Table of Contents

1 Safety instructions......................................................................4

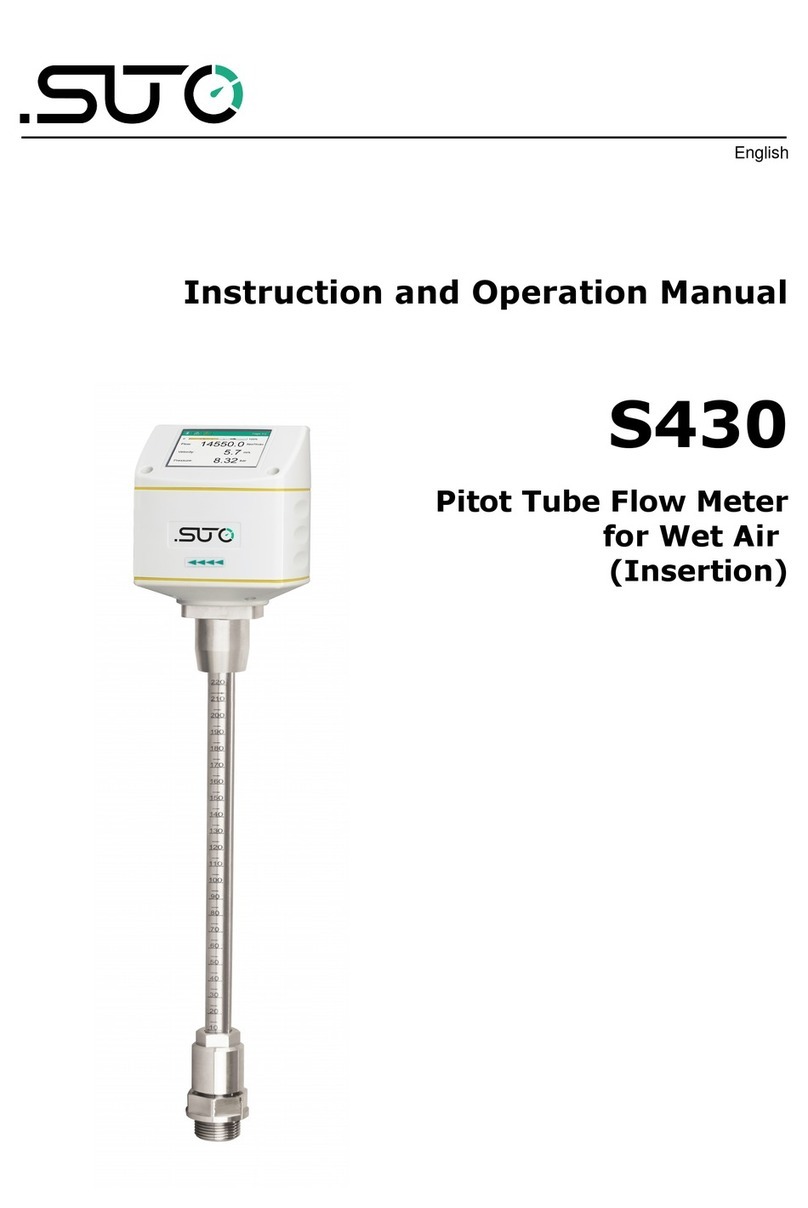

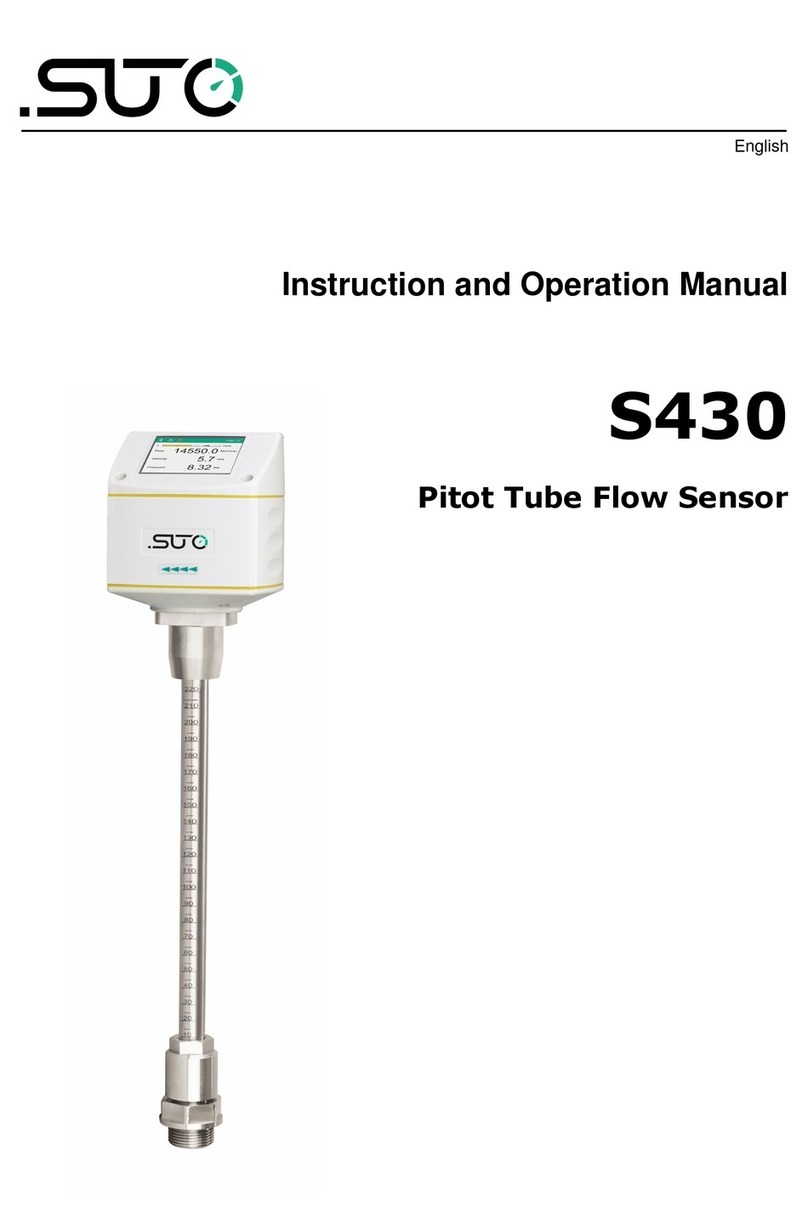

2 Applications................................................................................6

3 Features....................................................................................6

4 Technical Data............................................................................7

4.1 General......................................................................................7

4.2 Electrical Data.............................................................................7

4.3 Output-Signals............................................................................7

4.4 Accuracy ...................................................................................7

5 Determination of installation point.................................................8

6 Installation...............................................................................10

6.1 Configuration.............................................................................10

6.1.1 Usage of keypad ..................................................................10

6.1.2 Configuring the transducer parameters ...................................11

6.1.3 Description for the parameter settings ....................................11

6.2 Installation procedure ................................................................12

6.2.1 Installing the transducers.......................................................12

6.2.2 Removing a transducer..........................................................14

6.2.3 Installing the housing (Optional).............................................14

6.3 Electrical connection .................................................................14

6.4 Final check................................................................................15

7 Troubleshooting........................................................................16

7.1 Power-on errors and countermeasures..........................................16

7.2 Error codes and countermeasures.................................................16

7.3 Other problems and solutions......................................................18

8 Signal outputs..........................................................................19

8.1 Analog / Pulse output ................................................................19

8.2 Interface ..................................................................................19

9 Calibration................................................................................19

10 Maintenance...........................................................................20

11 Disposal or waste....................................................................20

12 Warranty................................................................................20

S 460 3