tau D703 User manual

1

D703

GUIDA ALL’INSTALLAZIONE

INSTALLATION GUIDE

INSTALLATIONSANLEITUNG

NOTICE D’INSTALLATION

GUÍA PARA LA INSTALACIÓN

D703

Quadro di comando per motore monofase-trifase 230/400 Vac

Control panel for 230/400 Vac single/three-phase motor

Steuerplatine für einphasigen-dreiphasigen 230/400 Vac Motor

Logique de commande pour moteur monophase-triphase 230/400 Vca

Panel de mandos para motor monofásico-trifásico 230/400 Vca

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) Italia

Tel +39 0444 750190 - Fax +39 0444 750376

info@tauitalia.com - www.tauitalia.com

IT - Istruzioni originali

D-MNL0D703M 18-04-2014 - Rev.22

300

230

124

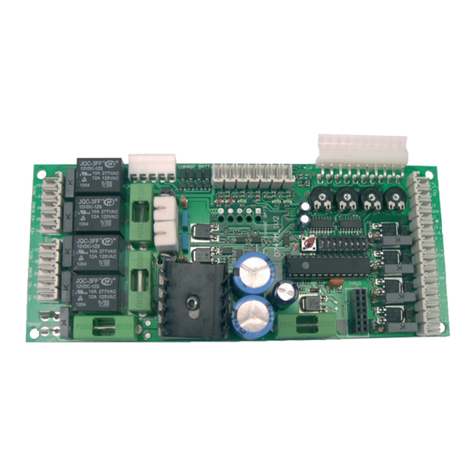

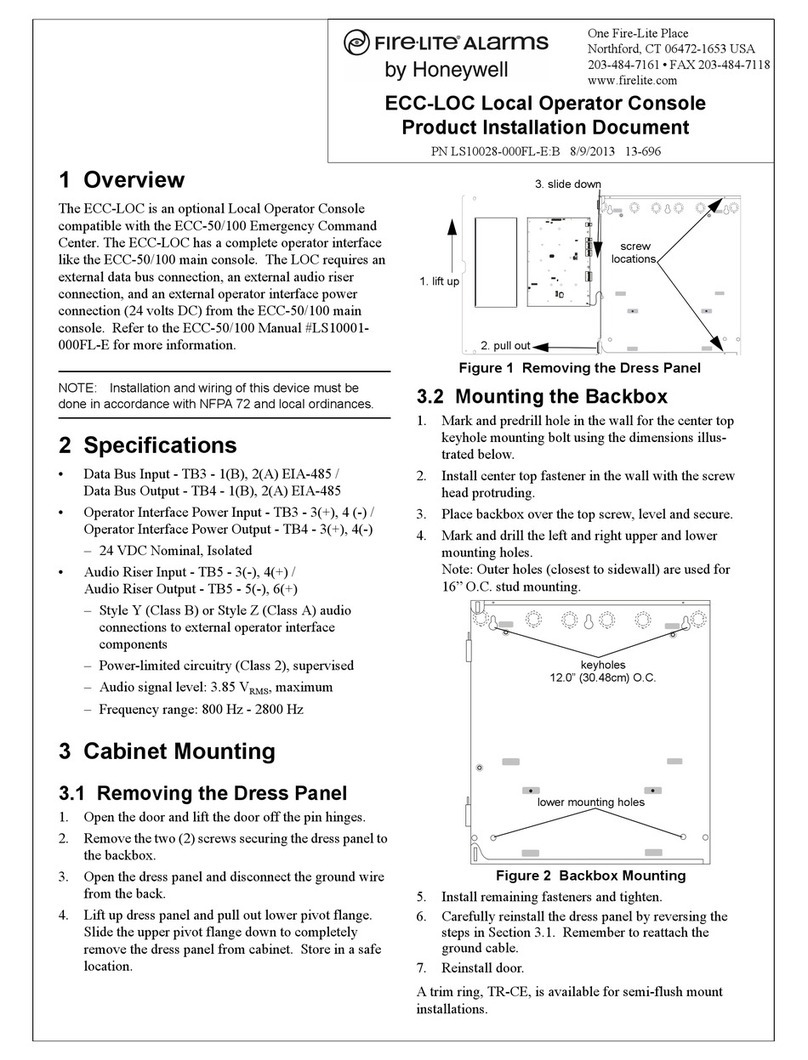

2

D703

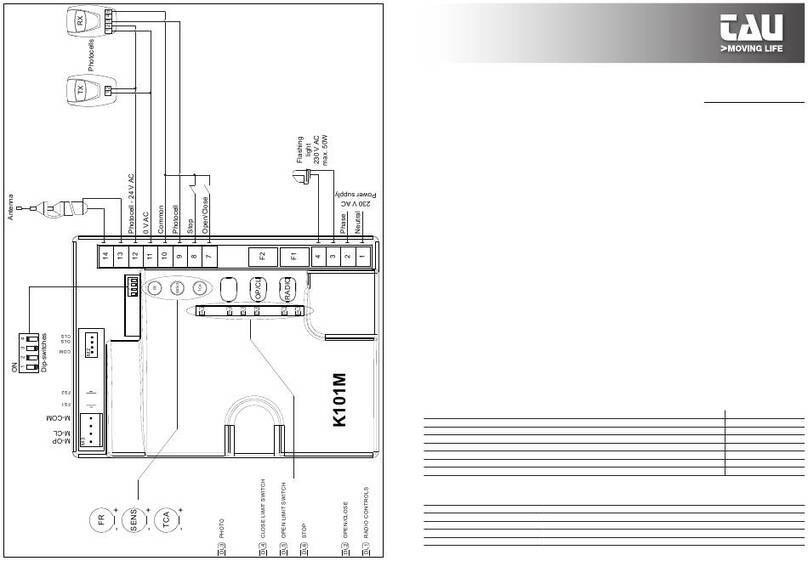

230Vac

Power supply

400Vac

Power supply

Flashing

light

230Vac

max. 20W

Cap

12,5µF

2

MASTER 20T

BIG18QI

Thermal

protector

OLS

CLS

Common

Common

Photocell

Fixed safety edge

Common

Common

Photocell

Common

Open

Close

Stop

Ped

O/C

Open

Close

3

D703

VOLTAGE

SELECTION

400Vac

230Vac

Radio connector

Gate open

warning light

max. 3W

Antenna

2nd radio

channel

OLS = Open limit switch

CLS = Close limit switch

O/C =Open/Close

Ped = Pedestrian

Cap = Capacitor

TX = Transmitter

RX = Receiver

M = Motor

COM = Common

ENC = Encoder

11

D703

WARNINGS

Important information:

ATTENTION: Capacitors C5, C6 and C7 located over the fuse “F1A” may be live even after

the panel has been disconnected from the mains supply. Short the 2 terminals of each

with a screwdriver before touching them.

-

-

-

-

Whoever ignores such standards shall be held responsible for any damage caused by

the system!

Installation

To connect the power supply of control board in 400 V, use at least a 2.5 mm² cable,

max. 40 m long.

-

The product must be properly earthed and the safety regulations in force in the

country of installation must be observed.

ENGLISH

12

D703

CONTROL PANEL FOR 230/400V AC SINGLE/THREE-PHASE MOTOR

ATTENTION:

- do not use single cables (with one single wire), ex. telephone cables, in order to

avoid breakdowns of the line and false contacts.

- do not re-use old pre-existing cables.

TESTING

on when the commands they are associated with are active.

TECHNICAL CHARACTERISTICS

Power input to board

Maximum power 1,5 Kw ca.

Input voltage of motor circuits

Input voltage of auxiliary circuits

Logic circuit input voltage

Box protected to IP43

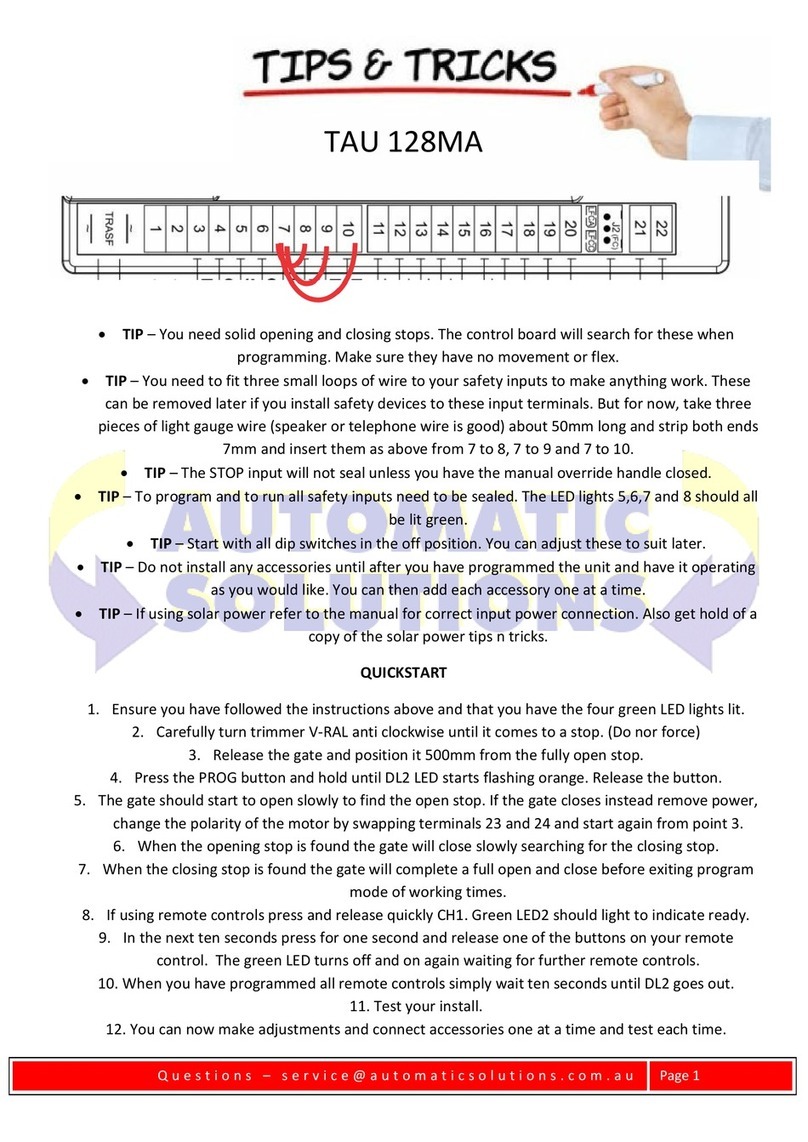

TERMINAL BOARD CONNECTIONS

Terminals Function Description

1 - 2 POWER SUPPLY

1 - 2 - 3 POWER SUPPLY

4 - 5 - 6 230-400V AC

MOTOR

for single-phase motors connect the capacitor between termi-

Note: select working voltage with jumper SW1 before

powering the board.

7 - 8 FLASHING LIGHT

already modulated for direct use. Flashing frequency increas-

9 - 10 STOP

automatic system. At the next command, the opposite opera-

ENGLISH

13

D703

9 - 11 PEDESTRIAN

opens the automatic system (by about 1 m) to allow pedestri-

12 - 13 OPEN/CLOSE -

12 - 14 OPEN -

12 - 15 CLOSE

16 - 17 FIXED SAFETY

EDGE

works during the opening phase by temporarily stopping the

16 - 18 PHOTOCELL

stops and then completely reopens. During the opening

phase it temporarily stops the gate until the detected obsta-

Note: the photocell transmitter must always be connect-

ed (terminals 27 and 28) as it is checked by the safety

system; the control unit will not work if it is disconnect-

ed. To disable the safety system move dip switch 6 to

OFF.

19 - 20 CLS (FCC)

19 - 21 OLS (FCA)

Note: the thermal protection (for MASTER20T and BIG-

18QI only) must be wired in series to the common of the

limit switch (terminal 19).

22 - 23 - 24 ENCODER

25 - 26 GATE OPEN

WARNING LIGHT

27 - 28 PHOTOCELL TX

29 - 30 PHOTOCELL

31 - 32 AERIAL

33 - 34 2nd RADIO CH

nd

Warning: to connect other devices to the 2nd Radio

Channel (area lighting, pumps, etc.), use an additional

auxiliary relay (with receiver connected).

CRECEIVER radio board connector.

ENGLISH

14

D703

LOGIC ADJUSTMENTS

TRIMMER

T.L.

T.C.A.

FR.

Note: turn the TRIMMER clockwise to increase adjustments; turn it anti-

clockwise to decrease.

Dip switches

1AUTOMATIC

CLOSING

On after opening, the gate automatically closes when the delay set on

Off

22 / 4 STROKE

On -

Off

in the same conditions, the same command sequence causes the

3MAN

PRESENT

On

Off

pushed, the automatic system performs a complete opening or clos-

Note: in the Man Present mode, the PP input (n° 13) is disabled, as is the radio receiver.

4

5ENCODER On -

Off

6PRE-FLASHING

FOTOTEST

On

Off

7

CLOSE

AFTER

PHOTOCELL

On

Off

8NO

REVERSE

On

Off

9

OPENING

PHOTOCELLS

OPERATION

On

during opening, the photocell cuts in to stop the gate until the ob-

stacle is removed. During closing, it stops the gate and then totally

reopens it.

Off during opening, the photocell does not trigger while during closing, it

10 BRAKING On

Off

Note: the braking system activates whenever the motor must stop (FCC - FCA - STOP

– change of direction) and reduces the inertia accumulated by the gear motor during

movement.

ENGLISH

15

D703

Clock function:

A timer can be connected to the open-close pushbutton in order to keep the gate open at certain

times during the day, after which it reverts to automatic closing.

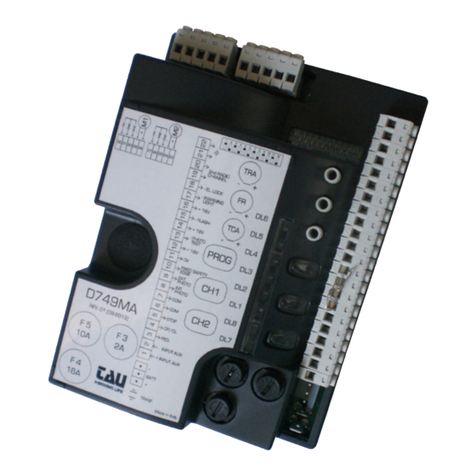

DIAGNOSTICS LED

DL1 STOP button green LED signal

DL2 PEDESTRIAN button red LED signal

DL3 STEP BY STEP button red LED signal

DL4 OPEN button red LED signal

DL5

DL6 SENSITIVE EDGE green LED signal

DL7

DL8

DL9

MALFUNCTIONS: POSSIBLE CAUSES AND SOLUTION

The automation does not start

d_ Set the dip 3 (man present function) to OFF, dip 5 (encoder) to ON, dip 6 (phototest) to

The radio control has very little range

The gate opens the wrong way

ENGLISH

NOTES ON USING THE BIG18 WITH A SINGLE PHASE TO THREE PHASE INVERTER

1. With all power removed convert the D703 to a single phase control board by moving the wire one

terminal at SW1.

2. The motor wires connected at terminals 4, 5 and 6 on the D703 need to be connected to terminals

U, V and W on the inverter.

3. You will need two 240 volt relays. Connect terminal 4 (COM) on the D703 to one side of the coil of

both relays.

4. Connect 5 (OPEN) from the D703 to the other side of the coil of one relay.

5. Connect 6 (CLOSE) to the other side of the coil on the second relay.

6. Take the COM from the relay side of both relays to DCM (COM) on the inverter.

7. Take the N/O from the OPEN relay to FOR on the inverter.

8. Take the N/O from the COSE relay to REV on the inverter.

9. Connect 240 volts to the inverter at R, S and E and also to the D703 at terminals 1 and 2.

You are now ready to start testing your installation for motor for drive both ways and correct direction as

well as limits.

Table of contents

Other tau Control Panel manuals

Popular Control Panel manuals by other brands

Chipkin

Chipkin Mircom PRO2000 FS-8705-17 instruction manual

Texecom

Texecom Veritas 8 installation manual

Bavaria Yachts

Bavaria Yachts 301 instruction manual

Plymovent

Plymovent CONTROLPRO instructions

Siemens

Siemens Multi Panel MP270 SIMATIC HMI Equipment manual

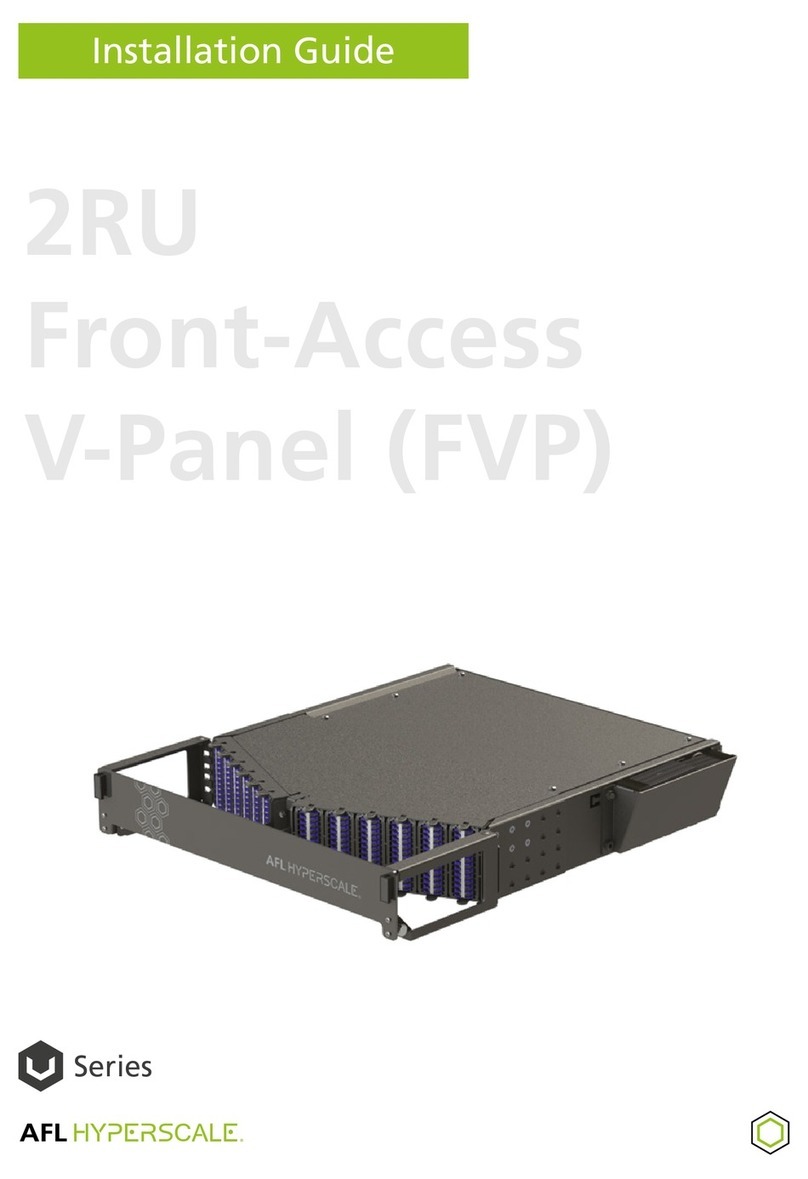

AFL Hyperscale

AFL Hyperscale U Series installation guide