Table of Contents

1 Safety instructions......................................................................4

2 Registered trademarks.................................................................6

3 RF e posure information and statement.........................................7

4 Application.................................................................................8

5 Features....................................................................................8

6 Technical data.............................................................................9

6.1 General data.........................................................................9

6.2 Electrical data.......................................................................9

6.3 Data logger.........................................................................10

6.4 Output signals.....................................................................10

6.5 Accuracy of flow..................................................................10

6.6 Accuracy of pressure............................................................11

7 Dimensional drawing..................................................................11

8 Installation...............................................................................13

8.1 Installation Considerations....................................................13

8.2 LED indicators.....................................................................14

8.3 Electrical connection ..........................................................14

9 Sensor signal outputs................................................................16

9.1 Analog output.....................................................................16

9.2 Pulse output.......................................................................16

9.3 Modbus Interface.................................................................18

9.3.1 Modbus Information.......................................................18

9.3.2 Connect Several S418-V to Modbus Master.......................19

9.3.2.1 Modbus/RTU Cable Length.........................................19

9.3.2.2 Modbus/RTU Wiring and Cable Type............................19

9.3.2.3 Create Daisy-Chain using RS-485 Splitter....................20

9.3.2.4 Topology of Modbus/RTU Daisy-Chain.........................21

10 Configuration..........................................................................23

11 Read and analysis of measurement data.....................................24

11.1 Features...........................................................................24

11.2 Operations........................................................................25

11.2.1 Logger configuration.....................................................25

11.2.2 Data read-out and analysis............................................25

12 Calibration..............................................................................27

13 Disposal or waste....................................................................27

14 Appendi - Specifications..........................................................28

14.1 Vacuum flow ranges...........................................................28

14.2 Error codes.......................................................................29

14.3 Order table.......................................................................29

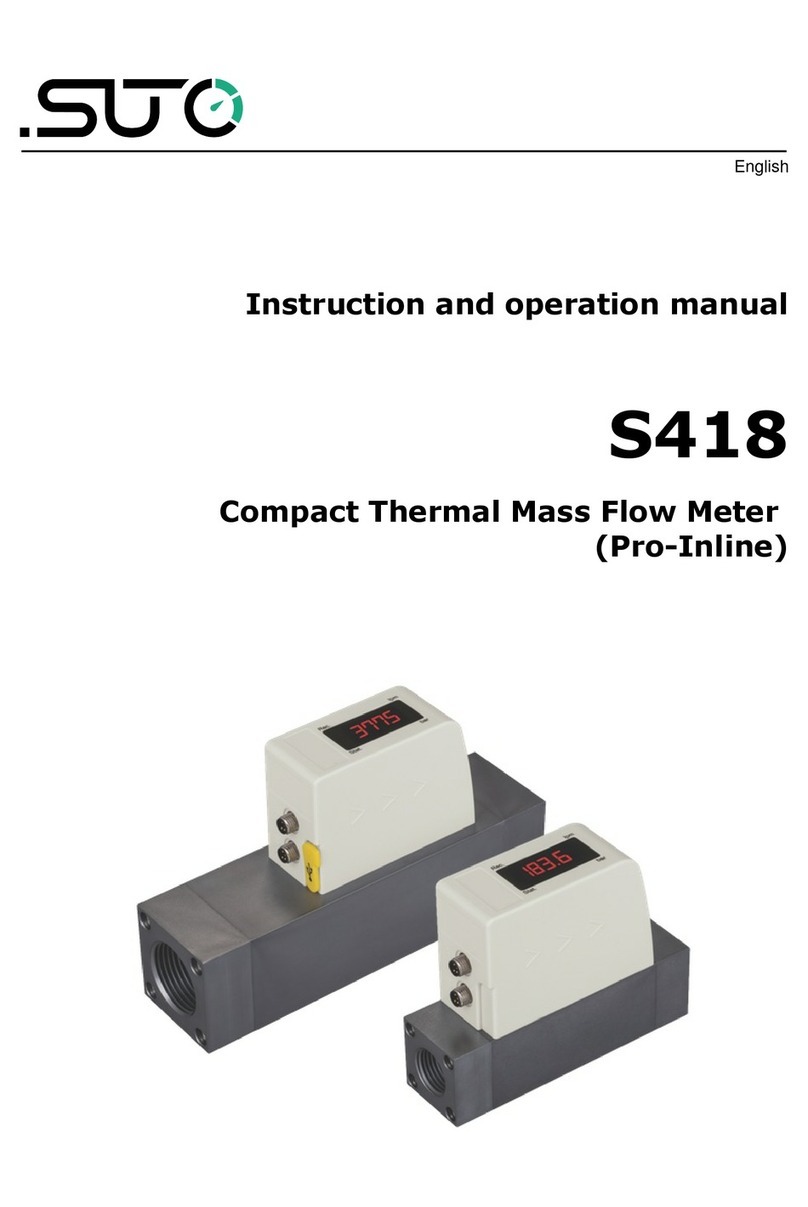

S418-V 3