Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND

CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

INSTRUCTIONS FOR:

PARTS CLEANING TANK EXTRA DEEP 136LTR

MODEL No: SM40D.V2

1.2. GENERAL SAFETY

WARNING! Ensure Health & Safety, local authority and general workshop practice regulations are adhered to when using this equipment.

Familiarise yourself with the application, limitations and potential hazards of the cleaning tank.

WARNING!Disconnect the cleaning tank from the mains power before changing accessories, servicing or performing any maintenance.

Maintain the cleaning tank in good condition (use an authorised service agent).

Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Locate the cleaning tank in a suitable work area. Ensure that the tank stands on a firm level surface. Keep the area clean and tidy and free

from unrelated materials. Ensure that the area is well ventilated and has adequate lighting.

Keep the cleaning tank away from heat sources such as heater, sparks, open flames etc.

Ensure that there are no flammable or combustible materials near the work area.

DO NOT use the cleaning tank where there are flammable liquids, solids or gases (e.g. paint solvents).

In case of fire in the unit, do not attempt to remove parts, or move the tank. The lid is fused and will

close automatically to extinguish the flames.

In case of fire in tank, do not attempt to move unit or remove parts from tank. The lid is fusible and will

automatically close extinguishing fire.

When cleaning parts ensure that nothing in the tank, including any parts basket, is in a position that

would prevent the lid from closing fully if and when the fusible link activates.

DO NOT use any solvent with a flash point below 140°F. We recommend you use Sealey Degreasing Solvent

(AK25), contact your local dealer for details.

WARNING! Only to be used with water soluble cleaning agents.

WARNING! Always wear approved eye or face protection when operating the cleaning tank.

Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and contain long hair.

Wear appropriate protective clothing.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons away from the work area.

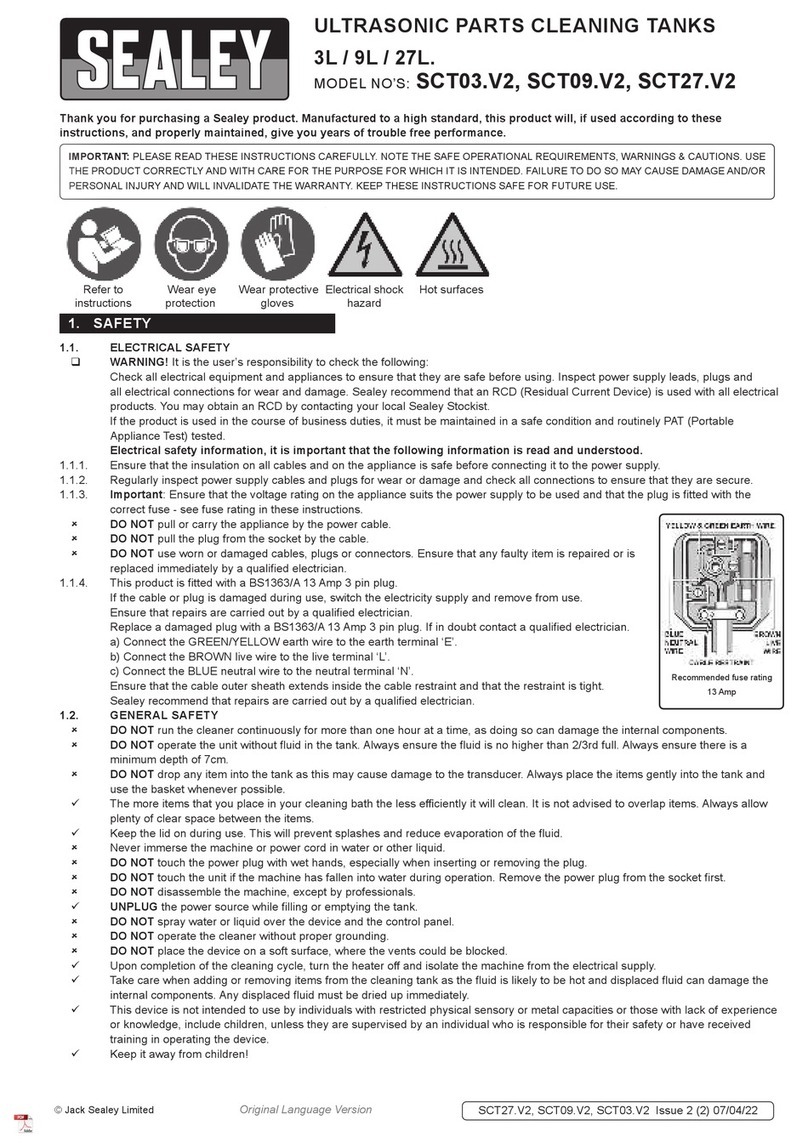

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to read, understand and comply with the following:

You must check all electrical equipment and appliances to ensure they are safe before using. You must inspect power supply leads, plugs and

all electrical connections for wear and damage. You must ensure the risk of electric shock is minimised by the installation of appropriate safety

devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main distribution board. We also recommend that an RCD

(Residual Current Device) is used with all electrical products. It is particularly important to use an RCD together with portable products that are

plugged into an electrical supply not protected by an RCCB. If in doubt consult a professional electrician. You may obtain a Residual Current

Device by contacting your Sealey dealer. You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by a qualified

electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of the appliance, and

the safety of the appliance operator. If in any doubt about electrical safety, contact a qualified electrician.

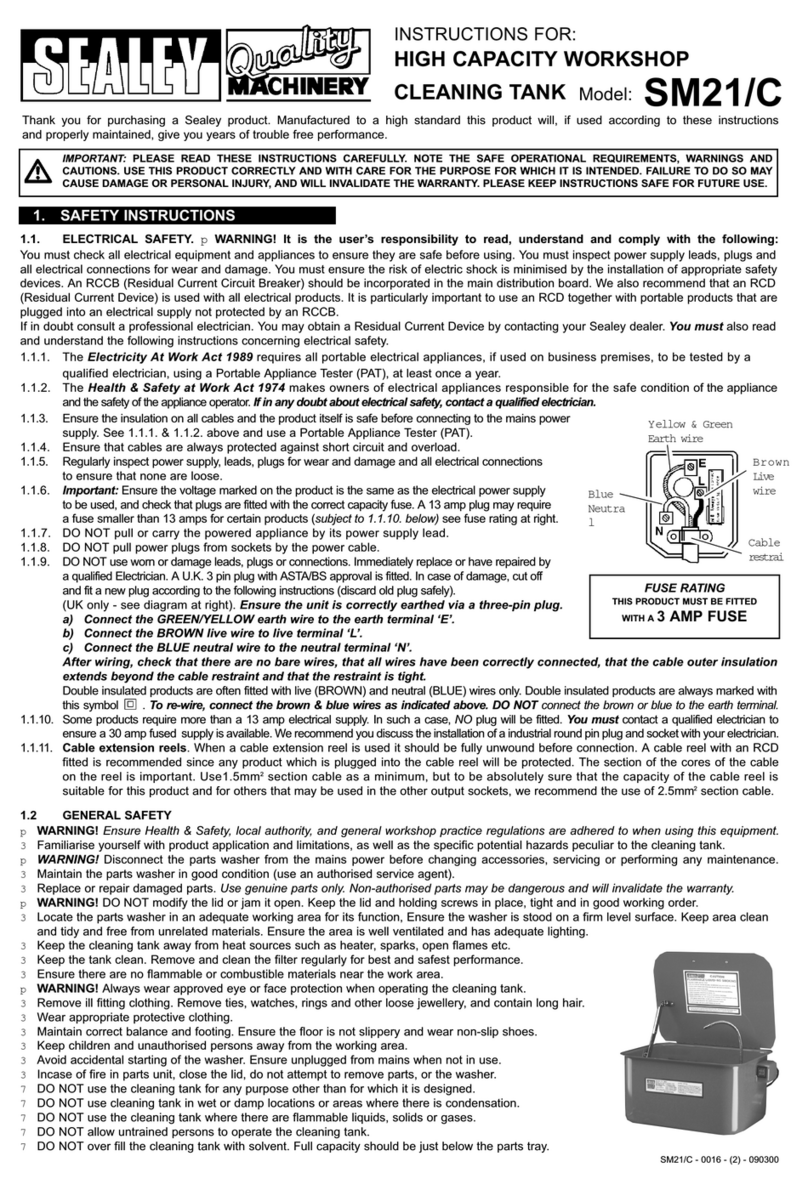

1.1.3. Ensure the insulation on all cables and the product itself is safe before connecting to the mains power

supply. See 1.1.1. & 1.1.2. above and use a Portable Appliance Tester (PAT).

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply, leads, plugs for wear and damage, and all electrical connections

to ensure that none is loose.

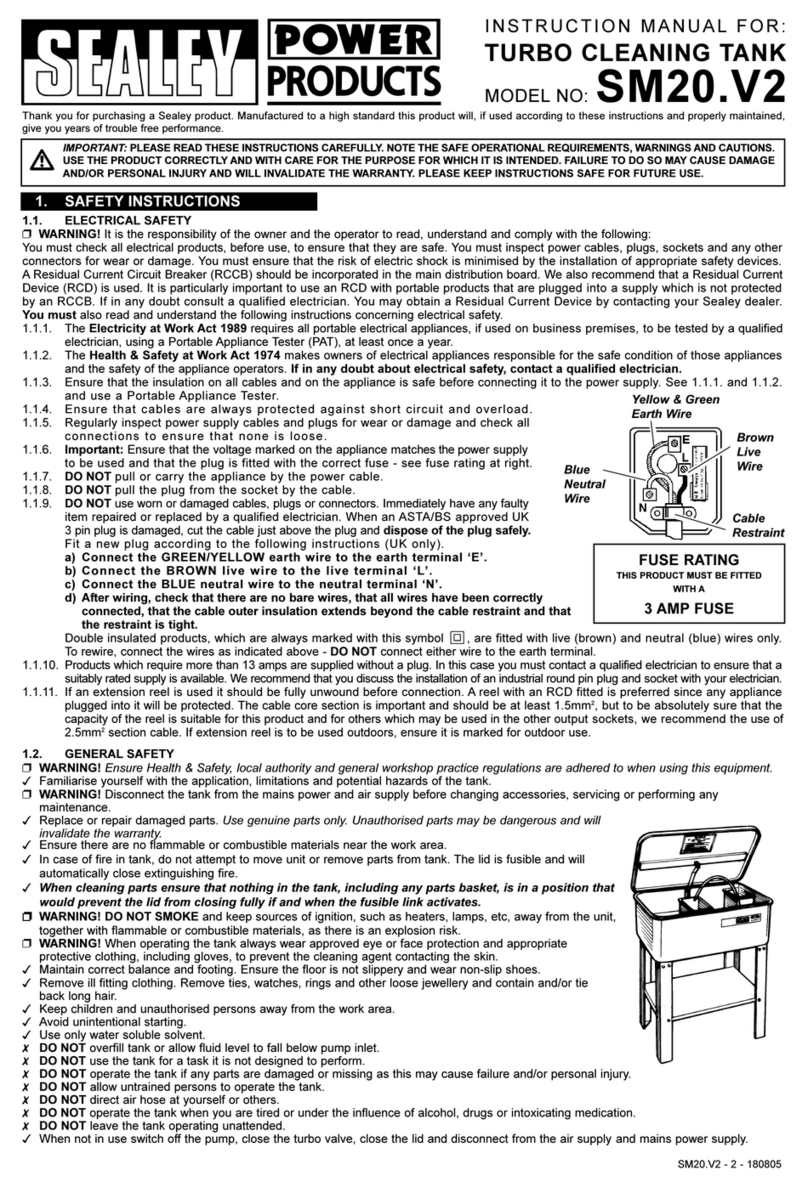

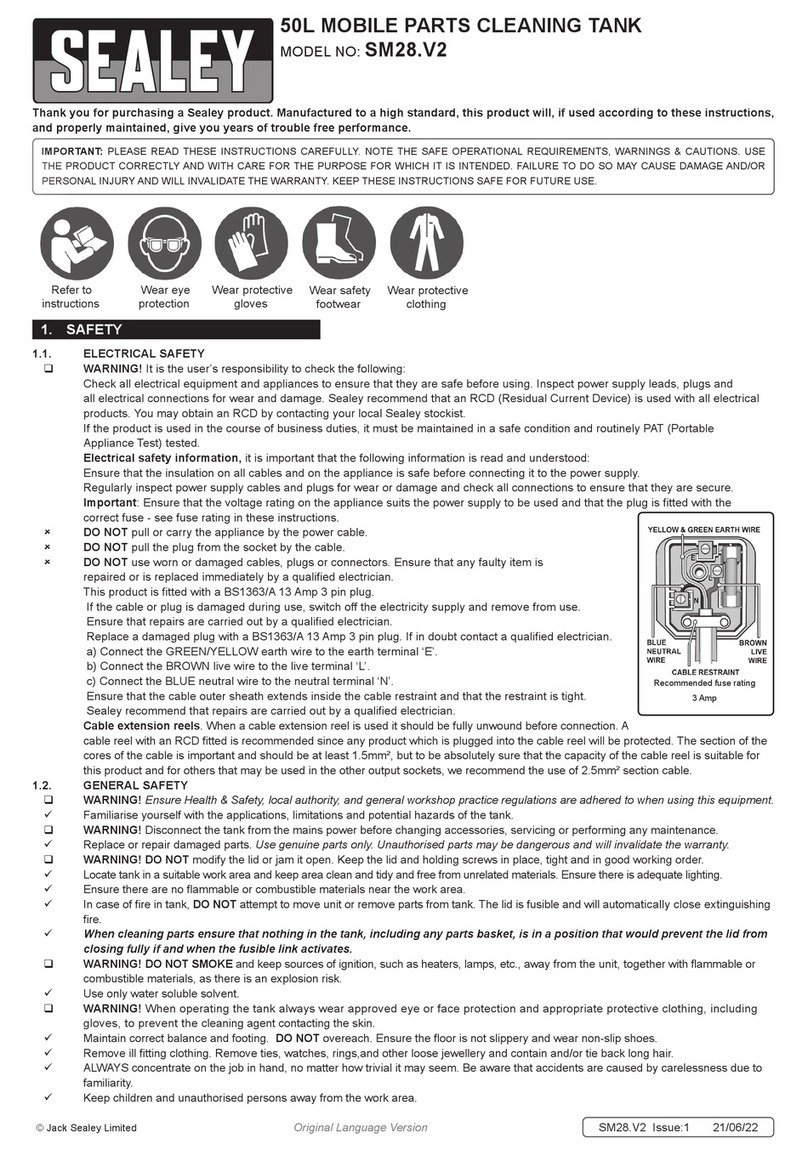

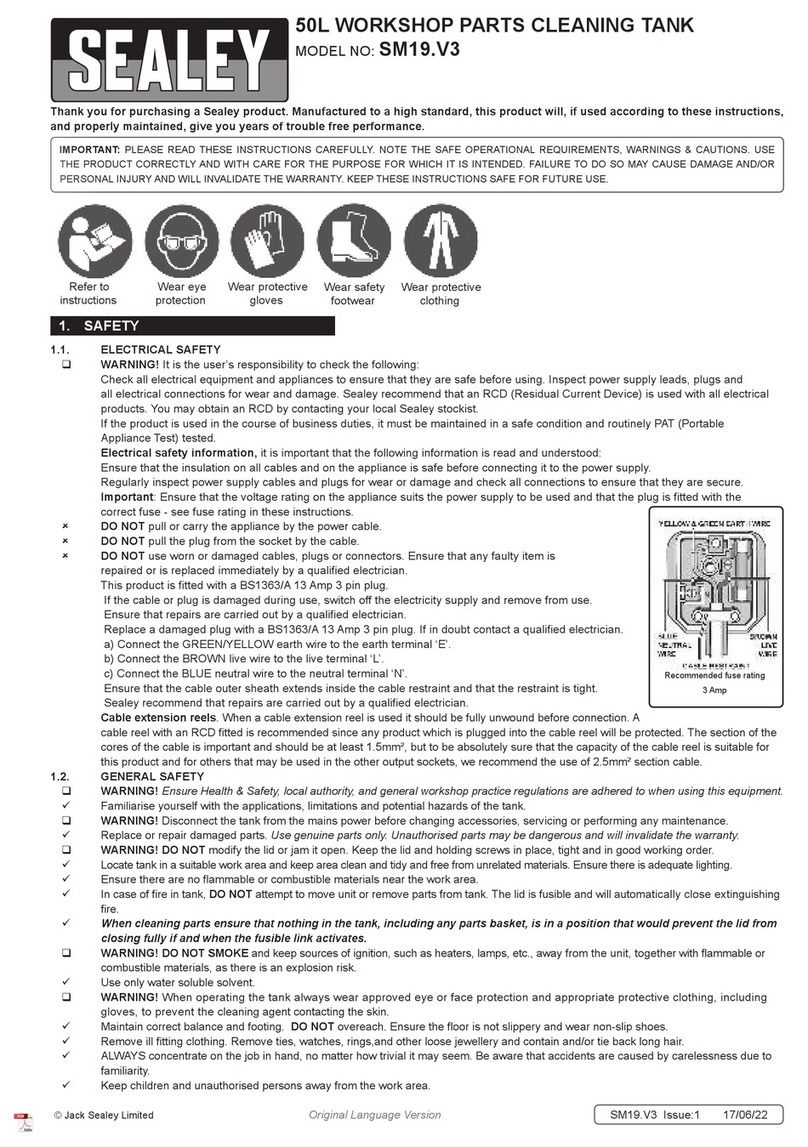

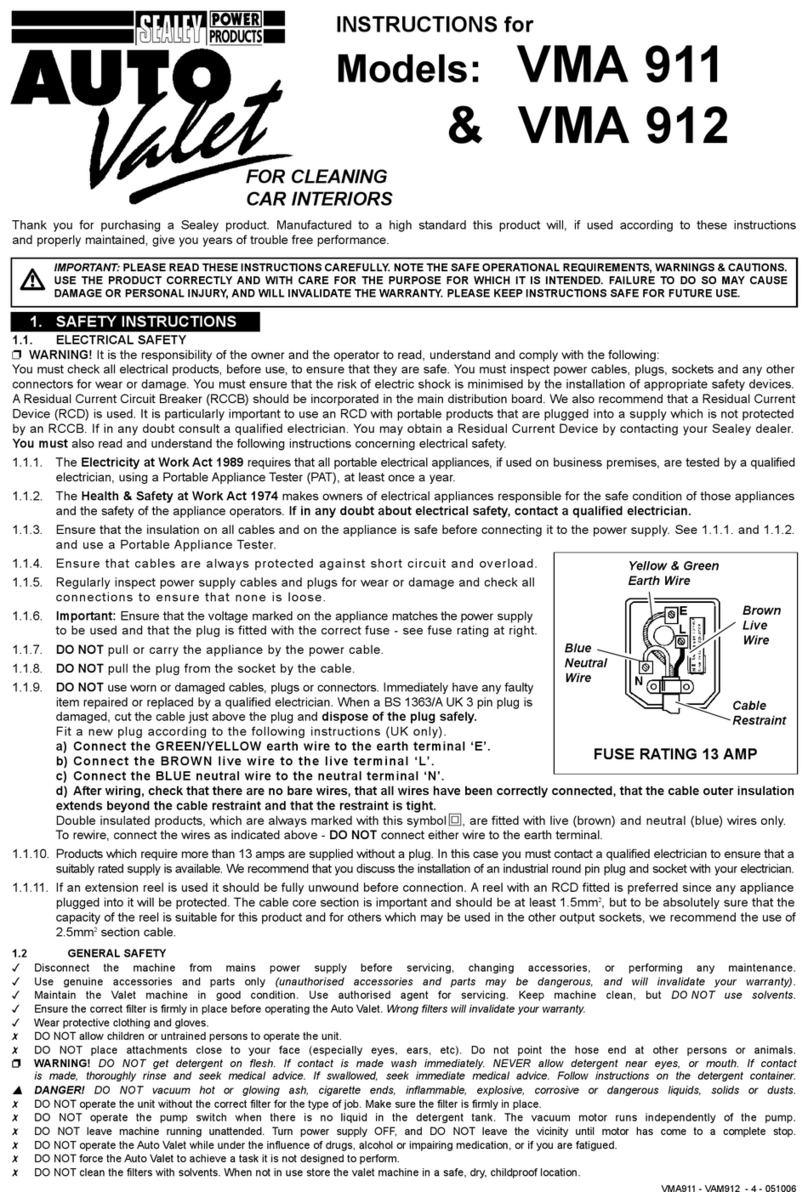

1.1.6. Important: Ensure the voltage marked on the product is the same as the electrical power supply to

be used, and check that plugs are fitted with the correct capacity fuse. A 13 amp plug may require

a fuse smaller than 13 amps for certain products, see fuse rating at right.

1.1.7. DO NOT pull or carry the powered appliance by its power supply lead.

1.1.8. DO NOT pull power plugs from sockets by the power cable.

1.1.9. DO NOT use worn or damage leads, plugs or connections. Immediately replace or have repaired by

a qualified Electrician. A U.K. 3 pin plug with ASTA/BS approval is fitted. In case of damage, cut off

and fit a new plug according to the following instructions (discard old plug safely).

(UK only - see diagram at right). Ensure the unit is correctly earthed via a three-pin plug.

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

d) After wiring, check that there are no bare wires, that all wires have been correctly connected,

that the cable external insulation extends beyond the cable restraint and that the restraint is tight.

Double insulated products are fitted with live (BROWN) and neutral (BLUE) wires only. Double insulated products are always marked

with this symbol . To re-wire, connect the brown & blue wires as indicated above. DO NOT connect the brown or blue to the

earth terminal.

1.1.10. Cable extension reels. When a cable extension reel is used it should be fully unwound before connection. A cable reel with an RCD

fitted is recommended since any product which is plugged into the cable reel will be protected. The section of the cores in the cable

is important and should be at least 1.5mm², but to be absolutely sure that the capacity of the cable is suitable for this product and

for others that may be used in the other output sockets, we recommend the use of 2.5mm² section cable.

FUSE RATING

3 AMP

Original Language Version SM40D.V2 Issue: 1 - 8/11/13

© Jack Sealey Limited