Operator’s manual

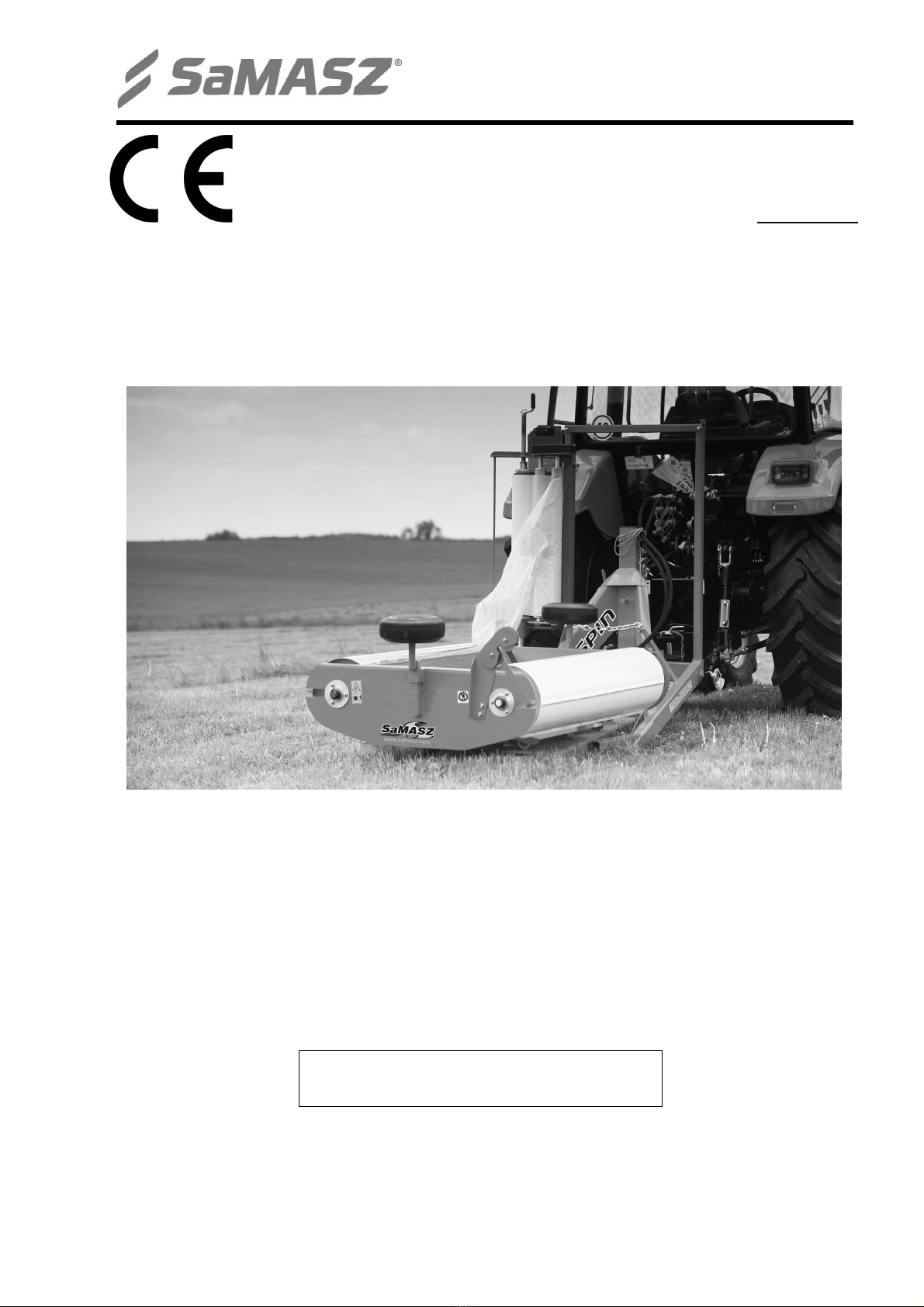

Bale wrapper

Spin

- 1 -

Table of contents page

1. IDENTIFYING THE MACHINE...........................................................................................2

2. INTRODUCTION ....................................................................................................................2

3. TECHNICAL DESCRIPTION.....................................................................................................3

3.1. Technical data ........................................................................................................................3

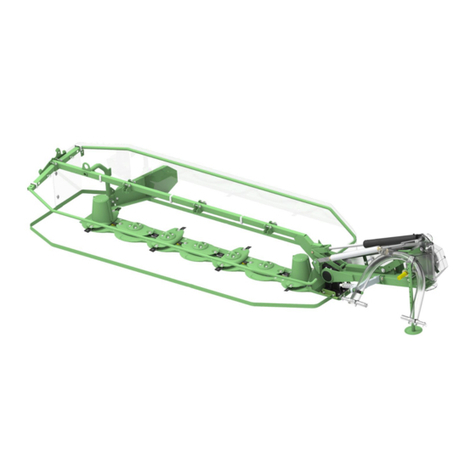

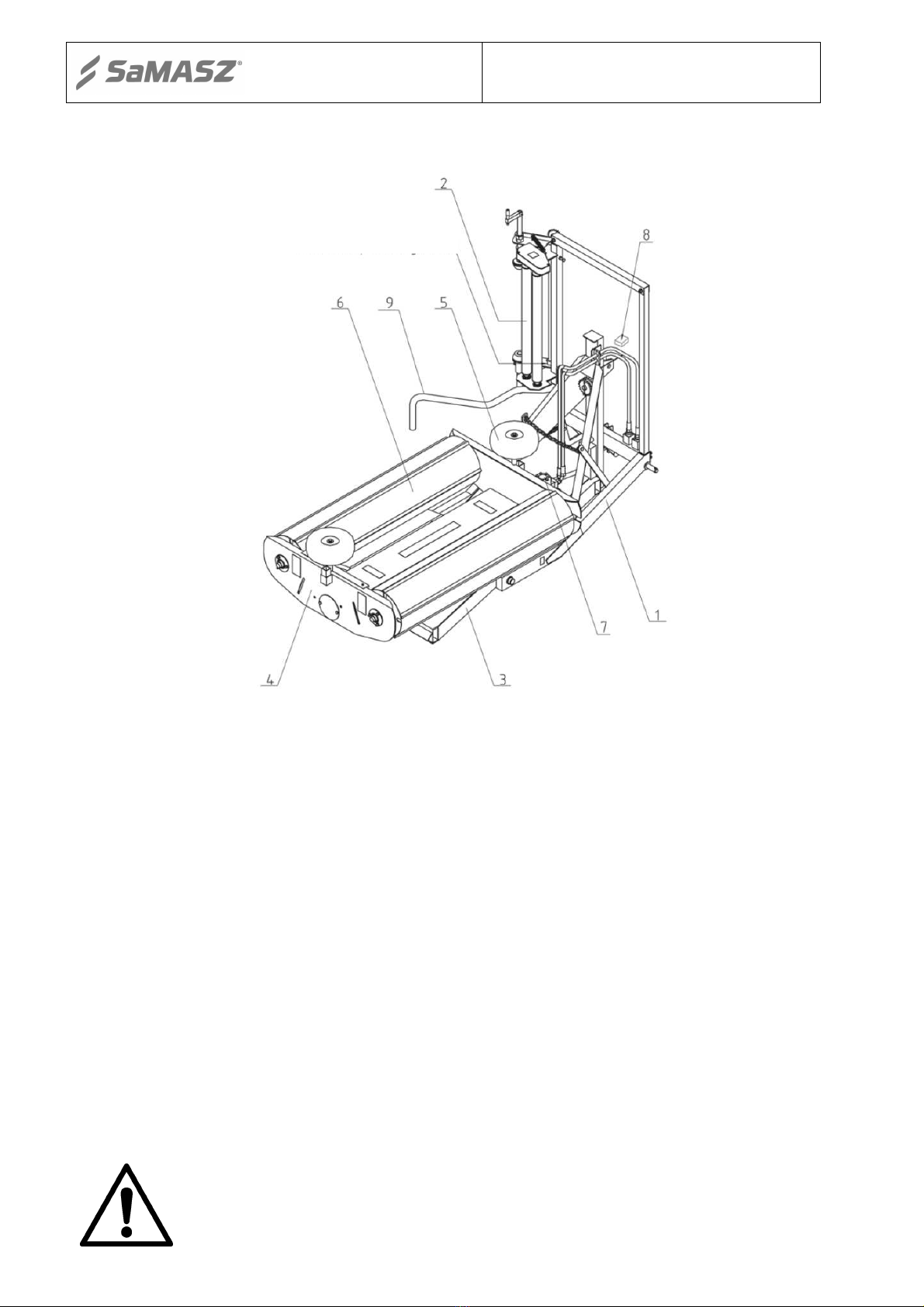

3.2 Wrapping machine construction ............................................................................................4

3.3. Intended use ...........................................................................................................................4

3.4. Standard equipment and spare parts.......................................................................................5

4. SAFETY PRECAUTIONS............................................................................................................5

4.2. Hazards...................................................................................................................................6

4.3. Transport................................................................................................................................7

4.4. Driving on public roads..........................................................................................................8

4.5. Warning signs and their meanings.........................................................................................8

5. DRIVE OPERATION..................................................................................................................11

5.1. Drive coupling.........................................................................................................................11

5.2. Disconnecting the drive........................................................................................................11

6. COMMISSIONING.....................................................................................................................11

6.1. Commissioning of the counter .............................................................................................12

7. CONTROLS AND ONGOING ADJUSTMENT.................................................................12

7.1. Location of the controls .......................................................................................................12

7.2. Location of ongoing adjustment points................................................................................13

8. WRAPPING MACHINE OPERATION..............................................................................14

8.1. Installing the film.................................................................................................................14

8.2. Hydraulic system..................................................................................................................15

8.3. Wrap counter........................................................................................................................15

8.4. Wrapping..............................................................................................................................17

8.5. Unloading the wrapped bale ................................................................................................18

8.6. Drive chain adjustment ........................................................................................................19

8.7. Finishing work .....................................................................................................................19

9. REGULAR INSPECTION.....................................................................................................20

9.1. User inspection.....................................................................................................................20

9.2. Service checks......................................................................................................................20

10. AUTHORIZED SERVICE ....................................................................................................20

10.1. Warranty service..............................................................................................................20

10.2. Ongoing maintenance ......................................................................................................20

10.3. Ordering replacement parts..............................................................................................21

11. STORAGE...............................................................................................................................21

12. MALFUNCTIONS AND THEIR REPAIR.............................................................................21

13. DISASSEMBLY AND WITHDRAWAL FROM USE........................................................21

14. WARRANTY CARD..............................................................................................................22

15. WARRANTY CONDITIONS...................................................................................................22

15.1. Warranty claims procedures...............................................................................................22

15.2. Warranty repairs record ...................................................................................................23