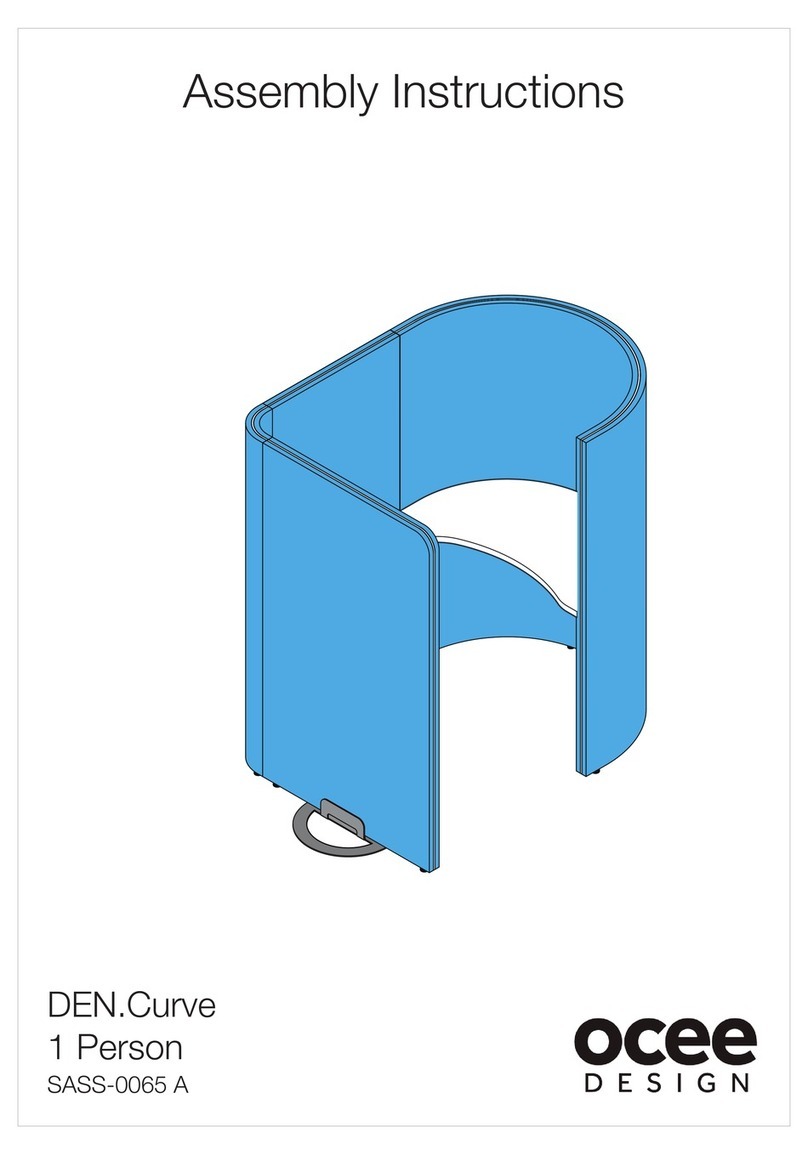

1.

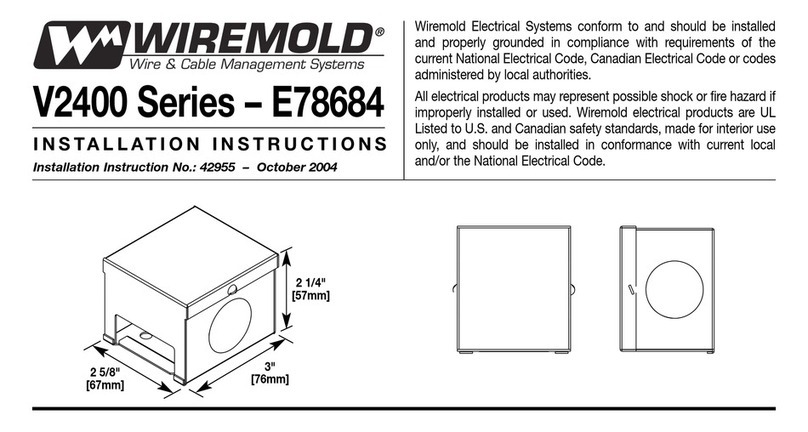

Insert the modular screws in the extended 3-way junction (A) into the keyholes in the

curved panel (C), making sure that all of the screws have engaged into the keyholes.

2.

After making sure all of the screws are engaged in the keyholes, tap the top of the

extended 3-way junction (A)with a cushioned mallet to fully engage. Tie the extended

3-way junction (A) and the curved panel (C) together using a bottom connector link

(Z). Insert this over one of the levellers (between the nut and the bottom of the

panel/junction) in the hooked slot and pivot around to insert the other leveller into the

straight slot. Fully tighten both nuts using a 13mm spanner to trap the connector (Z).

3.

Repeat steps 1 and 2 (above) to attach the extended 3-way junction (A) to the curved

panel (B) on the opposite side of the assembly.

Make sure to tap the top of the extended 3-way junction (A) with a cushioned mallet

to fully engage & tie the extended 3-way junction (A) to the curved panel (B) using a

bottom connector link (Z) (see step 2 for method).

4.

Attach the 850w side panel (D) into the keyholes in the extended 3-way junction (A),

making sure that all of the screws have engaged into the keyholes.

anel

Connector

M8 nut

Leveller

Junction

DEN.Curve Assembly Instructions DWG No: SASS-0033

Revision: B (27/10/15)

Drawn by: JB

Drawn date: 05/12/14

Z

Bottom Connector Link

A

Extended 3-Way Junction

C

Curved anel (RH)

B

Curved anel (LH)

D

850w Side anel