5

Einfrierkopf mit 2 Positionen für die Rohrgrößen ¼–½", ¾"–1". Einfriereinsätze

für die Rohrgrößen ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Deep-freezer head with 2 positions for tube sizes ¼–½", ¾"–1". Deep-freezer

inserts for tubes ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Tête de congélation à 2 positions pour diamètres de tubes ¼ –½", ¾"–1".

Adaptateurs de congélations pour diamètres de tubes ⅛" (10, 12 mm), 1¼"

(42 mm), 1½", 54 mm, 2" (60 mm).

Testina di congelamento con 2 posizioni per le dimensioni ¼– ½", ¾"–1".

Inserti di congelamento per le dimensioni ⅛" (10, 12 mm), 1¼" (42 mm), 1½",

Cabezal congelador con 2 posiciones para los diámetros ¼ – ½", ¾"–1".

Suplementos para los diámetros ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm,

Invrieskop met 2 posities voor de buisdiameters ¼–½", ¾"–1". Invriesschalen

voor de buisdiameters ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Fryshuvud med 2 lägen för rörstorlekar ¼ –½", ¾"–1". Frysinsats för rörstor-

lekar ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Innfrysingshode med 2 posisjoner for rørstørrelse ¼ –½", ¾"–1". Innfrysings-

innsatser for rørstørrelse ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Indfrysningshoved med 2 positioner til rørstørrelserne ¼ –½", ¾"–1". Indfrys-

ningsindsatser til rørstørrelserne ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm,

Jäädytyspää jossa 2 eri asentoa putkikokoja ¼– ½", ¾"–1" varten. Jäädytysosat

putkikokoja ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm) varten.

Cabeçal congelador com 2 posições para os diâmetros ¼ –½", ¾"–1". Suple-

por Cabeçal congelador com 2 posições para os diâmetros ¼ –½", ¾"–1". Suple-por

mentos para os diâmetros ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Dwugniazdowa głowica zamrażająca do rur o średnicach ¼ – ½", ¾"–1".

Wkładki zamrażające do rur o średnicach ⅛" (10, 12 mm), 1¼" (42 mm), 1½",

Zmrazovací hlava se 2 polohami pro velikosti trubek ¼ – ½", ¾"–1". Zmrazo-

vací vložky pro velikosti trubek ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm,

Zmrazovacia hlava s 2 pozíciami pre vel’kost’ rúr ¼ –½", ¾"–1". Zmrazovacie

vložky pre vel’kost’ rúr ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2"

Fagyasztófej két pozícióban az ¼ – ½" és ¾"–1". csőméretekhez. Fagyasz-

tóbetétek az ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm)

Glave za zamrzavanje 2 pozicije ¼ –½", ¾"–1". Dodatni umetci za zamrza-

vanje ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Zamrzovalna glava z 2 pozicijama za cevi velikosti ¼–½", ¾"–1". Zamrzovalni

nastavki za velikosti ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Cap de îngheţare cu 2 poziţii, pentru diametrele ¼ – ½", ¾"–1". Inserţii pentru

ţevi de ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Замораживающая колодка с 2 позициями для диаметра труб ¼ – ½",

¾"–1". Замораживающие вкладыши для для диаметра труб ⅛" (10, 12 мм),

1¼" (42 мм), 1½", 54 мм, 2" (60 мм).

Κεφαλή κατάψυξης με 2 θέσεις για μεγέθη σωλήνα ¼ – ½", ¾"–1". Εξαρτήματα

κατάψυξης για μεγέθη σωλήνα ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm,

Boru dondurma kafası 2 pozisyonlu olup, ¼ – ½", ¾"–1" boru ebatları için

tur Boru dondurma kafası 2 pozisyonlu olup, ¼ – ½", ¾"–1" boru ebatları için tur

tasarlanmıştır. Boru dondurma takımları ⅛" (10, 12 mm), 1¼" (42 mm), 1½",

54 mm, 2" (60 mm) boru ebatları için sunulmaktadır.

Замразяваща глава с 2 положения за тръби с размери ¼ – ½", ¾"–1".

Приставка за дълбоко замразяване на тръби с размери ⅛" (10, 12 mm),

1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

Užšaldymo galvutė su 2 pozicijomis vamzdžiams, kurių skersmuo ¼ – ½",

¾"–1". Šaldymo įdėklai vamzdžiams, kurių skersmuo ⅛" (10, 12 mm), 1¼"

Užšaldymo galvutė su 2 pozicijomis vamzdžiams, kurių skersmuo ¼ – ½",

¾"–1". Šaldymo įdėklai vamzdžiams, kurių skersmuo ⅛" (10, 12 mm), 1¼"

Užšaldymo galvutė su 2 pozicijomis vamzdžiams, kurių skersmuo ¼ – ½",

(42 mm), 1½", 54 mm, 2" (60 mm).

Sasaldēšanas galvā ir divas vietas cauruļu izmēriem ¼ – ½", ¾"–1". Ieliktņi ir

cauruļu izmēriem ⅛" (10, 12 mm), 1¼" (42 mm), 1½", 54 mm, 2" (60 mm).

2 positsiooniga külmutuspea torudele läbimõõtudega ¼ –½", ¾"–1". Külmu-

tusotsikud torudele läbimõõtudega ⅛" (10, 12 mm), 1¼" (42 mm), 1½",

Einfrierköpfe mit Spannband montieren. Einfrierstelle bei Beginn mehrmals

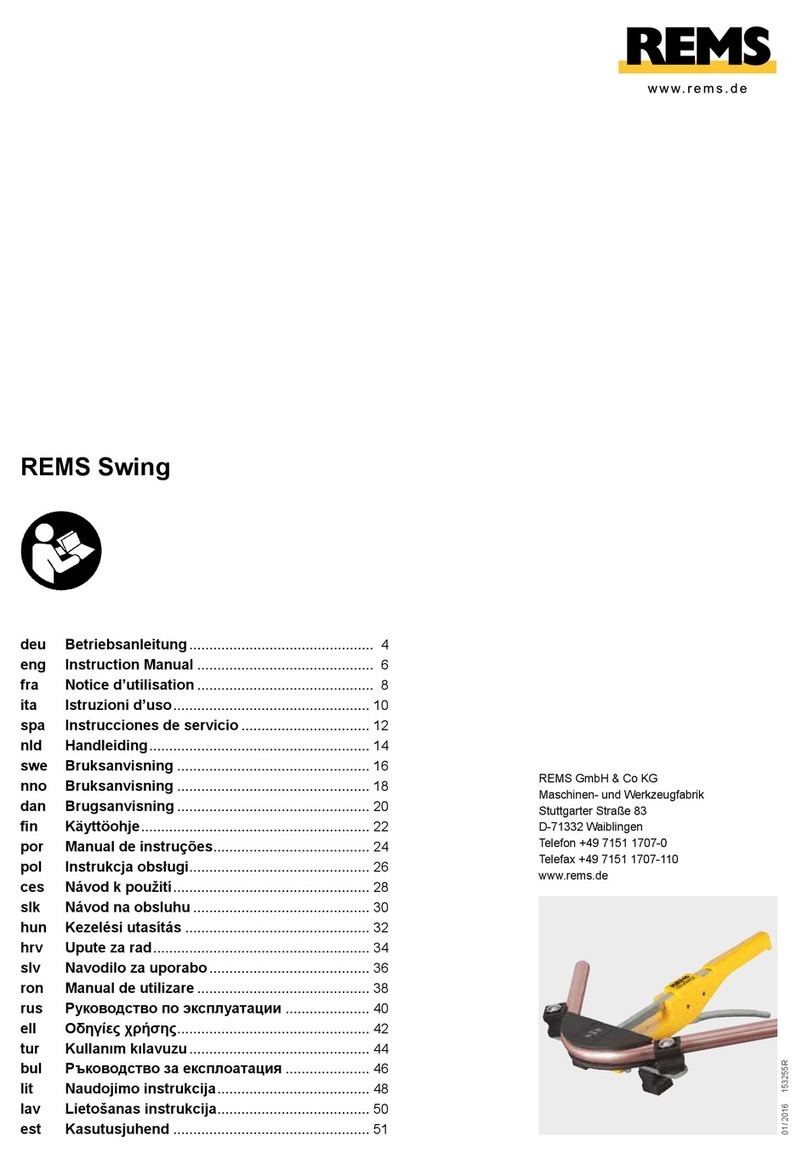

Mount deep-freezer heads with the tightening strap. Spray deep-freeze point

several times with water at the beginning.

Monter les têtes de congélation avec la sangle de serrage. Asperger plusieurs

fois la zone de congélation avec de l’eau au début.

Montare le testine di congelamento con il collare. All'inizio spruzzare ripetu-

tamente acqua sul punto di congelamento.

Montar los cabezales congeladores con brida de fl eje. Antes de comenzar

pulverizar varias veces la zona de congelación con agua.

Invrieskoppen met spanband monteren. Invriesplek in het begin meerdere

malen met water besproeien.

Montera fryshuvuden med spännband. Bespruta när du börjar stället som ska

frysas upprepade gånger med vatten.

Innfrysingshodene monteres ved hjelp av spennbånd. Innfrysingspunkt sprayes

ved begynnelse gjentatte ganger med vann.

Indfrysningshoveder monteres med spændebånd. Indfrysningssted sprøjtes

fl ere gange med vand i starten.

Asenna jäädytyspäät kiristysnauhan avulla. Suihkuta jäädytyskohtaa aluksi

Montar cabeçais de refrigeração com braçadeiras de aperto.

por Montar cabeçais de refrigeração com braçadeiras de aperto.por

lamento no início pulverizar várias vezes com água.

Głowice zamrażające zamontować za pomocą opasek mocujących. Zamrażane

Miejsce spryskać na początku kilkukrotnie wodą.

Zmrazovací hlavu namontovat s upínací páskou. Zmrazovací místo zpočátku

vícekrát postříkat vodou.

Zmrazovaciu hlavu namontovať s upínacou páskou. Zmrazovacie miesto

spočiatku viackrát postriekať vodou.

Rögzítse a fagyasztófejet a szorítóba. A fagyasztási helyet a munkamegkez-

désekor többször permetezze be vízzel.

Montirajte glave za zamrzavanje sa steznom trakom. Mjesto zamrzavanja na

hrv/ Montirajte glave za zamrzavanje sa steznom trakom. Mjesto zamrzavanja nahrv/

početku više puta poprskajte vodom.

Montirajte zamrzovalne glave z vpenjalnim trakom. Na začetku napršite

zamrzovalno mesto večkrat z vodo.

Montaţi capetele de îngheţare cu ajutorul benzii de fi xare. La începerea

procesului pulverizaţi sufi cientă apă în punctul de contact cu ţeava.

Монтаж замораживающих головок со стяжной лентой. Место заморажи-

вания в начале несколько раз промыть водой.

Τοποθετήστε τις κεφαλές κατάψυξης με ταινία σύσφιξης. Ψεκάστε αρκετές

φορές τη θέση κατάψυξης στην αρχή με νερό.

Boru dondurma kafalarını sıkıştırma bandıyla monte edin. Dondurulacak yere

tur Boru dondurma kafalarını sıkıştırma bandıyla monte edin. Dondurulacak yere tur

başlarken birkaç kez su püskürtün.

Монтиране на замразяващи глави със стягаща лента. В началото напръс-

кайте многократно мястото на замразяване с вода.

Užšaldymo galvutės montuojamos su tempimo diržu. Pradedant užšaldymo

vietą daug kartų apipurkškite vandeniu.

Montēt sasaldēšanas galviņas ar iespīlēšanas lenti. Sasaldēšanas vietu

sākumā vairākas reizes iesmidziniet ar ūdeni.

Paigaldage külmutuspead kinnitusrihmaga. Pihustage külmutuskohta alguses

REMS FRIGO 2

Fig. 1

Deep-freezer head with 2 positions for tube sizes ¼ – ½”,

¾”–1”. Deep-freezer inserts for tubes ⅛” (10, 12 mm), 1¼”

(42 mm), 1½”, 54 mm, 2” (60 mm).

Fig. 2

Mount deep-freezer heads with the tightening strap. Spray

deep-freeze point several times with water at the beginning.

Einfrierzeiten in Abhängigkeit von Umgebungstemperatur, der Wassertem-

peratur, der Rohrgröße, vom Rohrwerkstoff, bei Nutzung der entsprechenden

Position im Einfrierkopf und bei Verwendung der Einfriereinsätze. Die Einfrier-

zeiten gelten bei einer Umgebungs-/Wassertemperatur von ca. 20°C. Bei

Kunststoffrohren muß je nach Werkstoff mit teilweise wesentlich höheren

Einfrierzeiten gerechnet werden.

Wird in verschiedenen Höhen

eingefroren, sind auch die Temperaturen und dadurch auch die Einfrierzeiten

Deep-freeze times as a function of ambient temperature, water temperature,

tube size, tubing material when using the corresponding position in the deep-

freezer head and when applying the deep-freezer inserts. The deep-freeze

times apply with an ambient water temperature of about 20°C. With plastic

tubing depending on the material used, substantially higher deep-freeze times

If frozen at different heights, the temperatures and

subsequently the freezing times will be different.

La durée de congélation dépend de la température ambiante, de la tempéra-

ture de l'eau, de la taille du tube, du matériau du tube, de l’usage de la

position correspondante de la tête de congélation et de l’utilisation des

adaptateurs de congélation. Les durées de congélation sont valables pour

une température ambiante/eau d’environ 20°C. Pour tubes en plastique, il

faut, en partie et selon le matériau, compter sur des durées de congélations

Si la congélation est réalisée à des endroits de

hauteur différente, alors les températures et par conséquent les temps de

Tempi di congelamento in funzione della temperatura ambiente, della tempe-

ratura dell'acqua, della grandezza del tubo, del materiale del tubo, dell'uso

della relativa posizione nella testina di congelamento e dell'utilizzo degli inserti

di congelamento. I tempi di congelamento sono validi per una temperatura

ambientale e dell’acqua di circa 20°C. Per i tubi di plastica bisogna calcolare,

a seconda del materiale, tempi di congelamento in parte molto più alti.

se si congela ad altezza diverse, le temperature e di conseguenza i

tempi di congelamento cambiano.

Los tiempos de congelación dependen de la temperatura ambiente, la tempe-

ratura del agua, el tamaño del tubo, el material del tubo, al utilizar la posición

correspondiente en el cabezal congelador y los suplementos. Los tiempos

de congelación indicados en la tabla son valores de orientación y rigen con

una temperatura ambiente del agua de aprox. 20°C. Para congelar tubos de

plástico, habrá que contar con valores en parte considerablemente más

elevados, lo que depende del tipo de plástico.

diferentes alturas, la temperatura y el tiempo de congelación variarán.

Invriestijden afhankelijk van omgevingstemperatuur, watertemperatuur, buis-

diameter, buismateriaal, bij gebruik van de overeenkomstige positie op de

invrieskop en bij gebruik van de invriesschalen. De invriestijden gelden bij

een omgevings-/watertemperatuur van ca. 20°C. Bij kunststofbuizen moet al

naar gelang het materiaal met deels wezenlijk hogere invriestijden rekening

Als er op verschillende hoogtes wordt ingevroren

dan zijn ook de temperaturen en daardor ook de invriestijden verschillend.

Frystider är beroende av omgivningstemperaturen, vattentemperaturen

rörstorleken, rörmaterial, vid användning av motsvarande position i fryshuvudet

och vid användning av frysinsatserna. Frystiden gäller vid en vattentemperatur

på ca 20°C. När det gäller plaströr, måste man räkna med avsevärt längre

frystid, beroende på vilken typ av plastmaterial.

på olika höjd, är även temperaturerna och därmed också frystiderna olika.

Innfrysingstidene er avhengige av omgivelsestemperaturen, vanntemperaturen,

rørstørrelsen og av rørmaterialet ved bruk av den tilsvarende posisjonen i

innfrysingshodet og ved anvendelse av innfrysingsinnsatsene. Innfrysingstidene

gjelder for en omgivelses-/vanntemperatur på ca. 20°C. Avhengig av materi-

alet må man til dels påregne vesentlig lengre innfrysingstider for kunststoffrør.

Hvis innfrysing skjer i forskjellige høyder, vil også temperaturene og

dermed innfrysingstidene variere.

Indfrysningstider afhængigt af omgivelsestemperaturen, vandtemperaturen,

rørstørrelsen, rørmaterialet, ved brug af tilsvarende position i indfrysningsho-

vedet og ved brug af indfrysningsindsatserne. Indfrysningstiderne gælder ved

en temperatur i omgivelserne/vandtemperatur på ca. 20°C. Ved plastrør må

der, alt efter materialet, regnes med væsentligt længere indfrysningstider.

Indfryses der i forskellige højder er temperaturerne forskellige

og dermed også indfrysningstiderne.

Jäädytysajat riippuen ympäristön lämpötilasta, veden lämpötilasta, putkikoosta

ja putkimateriaalista, kun käytössä ovat jäädytyspään vastaava sijainti sekä

jäädytysosat. Jäädytysajat pätevät noin 20°C:n ympäristön-/vedenlämpötilassa.

Muoviputkien jäätymisajat ovat valmistusaineesta riippuen huomattavasti

Jos jäädytys tapahtuu eri korkeuksissa, lämpö-

tila ja siten myös jäädytysajat vaihtelevat.

Tempo de congelação dependente datemperatura ambiente, da temperatura

por Tempo de congelação dependente datemperatura ambiente, da temperaturapor

da água, do tamanho do tubo, do material do tubo, durante o uso da respec-

tiva posição na cabeça de refrigeração e durante a utilização dos acessórios

de refrigeração. Os tempos de congelação indicados na tabela são valores

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

Dimensioni tubo testina di congelamento

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

por Material Posição do Suplemento Tempo depor

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

pol

Średnica rury zamrażające zamrażająca zamrażania

pol

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

Dimensioni tubo testina di congelamento

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

Dimensioni tubo testina di congelamento

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

Dimensioni tubo testina di congelamento

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Einfrierzeiten in Abhängigkeit von Umgebungstemperatur, der Wassertem-

peratur, der Rohrgröße, vom Rohrwerkstoff, bei Nutzung der entsprechenden

Position im Einfrierkopf und bei Verwendung der Einfriereinsätze. Die Einfrier-

zeiten gelten bei einer Umgebungs-/Wassertemperatur von ca. 20°C. Bei

Kunststoffrohren muß je nach Werkstoff mit teilweise wesentlich höheren

Einfrierzeiten gerechnet werden.

Wird in verschiedenen Höhen

eingefroren, sind auch die Temperaturen und dadurch auch die Einfrierzeiten

Deep-freeze times as a function of ambient temperature, water temperature,

tube size, tubing material when using the corresponding position in the deep-

freezer head and when applying the deep-freezer inserts. The deep-freeze

times apply with an ambient water temperature of about 20°C. With plastic

tubing depending on the material used, substantially higher deep-freeze times

If frozen at different heights, the temperatures and

subsequently the freezing times will be different.

La durée de congélation dépend de la température ambiante, de la tempéra-

ture de l'eau, de la taille du tube, du matériau du tube, de l’usage de la

position correspondante de la tête de congélation et de l’utilisation des

adaptateurs de congélation. Les durées de congélation sont valables pour

une température ambiante/eau d’environ 20°C. Pour tubes en plastique, il

faut, en partie et selon le matériau, compter sur des durées de congélations

Si la congélation est réalisée à des endroits de

hauteur différente, alors les températures et par conséquent les temps de

Tempi di congelamento in funzione della temperatura ambiente, della tempe-

ratura dell'acqua, della grandezza del tubo, del materiale del tubo, dell'uso

della relativa posizione nella testina di congelamento e dell'utilizzo degli inserti

di congelamento. I tempi di congelamento sono validi per una temperatura

ambientale e dell’acqua di circa 20°C. Per i tubi di plastica bisogna calcolare,

a seconda del materiale, tempi di congelamento in parte molto più alti.

se si congela ad altezza diverse, le temperature e di conseguenza i

tempi di congelamento cambiano.

Los tiempos de congelación dependen de la temperatura ambiente, la tempe-

ratura del agua, el tamaño del tubo, el material del tubo, al utilizar la posición

correspondiente en el cabezal congelador y los suplementos. Los tiempos

de congelación indicados en la tabla son valores de orientación y rigen con

una temperatura ambiente del agua de aprox. 20°C. Para congelar tubos de

plástico, habrá que contar con valores en parte considerablemente más

elevados, lo que depende del tipo de plástico.

diferentes alturas, la temperatura y el tiempo de congelación variarán.

Invriestijden afhankelijk van omgevingstemperatuur, watertemperatuur, buis-

diameter, buismateriaal, bij gebruik van de overeenkomstige positie op de

invrieskop en bij gebruik van de invriesschalen. De invriestijden gelden bij

een omgevings-/watertemperatuur van ca. 20°C. Bij kunststofbuizen moet al

naar gelang het materiaal met deels wezenlijk hogere invriestijden rekening

Als er op verschillende hoogtes wordt ingevroren

dan zijn ook de temperaturen en daardor ook de invriestijden verschillend.

Frystider är beroende av omgivningstemperaturen, vattentemperaturen

rörstorleken, rörmaterial, vid användning av motsvarande position i fryshuvudet

och vid användning av frysinsatserna. Frystiden gäller vid en vattentemperatur

på ca 20°C. När det gäller plaströr, måste man räkna med avsevärt längre

frystid, beroende på vilken typ av plastmaterial.

på olika höjd, är även temperaturerna och därmed också frystiderna olika.

Innfrysingstidene er avhengige av omgivelsestemperaturen, vanntemperaturen,

rørstørrelsen og av rørmaterialet ved bruk av den tilsvarende posisjonen i

innfrysingshodet og ved anvendelse av innfrysingsinnsatsene. Innfrysingstidene

gjelder for en omgivelses-/vanntemperatur på ca. 20°C. Avhengig av materi-

alet må man til dels påregne vesentlig lengre innfrysingstider for kunststoffrør.

Hvis innfrysing skjer i forskjellige høyder, vil også temperaturene og

dermed innfrysingstidene variere.

Indfrysningstider afhængigt af omgivelsestemperaturen, vandtemperaturen,

rørstørrelsen, rørmaterialet, ved brug af tilsvarende position i indfrysningsho-

vedet og ved brug af indfrysningsindsatserne. Indfrysningstiderne gælder ved

en temperatur i omgivelserne/vandtemperatur på ca. 20°C. Ved plastrør må

der, alt efter materialet, regnes med væsentligt længere indfrysningstider.

Indfryses der i forskellige højder er temperaturerne forskellige

og dermed også indfrysningstiderne.

Jäädytysajat riippuen ympäristön lämpötilasta, veden lämpötilasta, putkikoosta

ja putkimateriaalista, kun käytössä ovat jäädytyspään vastaava sijainti sekä

jäädytysosat. Jäädytysajat pätevät noin 20°C:n ympäristön-/vedenlämpötilassa.

Muoviputkien jäätymisajat ovat valmistusaineesta riippuen huomattavasti

Jos jäädytys tapahtuu eri korkeuksissa, lämpö-

tila ja siten myös jäädytysajat vaihtelevat.

Tempo de congelação dependente datemperatura ambiente, da temperatura

por Tempo de congelação dependente datemperatura ambiente, da temperaturapor

da água, do tamanho do tubo, do material do tubo, durante o uso da respec-

tiva posição na cabeça de refrigeração e durante a utilização dos acessórios

de refrigeração. Os tempos de congelação indicados na tabela são valores

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

Dimensioni tubo testina di congelamento

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

por Material Posição do Suplemento Tempo depor

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

pol

Średnica rury zamrażające zamrażająca zamrażania

pol

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

Dimensioni tubo testina di congelamento

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

Dimensioni tubo testina di congelamento

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

Dimensioni tubo testina di congelamento

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Rohrwerkstoff Position im Einfriereinsatz Einfrierzeit

Rohrgröße Einfrierkopf Art.-Nr. T (min)

Tube material Position in Deep-freezer Deep-freeze

Tube size deep-freezer insert time

Matériau tube Position dans Adaptateur de Durée de

Diamètre du tête de congélation congélation

tube Ø congélation réf. n° T (min)

Materiale del Posizione nella Inserto di Tempo di

del tubo Ø congelamento Cod. art. T (min)

Material Posición del Suplemento Tiempo de

Diámetro cabezal congelador congelación

Ø congelador Código T (min)

Buismateriaal Positie op Invriesschaal Invriestijd

Buisdiameter invrieskop art.nr. T (min)

Rörmaterial Läge i frys- Frysinsats Frystid

Rördiam. huvudet art.nr T (min)

Rørmateriale Posisjon i Innfrysingsinnsats Innfrysingstid

Rørstørrelse innfrysingshodet Art.nr. T (min)

Rørmateriale Position i Indfrysnings- Indfrysnings-

Rørstørrelse indfrysnings- indsats tid T (min)

Putken Sijainti Jäädytysosa Jäädytysaika

Putken valmistusaine jäädytys- Tuote-nro T (min)

Material Posição do Suplemento Tempo de

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Ø congelador Código T (min)

Diâmetro cabeçal congelador congelação

Materiał Gniazdo Wkładka Czas

Średnica rury zamrażające zamrażająca zamrażania

Materiál trubky Poloha v Zmrazovací Čas

Velikost zmrazovací vložka zmrazování

trubky Ø hlavě Obj.č. T (min)

Materiál rúry Poloha v Zmrazovacia Čas

Vel’kost’ zmrazovacej vložka zmrazovania

rúry Ø hlave Obj.č. T (min)

Csőanyag Fagyasztófej Fagyasztó- Fagyasztási

Csőméret helyzete betét idő

Material Pozicija na Zamrzovalni Zamrzovalni

Velikost cevi zamrzovalni nastavek čas

Materijal Pozicija Umetci za Vrijeme

Promjer glava za zamrzavanje zamrzavanja

cijevi Ø zamrzavanje Br. Art. T (min)

Технический Положение Вкладыш Время

Диаметр материал в колодке Арт. № заморозки

Materialul Poziţia în Inserţie Timp de

Diametrul ţevii capul de necesară îngheţare

ţevii Ø îngheţare Cod articol T (min)

Υλικό σωλήνα Θέση στην Εξάρτημα Χρόνος

Μέγεθος κεφαλή κατάψυξης κατάψυξης

σωλήνα Ø κατάψυξης Αριθ. προϊόντος T (λεπτά)

Borunun Dondurma Dondurma Dondurma

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Ø konumu Ürün numarası T (asgari)

Boru ebadı malzemesi kafasındaki parçası Süresi

Материал Положение Приставка Време за

Диаметър в главата No. продукт замразяване

Vamzdžio Vamzdžio Padėtis Užšaldymo įdėklo Užšaldymo

skersmuo medžiaga užšaldymo Art.-Nr. Laikas

Caurules Caurules Vieta saldēšanas Ieliktņu Saldēšanas

diametrs materiāls galvā Art.-Nr. laiks

Materjal Positsioon Külmutusotsik Külmutusaeg

Torudiameeter külmutuspeas Art. Nr. T (min)

Deep-freeze times as a function of ambient temperature, water temperature,

tube size, tubing material when using the corresponding position in the

deep-freezer head and when applying the deep-freezer inserts. The deep-

freeze times apply with an ambient water temperature of about 20°C. With

plastic tubing depending on the material used, substantially higher deep-

freeze times must be expected. Note: If frozen at different heights, the

temperatures and subsequently the freezing times will be different.