Table of contents

1. Safety instructions.......................................................................4

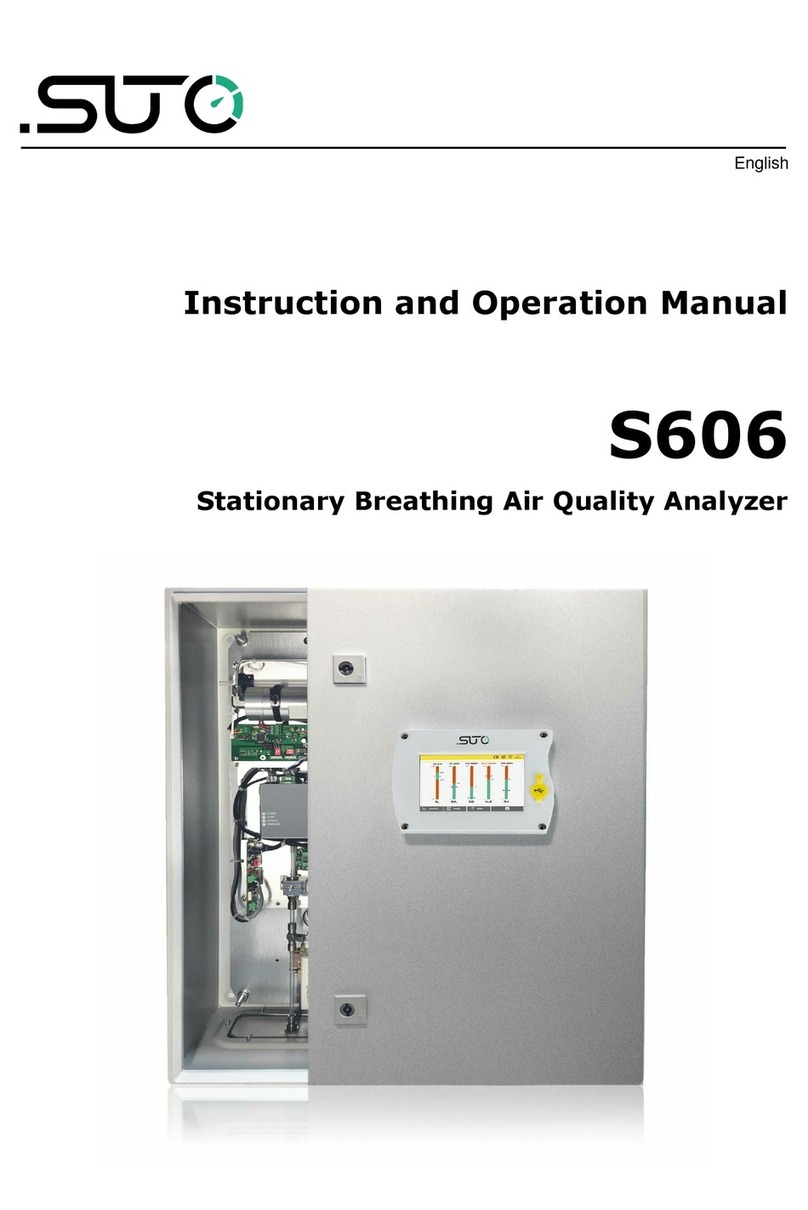

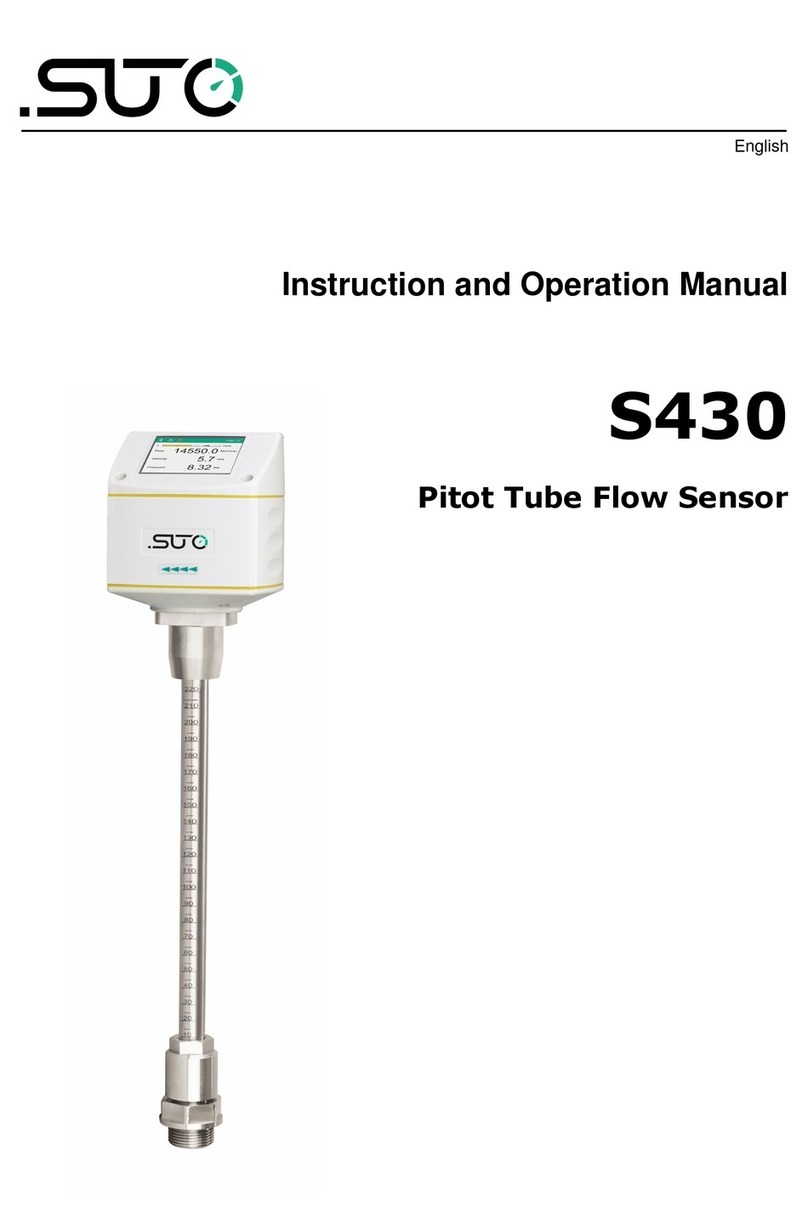

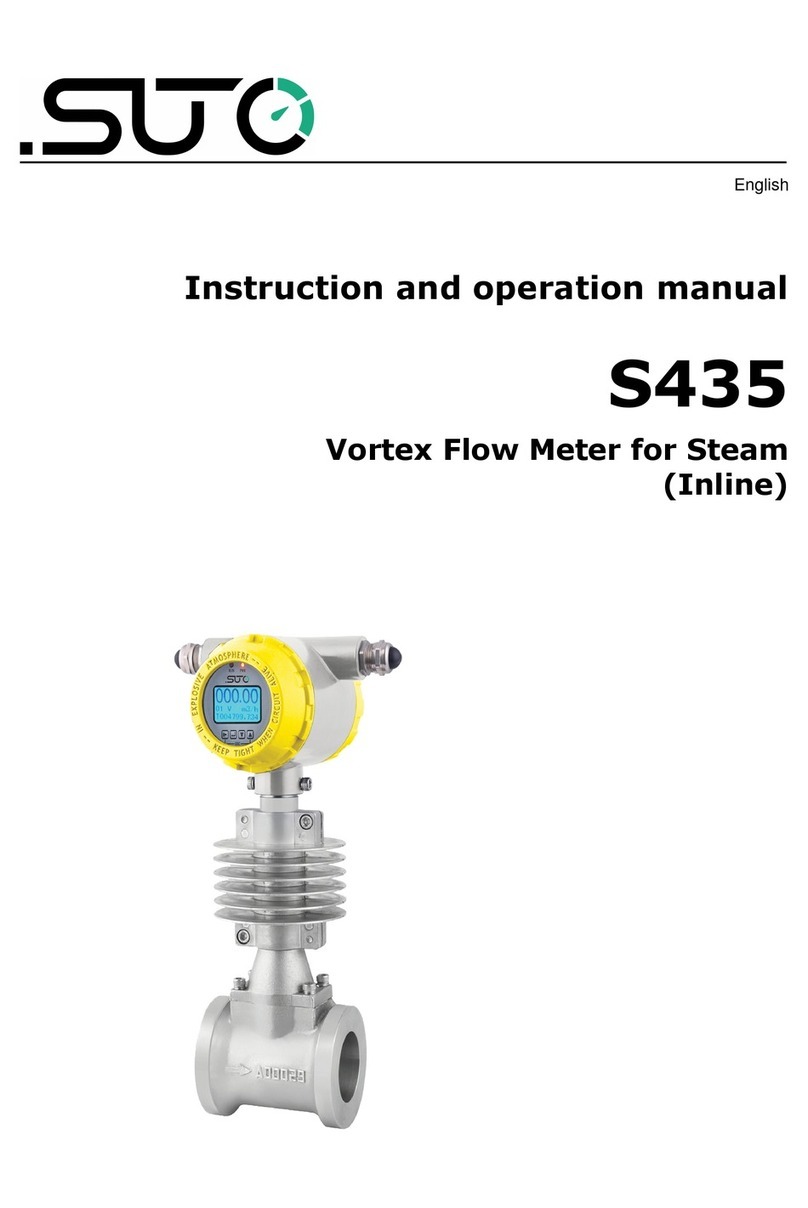

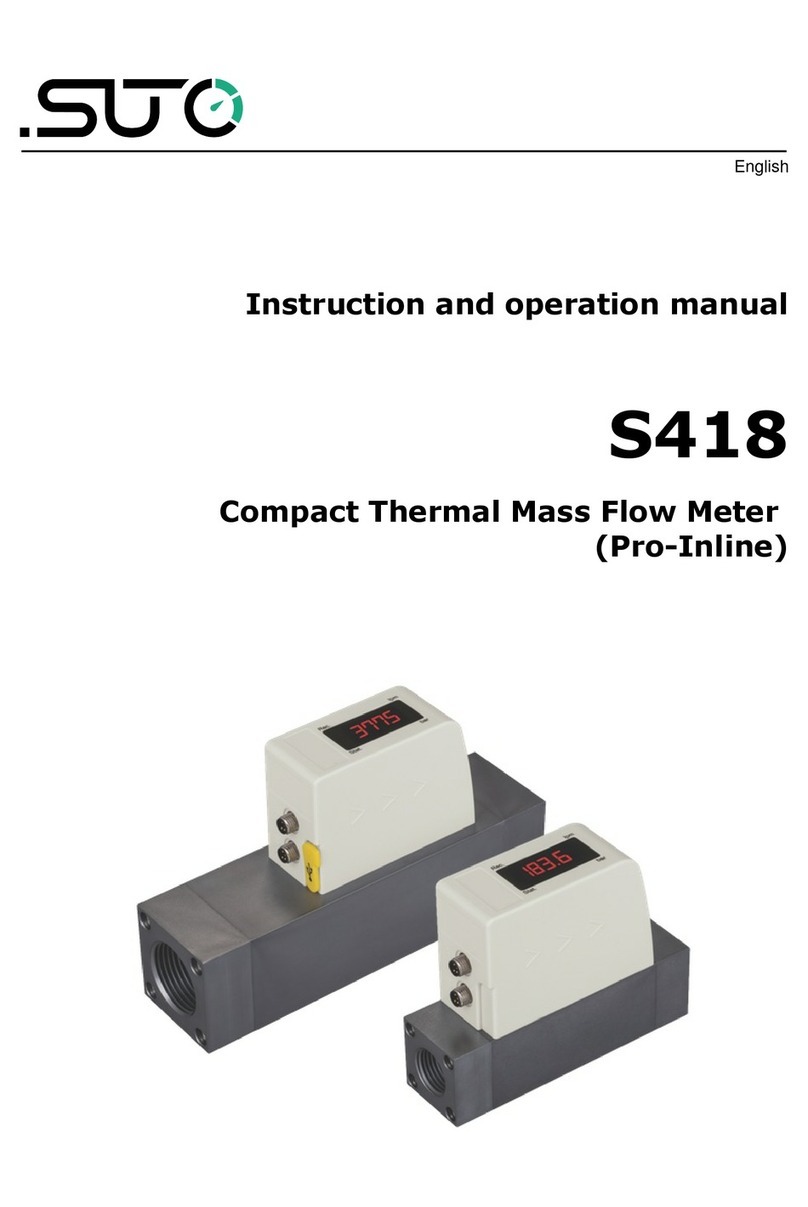

2. Application.................................................................................8

3. Features.....................................................................................8

4. Technical Data............................................................................9

4.1 General.................................................................................9

4.2 Electrical data .....................................................................10

4.3 Accuracy..............................................................................10

5. Dimensions...............................................................................11

6. Installation on site.....................................................................14

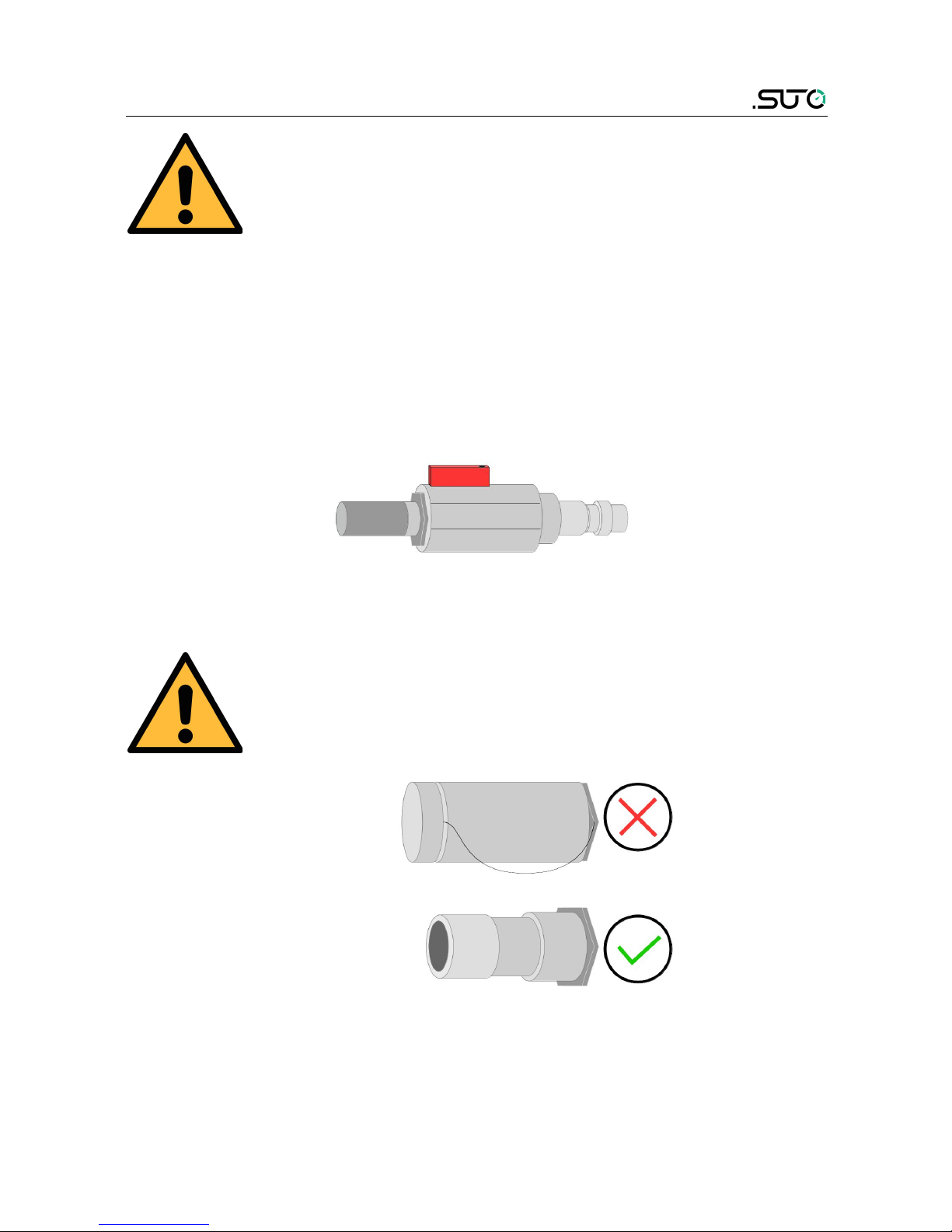

6.1 Installation requirements.......................................................14

6.2 Connecting the isokinetic sampling device to the S 600 analyzer

(Option)....................................................................................17

6.3 sing the S 600 without the isokinetic sampling device..............19

6.4 Electrical connections on the S 600.........................................19

6.5 Compressed air connections (In and outlet).............................20

7. Setup and configuration.............................................................21

8. Operation.................................................................................22

8.1 Value screen........................................................................23

8.2 The menu............................................................................24

8.3 Symbol description in the status bar........................................24

8.4 Graphic view........................................................................25

8.6 Files....................................................................................25

8.7 Service Info ........................................................................26

8.8 System Setting.....................................................................26

8.9 Report menu........................................................................27

9. Guided measurement.................................................................28

9.1 Guided measurement............................................................29

10. Optional accessories.................................................................34

11. Maintenance............................................................................34

12. Disposal or waste.....................................................................34

13. Warranty................................................................................35

S 600 3