Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Explanation of symbols............................................................................ 5

1.3 Scope of delivery....................................................................................... 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 7

2.3 Limitation of liability................................................................................. 7

2.4 Modifications and conversions................................................................ 7

2.5 Cybersecurity............................................................................................ 8

2.6 Requirements for skilled persons and operating personnel.................. 8

2.7 Operational safety and specific hazards................................................. 8

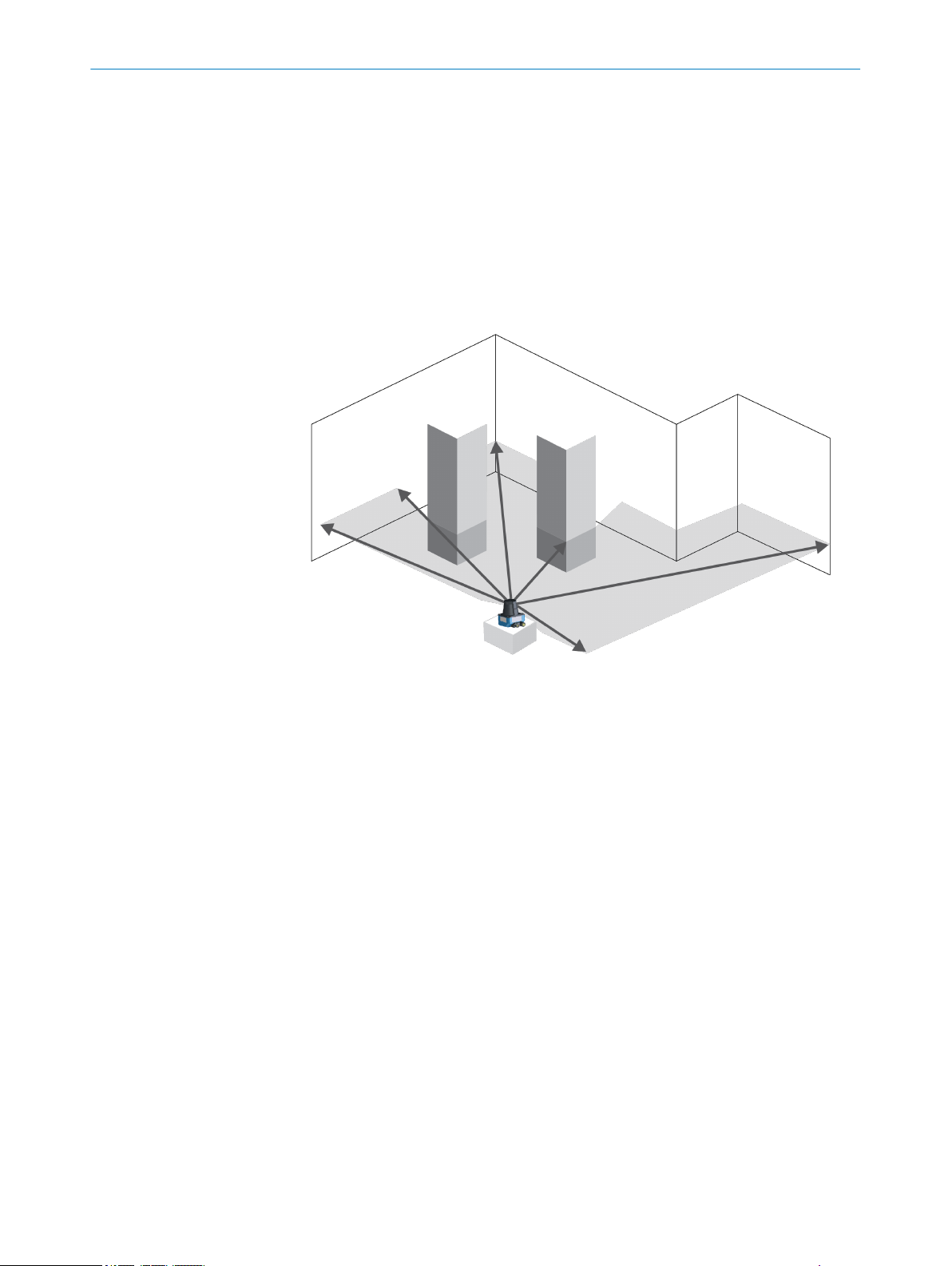

3 Product description........................................................................... 10

3.1 Product characteristics............................................................................ 10

3.2 Particle filter.............................................................................................. 11

3.3 Setup and dimensions............................................................................. 12

3.4 Status indicators....................................................................................... 13

3.5 Product ID.................................................................................................. 13

4 Transport and storage....................................................................... 15

4.1 Transport................................................................................................... 15

4.2 Unpacking.................................................................................................. 15

4.3 Transport inspection................................................................................. 15

4.4 Storage...................................................................................................... 15

5 Mounting............................................................................................. 16

5.1 Mounting instructions............................................................................... 16

5.2 Mounting device....................................................................................... 16

5.3 Mounting multiple devices....................................................................... 16

6 Electrical installation........................................................................ 18

6.1 Safety......................................................................................................... 18

6.2 Electrical connection of the sensor......................................................... 18

7 Operation............................................................................................ 20

7.1 Operation via SOPAS ET........................................................................... 20

7.2 Operation via IO-Link................................................................................ 22

7.2.1 Process data............................................................................ 23

7.2.2 Device data.............................................................................. 23

7.3 Operation using teach-in.......................................................................... 23

7.3.1 Teach-in parameters................................................................ 24

7.3.2 Preparations and procedure for teach-in............................... 25

7.3.3 Field evaluation via input circuit............................................. 26

CONTENTS

8020631/1DWW/2022-08 | SICK O P E R A T I N G I N S T R U C T I O N S | TiM1xx 3

Subject to change without notice