Table 3, continuation

The Detector Mode Indication Note

«Failure in channel 1»

«Failure in channel 2»

Orange LED indication dual

blinking with 12 sec period *

State indication

is on and

«Identification»

indication is off

«Normal» Indication is off

*) – LED indication of the Detector state

**) – Sound indication of the Detector state

6

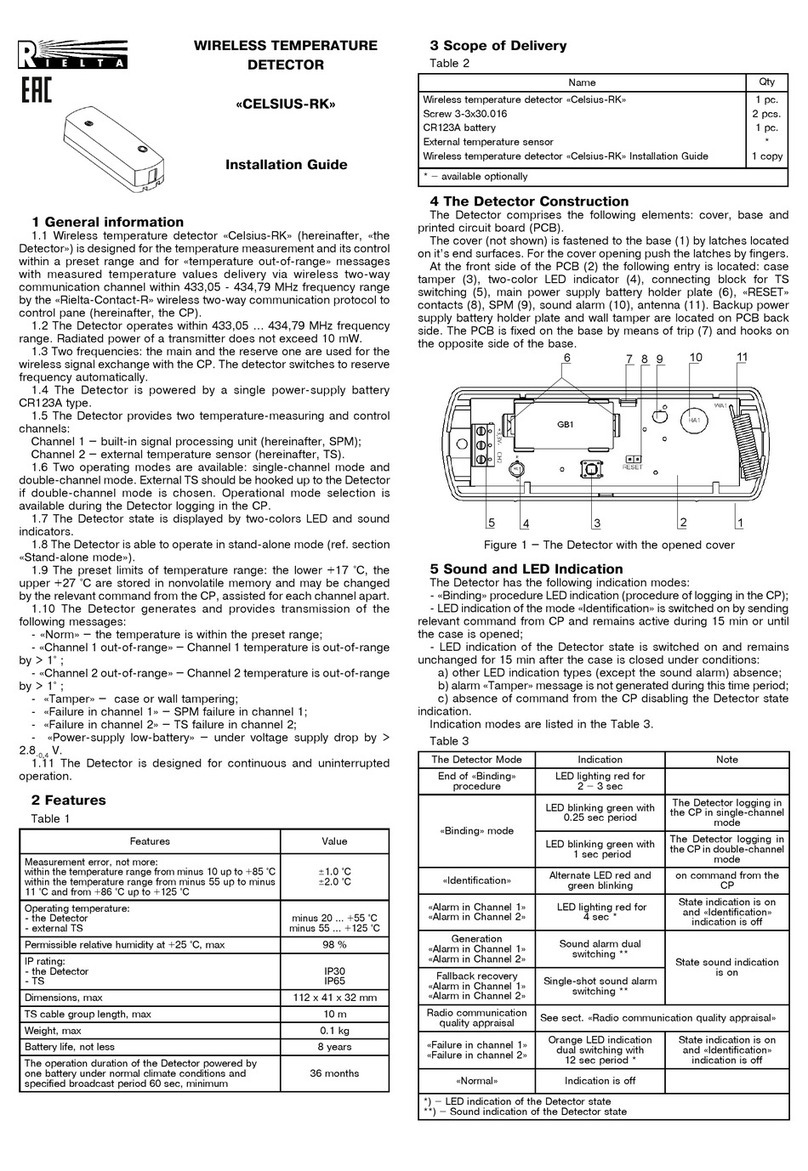

Binding with the CP

«

Binding

»

mode is used for logging the Detector in the CP and service

information exchange.

6.1 Prepare the CP in accordance with CP reference guide.

6.2 If it is necessary to log the Detector in double-channel mode, hook up TS

to the Detector as shown in Figure or short-circuit the terminals of the Detector

«

-

»

and

«

G 2

»

. For the single-channel mode neither hooking on, no short-circuit

is required.

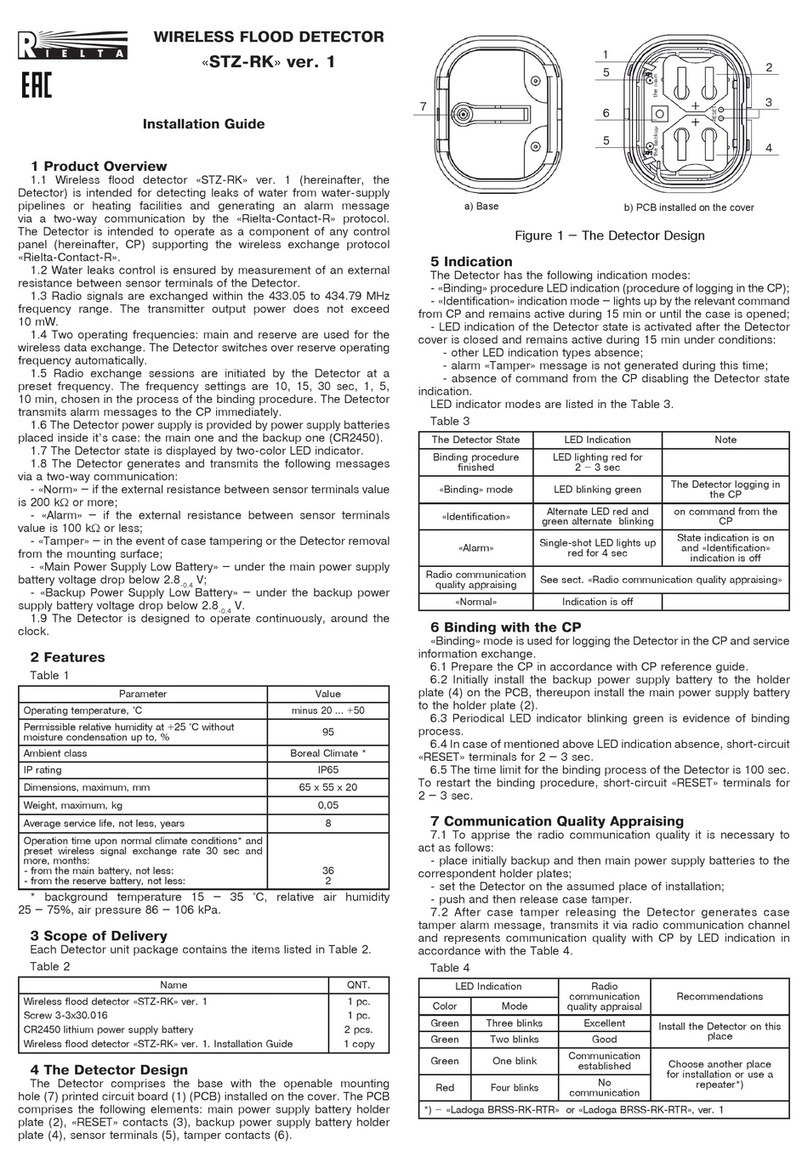

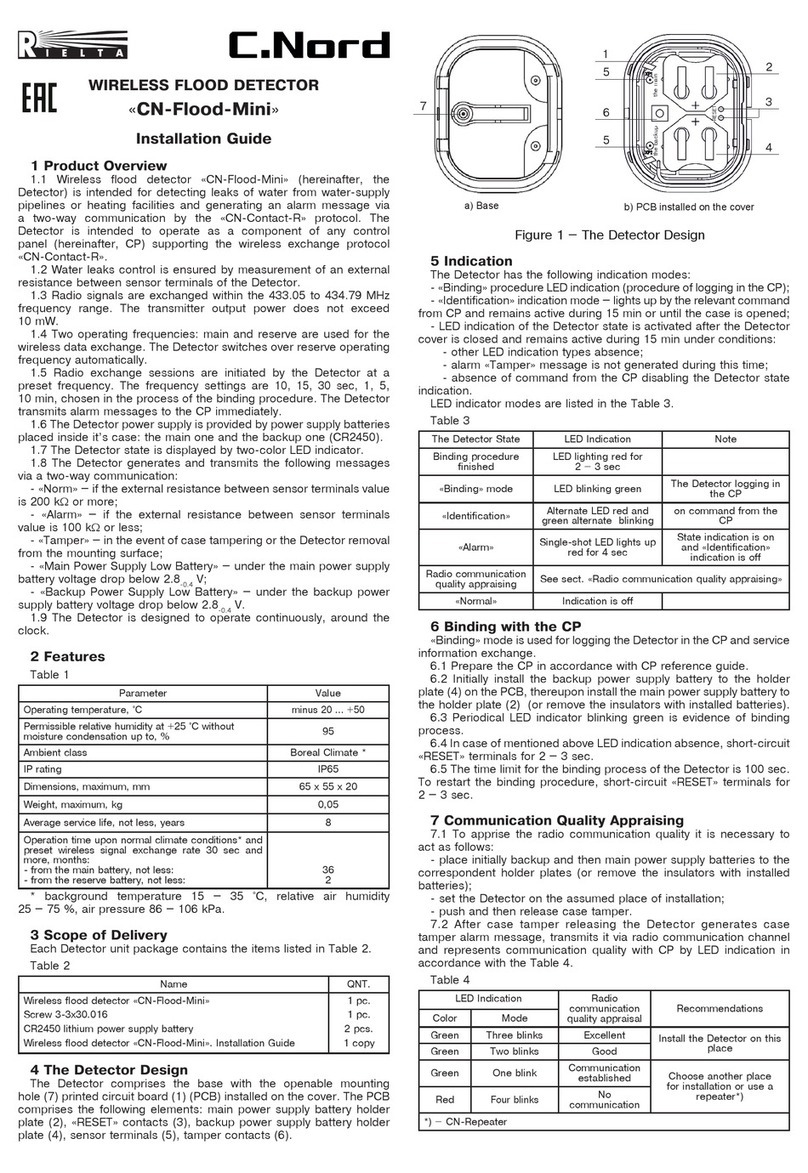

6.3 Insert backup battery to the holder plate(10) (if the battery is already set

into the holder, than pull out the insulating foil)

6.4 Insert main battery to the holder plate(5) (if the battery is already set into

the holder, than pull out the insulating foil).

6.5 Periodical LED indicator blinking green is evidence of binding process.

6.6 In case of mentioned above LED indication absence, short-circuit

«

Reset

»

terminals for 2 – 3 sec.

6.7 Successful binding procedure complying is indicated by LED indicator

lighting red for 2 – 3 sec.

6.8 The time limit for the binding process of the Detector is 70 sec. To restart

the binding procedure, short-circuit

«

Reset

»

terminals for 2 – 3 sec.

7

«

Stand Alone

»

mode

7.1 The Detector changes to stand alone mode upon the expiry of 100 sec

binding procedure.

7.2 During operation in the stand alone mode LED and sound indication is

always ON under condition of

«

Tamper

»

message absence.

7.3 The Detector has no communication with CP and its state is displayed

only by means of LED and sound indication (see Table 4).

Table 4

The Detector Mode Indication Period

«Main battery discharge»

«Backup battery discharge»

LED lighting orange for 2 sec

Sound indicator single-shot actuation 12 s

«Alarm in Loop 1»

«Alarm in Loop 2»

LED lighting red for 2 sec

Sound indicator single-shot actuation 4 s

«Failure in Loop 1»

«Failure in Loop 2»

Double-shot LED lighting orange for 2 sec

Sound indicator single-shot actuation 12 s

«Norm» Green LED single-shot blinking 12 s

8 Communication Quality Appraisal

8.1 For radio communication quality appraisal it is necessary to:

- set the Detector on the assumed place of installation;

- push and then release case tamper.

8.2 After case tamper releasing the Detector generates case tamper

alarm message, transmits it via radio communication channel and represents

communication quality with CP by LED indication in accordance with the Table 4.

Table 4

LED Indication Radio

communication

quality appraisal

Recommendations

Color Mode

Green Three

blinks Excellent Install the Detector on

this place

Green Two blinks Good

Green One blink Communication

established Choose another place

for installation or use a

repeater*)

Red Four blinks No communication

*) – «Ladoga-RK» system repeater

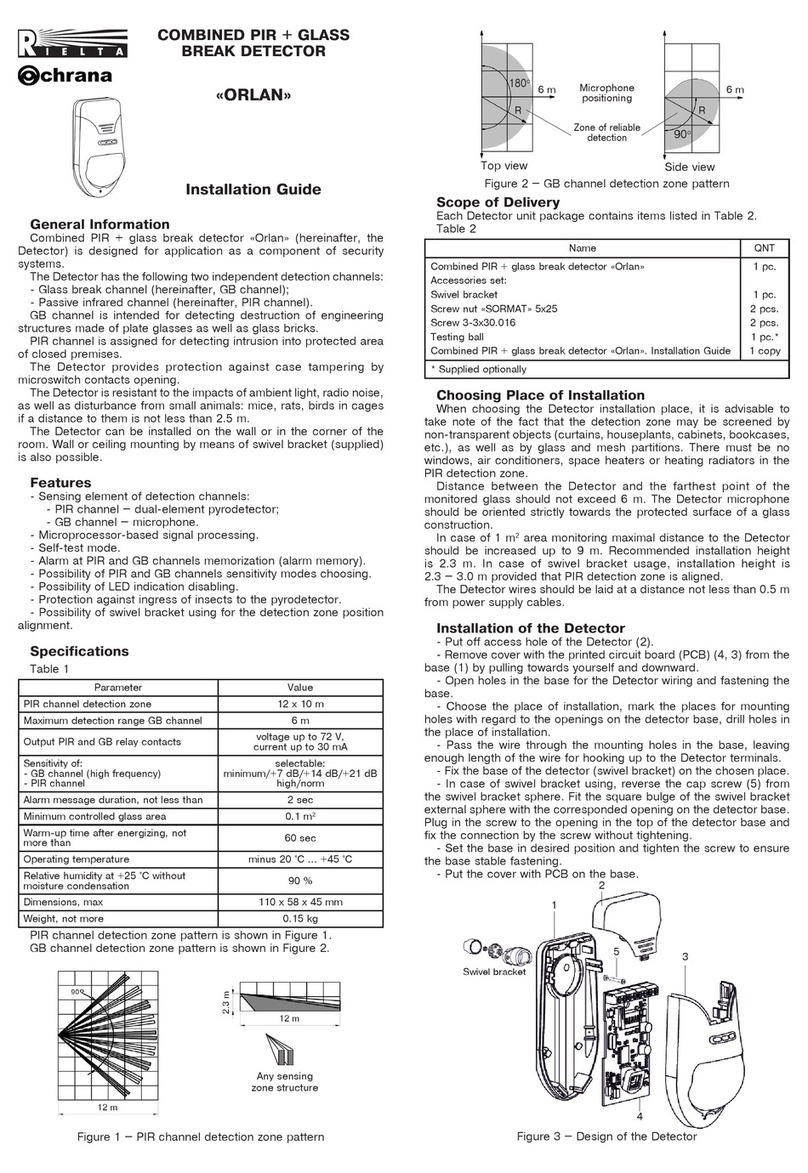

9 Installation

9.1 Drill holes for fastening the Detector elements. You may use the FD and

the SPM base without the PCB for marking out the holes.

The FS should be located in the place, where the water spilled in the

detection zone close the sensor contacts. The FS installation with the terminals

downwards ensures generation of alarm signal over appearance the liquid sheet

with a thickness exceeding 1 mm. The FS installation with the terminals sidewise

provides easy access to the sensor terminals for removal of a liquid from the FS

surface between the terminals after the leakage elimination.

9.2 Fasten the FS on the mounting surface with screws or a water-resistant

glue. Fasten the SPM base on the mounting surface with screws. For the wall-

tamper monitoring, the second screw must be screwed in a hole under the wall

tamper. Install the PCB, connect the FSs to the loop terminals (the red wire to

the «+» terminal). Install the cover.

«RIELA» JSC, www.rielta.com,

tel./fax: +7 (812) 233-0302, 703-1360,

Made in Russia

Rev. 4 of 19.02.18

№Э00439

v.11.1/ v.12

10 Troubleshooting

Table 5

CP Message Elimination Procedure

«Tamper» Check the security of the SPM fastening, close

it’s cover

«Alarm in Loop 1»

«Alarm in Loop 2»

In case there is no liquid (moisture) between the

FS contacts, check the absence of a short circuit

between the wires

«Failure in Loop 1»

«Failure in Loop 2»

Check the integrity of the wires connecting the

FS and the SPM and their fastening to the SPM

terminals

«Main power supply

battery fault»

Replace the main power supply battery and the

backup one

«Backup power supply

battery fault» Replace the backup power supply battery

11 Manufacturer’s Guarantees

11.1 The manufacturer guarantees conformity of the Detector to the

requirements of technical conditions provided the transportation, storage,

installation and operation conditions are observed.

11.2 The guaranteed shelf life of the Detector is 63 months since the date of

manufacture. The guaranteed useful life is 60 months since the day of putting

into operation within the limits of the guaranteed shelf life.

11.3 The detectors that are found non-conforming to the requirements of the

specifications will be repaired by the manufacturer, provided the installation and

operation rules have been observed.

Note – Warranty obligations do not apply to batteries.

12 Storage and Transportation

12.1

The Detectors are transported without power supply battery. The De-

tector in their original packaging are resistant to:

- transport jolting with the acceleration up to 30 m/sec2at impact frequency

range from 10 to 120 per minute or 15 000 strikes;

- ambient temperature range minus 50 ... +50 °С;

- relative air humidity (95 ± 3) % at a temperature +35 °С.

12.2 The Detector in original package may be transported by any means

of transportation in closed vehicles over any distances in compliance with the

existing shipping rules concerning the respective means of transportation.

13.3 After transportation under the conditions different to exploitation

conditions the Detector shall be ready to operate after a maximum of six hours.

14.4 The storage room shall be free from current-conducting dust, acid va-

pors, alkali and gases that cause corrosion and destroy insulation.

13 Packing Certificate

Wireless flood sensor «STZ-RK» manufactured in accordance with current

technical documentation is classified as fit for operation and is packed by

«RIELTA» JSC.

Packing date _______________________________

month, year

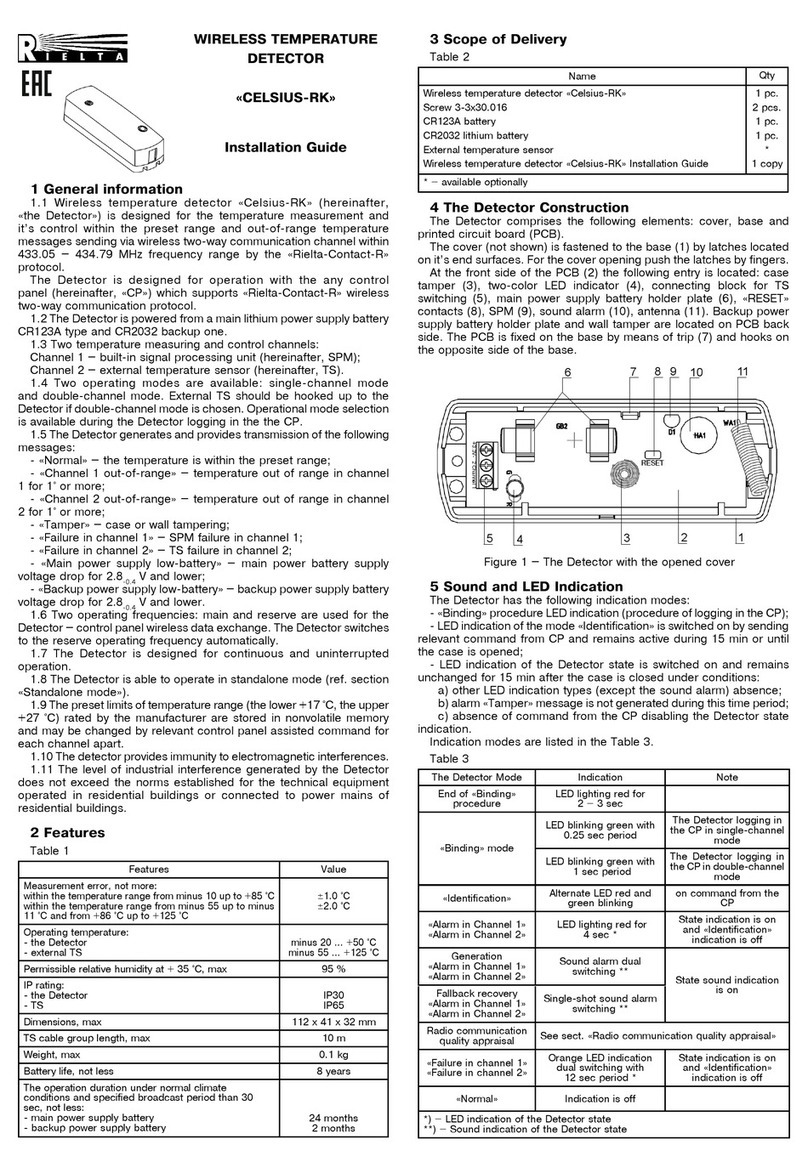

Figure 3 - SPM base

9.3 Fasten the FS on the mounting surface

with screws or a water-resistant glue. Fasten

the SPM base on the mounting surface with

screws. To ensure the wall-tamper control,

the second screw must be screwed in the wall

tamper fixing arm. Install the PCB, connect

the FSs to the loop terminals in accordance

with the Figure 1 . Install the cover.

ATTENTION! Antenna should be installed

into the holder (see Figure 3). Antenna

installation outside of the holder essentially

reduces communication range.

Fixation holes for

fastening base to

mounting surface

Antenna holder

Wall tamper fixing

arm