Table o contents

1 Safety instructions......................................................................4

2 Registered trademarks.................................................................6

3 RF e posure information and statement.........................................7

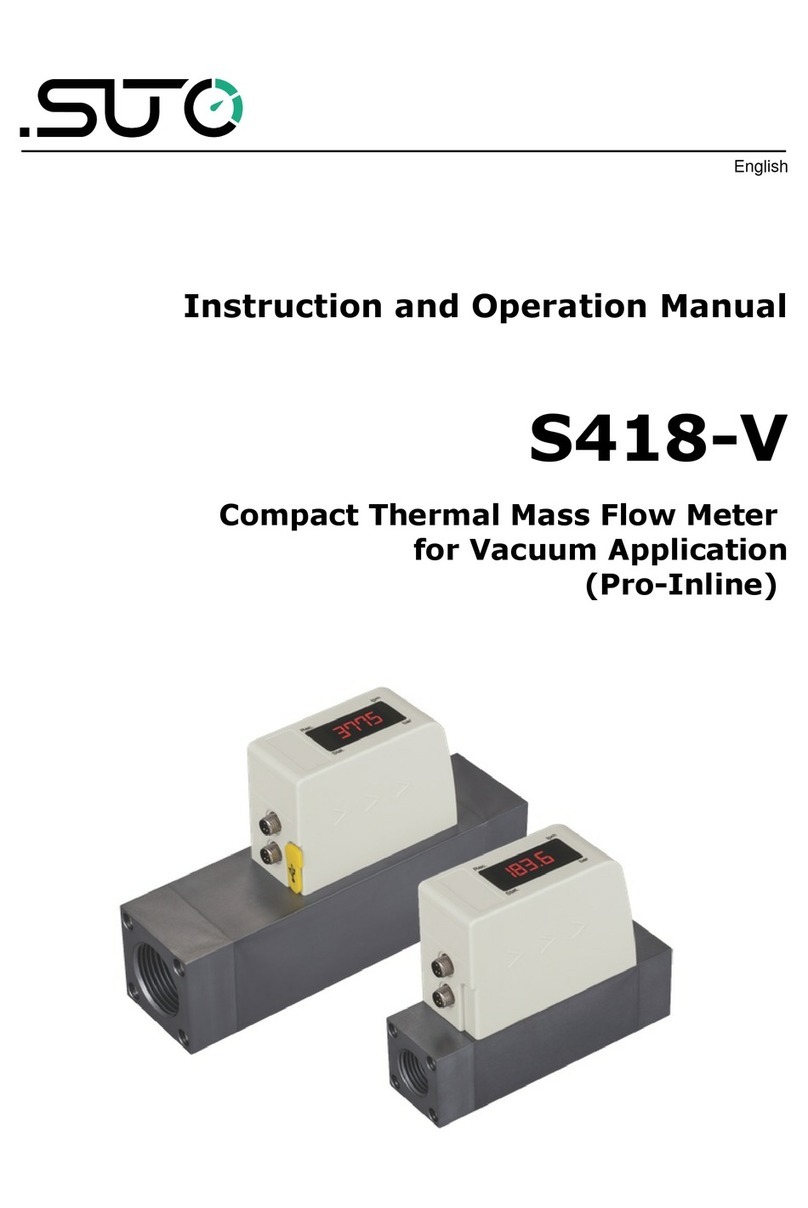

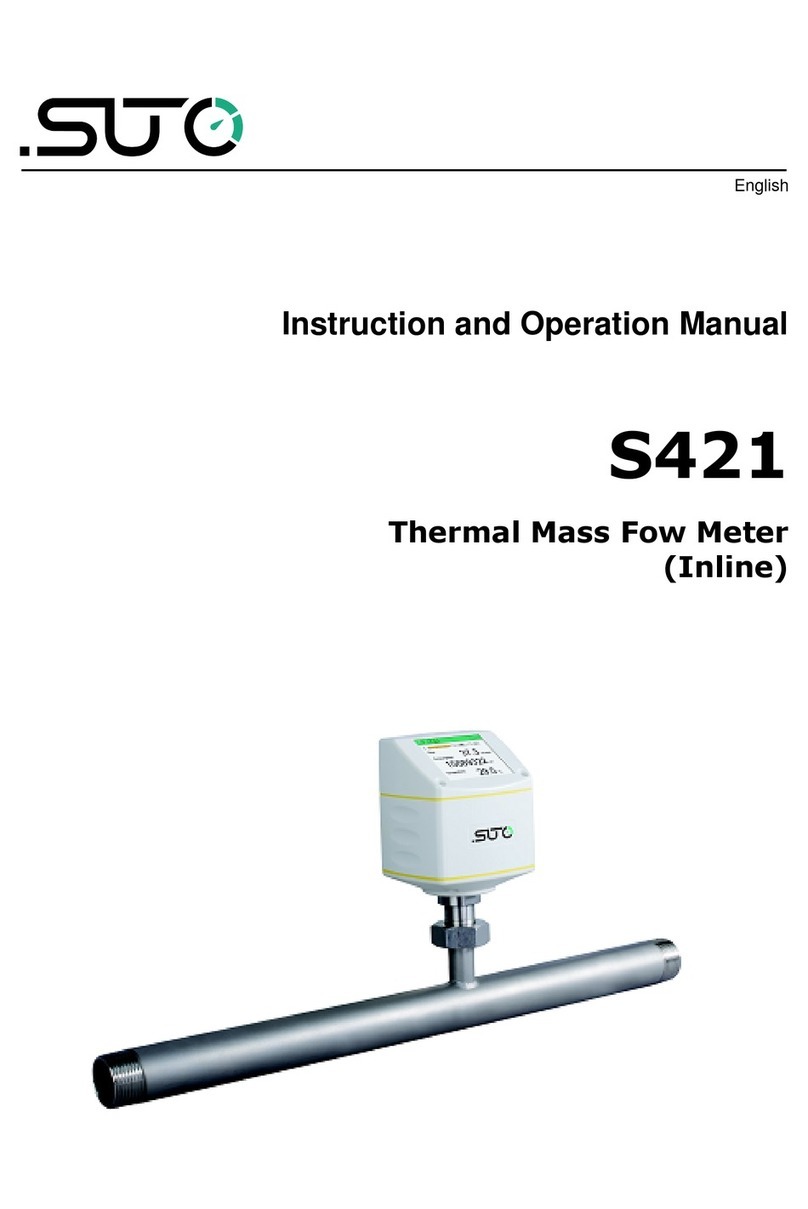

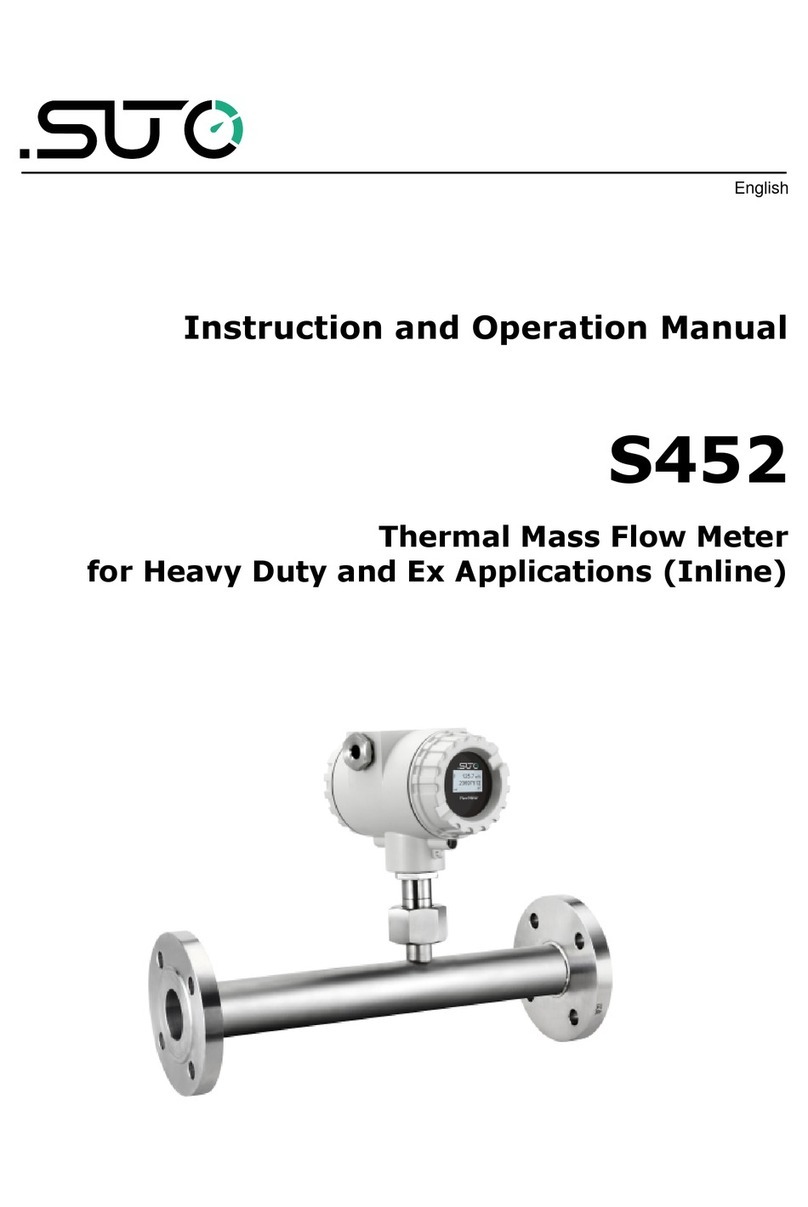

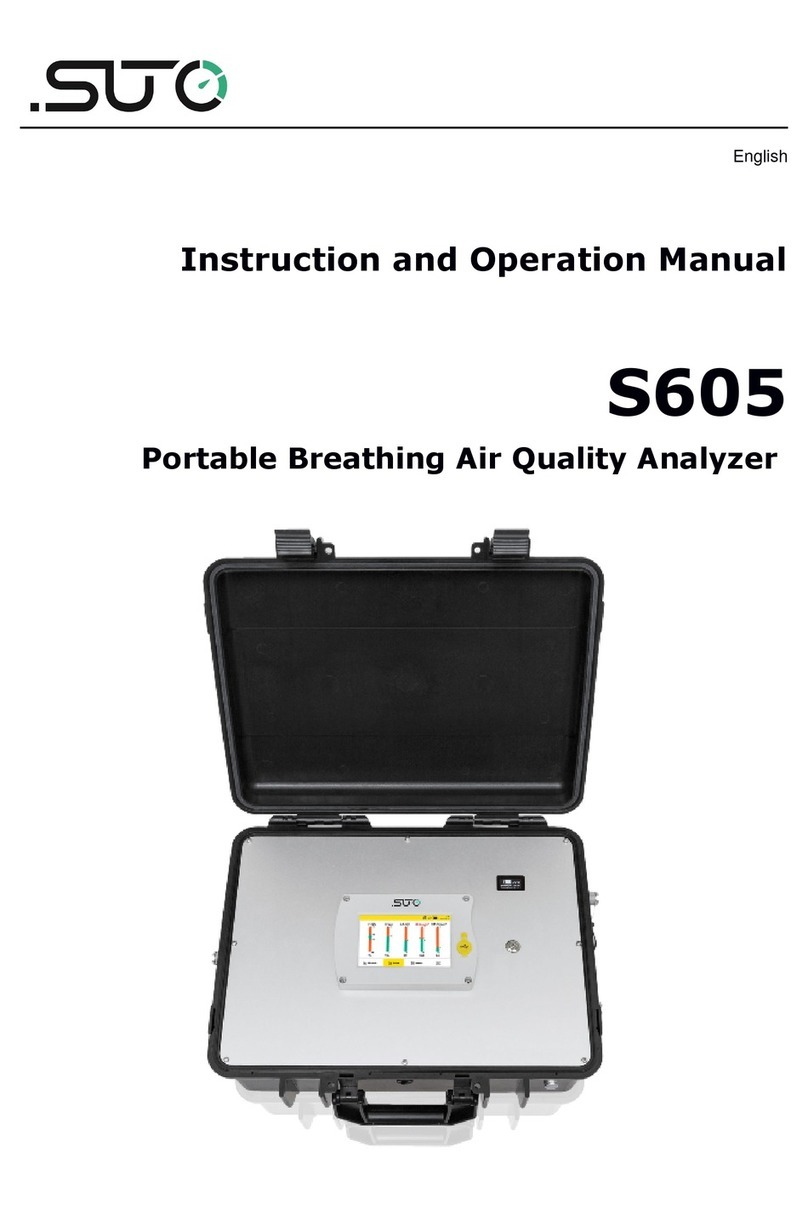

4 Application.................................................................................8

5 Features....................................................................................8

6 Technical data.............................................................................9

6.1 General data.........................................................................9

6.2 Signal / Interface and Supply................................................10

6.3 General data.......................................................................10

6.4 Flow ranges........................................................................12

7 Dimensional drawing..................................................................13

8 Installation...............................................................................14

8.1 Installation Options..............................................................14

8.2 Inlet and utlet sections ........................................................14

8.3 Welding Nipple and Welding Fi ture.......................................16

8.4 Removing the sensor ..........................................................19

8.5 Performing the electrical connection.......................................20

9 Configuration............................................................................21

9.1 Registering.........................................................................21

9.2 Using Service App S4C-FS....................................................22

9.2.1 Flow Settings..............................................................23

9.2.2 Unit Settings...............................................................24

9.2.3 Calibration..................................................................25

9.2.4 Uploading Settings......................................................26

9.2.5 Downloading Settings..................................................26

10 Signal outputs.........................................................................27

10.1 Analog output...................................................................27

10.2 Pulse output......................................................................27

10.2.1 Pulse connection diagram...........................................29

10.3 Modbus output .................................................................30

11 Maintenance...........................................................................32

12 Disposal or waste....................................................................32

S431 OEM 3