EL950.1.1.1062C.4-2017Page3

Introduction................................................................................................................................2

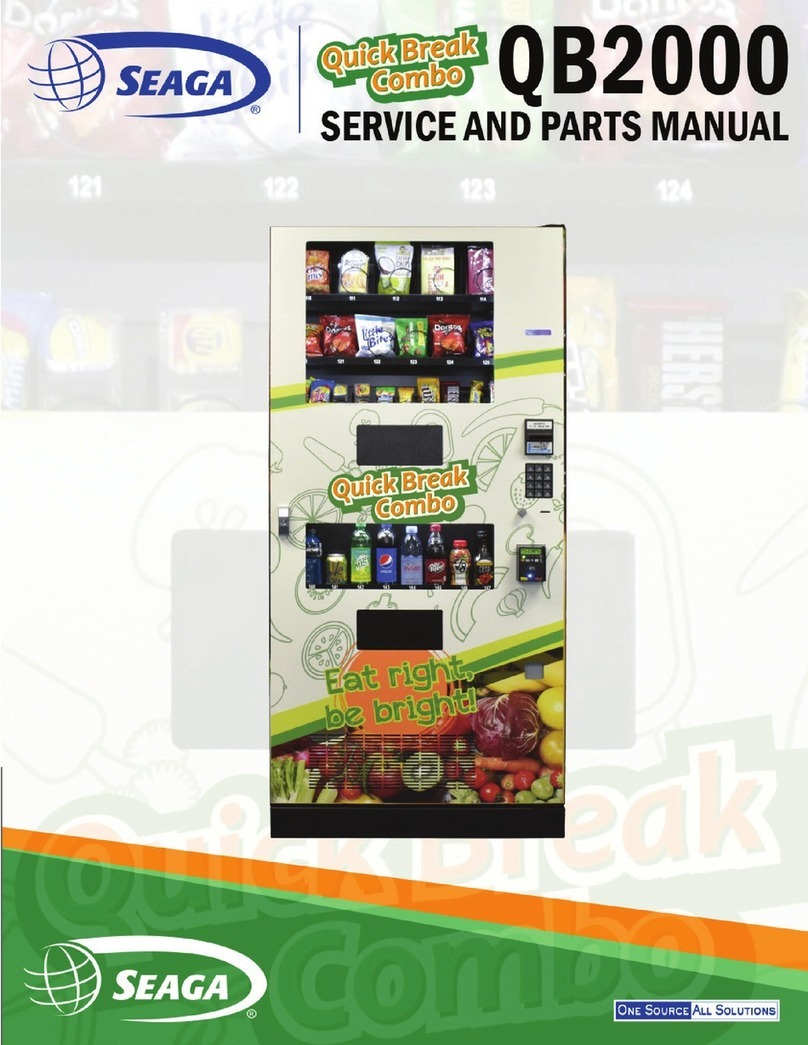

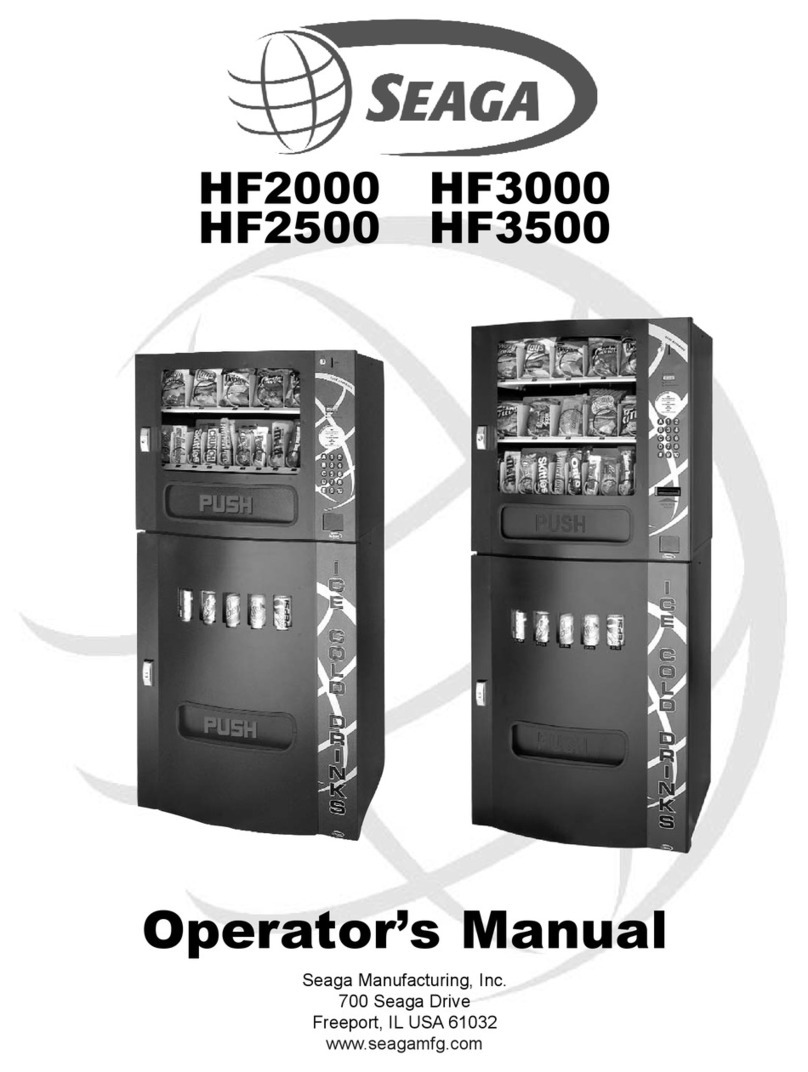

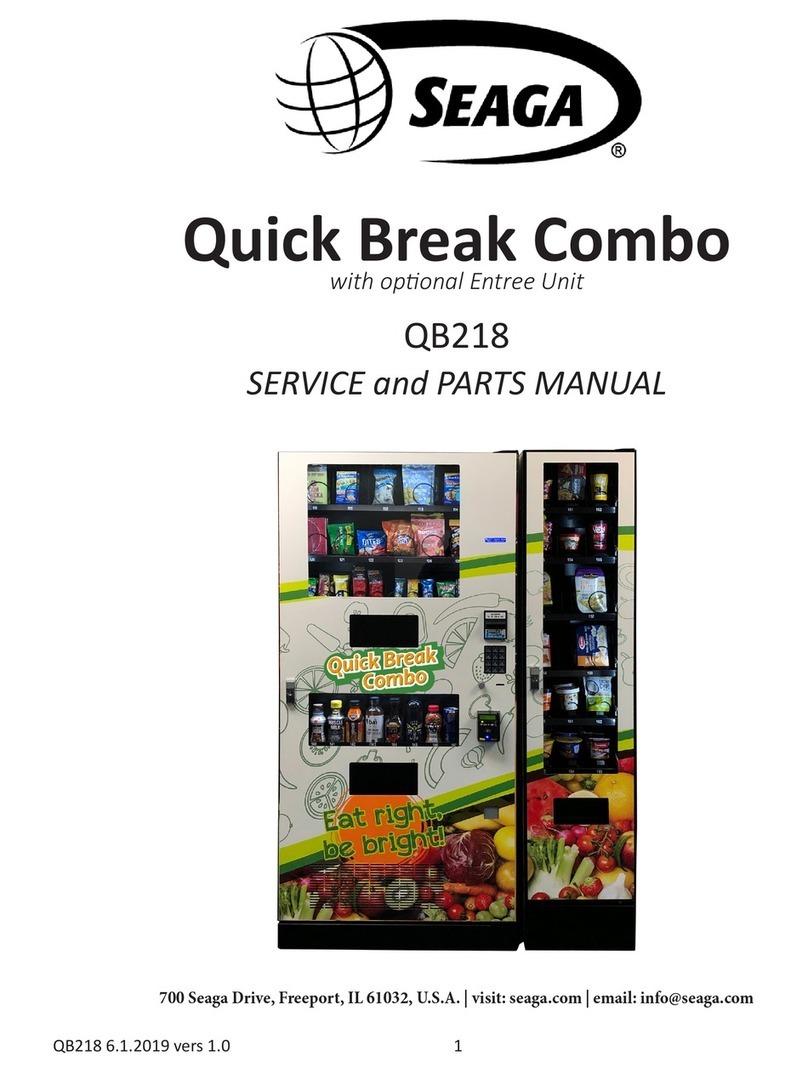

PreliminaryInformation..............................................................................................................4

InitialSetup.................................................................................................................................7

EquipmentSetup........................................................................................................................8

LoadingSnackTrays....................................................................................................................9

RemovingSnackTrays...............................................................................................................11

AdjustingCoils...........................................................................................................................12

ReplacingSnackMotors............................................................................................................14

LoadingBeverageLanes............................................................................................................15

CustomerInterface...................................................................................................................21

SettingUpandLoadingthePaymentSystems...........................................................................22

CoinChanger.............................................................................................................................22

LoadingChanger.......................................................................................................................22

CoinRetrieval............................................................................................................................23

ClearingCoinJams....................................................................................................................24

RemovalofCoinChanger..........................................................................................................25

BillValidator..............................................................................................................................27

BillValidatorCapacity...............................................................................................................27

BillRetrieval..............................................................................................................................27

RemovingBillValidator.............................................................................................................28

ClearingBillJams.......................................................................................................................30

Programming............................................................................................................................31

Refrigeration.............................................................................................................................32

CleaningtheCondensor............................................................................................................69

Refrigeration.............................................................................................................................70

RefrigerationStatusDisplay......................................................................................................71

Troubleshooting........................................................................................................................72