BP 5276 BEN (2010-10)

A PASSION

FOR PERFECTION

UVH 016 … 063 CU

All-Metal Angle Valve, manually actuated, bellows

sealed, metal valve seat seal

Instruction Sheet

Produktidentifikation

In all communications with Pfeiffer Vacuum, please specify

the information on the product nameplate. For convenient

reference copy that information into the space provided

below.

Typ:

No:

F-No:

Pfeiffer Vacuum, D-35614 Asslar

Validity

This document applies to products with the following part

numbers:

PFK32032 (UVH 016 CU DN 16 CF)

PFK52032 (UVH 040 CU DN 40 CF)

PFK62032 (UVH 063 CU DN 63 CF)

The part number (No) can be taken from the product name-

plate.

If not indicated otherwise in the legends, the illustrations in

this document correspond to the valve with the nominal

diameter DN 40. They apply to valves with other nominal

diameters by analogy.

We reserve the right to make technical changes without prior

notice.

Intended Use

The product is used as shut-off valve for XHV and UHV appli-

cations. It can be baked out at 300 °C. The welded housing

is suited for high-purity and toxic gases.

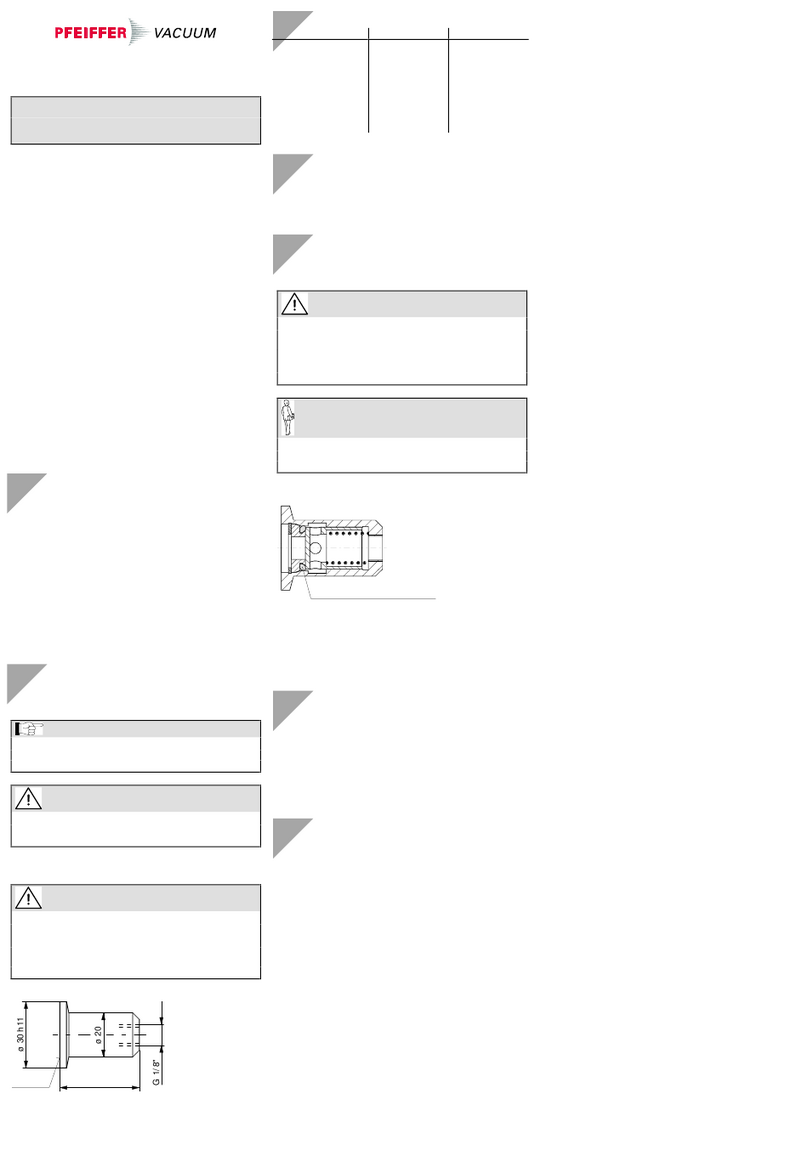

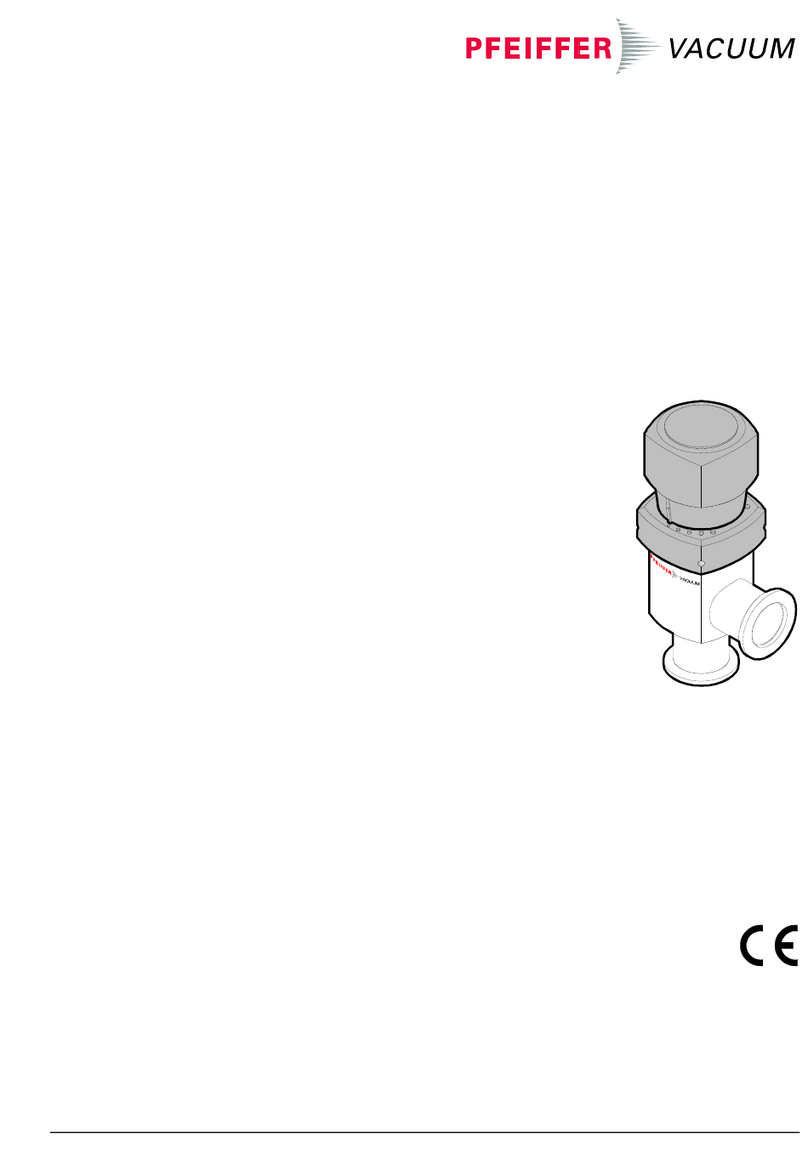

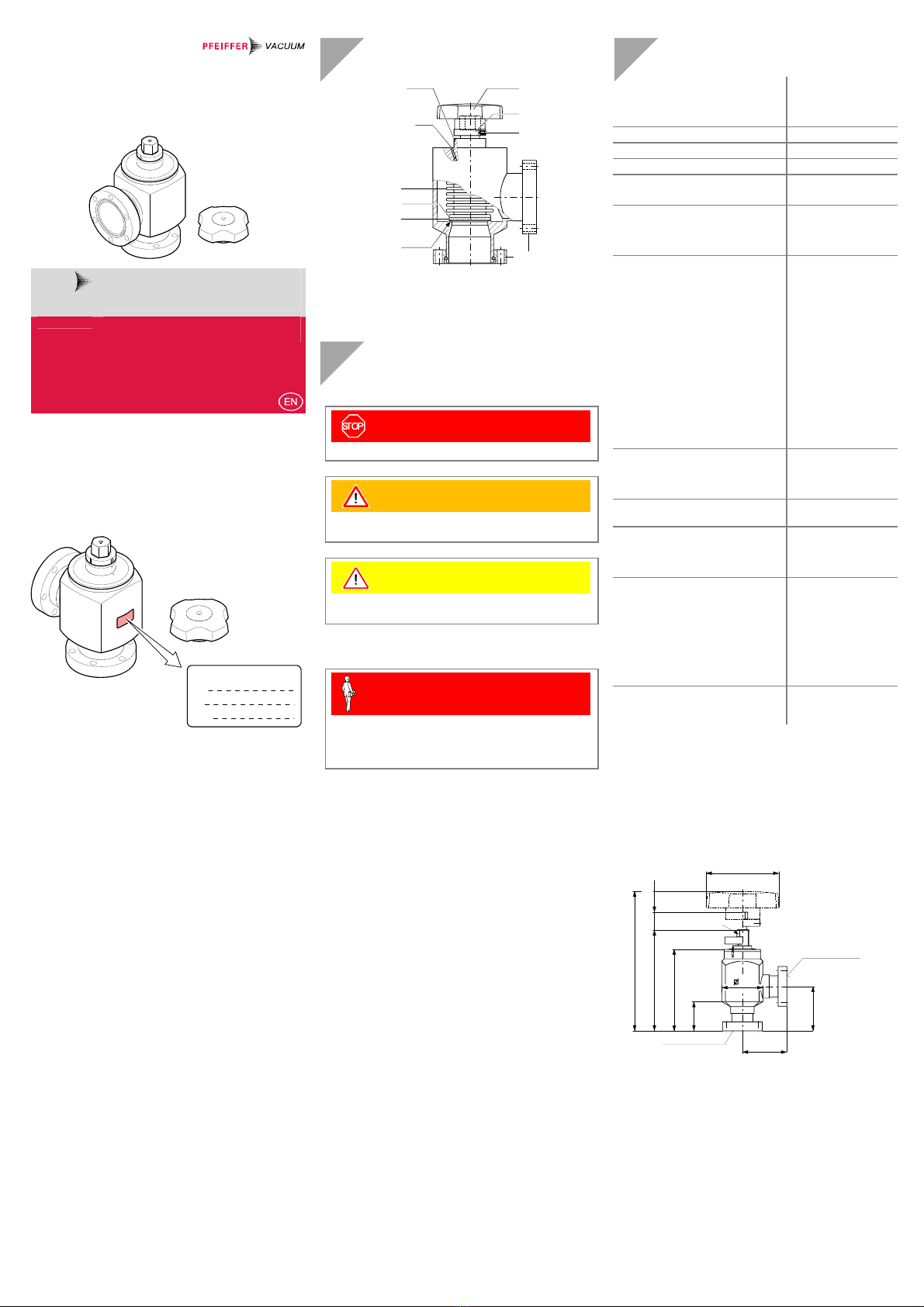

Description

Valve plate

Bellows

Valve plate base

CF flange

DN 16 ... 63 CF-R

(rotatable)

Rotary knob

(enclosed)

Mark on the valve

housing

Leak detection bore

Adjustment ring

Hex socket set

screw

Sealing edge

Safety

Symbols Used

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and en-

vironmental damage.

Caution

Information on correct handling or use. Disregard can lead

to malfunctions or minor equipment damage.

Personnel Qualifications

Skilled personnel

All work described in this document may only be carried

out by persons who have suitable technical training and

the necessary experience or who have been instructed by

the end-user of the product.

General Safety Instructions

•Adhere to the applicable regulations and take the nec-

essary precautions for the process media used.

Consider possible reactions between the materials

(→"Technical Data") and the process media.

•Adhere to the applicable regulations and take the nec-

essary precautions for all work you are going to do and

consider the safety instructions in this document.

•Before beginning to work, find out whether any vacuum

components are contaminated. Adhere to the relevant

regulations and take the necessary precautions when

handling contaminated parts.

Communicate the safety instructions to all other users.

Liability and Warranty

Pfeiffer Vacuum assumes no liability and the warranty be-

comes null and void if the end-user or third parties

•disregard the information in this document

•use the product in a non-conforming manner

•make any kind of interventions (modifications, alterations

etc.) on the product

•use the product with accessories not listed in the corre-

sponding product documentation.

The end-user assumes the responsibility in conjunction with

the process media used.

Failures due to contamination or wear and tear, as well as

expendable parts (e.g. seals), are not covered by the

warranty.

Technical Data

Connection flanges, rotatable

UVH 016 CU

UVH 040 CU

UVH 063 CU

DN 16 CF-R

DN 40 CF-R

DN 63 CF-R

Installation angle any

Flow direction any

Tightness 1×10-12 mbar l/s

Pressure range (absolute)

Bursting pressure

1×10-11 mbar … 4 bar

8 bar

Conductance 1)

UVH 016 CU

UVH 040 CU

UVH 063 CU

3 l/s

38 l/s

100 l/s

Temperatures

Ambiance

Operation

Bakeout

(without rotary knob, closed,

pressure in vacuum system

<1×10-4 mbar or vacuum

system vented with inert gas)

Rotary knob

Continuous

Temporary

Storage

Temperature increase

UVH 016 CU

UVH 040 CU

UVH 063 CU

0 °C … 55 °C

≤300 °C

≤300 °C

≤80 °C

80 … 110 °C

+5 … +45 °C

-15 … +45 °C 2)

≤4 °C/minute

≤4 °C/minute

≤2 °C/minute

Closing torque

UVH 016 CU

UVH 040 CU

UVH 063 CU

2 … 10 Nm

8 … 30 Nm

30 … 60 Nm

Service life of sealing plate

(cold closing operations)

1000 cycles 3)

Lift (opening)

UVH 016 CU

UVH 040 CU

UVH 063 CU

12 mm

23 mm

33 mm

Materials

Housing / spindle flange

Spindle

Bellows

Valve plate base

Valve plate

Forming ring

Sealing plate

Rotary knob

stainless steel 1.4301

CuSn8 2.1030.26

stainless steel 1.4541

st. steel 1.4301 ESU

stainless steel 1.4301

copper

PA 15% GF

Weight

UVH 016 CU / UVH 040 CU

UVH 063 CU

0.4 kg / 2.0 kg

5.0 kg

1) For air with molecular flow.

2) Ambiance free of condensable gases.

3) Cycles without expandable parts (seals) and under clean

operating conditions.

If the valve is operated under harsh or dirty conditions, it

should be cleaned / maintained before the specified service

time to maintenance has been reached.

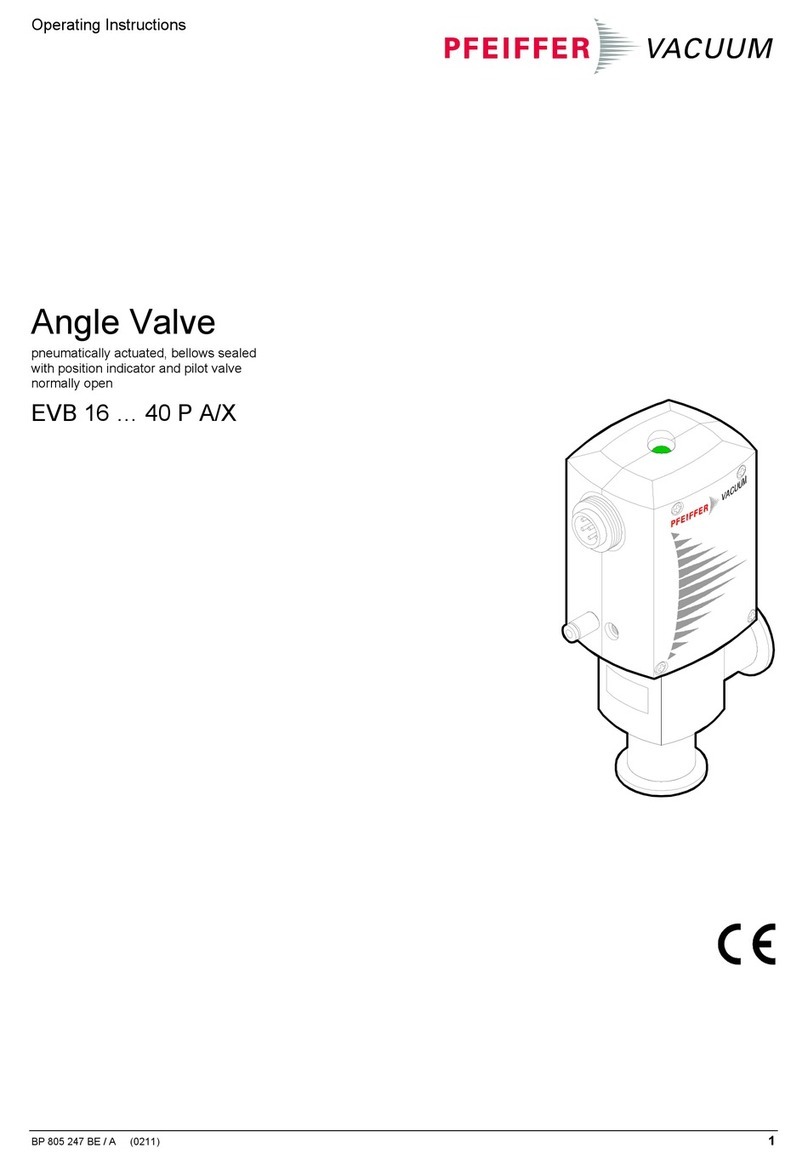

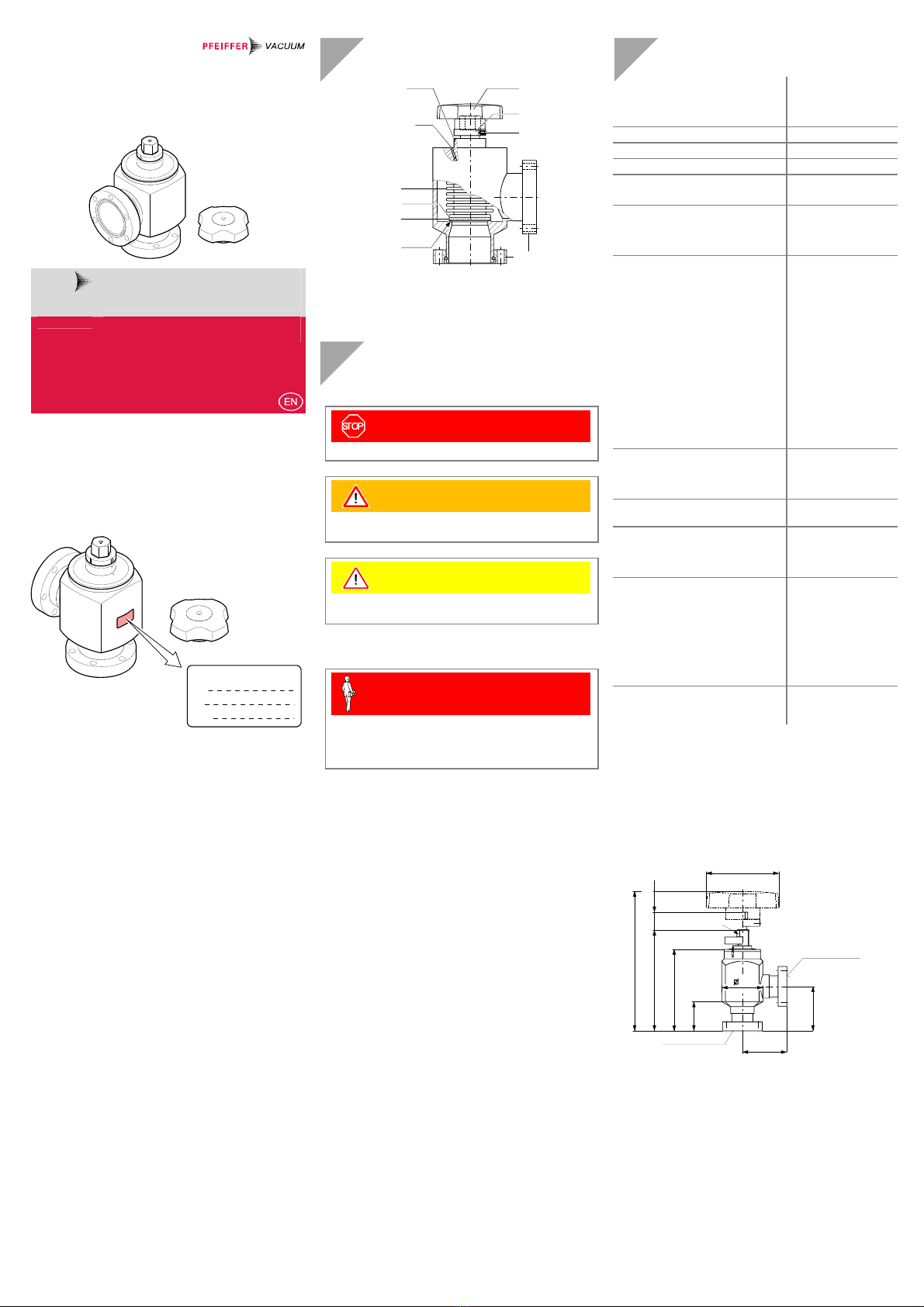

Dimensions [mm]

69.6

25.6

88.2

AF 8

38

38

35

ø 62

DN 16 CF-R

(rotatable)

UVH 016 CU

DN 16 CF-R

(rotatable)

119.4

Spindle lift

15