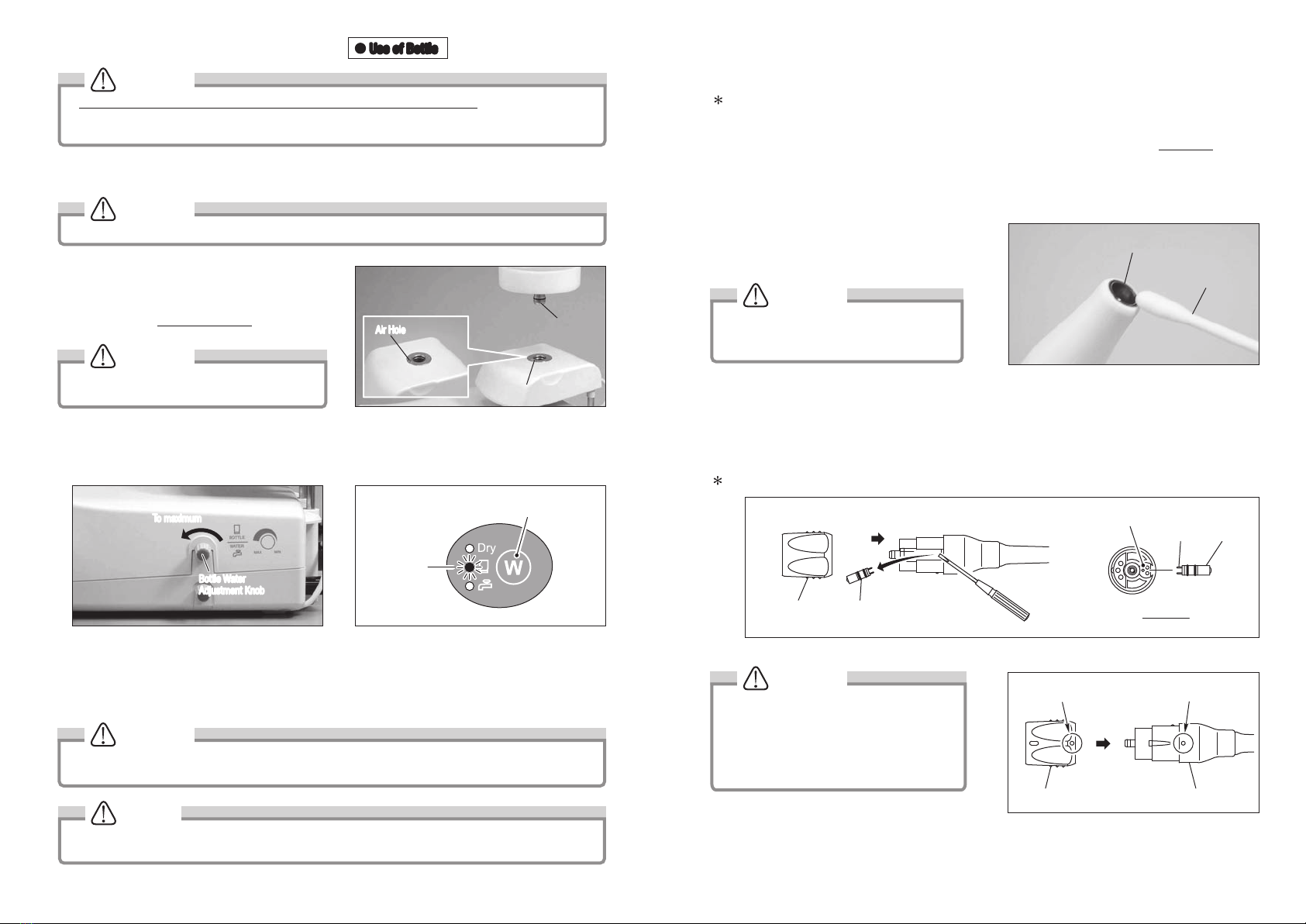

· Be sure to firmly mount the Tip with provided Wrench, or the Tip will not generate enough vibration.

· Check to see if dust does not stick on the screw of the Tip before use. If not clean, Tips will not generate enough vibration.

· Be sure to turn the Power Switch after mounting the handpiece.

· Be sure to attach NSK genuine Tips when using NSK Varios Ultrasonic Scaler (Varios 750 or Varios 750 LUX) The

problems such as damage, failure and accident of Handpieces resulting from use of Non-NSK Tips are not included in the

warranty. The following are the possible failuer that could happen when using the Non-NSK Tips.

· Vibration failure caused by using nonconformable screws.

· Patients’ accidental ingestion of damaged Tips.

· Damage of thread ridge of handpiece.

· Do not sterilize by ultraviolet light. Handpiece could discolor.

· If chemical, solvent or antiseptic solution is deposited on this product, immediately wipe it away. Discoloration or

deformation may occur if left as it is.

· If water is spilled on the irrigation pump, please wipe it off thoroughly and allow to dry completely prior to use. If water

gets inside the irrigation pump the roller may slip and fail to pump irrigation.

· Remove the handpiece after Tip is taken off.

· Do not put liquid such as high acid water in the bottle.

· Implant maintenance scaler tips should be inspected for proper resin coating prior to use and any possible exposure of

the metal core to a dental implant should warrant replacement of the scaler tip.

CAUTION

· During vibration, the handpiece and the handpiece cord may affect computer and LAN cable. Noise could be heard during

operation near a radio receiver.

· Be sure to turn off the Power Switch after use. Remove the power plug and water inside of the control unit if not used for

a long time.

· Users are responsible for operational control, maintenance and inspection.

· When trouble is found, send to dealer.

· This product does not consider patient’s age (except infants), gender, weight or nationality.

· No special training is required for this device.

NOTICE

· Applied parts for patient and/or operator are/ is tip and handpiece.

· There is the judgment that applies this product to a patient in the user side.

· The system is capable wide range from low power for periodontal procedures to high power for excavating procedures.

· Use supplied bottle for saline and other irrigant.

· The Control Unit can simply be wiped off so spills are very easy to clean up, and the Front Control Panel is extremely easy

to read.

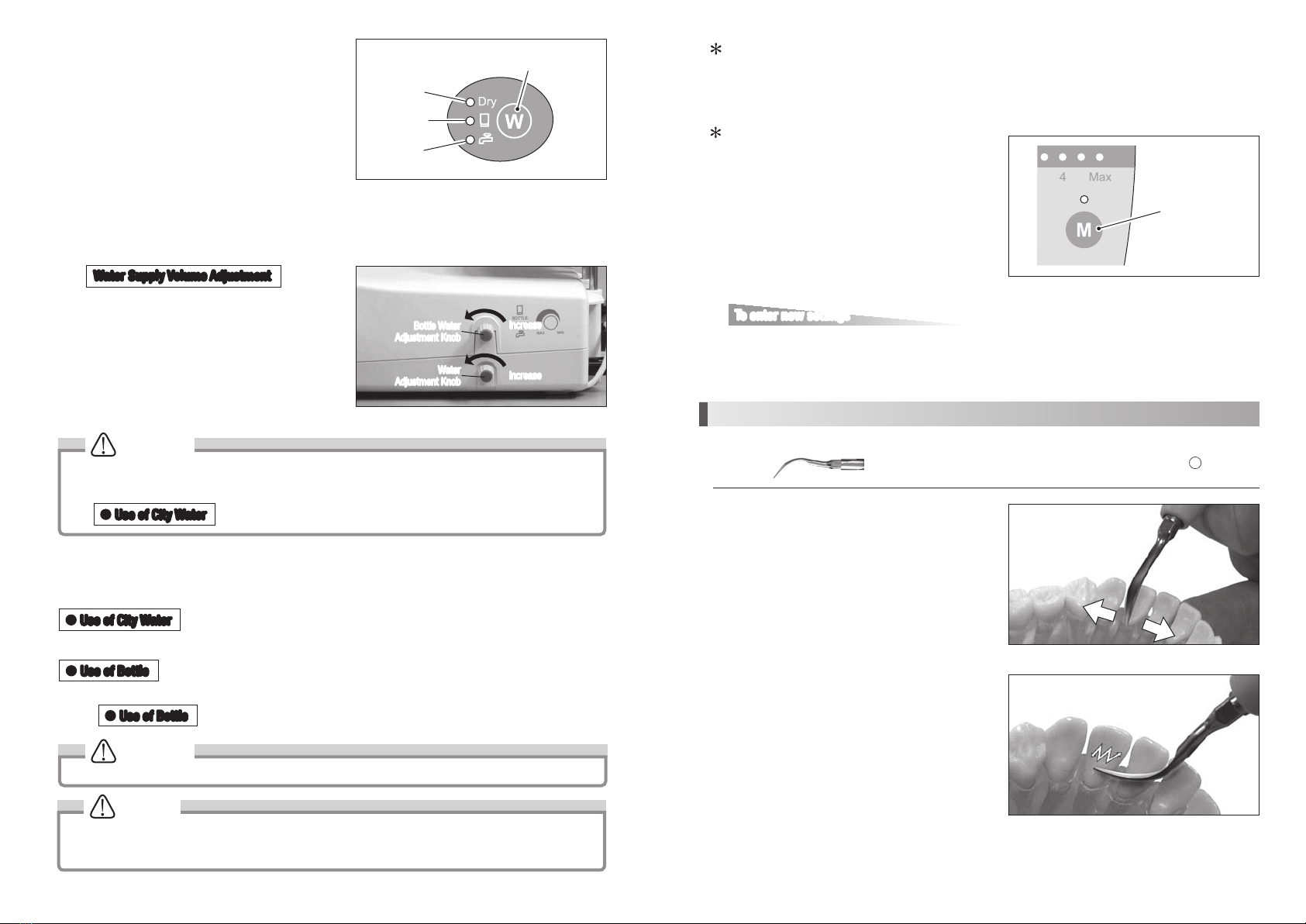

· Three modes of irrigation system operation are available : irrigation from dental unit or city water, irrigation from bottle and

no irrigation.

· The Irrigation Tube from the pump is exposed outside of the Control Unit, and solution could not enter the Control Unit.

· Various operation presets can be input into the system memory.

· The handpiece ring light is extremely bright for easy viewing of the operating area. (Varios 750 LUX)

· The Control Unit has provision to operate the handpiece with light or the one without.

· The handpiece is autoclavable at 135°C

1. Features

2. Component Names

Control Unit

Bottle 2pcs Water Connecter

(AC120V Only)

Tip Wrench

Tip Cover S

Water Tube

Tip G1

Tip G4

Tip G6

Spanner Wrench (5x8) 2pcs Power Cord

Handpiece Cord

Handpiece Lamp

Handpiece Cord

Handpiece O-ring

2pcs

Foot Control

O-ring for Bottle 4pcs

Tip Holder

<Varios 750LUX>

<Varios 750>