Siko AP10S User manual

110/20

AP10S

Absolute / Electronic Position Indicator with

plug connector for magnetic sensor and

interface

User manual

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 2 of 44

Table of contents

1General Information .................................................................................................. 5

1.1 Documentation ........................................................................................................5

1.2 Definitions ..............................................................................................................5

1.3 Intended use ...........................................................................................................5

1.4 Switching on the operating voltage.............................................................................6

2Display and control elements...................................................................................... 6

2.1 LCD - Anzeige ..........................................................................................................6

2.1.1 Extended display range ..........................................................................................7

2.2 LED display..............................................................................................................7

2.2.1 Device status........................................................................................................7

2.3 Control keys.............................................................................................................7

2.3.1 Key lock and enable time .......................................................................................8

3Functional Description ............................................................................................... 8

3.1 Operating modes ......................................................................................................8

3.1.1 Absolute position operating mode ...........................................................................8

3.1.1.1 Positioning.......................................................................................................8

3.1.1.2 Loop positioning .............................................................................................10

3.1.1.3 ControlWord in Absolute Position operating mode ................................................10

3.1.1.4 StatusWord in Absolute Position operating mode .................................................11

3.1.2 Alpha-numeric display operating mode...................................................................12

3.1.2.1 ControlWord: Alpha-numeric display ...................................................................13

3.1.2.2 StatusWord: Alpha-numeric display ....................................................................13

3.2 Battery buffering....................................................................................................14

3.3 Parameterization of the position indicator .................................................................14

3.3.1 Manual parameterization......................................................................................15

3.3.1.1 Starting parameterization .................................................................................15

3.3.1.2 Value input.....................................................................................................15

3.3.1.3 Value selection................................................................................................15

3.3.1.4 Overview of the operating menu ........................................................................16

3.3.1.5 "Changeable parameters" menu .........................................................................16

3.3.1.6 Positioning.....................................................................................................17

3.3.1.7 Visualization...................................................................................................17

3.3.1.8 LED function...................................................................................................17

3.3.1.9 Device options ................................................................................................18

3.3.2 Parameterization via interface ..............................................................................18

3.4 Calibration ............................................................................................................18

3.5 Sensor ..................................................................................................................19

3.6 Alignment travel ....................................................................................................19

3.7 Additional functions ...............................................................................................19

3.7.1 Device data........................................................................................................19

3.7.2 Restore factory settings .......................................................................................20

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 3 of 44

3.8 Warnings / Errors....................................................................................................20

3.8.1 Warnings ...........................................................................................................20

3.8.2 Errors ................................................................................................................20

3.8.3 Corrective actions ...............................................................................................21

4Parameter ............................................................................................................... 21

4.1 Process data ..........................................................................................................22

4.1.1 ControlWord .......................................................................................................22

4.1.2 StatusWord ........................................................................................................22

4.1.3 TargetValue........................................................................................................22

4.1.4 ActualValue........................................................................................................23

4.1.5 DisplayData........................................................................................................23

4.1.6 TargetValueLeft...................................................................................................24

4.2 Positioning............................................................................................................24

4.2.1 Resolution .........................................................................................................24

4.2.2 DecimalPlaces.....................................................................................................24

4.2.3 DisplayDivisor.....................................................................................................25

4.2.4 CountingDirection ...............................................................................................26

4.2.5 CalibrationValue..................................................................................................26

4.2.6 TargetWindow.....................................................................................................27

4.2.7 LoopType ...........................................................................................................27

4.2.8 LoopLength........................................................................................................28

4.3 Visualization..........................................................................................................28

4.3.1 DisplayOrientation ..............................................................................................28

4.4 LEDs .....................................................................................................................29

4.4.1 LEDMode............................................................................................................29

4.4.2 Led1GreenMode ..................................................................................................29

4.4.3 Led2GreenMode ..................................................................................................30

4.4.4 Led1RedMode .....................................................................................................30

4.4.5 Led2RedMode .....................................................................................................31

4.4.6 ActiveLedsFlashing..............................................................................................31

4.5 Device options .......................................................................................................32

4.5.1 SensorType.........................................................................................................32

4.5.2 KeyEnableTime....................................................................................................32

4.5.3 KeyCalibration ....................................................................................................33

4.5.4 KeyIncremental...................................................................................................33

4.5.5 OperatingMode ...................................................................................................34

4.5.6 PINChange .........................................................................................................34

4.5.7 LoadDefault........................................................................................................35

4.5.8 CODE .................................................................................................................35

5IO-Link ................................................................................................................... 35

5.1 Process data input / output .....................................................................................36

5.1.1 Process data in Absolute position operating mode ...................................................37

5.1.1.1 Process data output (master device) ..............................................................37

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 4 of 44

5.1.1.2 Process data input (device master) ................................................................38

5.1.2 Process data in Alphanumeric display operating mode ..............................................38

5.1.2.1 Process data output (master device) ..............................................................39

5.1.2.2 Process data input (device master) ................................................................39

5.2 Directory of objects ................................................................................................40

5.2.1 IO-Link specific objects........................................................................................40

5.3 SystemCommands ...................................................................................................41

5.4 DeviceAccessLocks ..................................................................................................42

5.5 EventCodes............................................................................................................42

5.6 ErrorCodes .............................................................................................................42

6Block diagram ......................................................................................................... 43

General Information

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 5 of 44

1General Information

1.1 Documentation

The following documents describe this product:

The data sheet describes the technical data, the dimensions, the pin assignment, the

accessories and the order key.

The installation instructions describe the mechanical and electrical installation with all

safety-relevant conditions and the associated technical specifications.

User manual for connecting the display to an IO-Link master and for commissioning.

IODD file (IO-Link Device Description); with the help of this file, the connection and

configuration with an IO-Link master is possible by means of commercially available IO-

Link masters and their configurators.

You can also download these documents at http://www.siko-global.com/p/ap10s.

1.2 Definitions

If not explicitly stated otherwise, decimal values are given as figures without an extension (e.

g. 1234), binary values are marked after the figure with a b (e. g. 1011b), hexadecimal values

with an h (e. g. 280h).

1.3 Intended use

Unless otherwise described, normal operation of the system with unchanged factory setting is

assumed for the further description of functions.

The present device is an absolute position indicator with integrated IO-Link interface and a

plug-in connection for MS500H magnetic sensor for direct linear distance measurement

(combined with MB500/1 magnetic tape) or a supported GS04 magnetic sensor for direct shaft

mounting. Indicators, control buttons and interface are only active with external power

supply. The sensor of measurement encoder works magnetically incrementally. Without an

external power supply, encoder changes are recorded with battery support. The status of the

replaceable battery is monitored. A volatile TargetValue can be displayed below the

ActualValue via the backlit two-line LC display A direction display (indicator) is displayed if

there is a deviation between the actual value and the target window (target value including

TargetWindow parameter). The arrow direction indicates in which direction the shaft must be

rotated to reach the target window. In addition, the position status of two two-color LEDs

(green and red) is displayed. Device malfunctions or inadmissible operating conditions are

displayed. Since both linear magnet sensors are used with the AP10S, a clockwise direction of

rotation must be equated with a positive travel path.

Display and control elements

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 6 of 44

The buttons can be used to select various functions and to adapt the device parameters of the

application stored in non-volatile memory. The actual value can be queried via the interface,

the target value can be changed and all device parameters can be adjusted.

1.4 Switching on the operating voltage

The AP10S will be initialized after switching on the supply voltage. A system and display test

is executed during initialization, the LEDs are lighted consecutively and the parameters are

loaded from the non-volatile memory into the RAM of the controller.

At first use, the default values are used during initialization. After the return of the external

power supply or software reset (warm start), the AP10S works with the last saved parameters.

If no fault has been detected, the AP10S starts normal operation and can communicate with

an IO-Link Master.

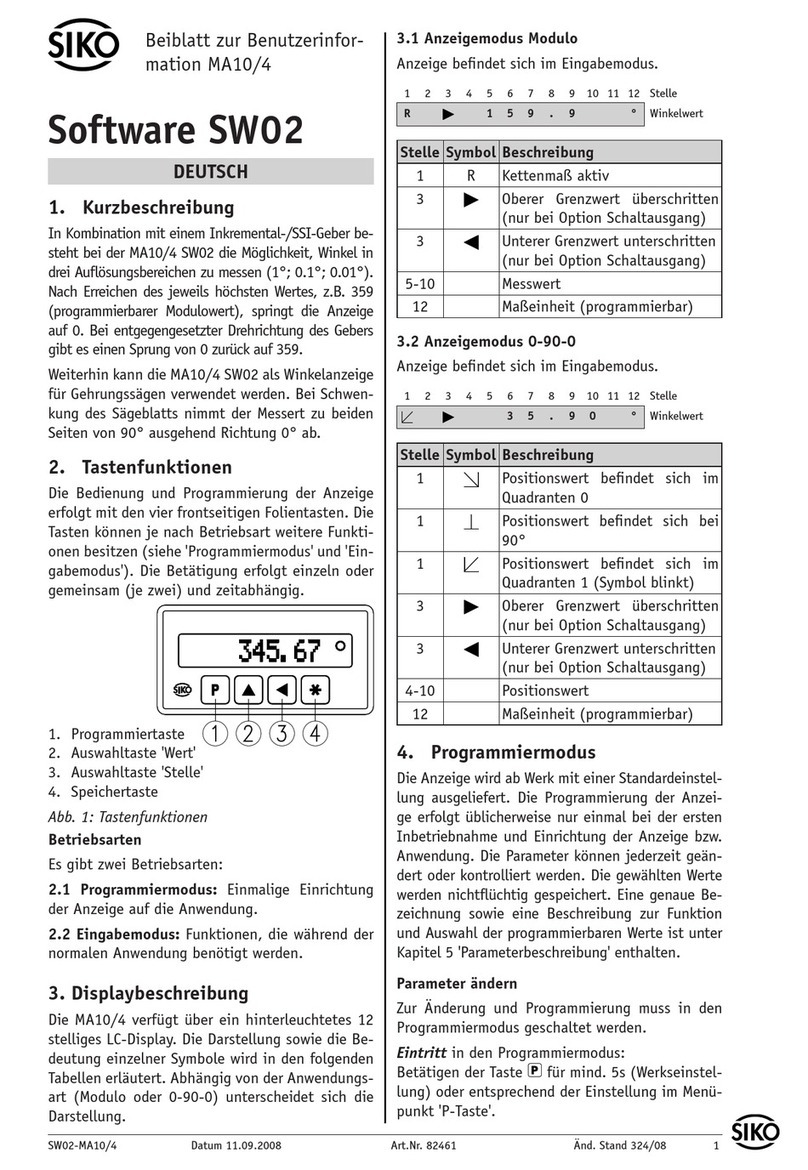

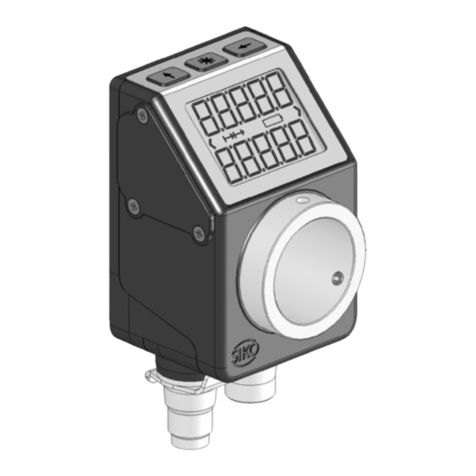

2Display and control elements

The position indicator has a two-line display with special characters and three control keys.

The actuator can be configured and controlled via the keys.

Two LEDs (LED1, LED2) serve for monitoring positioning.

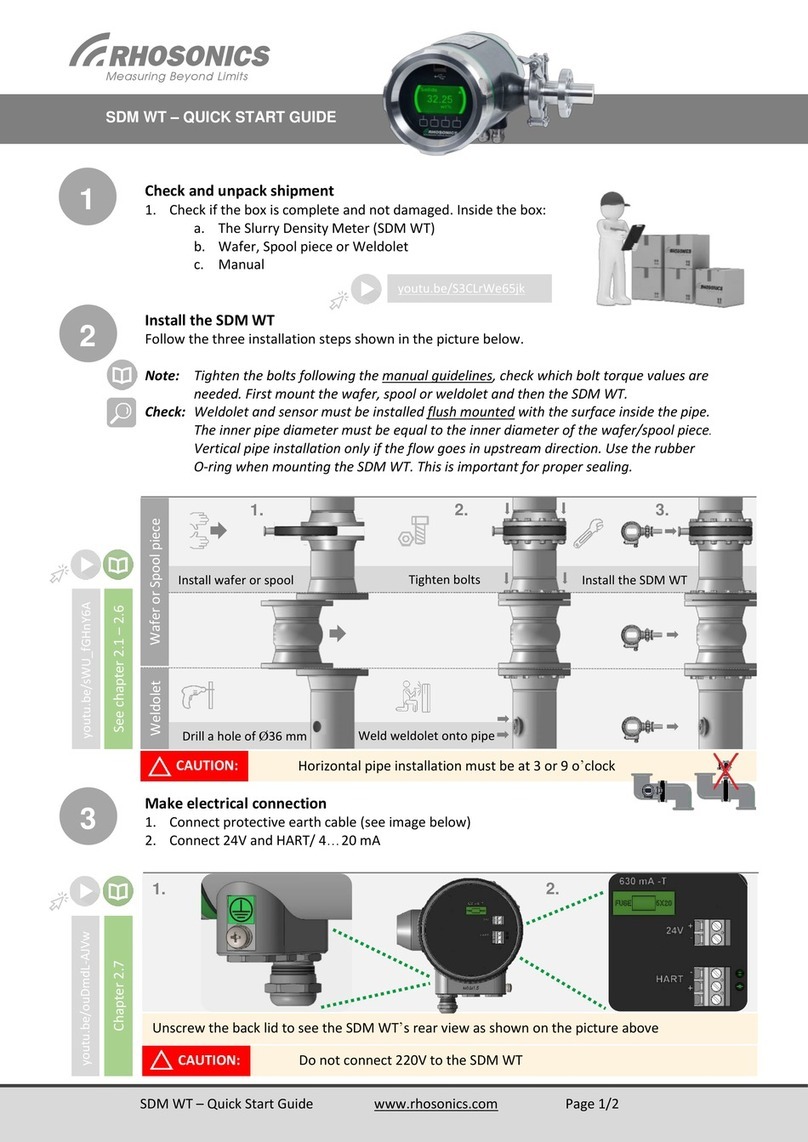

Fig. 1: Display and control elements

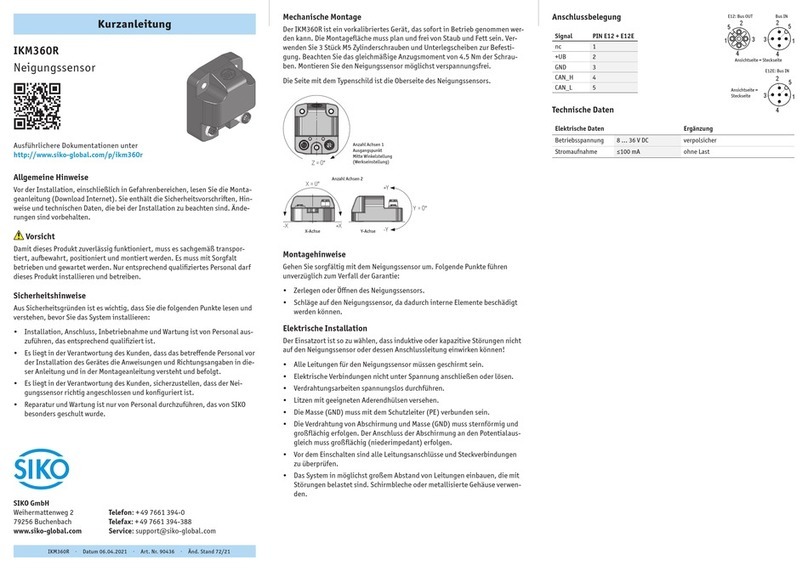

2.1 LCD - Anzeige

The display range is limited to -199999 … 999999. Values outside this

range are displayed with "FULL".

When the operating voltage is applied, the actual value (absolute position value, ActualValue)

is displayed in the first line. If there is no valid target value, " --- " appears in the second

line. If a target value is declared valid by means of the control bit in the process data (see e.

g. bc09_TargetValueActive), this is displayed in the 2nd line. The values displayed are

determined by the operating mode.

Direction indicators (arrows) support positioning.

The battery symbol is shown with a critical or insufficient battery status. If battery

voltage drops to a critical value, the battery symbol on the display will flash. If it falls below

the minimum value, the symbol will glow permanently.

LED1

LED2

Display

Key configuration

Key calibration

Key incremental

measurement

Display and control elements

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 7 of 44

With incremental measurement function activated, the incremental measurement symbol

is shown.

This is signaled in red letters in the event of a fault.

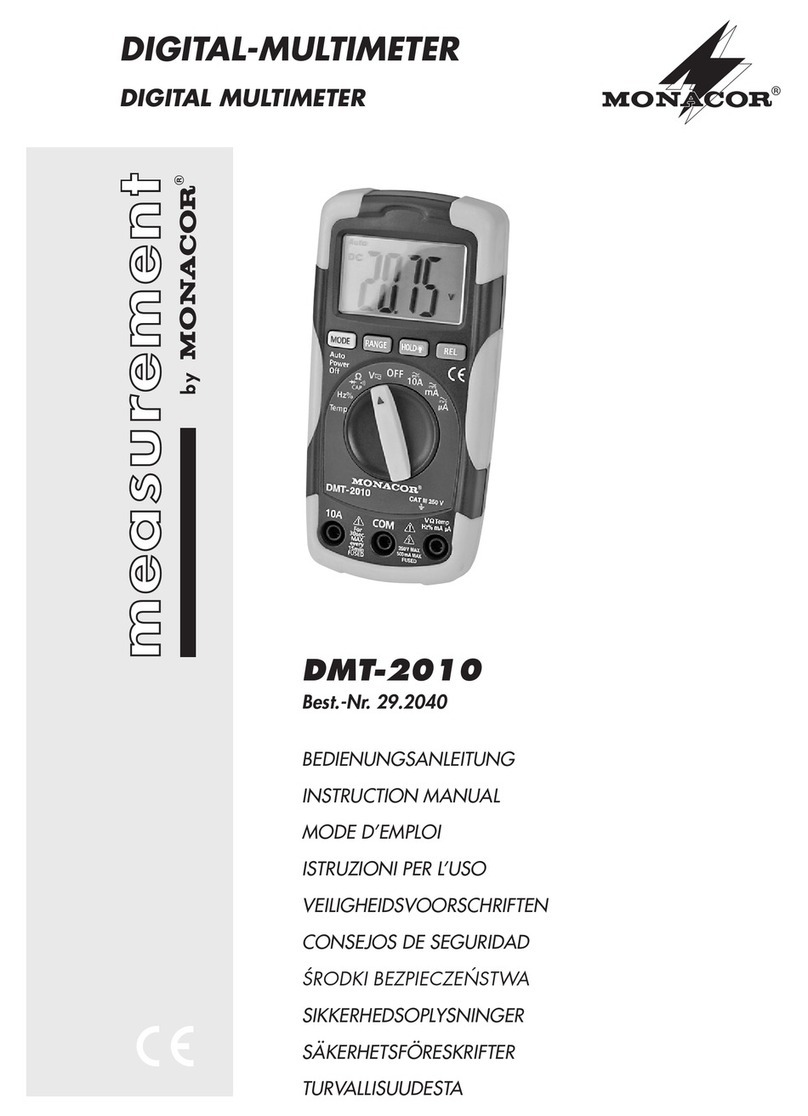

Fig. 2: Two-line 14 segment LCD display

2.1.1 Extended display range

Values up to -199999 can be displayed by means of the ControlWords (see

bc03_DisplayRange). If the relevant bit has been set and the value to be displayed is between

-199999 and -999999, then the negative sign and the digit of the highest order will flash

alternately. If the value range drops below -999999, "FULL" will be displayed.

2.2 LED display

2.2.1 Device status

A test sequence is executed on these LEDs during initialization.

In its basic state (factory setting) the LED display has different meanings depending on the

operating mode (see chapter 3.1).

In order for LED1 or LED2 to be controlled via the ControlWord, this function of the LEDs must

be activated by means of parameters (see chapter 3.1.1.3, 3.1.2.1, 4.4 and 5.1).

2.3 Control keys

Pressing the Incremental button switches the increment function or a relative

measurement on or off.

Pressing the Calibration button starts the calibration and acknowledges an existing fault.

In the "Alphanumeric display" operating mode, the receipt of a target value is acknowledged

by this action.

Pressing the Configuration button starts the parameterization.

See also chapter 3.3.1 and Fig. 1.

Incremetal

measurement

symbol

Counterclockwise

rotation direction

Display line 1

Battery symbol

Clockwise rotation

direction

Display line 2

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 8 of 44

2.3.1 Key lock and enable time

The key access to the chain dimension function and calibration can be generally blocked with

the parameters KeyCalibration and KeyIncremental (see chapter 4.5.3). The time during which

the button must be pressed until you can enter the menu can be set in the Options menu.

Access via keys to the changeable device parameters can only be obtained after entering the

PIN. This can be defined using the parameter PINChange (see chapter 4.5.6).

3Functional Description

3.1 Operating modes

The following position-dependent operating modes are differentiated: Absolute position and

the position-independent operating mode Alpha-numeric display.

Operating mode

Absolute position

Alpha-numeric Display

Line 1

Actual value

(ActualValue)

Target value 1 (DisplayData)

Line 2

Target value

(TargetValue)

Target value 2 (TargetValue)

Table 1: Display with different operating modes

3.1.1 Absolute position operating mode

The measured absolute position value is calculated depending on the parameters Resolution,

DisplayDivisor and DecimalPlaces and displayed as actual value. The actual value (ActualValue)

of higher-level control can be provided via the interface and a target value can be set as a

default. The target value must be set to valid in the ControlWord (bc09_TargetValueActive).

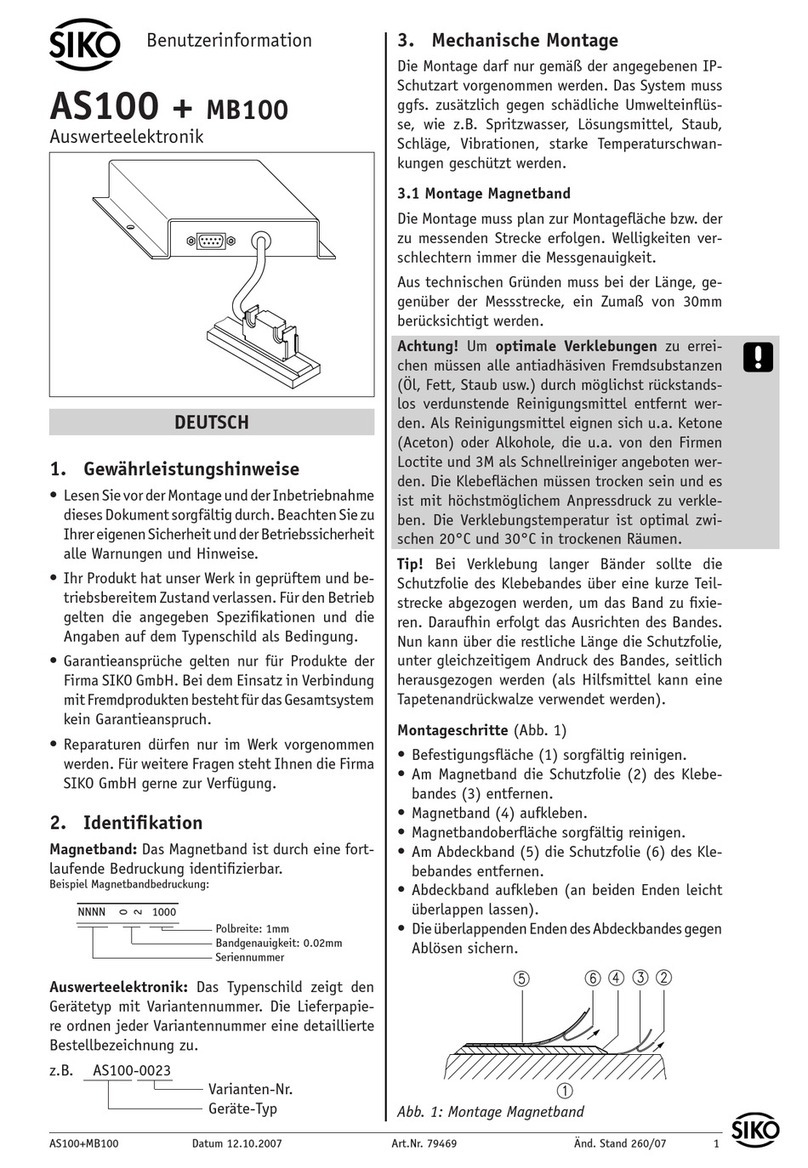

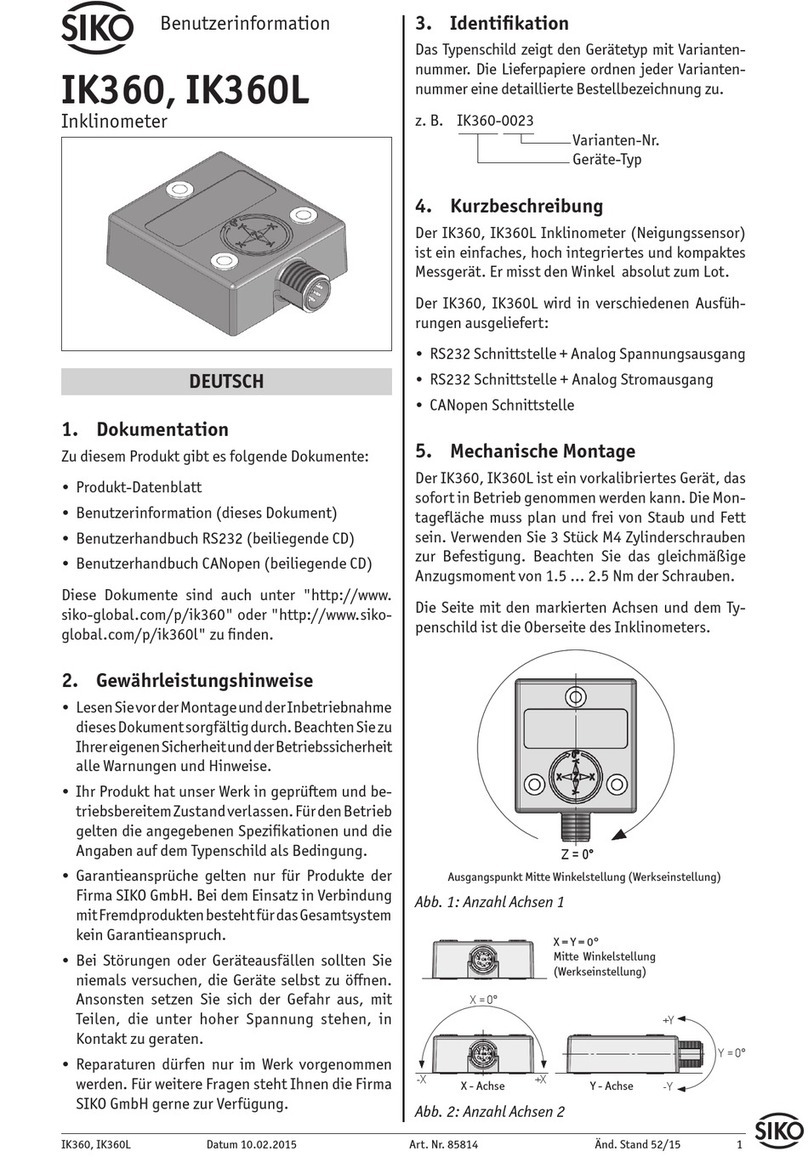

3.1.1.1 Positioning

Target window:

A target window is formed to be able to define a tolerance range.

Target window = TargetValue ± TargetWindow

Example Position monitoring:

TargetWindow = 5

TargetValue = 100

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 9 of 44

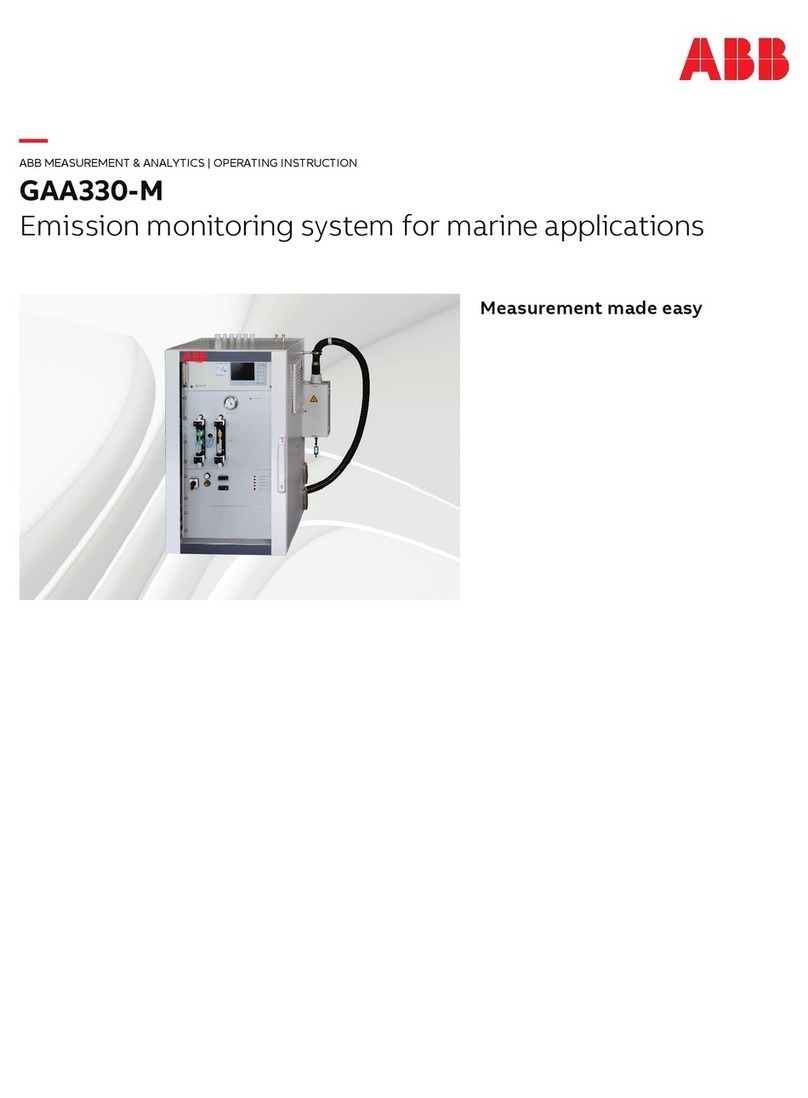

Fig. 3: Positioning monitoring with TargetWindow

Directional arrows:

To assist in positioning, direction arrows are displayed in the display as long as the current

actual value is outside the valid target window. The arrow direction indicates in which

direction the sensor position must be changed to reach the target window.

LED display:

With factory setting, the LED glows green as long as the actual value is within the

programmed window. When leaving target window, the LED glows red. The sensor position

must be changed in the direction of the glowing LED in order to arrive at the target value.

The red glowing LED1 (left): method of the sensor in negative counting direction. Red

glowing LED2 (right): method of the sensor in positive counting direction.

With factory settings, the LED display (see chapter 4.4) has the following meaning:

Operating state

LED

Meaning

There is no valid target

value or no operating

voltage.

Both LEDs

inactive

No position monitoring active.

There is a valid target

value.

Both LEDs

green

The actual value is within the programmed target

window.

LED1 red

The actual value is outside the programmed target

window. The sensor must be moved in negative

counting direction in order to reach the target.

LED2 red

The actual value is outside the programmed target

window. The sensor must be moved in positive

counting direction in order to reach the target.

Table 2: LED display

100

+

-

Target

window

95

105

LED1

Positioning monitoring

LED2

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 10 of 44

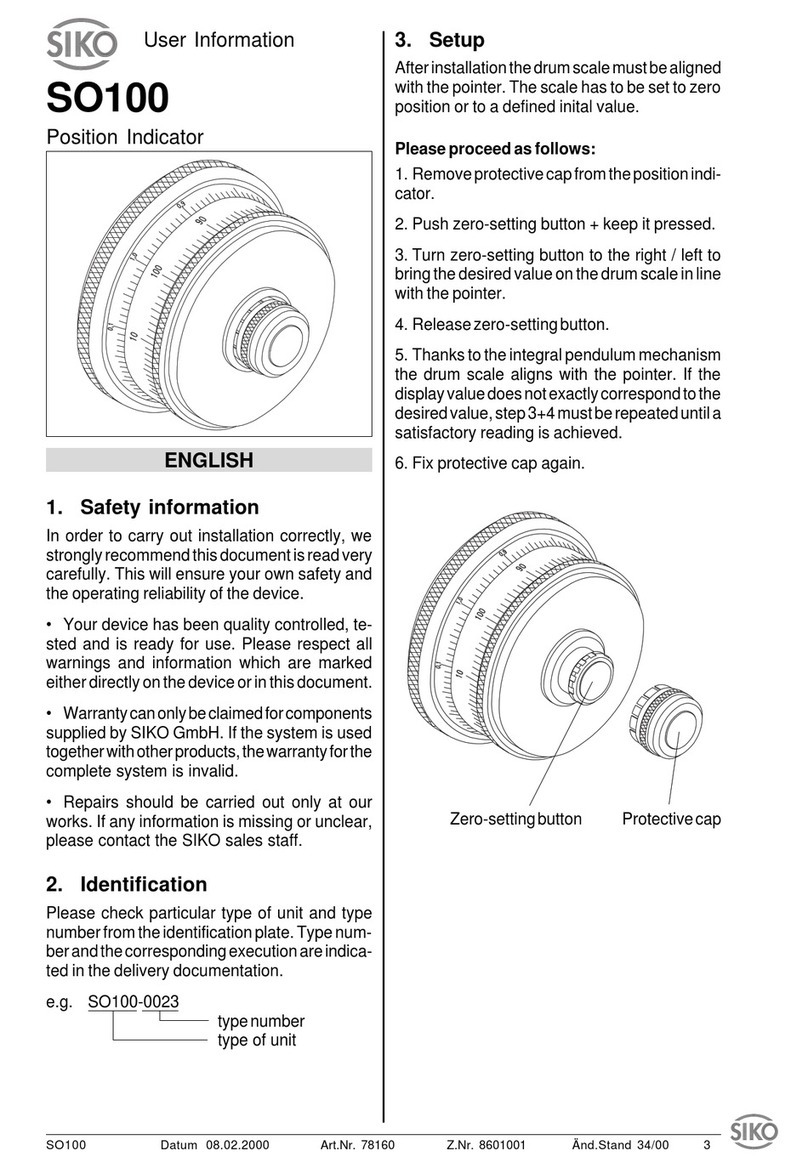

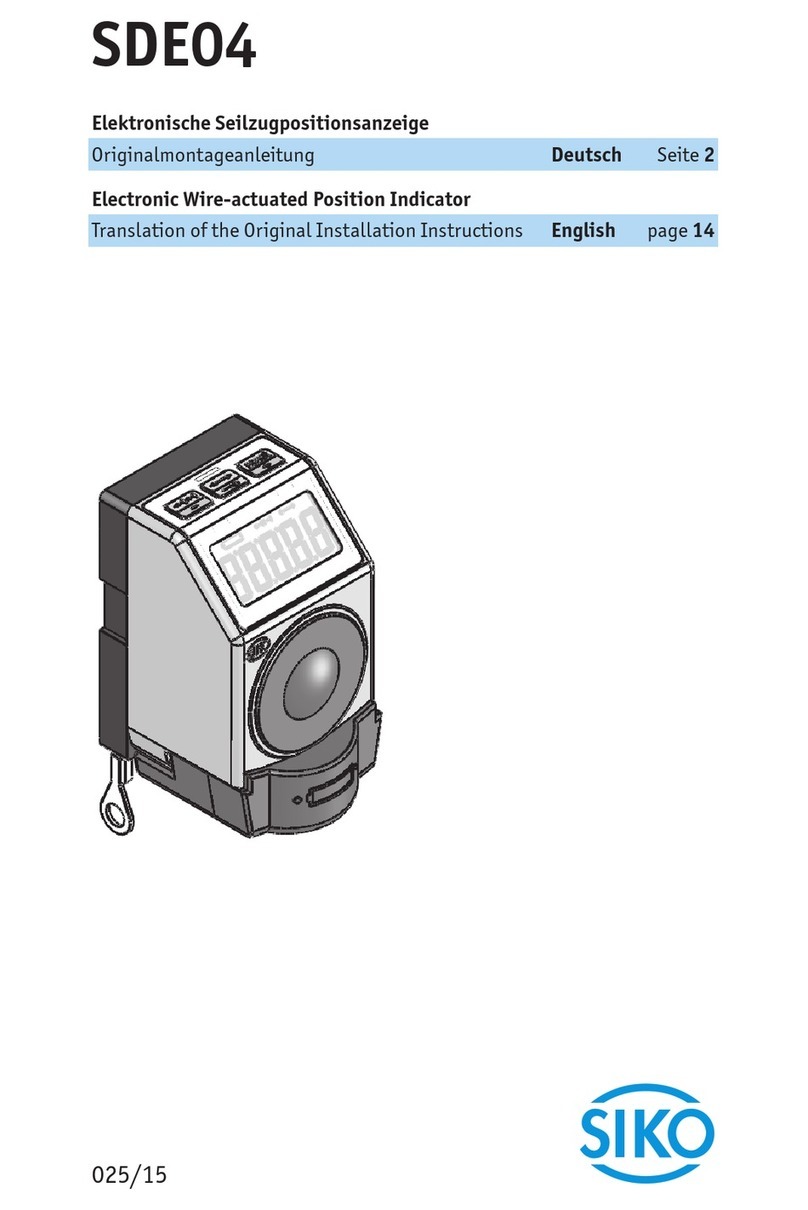

3.1.1.2 Loop positioning

Target window is also applied to the loop length.

The behavior of the clearance compensation is independent of the set

counting direction of the display. The loop type must be changed to change

the clearance compensation.

If the position indicator is operated on a spindle or an additional gear, the spindle or external

gear backlash can be compensated by means of loop positioning. Therefore, movement

towards the target value is always in the same direction. This direction of approach can be

defined.

Since both linear magnet sensors are used with the AP10S, a clockwise direction of rotation

must be equated with a positive travel path.

Example:

Each target position should be approached with a clockwise rotation (CW) of the shaft.

The parameter LoopType = 1 (POS) is set for this.

Case 1 the new position is greater than actual value:

The target position is approached directly clockwise (CW).

Case 2 the new position is smaller than actual value:

The directional arrows of the position indicator indicate that the LoopLength is to be

moved counterclockwise (CCW) beyond the target position. The target value is then

approached clockwise, i. e. in positive direction.

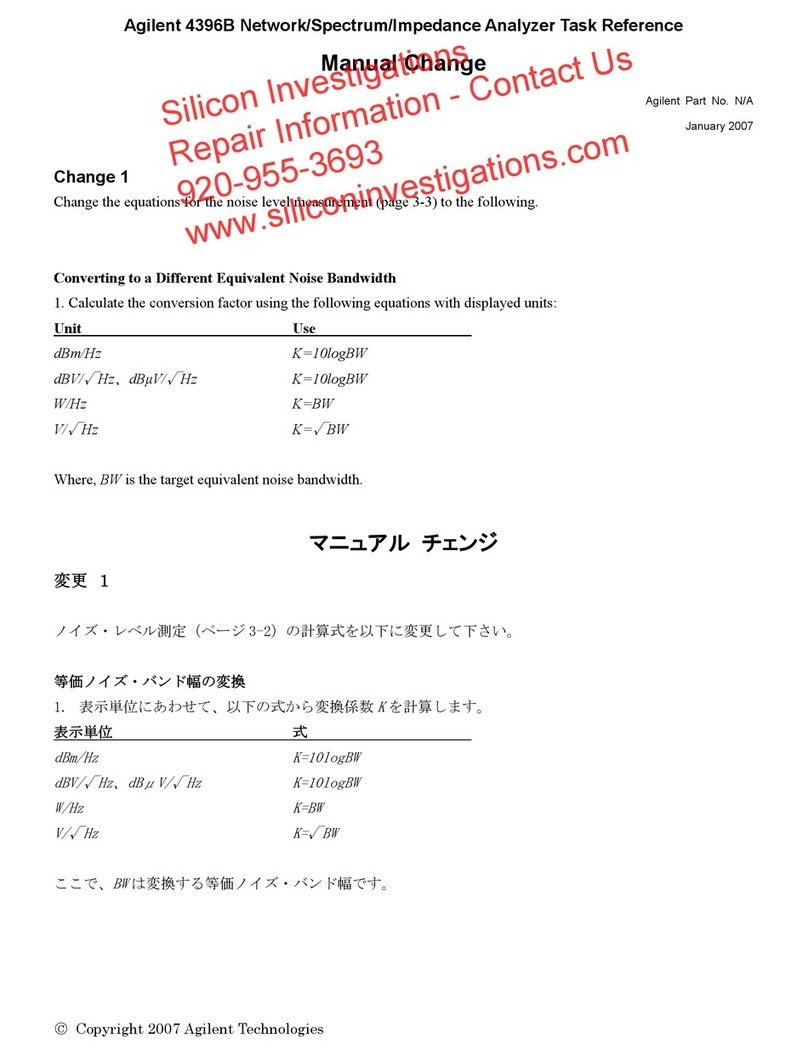

Fig. 4: Positioning loop

POS

3.1.1.3 ControlWord in Absolute Position operating mode

The ControlWord differs in function depending on operating mode.

The designation of the individual bits of the ControlWord as well as their meaning:

Bit

Meaning

Value = 0

Value = 1

0

bc00_CalibrationExecute

-

Trigger calibration (edge

controlled, positive)

1

bc01_Reserved

ever 0

-

Target value

CW

positive

CCW

negative

Clockwise

positioning (POS)

Counterclockwise

positioning (NEG)

Positioning: loop POS

Loop length

Target window

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 11 of 44

Bit

Meaning

Value = 0

Value = 1

2

bc02_Reserved

ever 0

-

3

bc03_DisplayRange

Normal display area

Extended display area

4

bc04_GuardingBit

is mirrored in

StatusWord

is mirrored in

StatusWord

5

bc05_ErrorAck

-

Acknowledge error

6

bc06_Reserved

ever 0

-

7

bc07_Reserved

ever 0

-

8

bc08_Reserved

ever 0

-

9

bc09_TargetValueActive

-

Activate target value

10

bc10_Reserved

ever 0

-

11

bc11_Led1Green

Release via LED

parameters

required

Deactivate LED

Activate LED

12

bc12_Led1Red

Deactivate LED

Activate LED

13

bc13_Led2Green

Deactivate LED

Activate LED

14

bc14_Led2Red

Deactivate LED

Activate LED

15

bc15_LedBlinking

Deactivate LED

Activate LED

Table 3: ControlWord in Absolute Position operating mode

3.1.1.4 StatusWord in Absolute Position operating mode

The Status Word shows the current status of the AP10S.

The designation of the individual bits of the StatusWord as well as their meaning:

Bit

Meaning

Value = 0

Value = 1

0

bs00_DirIndicationCW

Target value can be

reached counterclockwise

or in negative direction

Target value can be

reached clockwise or in

positive direction

1

bs01_DirIndicationCCW

Target value can be

reached clockwise or in

positive direction

Target value can be

reached counterclockwise

or in negative direction

2

bs02_CalibrationExecuted

No calibration is currently

being carried out

A calibration is currently

being carried out

3

bs03_Reserved

ever 0

-

4

bs04_GuardingBit

mirrored from ControlWord

mirrored from ControlWord

5

bs05_TargetWindowReached

Target window is not

reached

Target window is reached

6

bs06_Deviation

Deviation

Actual value <= target

value

Deviation

Actual value > target value

7

bs07_GeneralError

No error

There is an error

8

bs08_Reserved

ever 0

-

9

bs09_IncMeasurement

Increment measurement is

deactivated

Increment measurement is

activated

10

bs10_TargetValueState

Target value is not

activated

Target value is activated

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 12 of 44

Bit

Meaning

Value = 0

Value = 1

11

bs11_BatteryState

Battery

Charging state is OK

Battery

Charging state is critical

12

bs12_SensorError

There is no SensorError

There is a SensorError

13

bs13_KeyConfiguration

Button is not pressed

Button is pressed

14

bs14_KeyCalibration

Button is not pressed

Button is pressed

15

bs15_KeyIncremental

Button is not pressed

Button is pressed

Table 4: StatusWord in Absolute Position operating mode

3.1.2 Alpha-numeric display operating mode

Two 6-digit target values can be displayed in this operating mode. The target values are

acknowledged by pressing the button (see chapter 2.3).

Alpha-numeric display:

Both lines are freely writable. The content of the display line can be transmitted via the

DisplayData parameter, and the content of the display line can be transmitted via the

TargetValue parameter. In ControlWord, the values must be switched to valid (see e. g.

bc09_TargetValueActive) and the bits for data identification must be set correctly (see e. g.

bc07_TargetValueTypeSelect). The data identifier is used to distinguish whether the data is

interpreted and displayed as a number or as an alphanumeric character (ASCII)

(see chapter 4.1.1, 4.1.3 and 4.1.5).

LCD display:

If there is no valid target value, the 1st display line is displayed blank. "----" appears in

the 2nd display line.

A valid target value is displayed flashing until its receipt is acknowledged. If neither target

value has been acknowledged, both values are acknowledged jointly by pressing the key.

Acknowledgment can also take place via the corresponding control bit via the interface.

LED display:

Status LED1 and LED2:

With factory settings, the LED display (LED1, LED2) works according to the following table.

Operating state

State

Meaning

There is no valid target value.

Both LEDs off

There is a valid target value.

LED1 red

Display data not acknowledged

LED1 green

Display data acknowledged

LED2 red

Target value not acknowledged

LED2 green

Target value acknowledged

Table 5: Status LED display in the alpha-numeric display operating mode

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 13 of 44

3.1.2.1 ControlWord: Alpha-numeric display

The ControlWord differs in function depending on operating mode.

The designation of the individual bits of the ControlWord as well as their meaning:

Bit

Meaning

Value = 0

Value = 1

0

bc00_Reserved

ever 0

-

1

bc01_Reserved

ever 0

-

2

bc02_DisplayDataActive (display

line 1)

-

Activate upper line

display

3

bc03_DisplayRange

Normal display area

Extended display area

4

bc04_GuardingBit

is mirrored in

StatusWord

is mirrored in

StatusWord

5

bc05_ErrorAck

-

Acknowledge error

6

bc06_TargetValueAckMode (display

line 2)

Manually acknowledge

target value

Acknowledge target

value

7

bc07_TargetValueTypeSelect

(display line 2)

Interpret target value as

a number

Interpret target value as

ASCII character

8

bc08_DisplayDataTypeSelect

(display line 1)

Interpret display data as

a number

Interpret display data as

ASCII character

9

bc09_TargetValueActive (display

line 2)

-

Activate bottom line

display

10

bc10_DisplayDataAckMode (display

line 1)

Manually acknowledge

target value

Acknowledge target

value

11

bc11_Led1Green

Release via LED

parameters

required

Deactivate LED

Activate LED

12

bc12_Led1Red

Deactivate LED

Activate LED

13

bc13_Led2Green

Deactivate LED

Activate LED

14

bc14_Led2Red

Deactivate LED

Activate LED

15

bc15_LedBlinking

Deactivate LED

Activate LED

Table 6: ControlWord alpha-numeric display operating mode

3.1.2.2 StatusWord: Alpha-numeric display

The Status Word shows the current status of the AP10S.

The designation of the individual bits of the StatusWord as well as their meaning:

Bit

Meaning

Value = 0

Value = 1

0

bs00_Reserved

ever 0

-

1

bs01_Reserved

ever 0

-

2

bs02_DisplayDataActive

(display line 1)

DisplayData is not

activated

DisplayData is activated

3

bs03_TargetValueAck

(display line 2)

Target value not

acknowledged

Target value acknowledged

4

bs04_GuardingBit

mirrored from ControlWord

mirrored from ControlWord

5

bs05_DisplayDataAck

(display line 1)

DisplayData not

acknowledged

DisplayData acknowledged

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 14 of 44

Bit

Meaning

Value = 0

Value = 1

6

bs06_Reserved

ever 0

-

7

bs07_GeneralError

No error

An error exists

8

bs08_DisplayDataType

(display line 1)

DisplayData are interpreted

as a number

DisplayData are interpreted

as an ASCII character

9

bs09_TargetValueType

(display line 2)

Target value is interpreted

as a number

Target value is interpreted

as an ASCII character

10

bs10_TargetValueState

(display line 2)

Target value is not

activated

Target value is activated

11

bs11_BatteryState

Battery

Charging state is OK

Battery

Charging state is critical

12

bs12_SensorError

There is no SensorError

There is a SensorError

13

bs13_KeyConfiguration

Button is not pressed

Button is pressed

14

bs14_KeyCalibration

Button is not pressed

Button is pressed

15

bs15_KeyIncremental

Button is not pressed

Button is pressed

Table 7: StatusWord alpha-numeric display operating mode

3.2 Battery buffering

Without an external power supply, encoder changes are recorded with battery support.

Depending on the duration of battery operation (including storage) and the frequency of

adjustments without an external power supply, the battery life is approximately 8 years.

Battery voltage is checked at intervals of approx. 10 min. If battery voltage drops below a

specified value, the battery symbol will blink on the display. If the battery voltage

continues to drop, will be displayed permanently. The battery should be replaced within

approx. three months after the first appearance of the battery symbol. For battery

replacement it is mandatory to follow the instructions of the installation instructions.

Replacement can also take place at the SIKO distribution partners or in the SIKO main plant.

Behavior of the StatusWord:

The charge status of the battery is signified in the StatusWord. In the case of a critical

charging voltage, bs11_BatteryState is set, and in the case of an empty or non-existing

battery, a fault is additionally signaled with bs07_GeneralError.

3.3 Parameterization of the position indicator

The position indicator can be fully parameterized via the IO-Link interface. All parameters can

also be set manually with the help of the keyboard.

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 15 of 44

3.3.1 Manual parameterization

3.3.1.1 Starting parameterization

The time until menu release is displayed when the button is pressed. Parameterization

starts if it is actuated for the duration of the enable time (see chapter 2.3 and 4.5.2).

3.3.1.2 Value input

When you enter values via the keys, the display range is limited to -199999

… 999999. If values beyond this range are entered via the interface,

"FULL" will be displayed when the parameter is called up.

Enter values via the key and the key.

Confirm values entered by pressing the key.

- decimal place selection key

- value input key

3.3.1.3 Value selection

For some parameters you can select values from a list. Direct value input is not possible there.

Pressing the key, the value can be selected from the list. By pressing the key, the

selection is confirmed.

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 16 of 44

3.3.1.4 Overview of the operating menu

Start

KeyEnableTime

expired?

Changeable parameter

chPARA

Read-only device data

RdONLY

End

yes

PIN correct? yes

PIN entry

required

Quit

>QUIT<

nein

On the Display:

Countdown

KeyEnableTime

CONFIG

5

“Changeable

parameters“ menu

Device data

Hold down the key

Fig. 5: Menu selection

3.3.1.5 "Changeable parameters" menu

The "Changeable parameters" menu is structured as follows:

Description

Display

Page

Positioning

POSI

17

Visualization

VISUAL

17

LED function

LEDS

17

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 17 of 44

Description

Display

Page

Device options

OPTION

18

Table 8: "Changeable parameters" menu structure

3.3.1.6 Positioning

The following parameters can be set in the "Positioning" menu:

Description

Display

Chapter

Resolution

RESOL

4.2.1

DecimalPlaces

DEC PL

4.2.2

DisplayDivisor

DISDIV

4.2.3

CountingDirection

CntDIR

4.2.4

CalibrationValue

CALVAL

4.2.5

Calibration

selection

CALVAL

YES

No

3.4

TargetWindow

TW

4.2.6

LoopType

LOOP

4.2.7

LoopLength

LOOP L

4.2.8

Table 9: "Positioning" menu

3.3.1.7 Visualization

The following parameters can be set in the "Visualization" menu:

Description

Display

Chapter

DisplayOrientation

DISPL

4.3.1

Table 10: "Visualization" menu

3.3.1.8 LED function

The following parameters can be set in the "LED function" menu:

Description

Display

Chapter

Led1GreenMode

LED1GN

4.4.2

Led2GreenMode

LED2GN

4.4.3

Led1RedMode

LED1RD

4.4.4

Led2RedMode

LED2RD

4.4.5

ActiveLedsFlashing

LED FL

4.4.6

Table 11: "LED function" menu

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 18 of 44

3.3.1.9 Device options

The following parameters can be set in the "Additional device options" menu:

Description

Display

Chapter

SensorType

SENSOR

4.5.1

KeyEnableTime

K TIME

4.5.2

KeyCalibration

K CAL

4.5.3

KeyIncremental

K INC

4.5.4

OperatingMode

OPMODE

4.5.5

PINChange

PIN

4.5.6

LoadDefault

LOAD P

4.5.7

CODE

CODE

4.5.8

Table 12: "Additional device options" menu

3.3.2 Parameterization via interface

The position indicator can be completely parameterized in the IO-Link interface

(see chapter 5.2).

3.4 Calibration

Calibration is only possible if the chain dimension is not active and the

actual value is not 0.

Two steps are required for executing calibration:

Write calibration value: Parameter CalibrationValue (see chapter 4.2.5).

Execute calibration (using operating keys, see chapter 2.3 or SystemCommand

see chapter 5.3 or ControlWord see chapter 5.1.1.1).

Since the measuring system is an absolute system, calibration is necessary only once with

commissioning. With calibration, the CalibrationValue is adopted for calculation of the actual

value. The following equation is applied in case (time) of calibration:

Actual value = ActualValue = 0 + CalibrationValue

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 19 of 44

3.5 Sensor

Alignment travel is required if a new sensor is connected (see chapter 3.6).

Mounting of the sensors as well as installation of the sensor cable is explained in the

documentation pertaining to the sensor MS500H or GS04. With 24 V supply voltage operation

the display controls the connected sensor. If no sensor is connected or if the sensor is lifted

from the tape (MS500H), an error will be detected and the position value displayed red with

flashing "Error". This status persists even with power supply failure. The error must be

corrected after checking the sensor connection or sensor position with calibration

(see chapter 2.3 and chapter 3.4). If both battery supply and power supply fail simultaneously

(e. g. during a battery change), the absolute position value can get lost. For making the

measuring system work again, calibration is required (see also chapter 3.8 and 3.4).

3.6 Alignment travel

The AP10S is fully functional as delivered. To adjust the display to the connected sensor and

to achieve optimum measuring accuracy, alignment travel must be carried out whenever a

new/different sensor is connected to the AP10S. A safe sensor error detection is also only

possible after a alignment travel has been carried out.

For calibration, the sensor must have been mounted correctly (see documentation MS500H or

GS04).

1. By entering CODE 000100, AP10S is set to the alignment mode (see chapter 3.3.1.9).

Display: 1st line "ADJUST"

2nd line "100" this value may vary by ±1.

2. When connecting sensor MS500H, it must be moved by a few millimeters in the direction

of the cable outlet (speed <1 cm/s).

When connecting sensor GS04, the shaft must be rotated clockwise by a few millimeters

(speed <<1 U/min).

In the lower line, the value will change in positive direction up to "103".

3. The alignment process will be completed when this value is finally exceeded. AP10S has

returned to normal operation and shows the corresponding display. If values above

"103" are displayed during alignment, then travel speed must be slowed down during

alignment.

It is not unusual that the position value cannot be displayed immediately after alignment

travel and "FULL" is displayed instead of the value. The display should be calibrated in this

case (see chapter 3.4).

3.7 Additional functions

3.7.1 Device data

The following values can be read in the "Read Only" menu:

Description

Display

Chapter

Voltage of Battery

UBATT

Actual CalibrationValue

CAL.ACT

4.2.5

Functional Description

AP10S Date: 12.05.2020 Art. No. 90304 Mod. status 110/20 Page 20 of 44

Description

Display

Chapter

Firmware Revision

VERSoN

5.1.2

Table 13: "Device data" menu

3.7.2 Restore factory settings

There are various options for restoring the factory settings of the device:

Access

Coding

Factory settings are restored

Manual

CODE

(see chapter 4.5.8)

011100

all parameters

Load Default

(see chapter 4.5.7)

ALL

all parameters

Interface

SystemCommands

(see chapter 5.3)

130 (82h)

all parameters

Table 14: Access to factory settings

3.8 Warnings / Errors

3.8.1 Warnings

Warnings have no influence on the recording of the actual value.

Warnings are deleted after removing the cause.

Possible warnings:

Battery voltage for absolute position detection is below limit immediately exchange

battery!

This warning is displayed with a blinking battery symbol. Warning messages are output via

the interface via the StatusWord (see chapter 3.7).

Display

Bit assignment in the StatusWord

Error

flashing

bs11_BatteryState

Low battery voltage (critical)

PositionValue is still valid!

Table 15: Warnings

3.8.2 Errors

Calibration may also be required Depending on the error type.

Error states are signaled via display (written in red or battery symbol) and interface. The

cause of the fault can be determined using the event or error code (see chapter 5.5 and 5.6).

To return to normal operation, the cause must be removed (see Table 16). Error signaling can

then be acknowledged or deleted with the key (see chapter 2.3).

If calibration is required, this is indicated in the display as "CALIB". Independent of

acknowledgment of the error status.

Other manuals for AP10S

2

Table of contents

Other Siko Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ABB

ABB GAA330-M operating instructions

Agilent Technologies

Agilent Technologies Agilent 4396B manual

Projoy Electric

Projoy Electric PEEM-S100 user manual

Pentax

Pentax R-2500DN Series instruction manual

LumaSense technologies

LumaSense technologies INNOVA 1316A-1 instruction manual

anvajo

anvajo fluidlab R-300 user manual

Hanna Instruments

Hanna Instruments HI 8733 instruction manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 607A11-0011 Installation and operating manual

Leviton

Leviton 6F101 installation manual

HunterLab

HunterLab MiniScan EZ Supplemental manual

PCE Instruments

PCE Instruments PCE-T 240 user manual

LEGRAND

LEGRAND LG-41492 quick start guide