Table of contents

1 Safety instructions......................................................................5

2 Registered trademarks.................................................................7

3 RF e posure information and statement.........................................8

4 Application.................................................................................9

5 Features...................................................................................10

6 Technical data...........................................................................11

6.1 General data.......................................................................11

6.2 Electrical data.....................................................................12

6.3 Output signals.....................................................................12

6.4 Accuracy ...........................................................................13

7 Dimensional drawing..................................................................15

8 Installation...............................................................................16

8.1 Installation requirements......................................................16

8.2 Determining the installation point..........................................17

8.2.1 Inlet and outlet sections...............................................17

8.2.2 Insertion angles..........................................................19

8.3 Calculating the insertion depth..............................................20

8.3.1 Center installation.......................................................21

8.3.2 100 mm-depth installation............................................22

8.4 Installing the sensor............................................................23

8.5 Performing the zero flow calibration.......................................24

8.5.1 Prerequisites...............................................................24

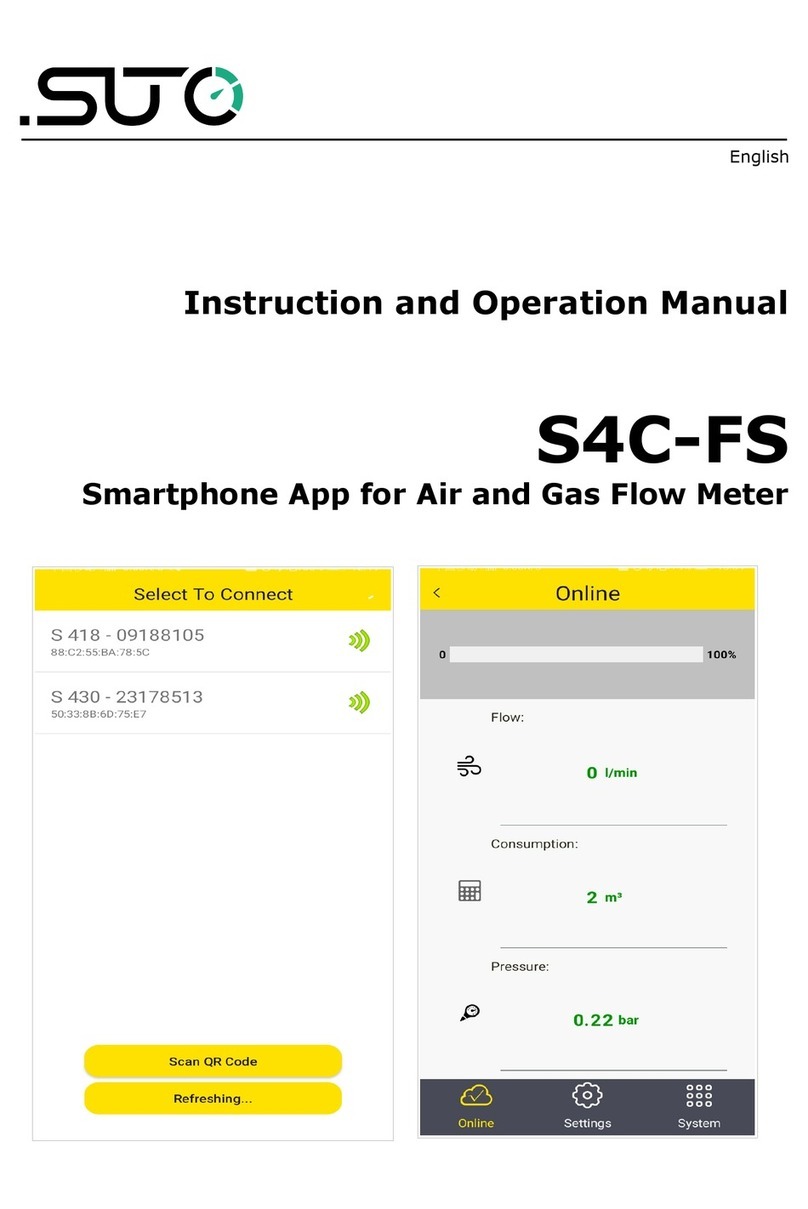

8.5.2 Using the service App S4C-FS.......................................25

8.5.3 Using the local display.................................................26

8.6 Removing the sensor ..........................................................27

8.7 Making electrical connection..................................................27

8.7.1 M12 connector plugs ...................................................28

8.7.2 Ethernet connection.....................................................29

9 Configuration............................................................................31

9.1 Description of sensor settings...............................................31

9.1.1 Flow settings..............................................................31

9.1.2 Unit settings...............................................................31

9.1.3 Reference conditions....................................................31

9.1.4 Factory settings..........................................................32

9.1.5 Output settings...........................................................32

9.1.6 Language setting.........................................................32

9.2 Configuration using the service App S4C-FS............................32

9.3 Configuration using the optional sensor display.......................33

9.3.1 Starting process..........................................................33

9.3.2 About the home page..................................................33

9.3.3 Configuration instructions.............................................34

S430 3