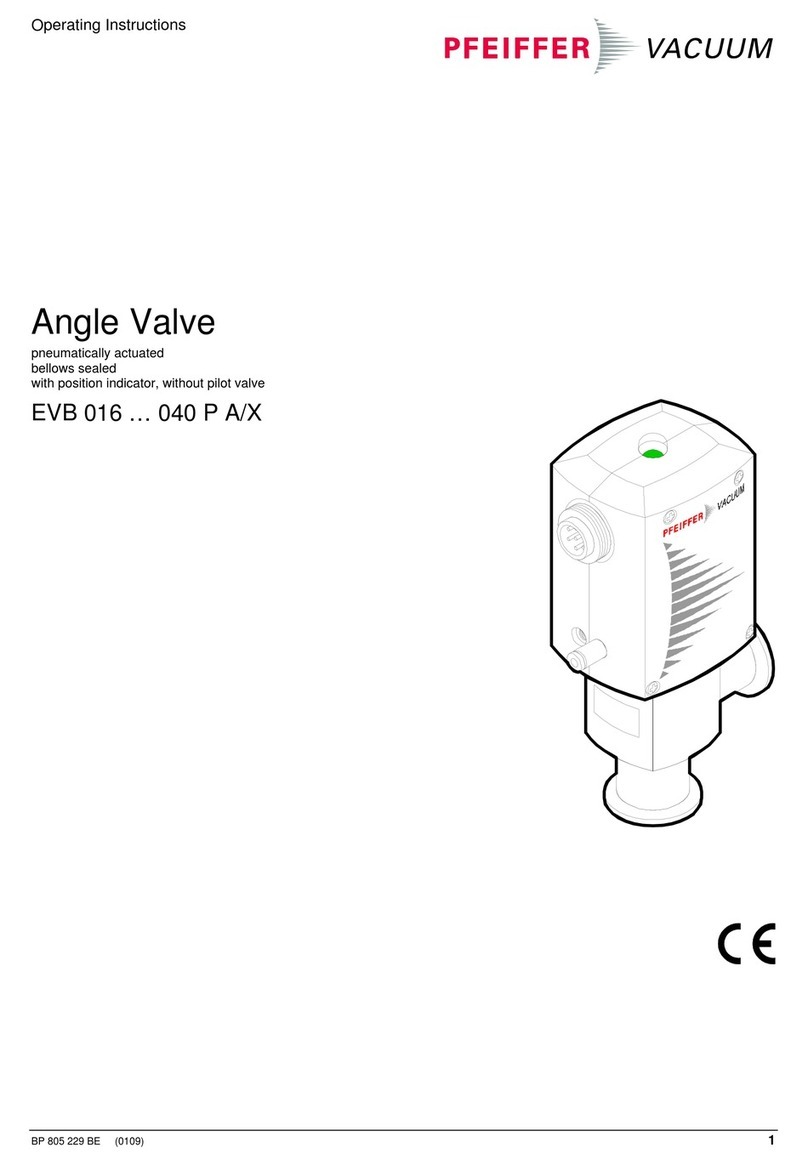

Operation

The product is ready for operation as soon as it has been

installed.

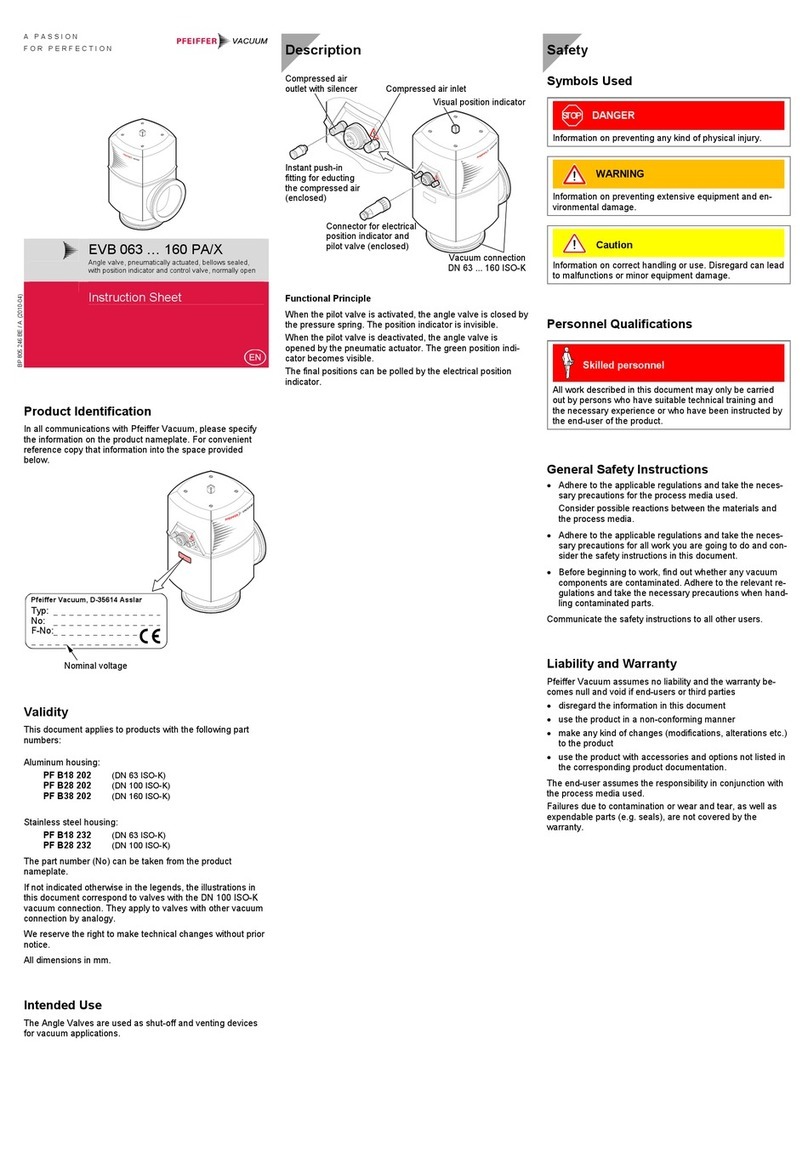

Valve positions

open

closed

Valve positionNominal voltage

supplied

supplied

not supplied

not supplied

Compressed air

not supplied

supplied

supplied

not supplied

In the event of a power failure, the pilot valve can be

manually actuated with the emergency button, if

compressed air is supplied:

· Open the valve by pressing the emergency button

· Close the valve by releasing the emergency

button.

Emergency button

Pressure difference Dp in closing direction

Caution

Closing direction

Caution: pressure differ-

ence

At Dp > 3 bar the valve

may be damaged.

Avoid pressure differences

Dp > 3 bar.

Pressure difference Dp in opening direction

Caution

Opening direction

Caution: pressure differ-

ence

At Dp > 3 bar the valve is

opened.

Avoid pressure differences

Dp > 3 bar.

Opens against a pressure difference Dp

Caution

Opening

Caution: pressure differ-

ence

At Dp > 3 bar the valve

may be damaged.

Avoid pressure differences

Dp > 3 bar.

Deinstallation

DANGER

Caution: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

DANGER

Caution: compressed air

Physical injury can result if a pressurized com-

pressed air line is disconnected.

Before doing any work, turn off the compressed

air supply and relieve the compressed air lines.

Caution

Caution: vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take

appropriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

Preconditions

· Vacuum system vented

· Compressed air supply interrupted

· Compressed air line vented

· Control system turned off

Procedure

Disconnect the valve from the control system.

red

black

Press the thrust ring towards the valve and pull the

plastic tube.

Deinstall the valve from the valve seat.

Size 2.5 mm

Protective lid

Maintenance, Repair

See Operating Manual BP 805 054 BE. It can be downloaded

from our website.

Returning the Product

WARNING

Caution: forwarding contaminated products

Contaminated products (e.g. radioactive, toxic,

caustic or microbiological hazard) can be detri-

mental to health and environment.

Products returned to Pfeiffer Vacuum should

preferably be free of harmful substances. Adhere

to the forwarding regulations of all involved

countries and forwarding companies and enclose

a duly completed declaration of contamination.

Products that are not clearly declared as "free of harmful sub-

stances" are decontaminated at the expense of the customer.

Products not accompanied by a duly completed declaration of

contamination are returned to the sender at his own expense.

Disposal

DANGER

Caution: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

N

WARNING

Caution: substances detrimental to the environ-

ment

Products or parts thereof (mechanical and elec-

tric components, operating fluids etc.) can be de-

trimental to the environment.

Dispose of such substances in accordance with

the relevant local regulations.

Separating the components

After disassembling the product, separate its components

according to the following criteria:

· Contaminated components

Contaminated components (radioactive, toxic, caustic, or

biological hazard etc.) must be decontaminated in accor-

dance with the relevant national regulations, separated

according to their materials, and disposed of.

· Other components

Such components must be separated according to their

materials and recycled.