2Oneida Air Systems

System Start-Up Information

1. Install ductwork completely before operating collector

a. Seal ductwork with silicone sealant or duct tape.

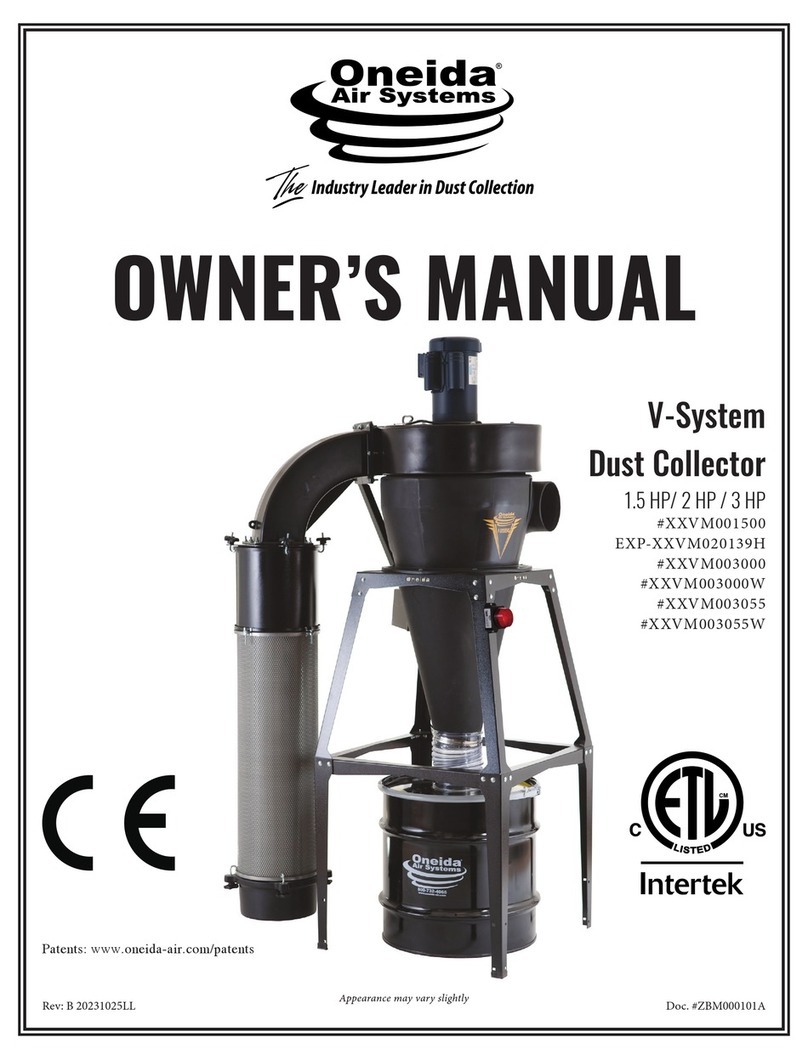

b. Have dust drum in place and sealed.

2. DO NOT operate Fan / Blower unless Fan Housing is attached to Cyclone body and Dust Drum is in place. Dust Drum and

Cyclone must be in place and sealed or motor will overheat!

3. DO NOT operate without lter in place. Fan blade can cause serious injury.

4. e Direct Drive Fan / Blower makes the system top heavy! Use extreme care when setting the unit up! It is recommended

that at least two people li the system up.

5. Check amperage draw on motor with all gates open. Current draw should not exceed maximum motor amperage as stated

on motor plate. (Oneida Air Systems is not responsible for damage to motors caused by improper installation, wiring or

failure to follow these directions).

6. is equipment incorporates parts such as switches, motors or the like that tend to produce arcs or sparks that can cause an

explosion.

7. To reduce the risk of Electric Shock, DO NOT use outdoors or on wet surfaces.

8. Exhaust air should not be vented into a wall, a ceiling, or a concealed space of a building.

9. To reduce the risk of injury from moving parts - unplug BEFORE servicing.

WARNING

FIRE HAZARDS

1. Wood shaping and cutting processes generate wood chips, shavings and dust. ese materials are considered combustible.

Air borne wood dust below 420 microns in size (0.17 of an inch) in certain concentration ranges when ignited can deagrate

(burn quickly). An ignition source such as a spark or ember can ignite a dust mixture resulting in an expanding ame

front, which can cause an explosion if tightly contained. A disturbance that raises a cloud of accumulated ne dust can raise

additional dust clouds, which can cause a series of explosions that can level an entire building. Until this type of re has been

witnessed, it is dicult to believe the devastation. is type of re is rare but worth safeguarding against.

2. e best way to avoid a wood shop re is to keep the shop clean. A shop ankle deep in dust with layers of ne dust

everywhere is an accident waiting to happen. A good dust collection system reduces overall re hazards but also adds new

concerns. A re hazard is still present. Combustible material is now in the dust collector and storage container.

3. e following points are worth heeding:

a. It is the buyer’s responsibility to follow all applicable federal, state, local, OSHA, NFPA, or authorities having jurisdiction

codes and regulations when installing and operating this dust collector.

b. Fire Marshals may want the unit located outside of the building. If the collector is located inside the facility, controls

such as spark detection, suppression, or explosion venting may be required.

c. Most local jurisdictions consult or adopt NFPA (National Fire Protection Agency) codes. However, other codes may

apply. Local codes may vary from jurisdiction to jurisdiction.

Make sure to read and understand the installation and maintenance instructions as well as all

recommended safety practices.