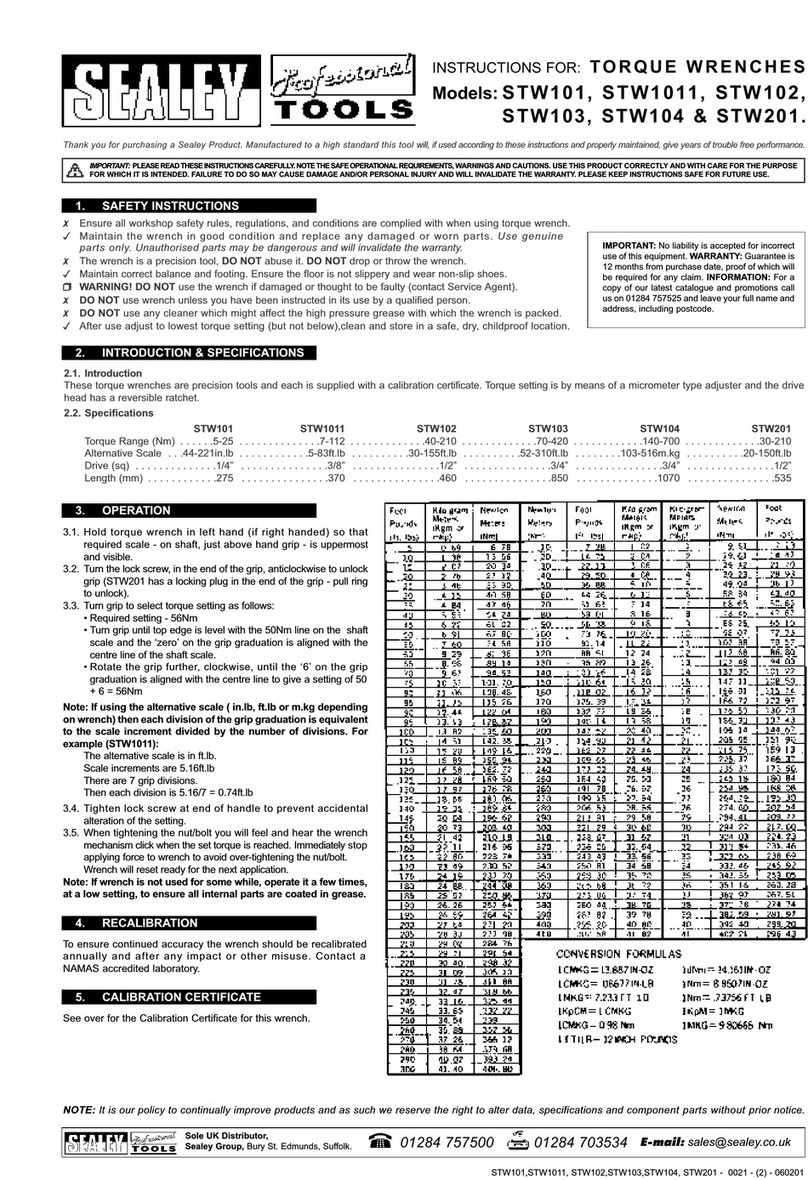

Collet size: .................Ø6mm

Free speed: ............. 22000rpm

Air consumption:.............. 4cfm

Operating pressure: ...........90psi

Air inlet: ..................1/4”BSP

Weight: ....................0.58kg

Noise Power: .......... 102.94dB(A)

Noise Pressure: ......... 91.94dB(A)

Vibration Emission:......... 2.53m/s²

Drive: ..................1/2” Sq

Max Torque: ..............60lb.ft

Air Consumption: ...........4cfm

Operating Pressure: ........ 90psi

Air Inlet: ...............1/4”BSP

Weight: .................. 1.2kg

Noise Power: ........108.47dB(A)

Noise Pressure: .......97.47dB(A)

Vibration Emission:.......6.56m/s²

Drive: .....................1/2” Sq

Working/Max Torque: ..... 230/300lb.ft

Ultimate Torque: ............ 420lb.ft

Air Consumption: ..............4cfm

Operating Pressure: ............90psi

Air Inlet: ..................1/4”BSP

Weight: ..................... 2.2kg

Noise Power: ...........100.01dB(A)

Noise Pressure: ..........89.01dB(A)

Vibration Emission:..........5.67m/s²

Chisel Shank: .......0.401” Parker Taper

Speed: .....................4500bpm

Stroke: .......................41mm

Air Consumption: ................ 4cfm

Operating Pressure: ..............90psi

Air Inlet: .................... 1/4”BSP

Weight: ........................1.1kg

Noise Power: .............116.03dB(A)

Noise Pressure: ...........105.03dB(A)

Vibration Emission:...........13.25m/s²

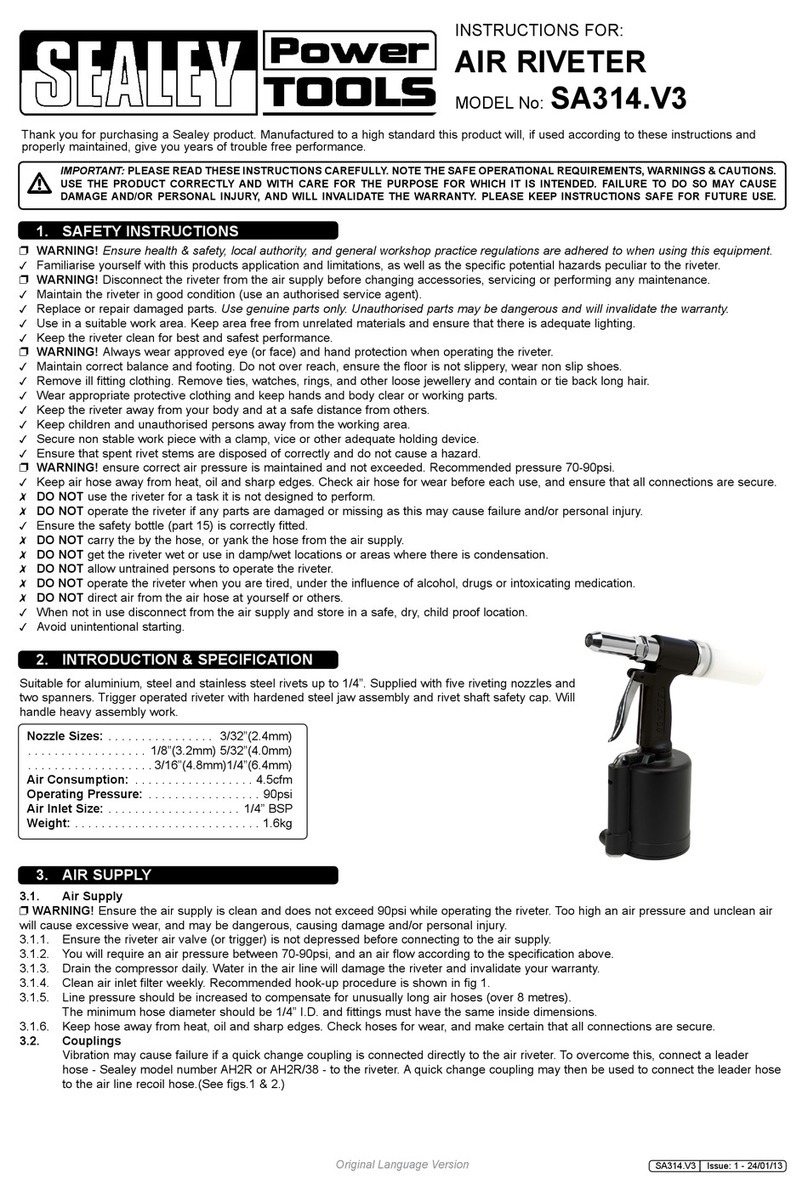

SA12/S.V2

150mm AIR HAMMER

SA2

IMPACT WRENCH

SA21/S

RATCHET WRENCH

SA67.V3

AIR DIE GRINDER

3. SPECIFICATIONS

4. PREPERATION FOR USE

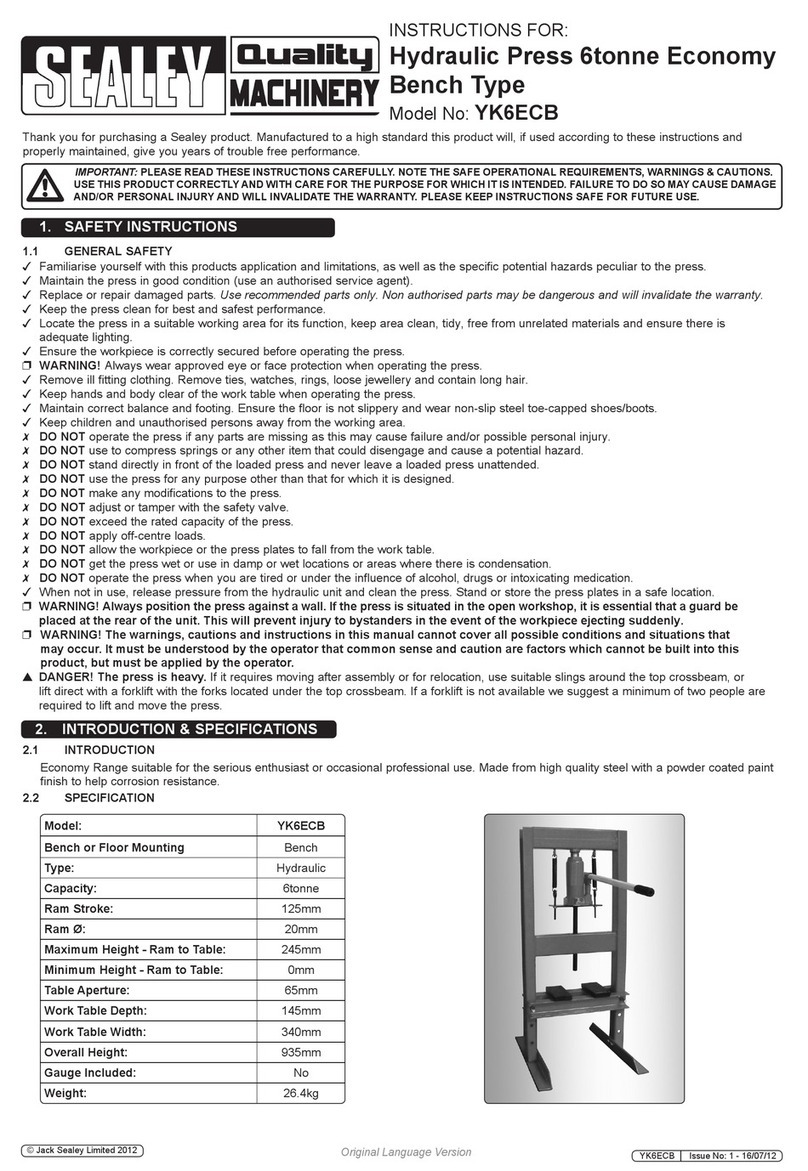

Recommended hook-up is shown in fig.1.

WARNING! Ensure that the air supply is clean and does not exceed 90 psi while operating these tools. Too much air pressure and/or

unclean air will cause excessive wear and may be dangerous, causing damage and/or personal injury.

4.1. Ensure that the tool trigger is not depressed before connecting to the air supply.

4.2. You will require an air pressure of 90psi, and an air flow of 4cfm per tool.

4.3. Drain the air tank daily. Water in the air line will damage the tools and invalidate your warranty.

4.4. Clean the compressor air inlet filter weekly.

4.5. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose bore should be 1/4”

and fittings must have the same inside dimensions.

4.6. Keep hoses away from heat, oil and sharp edges. Check hoses for wear and make certain that all connections are secure.

4.7. Couplings - vibration may cause failure of a quick change coupling that is connected directly to the air tool.

To overcome this, connect a leader hose (Sealey model number AH2R) to the tool.

A quick change coupling may then be used to connect the leader hose to the air line recoil hose. See figs.1 & 2.

5. SA2 - AIR IMPACT WRENCH

Tough professional air impact wrench with fully polished alloy housing and rubber bumper. Through type forward/reverse control. 4 position

adjustable air/torque selection. Fitted with standard 1/2” square drive. Fitted with rocking-dog type clutch and hardened impact anvil. Suitable for

general garage use.

WARNING! Ensure that you read, understand and apply the safety instructions in Section 1 before use. Additionally the following

safety instructions are specific to this tool.

Use only impact sockets, since these are specifically designed for use with an impact wrench. Standard sockets may shatter.

DO NOT use any additional force upon the wrench in order to tighten or remove a nut.

Take care not to over-tighten fixings.

Operation

5.1. Connect the wrench to the air supply as in Section 4.

5.2. Fit a socket onto the square drive and then place the socket over the nut. Squeeze the trigger to operate the wrench.

5.3. To change direction push the button at the top of the handle, direction “F” for forward and “R” for reverse.

5.4. The flow of air (torque) may be regulated by adjusting flow valve at the base of the handle, push in the adjuster and turn clockwise until

correct setting (1 to 4) is reached, then let adjuster click out to lock.

fig.2

fig.1

Original Language Version SA2004KIT Issue:3(SP)-18/06/13

© Jack Sealey Limited