tau K590M User manual

GUIDA ALL’INSTALLAZIONE

INSTALLATION GUIDE

INSTALLATIONSANLEITUNG

NOTICE D’INSTALLATION

GUÍA PARA LA INSTALACIÓN

GUIA DE INSTALAÇÃO

IT - Istruzioni originali

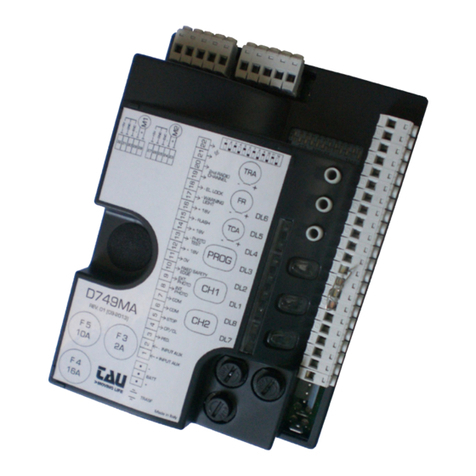

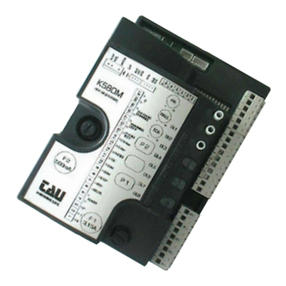

K590M

1 2 3 4 5 6 7 8 9 10

K590M

M5

SM

D-MNL0K590M 14-01-2021 - Rev.00 Ver. Firmware 8.xx

2

FR

SENS

TCA

12

13

14

15

16

17

18

19

20

21

22

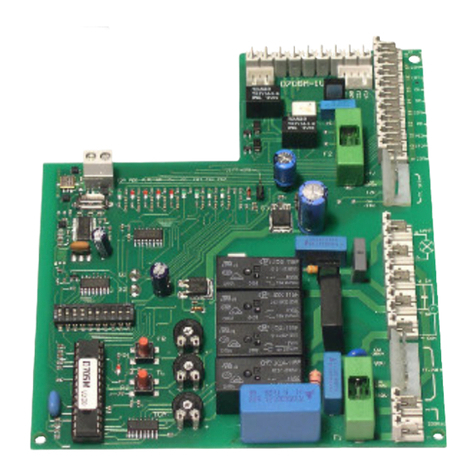

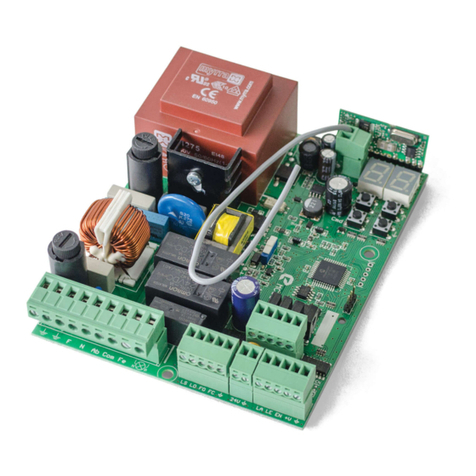

1

2

3Neutral

230 Vac

Power supply

Phase

M-OP

ENC

AUX

FC

FS2

FS1

M-COM

M-CL

CH2

CH1

PROG

F1

3,15A

F2

500mA

DL1V

DL1R

DL2

DL3

DL4

DL5

DL6

DL7

DL8

DL9

4

5

6

7

8

9

10

11

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

Open/Close

Pedestrian

Stop

Common

Open

Gate open warning

light max. 3W

2nd radio

channel

K590M

Dip-switchesON

M1

M5

SM

M4

M2

M3

TCA

+-

SENS

+-

FR

+-

Photocells

Photocell (N.C.)

Photocell TX

Fixed safety edge

Common

RX

12345

TX

1 2

0 Vac

Signal

GND

+ VLED

- VLED

Photocell RX - 24 Vac

Trimmer:

Lamp

(VLED)

DL1R

DL1V

DL2

DL3

DL4

DL5

DL6

ERRORS - RADIO

RECEIVERS

OPEN

OPEN/CLOSE

PEDESTRIAN

STOP

FIXED SAFETY EDGE

DL7 PHOTO

DL8 FCA

DL9 FCC

LEDs:

SCHEMA

CABLAGGIO

K590M

K590M

WIRING

DIAGRAM

SCHALTPLAN

DER K590M

SCHÉMA

CÂBLAGE

K590M

ESQUEMA DEL

CABLEADO

K590M

ESQUEMA

DE LIGAÇÕES

K590M

3

FR

SENS

TCA

12

13

14

15

16

17

18

19

20

21

22

1

2

3Neutral

230 Vac

Power supply

Phase

M-OP

ENC

AUX

FC

FS2

FS1

M-COM

M-CL

CH2

CH1

PROG

F1

3,15A

F2

500mA

DL1V

DL1R

DL2

DL3

DL4

DL5

DL6

DL7

DL8

DL9

4

5

6

7

8

9

10

11

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

Open/Close

Pedestrian

Stop

Common

Open

Gate open warning

light max. 3W

2nd radio

channel

K590M

Dip-switchesON

M1

M5

SM

M4

M2

M3

TCA

+-

SENS

+-

FR

+-

Photocells

Photocell (N.C.)

Photocell TX

Fixed safety edge

Common

RX

12345

TX

1 2

0 Vac

Signal

GND

+ VLED

- VLED

Photocell RX - 24 Vac

Trimmer:

Lamp

(VLED)

DL1R

DL1V

DL2

DL3

DL4

DL5

DL6

ERRORS - RADIO

RECEIVERS

OPEN

OPEN/CLOSE

PEDESTRIAN

STOP

FIXED SAFETY EDGE

DL7 PHOTO

DL8 FCA

DL9 FCC

LEDs:

14

WARNINGS

This manual has been especially written for use by quali ed tters. No information given in this manual

can be considered as being of interest to end users. This manual is enclosed with control unit K590M and

may therefore not be used for dierent products!

Important information:

Disconnect the panel from the power supply before opening it.

The K590M control unit has been designed to control an electromechanical gear motor for automating

gates and doors of all kinds.

Any other use is considered improper and is consequently forbidden by current laws.

Please note that the automation system you are going to install is classi ed as “machine construction”

and therefore is included in the application of European directive 2006/42/EC (Machinery Directive).

This directive includes the following prescriptions:

- Only trained and qualied personnel should install the equipment;

- the installer must rst make a “risk analysis” of the machine;

- the equipment must be installed in a correct and workmanlike manner in compliance with all the

standards concerned;

- after installation, the machine owner must be given the “declaration of conformity”.

This product may only be installed and serviced by qualied personnel in compliance with current, laws,

regulations and directives.

When designing its products, TAU observes all applicable standards (please see the attached declaration

of conformity) but it is of paramount importance that installers strictly observe the same standards when

installing the system.

Unqualied personnel or those who are unaware of the standards applicable to the “automatic gates

and doors” category may not install systems under any circumstances.

Whoever ignores such standards shall be held responsible for any damage caused by the system!

Do not install the unit before you have read all the instructions.

INSTALLATION

Before proceeding, make sure that the gate opens and closes easily without mechanical impedi-

ments of any kind. Also check that the gear motor assembly has been installed according to the

instructions and also that the relative rack has been installed on the gate so as not to create

mechanical obstacles during opening and closing.

THE EQUIPMENT MUST BE INSTALLED “EXPERTLY” BY QUALIFIED PERSONNEL AS REQUIRED BY LAW.

Note: it is compulsory to earth the system and to observe the safety regulations that are in

force in each country.

IF THESE ABOVE INSTRUCTIONS ARE NOT FOLLOWED IT COULD PREJUDICE THE PROPER WORKING

ORDER OF THE EQUIPMENT AND CREATE HAZARDOUS SITUATIONS FOR PEOPLE. FOR THIS REASON

THE “MANUFACTURER” DECLINES ALL RESPONSIBILITY FOR ANY MALFUNCTIONING AND DAMAGES

THUS RESULTING.

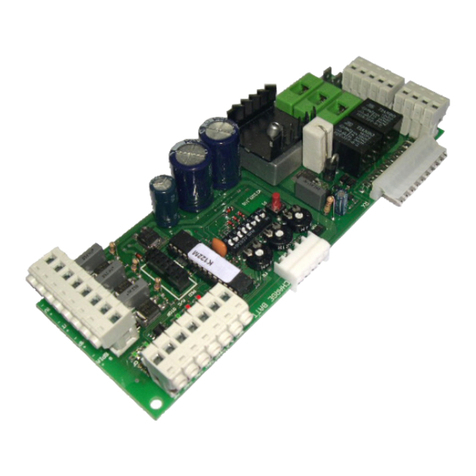

1. CONTROL PANEL FOR ONE 230V AC MOTOR

• MICROPROCESSOR-CONTROLLED LOGIC

• INPUT STATUS LED’S

• LINE INPUT FUSE

• BUILT-IN FLASHING LIGHT CIRCUIT

• 433.92 MHz 2 CHANNEL BUILT-IN RADIO RECEIVER (CH)

• OPERATING TIME FIXED AT 120 sec.

• AUTOMATIC DETECTION OF THE POWER SUPPLY FREQUENCY (50 or 60 Hz)

• MOTOR TORQUE CONTROL AND OBSTACLE DETECTION BY MEANS OF ENCODER

• ADJUSTABLE DECELERATION

• “SLOW-DOWN” FUNCTION IN OPENING AND IN CLOSING PHASE

• DIAGNOSTICS OF MALFUNCTIONS SIGNALLED BY LED

ENGLISH

15

ENGLISH

• COMPATIBILITY WITH OUR APPS: TAUOPEN AND TAUAPP

ATTENTION:

- do not use single cables (with one single wire), ex. telephone cables, in order to avoid break-

downs of the line and false contacts;

- do not re-use old pre-existing cables.

- In case of long sections of cables (> 20 m) for N.O./N.C. controls (e.g. OPEN / CLOSE, STOP, PEDE-

STRIAN, etc.), in order to avoid gate malfunctions, it will be necessary to uncouple the various

controls using RELAYS or using our 750T-RELE device.

2. TESTING

When you have completed the connection:

• All the green LEDs (from 3 to 6) must be on (each of them corresponds to a Normally Closed input).

They go o only when the controls to which they are associated are operated.

• The red opening command LEDs must all be unlit (each corresponding to a Normally Open input)

and illuminate only when the commands they are associated with are given; The green led DL1V

will ash every 4 seconds.

3. TECHNICAL CHARACTERISTICS

Power input to board 230V AC - 50 Hz

Nominal power 400 W

Fast acting fuse for protection of input power supply 230V AC (F1 - 5x20) F 3,15 A

Input voltage of motor circuits 230V AC

Input voltage of auxiliary circuits 24V AC

Fast acting fuse for protection of auxiliary circuits 24V AC (F2 - 5x20) F 500 mA

Working temperature -20°C ÷ +55°C

Box degree of protection IP 44

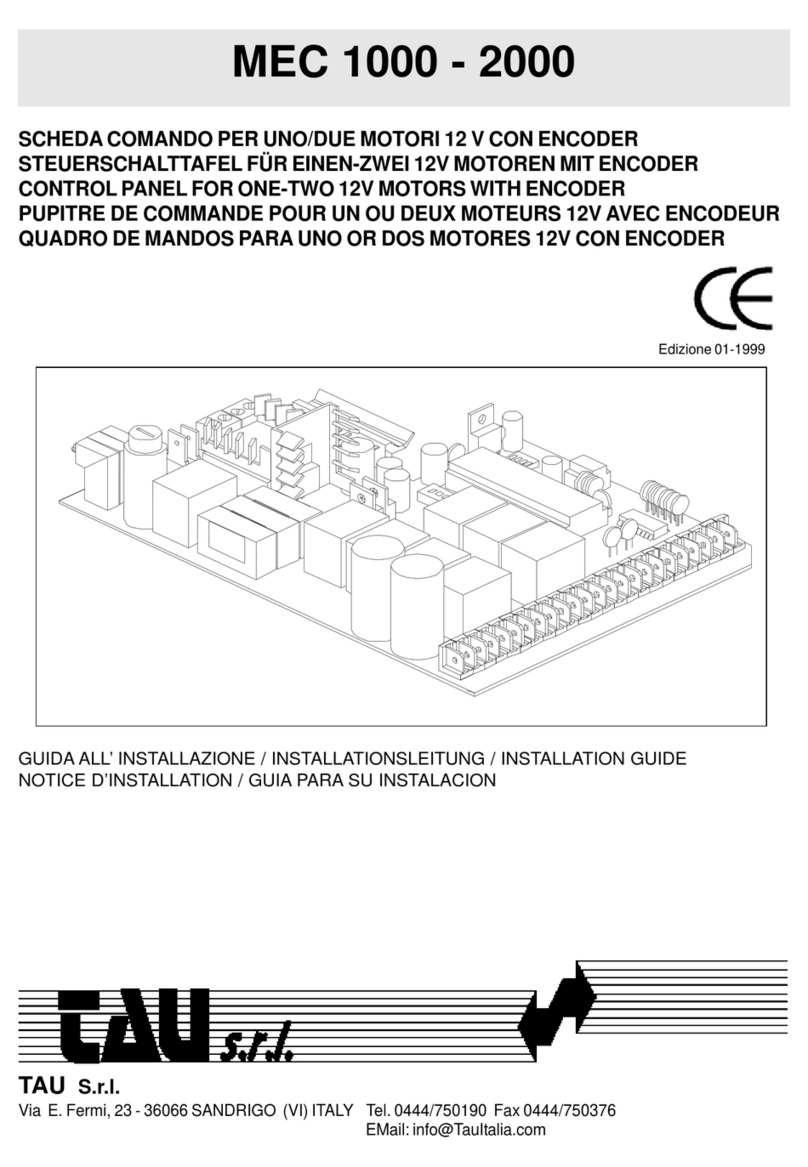

4. TERMINAL BOARD CONNECTIONS

Terminals Function Description

1 - 2 - 3 POWER

SUPPLY

POWER input 230V AC - 50Hz (115V AC - 60 Hz).

1=PHASE 2= EARTH 3= NEUTRAL;

4 - 8 OPEN OPEN pushbutton input (Normally Open contact); (8=COMMON, 4=OPEN)

5 - 8 OPEN/CLOSE OPEN/CLOSE pushbutton input (Normally Open contact); (8=COMMON,

5=OPEN/CLOSE)

6 - 8 PEDESTRIAN

PEDESTRIAN pushbutton input (Normally Open contact);

NOTE by factory settings the automation will open Equal to one

third of the total strike. (8= COMMON, 6= PEDESTRIAN)

7 - 8 STOP STOP pushbutton input (Normally Closed contact);(8=COMMON, 7=STOP)

9 - 10 SENSITIVE

EDGE

SAFETY EDGE input (Sensitive edge with resistive or N.C. contact). During

the opening phase, it temporarily stops the gate and makes it close again

for about 20 cm, thus allowing to free the potential obstacle.

During the closing phase, it stops the gate and makes it totally reopen. In

this case, if programmed, the automatic closing will be inhibited. Jumper

terminals if not used. (9 = COMMON - 10 = SENSITIVE EDGE)

NOTE: if a resistive sensitive edge 8K2 Ohm is connected, set dip-

switch no. 12 to ON;

If a xed safety edge with NC contact is connected, set dip-switch

no. 12 to OFF;

16

9 - 11 PHOTOCELLS

Input for PHOTOCELLS OR SAFETY DEVICES active during closure (Normally

Closed contact); They stop the gate during closing and totally reopen it; they

temporarily stop the gate during opening in order to allow the obstacle to

be removed (if dip switch n° 3 set to ON). If there is more than one safety

device, connect all the NC contacts IN SERIES.

(9=COMMON, 11= PHOTOCELLS)

Note: the photocell transmitter must always be supplied by terminals

no. 13 - 15, since the safety system test (photo-test) is carried out on

it. To override the testing of the safety system, or when the photocells

are not used, set dip-switch no. 6 to OFF. If the photo-test is not

successful, the control unit will not operate.

12 - 13 2nd RADIO

CHANNEL

2nd RADIO CHANNEL output to be used for opening/closing another gate,

for controlling garden lights or for the “ZONE LIGHTING” function; (to be

programmed via TauApp);

Warning: to connect other devices to the 2nd Radio Channel (area

lighting, pumps, etc.), use an additional auxiliary relay.

14 - 15 GATE OPEN

LED

GATE OPEN LED output 24V AC - max. 3W; during opening of the gate

the warning light ashes slowly, when the gate is open it remains steadily

illuminated and during closure it ashes twice as fast. 14= 0Vac, 15= 24Vac;

16 - 18 TX

PHOTOCELL

24V AC 10 W POWER output for PHOTOCELL TX (only the one that

performs the Phototest) max. no. 1 photocell transmitter.

18= 0Vac, 16= 24Vac;

17 - 18 RX

PHOTOCELLS

24V AC 10W output to POWER THE RX AND/OR OTHER TX OF OHER

INSTALLED PHOTOCELLSPHOTOCELLS AND/OR EXTERNAL RECEIVERS,

etc.; connect a max. of 3 pair of photocells. 18= 0Vac, 17= 24Vac;

19 - 20 FLASHING

LIGHT

LEDS FLASHING LIGHT output 12V dc, 200mA max.

(NEGATIVE=19 - POSITIVE=20) The signal is already modulated for direct use.

Flashing frequency is double during closing;

21 - 22 AERIAL 433,92 MHz built-in RX antenna input; 21= EARTH, 22= SIGNAL;

M1 LIMIT

SWITCH

Quick coupling for LIMIT SWITCH connection (Normally Closed contacts).

Orange= Closure Limit Switch (CLS),

ed= Opening Limit Switch (OLS), grey= Common (COM);

M2 ENCODER Quick coupling for ENCODER connection. Blue= 0V DC (GND), brown= 5V

DC (+5V), white= ENCODER SIGNAL (ENC);

FS1 - FS2 CAPACITOR Faston for motor CAPACITOR connection;

M3 230V AC

MOTOR Quick coupling for 230 Vac single-phase MOTOR connection common=

BLUE (M-COM); closure= BROWN (M-CL); opening= BLACK (M-OP).

M4 AUX Quick coupling for the connection of the T-WIFI and T-CONNECT devices

M5 MEMORY CARD Quick plug-in for MEMORY CARD connection for transmitters codes.

5. LOGIC ADJUSTMENTS

TRIMMER

FR. Motor torque adjustment. The trimmer is set to provide sucient thrust to work the gate

without exceeding the limits established by current standards (EN 12453). Turning the

trimmer clockwise (+) increases the motor torque, turning it anticlockwise (-) reduces it.

SENS Adjustable only with ENCODER enabled (DIP 11 ON).

Obstacle detection additional adjustment;

Note: by rotating the TRIMMER FR. clockwise the sensitivity to obstacles of the oper-

aor decreases and therefore the thrust force increases; vice-versa, by rotating it anti-

clockwise, the sensitivity to obstacles of the operator increases and therefore the

thrust force decreases.

WARNING: with the trimmer at maximum, the obstacle detection is disabled!!

T.C.A. Automatic closing time adjustment from 5 to 120 seconds.

ENGLISH

17

Dip switch

1AUTOMATIC

CLOSING

On after opening, the gate automatically closes when the delay set on the

T.C.A. trimmer expires.

O automatic closing disabled.

22 / 4 STROKE

On with automatic closing enabled, a sequence of open/close commands

causes the gate to OPENCLOSE-OPEN-CLOSE etc (see also dip switch 4).

O in the same conditions, the same command sequence causes the gate

to OPEN-STOP-CLOSESTOP-OPEN-STOP (step-by-step).

3

OPENING

PHOTOCELLS

OPERATION

On during opening, cutting photocell stops the gate until the obstacle is

removed. When the obstacle is removed the gate resumes opening;

O during opening, the photocell does not cut in.

4NO

REVERSE

On NO-REVERSE function activated; the gate ignores the closure commands

during opening; reversal of movement occurs only during closure;

O the open-close pushbutton reverses the direction of movement of the

gate even while it is opening.

5PRE-

FLASHING

On pre-ashing function enabled.

O pre-ashing function disabled.

6PHOTOCELL

TEST

On “photocell test” function is enabled;

O “photocell test” function is disabled.

Note: to be used when the photocells are not used.

7PEDESTRIAN ENTRY

FUNCTION

On CLOSE button input (Normally Open contact)

O PEDESTRIAN button input (Normally Open contact);

8DEAD MAN’S

SWITCH

On Dead man’s switch active for the OPEN and CLOSE keys (term. 4-8 and

6-8 with dip switch 7 in ON);

O Dead man’s switch not active

9GATE

TYPE

On settings for heavy gates or particularly dicult to open and close;

O settings for standard gates.

10

OPENING

DIRECTION

SETUP

On left-hand leaf opening function;

O right-hand leaf opening function;

11

ENCODER On ENCODER enabled: encoder obstacle detection function activated (use

the trimmers FR and SENS to adjust the sensitivity to obstacles);

O ENCODER disabled - obstacle detection disabled;

NOTE: moving DIP 11 from ON to OFF (or vice versa), learning process has to be

initialized again.

12 SENSITIVE

EDGE

On RESISTIVE SENSITIVE EDGE 8K2 Ohm (terminal no. 11);

O FIXED EDGE (NC contact – terminal no. 11).

OBSTACLE DETECTION

If the obstacle detection function (which can be set through trimmers FR and SENS) gets activated dur-

ing an opening manoeuvre, the gate closes approx. 20 cm., if it is activated during a closing manoeu-

vre, the gate opens fully.

WARNING: the control panel logics may interpret mechanical friction as an obstacle.

ENGLISH

18

6. STROKE SETTINGS PROCEDURE WITH OR WITHOUT SLOWDOWN (SETUP)

WARNING: The learning process has to be done even if ENCODER function is

disabled (DIP 11 OFF).

It is recommended to start the learning process already on the FCC closing limit switch.

Press the PROG key and keep it pressed until the DL1R and DL1V leds start ashing quickly. After re-

leasing it, the procedure carries out the following steps:

1_If the automation is already on the FCC limit switch, it goes directly to point 2.

Otherwise, if the automation is not on the FCC, it starts to look for the closing limit switch;

If the automation opens instead of closing, stop the learning process (by cutting the

photocells or opening the STOP contact), invert DIP 10 and continue the learning process

by pressing PROG briey.

2_ The automation starts to measure the stroke from FCC to the opening limit switch FCA;

WARNING: - SETTING SLOWDOWN: (skip this procedure to disable slowdown) During

the opening cycle press PROG or close the OPEN/CLOSE contact at the desired position

where to start the slowdown.

3_ Once the opening is done, the automation starts to measure the stroke from the opening limit

switch FCA to the closing limit switch FCA;

SETTING SLOWDOWN: (skip this procedure to disable slowdown) During the opening cy-

cle press PROG or close the OPEN/CLOSE contact at the desired position where to start

the slowdown.

4_ The green led DL1V will ash every 4 sec. Learning process procedure is terminated.

WARNING: if during the learning process either the STOP, or PHOTOCELLS or SAFETY

EDGE contact will be opened the automation stops. By pressing PROG or closing the

OPEN/CLOSE contact the learning process starts again from pont nr. 1

7. 433.92 MHz BUILT-IN RADIO RECEIVER

The radio receiver can learn up to a maximum of 30 rolling codes (BUG2R, BUG4R, K-SLIM-RP, T-4RP)

which can be set on both the two channels as desired.

The rst channel directly commands the control board for opening the automatic device; the second

channel commands a relay for a N.O. dry contact (terminals 12 and 13, max. 24 Vac, 1 A).

LEARNING PROCEDURE FOR TRANSMITTERS

CH1 = OPEN/CLOSE CH2 = 2nd channel CH3 = 3rd channel (PEDESTRIAN)

1_ press button CH1 briey to associate a transmitter with the OPEN/CLOSE function;

2_ LED (green) DL1V turns on to indicate that the code learning mode has been activated (if no code

is entered within 10 seconds, the board exits the transmitters learning mode);

3_ press the desired channel of the transmitter to be memorized;

4_ the LED (green) DL1V turns o to indicate saving is complete and then turn on immediately waiting

for another transmitter to be memorized (if this is not the case, try to re-transmit or wait 5 seconds

and restart from point 1);

5_ to memorise other transmitters, press the desired channel of the new transmitter within 5 sec

otherwise the learning procedure will be automatically closed and LED (green) DL1V turns o. To

repeat the procedure to learn new remote controls start again from point 1 (up to a maximum of

30 transmitters);

6_ to memorise codes on the 2nd channel, repeat the procedure from point 1 using button CH2 in-

stead of CH1; (in this case the red/ green leds DL1R and DL1V will light up);

7_ to program transmitters into the third channel, repeat procedure from point 1 using CH1 and CH2

buttons at the same time (DL8 will turn on red);

If the maximum number of radio controls is reached (30), the DL1V (green) led for CH1

and the DL1R (red) led for CH2 ash for about 3 seconds without however, carrying out

the memorization.

ENGLISH

19

REMOTE PROGRAMMING BY MEANS OF T-4RP and K-SLIM-RP (V 4.X)

With the new version of software V 4.X it is possible to carry out a remote self-learning of transmitters

T-4RP and K-SLIM-RP (new version V 4.X), without pressing the receiver’s programming buttons.

It will be sucient to have an already programmed transmitter on the receiver in order to start the

procedure of remote programming of the new transmitters. Follow the procedure written on the in-

structions of the transmitters T-4RP and K-SLIM-RP (V 4.X).

CANCELLING CODES FROM RADIO CONTROL DEVICES

1_ keep button CH1 pressed for 3 seconds in order to cancel all the associated transmitters;

2_ The green LED DL1V ashes slowly to indicate that the cancellation mode has been activated;

3_ press button CH1 again for 3 seconds;

4_ The green LED DL1V turns o for approx. 3 seconds and then remains steady to indicate that the

codes has been cancelled;

5_ repeat the procedure from point 1 using button CH2 to cancel all the associated transmitters;

6_ repeat procedure from point 1 using CH1 and CH2 buttons at the same time to erase all transmit-

ters programmed into the third channel;

7_ to exit the cancelling mode without deleting any code, press button CH1 or CH2 briey.

MEMORY CAPACITY

The code memory capacity* can be expanded from 30 to 126, 254 or 1022 codes (transmitters) by replacing

the memory cards as follows

(plug them onto M5 connector, see wiring diagram)

:

126 codes Art. 250SM126

254 codes Art. 250SM254

1022 codes Art. 250SM1022

* Control units are supplied with a standard built-in 30-code memory. The memory card for enhancing the

code memory capacity must be ordered separately.

To allow the previously stored codes (max. 30) to be moved to the control unit, it is required to install

a memory card, making sure that the control unit is at that time o and that the memory card is brand

new and therefore completely empty.

When the control unit is restarted, the codes will automatically move to the memory card.

Moving the codes from the control unit to the memory card does not work if on the memory

card used, radio control codes have already been stored and the memory card has been subse-

quently erased.

To insert new radio controls, the operation described above shall be repeated.

WARNING: Control unit must be turned OFF to insert / remove a memory card.

RADIO MEMORY RESET:

- press without releasing the keys CH1 and PROG until the DL1R (red) led stays on and the DL1V

(green) led starts ashing quickly. At this point release the keys and press them again till the LEDs

go o conrming the operation is complete.

HARD RESET (factory setting):

- press without releasing keys CH2 and PROG till LED DL1R start ashing quickly with a red light. At

this point release the keys and press them again till the LED go o (reset in progress), conrming

the operation is complete. When the unit starts again saving will be required.

In case of Hard Reset the memory of the radio receiver will not be erased: all existing

transmitters remain programmed.

8. ADVANCED FUNCTIONS

Clock function: a timer can be connected to the open-close pushbutton in order to keep the gate open

at certain times during the day, after which it reverts to automatic closing.

Note: the gate remains open as long as the Op/Cl input continues to be activated.

ENGLISH

20

9. DIAGNOSTICS LED

DL1V (green) + DL1R

(red)Led indicating the programming of REMOTE CONTROLS, ERRORS and the

status of the control unit

DL2 - red OPEN button LED signal

DL3 - red OPEN/CLOSE button LED signal

DL4 - red PEDESTRIAN button LED signal

DL5 - green STOP button LED signal

DL6 - green SENSITIVE EDGE LED signal

DL7 - green PHOTOCELL LED signal

DL8 - green OPEN LIMIT SWITCH LED signal (FCA)

DL9 - green CLOSE LIMIT SWITCH LED signal (FCC)

LED: DL1V (green) + DL1R (red)

Leds DL1R and DL1V displays any mistakes with a series of pre-set ashes:

Key: led always on; led ashing; led o;

/ Alternate ashing (Red/Green): Saving to be performed;

/ Fast ashing of both

(Red/Green): Saving in progress;

/ 1 ash every 4 seconds Status of the unknown position - Next maneuver

REALIGNMENT

/ No. 8 ashes interspersed with

a pause of 1 sec. (Red/Green): Eeprom data error;

Perform procedure RADIO MEMORY RESET;

LED: DL1V (green) + DL1R (red led always o)

1 ash every 4 seconds (green): Normal operation;

1 ash every 1 seconds (continuous

ashing) Radio memory of the card is read by TAUSOFT

Always on (green): Channel CH1 waiting to be saved;

Fast ashing (green): CH1 channel memory full;

Flashing (green): CH1 channel waiting to be cancelled;

Led o: Cancelling of channel CH1 in progress;

LED: DL1V (green led always o) + DL1R (red)

Led o: Normal operation;

1 ash every 1 seconds (red): Phototest error

Disable phototest (dip-switch 6 OFF), check the operation of the pho-

tocells and their connection;

No. 2 ashes interspersed with

a pause of 1 sec.(red):obstacle motor ;

Make sure there are no obstacles across the path of the gate and that

it slides smoothly;

No. 3 ashes interspersed with

a pause of 1 sec.(red):Faulty encoder or disconnected from M1

Check wiring, check encoder by TEST-ENCODER (optional);

No. 6 ashes interspersed with

a pause of 1 sec. (red)

Reached maximum number of failed automatic closing attempts

Obstacle detected (only with dip 11 ON);

ENGLISH

21

Make sure there are no obstacles across the path of the gate and that

it slides smoothly;

No. 7 ashes interspersed

with a pause of 1 sec. (red):Sensitive edge safety intervention

A command pulse is required to carry out the closure;

No. 8 ashes interspersed with

a pause of 1 sec.(red):Eeprom external memory fault;

Replace the external memory module;

10. SET-UP FOR OPERATION WITH TAU APPS

In order to use the TauApp and TauOpen apps, it will be necessary to connect to input M4 of the

control unit using the supplied cable, the respective T-WIFI and T-CONNECT devices. To activate the

operation of the apps see the respective instructions.

11. RESTORING AUTOMATIC OPERATION

Should the gate needs to be operated manually, use the release system. After a manual operation:

If the reset occurs after a black-out or after a manual intervention, before powering the control board

again it is necessary to place the gate in the totally open or completely closed position.

12. MALFUNCTIONS: POSSIBLE CAUSES AND SOLUTION

The automation does not start

a- Check there is 230Vac power supply with the multimeter;

b- Check that the N.C. contacts on the card really are normally closed (5 green LEDs illuminated)

and that the red opening command LEDs are turned o;

c- make sure the green DL1V led ashes every 4 seconds;

d- Set dip 6 (phototest) to OFF;

e- Check that the fuses are intact with the multimeter.

The radio control has very little range

a- Check that the ground and the aerial signal connections have not been inverted;

b- Do not make any joints on the antenna cable;

c- Do not install the aerial in a low position or behind walls or pillars;

d- Check the state of the radio control batteries.

The gate opens the wrong way

a_ Invert the position of dip-switch No. 10 after having turned o the power to the control unit.

13. GUARANTEE: GENERAL CONDITIONS

TAU guarantees this product for a period of 24 months from the date of purchase (as proved by the

sales document, receipt or invoice).

This guarantee covers the repair or replacement at TAU’s expense (ex-works TAU: packing and trans-

port at the customer’s expense) of parts that TAU recognises as being faulty as regards workmanship

or materials.

For visits to the customer’s facilities, also during the guarantee period, a “Call-out fee” will be charged

for travelling expenses and labour costs.

The guarantee does not cover the following cases:

• If the fault was caused by an installation that was not performed according to the instructions

provided by the company inside the product pack.

ENGLISH

22

MANUFACTURER’S DECLARATION OF INCORPORATION

(in accordance with European Directive 2006/42/EC App. II.B)

Manufacturer: TAU S.r.l.

Address: Via E. Fermi, 43 - 36066 Sandrigo (Vi) - ITALY

Declares under its sole responsibility, that the product: Electronic control unit

designed for automatic movement of: Sliding Gates

for use in a: Residential / Communities complete with: Radioreceiver

Model: K590M Type:K590M

Serial number: see silver label

Commercial name: Control panel for T-ONE5, T-ONE8, T-ONEXL and

MASTER20QR/QM gearmotor

Has been produced for incorporation on an access point (sliding gate) of for assembly with other devices used

to move such an access point, to constitute a machine in accordance with the Machinery Directive 2006/42/EC.

Also declares that this product complies with the essential safety requirements of the following EEC directives:

- 2014/35/EU Low Voltage Directive

- 2014/30/EU Electromagnetic Compatibility Directive

and, where required, with the Directive:

- 2014/53/EU Radio equipment and telecommunications terminal equipment

Also declares that it is not permitted to start up the machine until the machine in which it is incorporated or of

which it will be a component has been identied with the relative declaration of conformity with the provisions of

Directive 2006/42/EC.

The following standards and technical specications are applied:

EN 61000-6-2; EN 61000-6-3; EN 60335-1; ETSI EN 301 489-1 V1.9.2; ETSI EN 301 489-3 V1.6.1;

EN 300 220-2 V3.1.1; EN 12453:2000; EN 12445:2000; EN 60335-2-103.

The manufacturer undertakes to provide, on sufciently motivated request by national authorities, all information

pertinent to the quasi-machinery.

Sandrigo, 31/10/2017 Legal Representative

_________________________________________

Loris Virgilio Danieli

Name and address of person authorised to draw up all pertinent technical documentation:

Loris Virgilio Danieli - via E. Fermi, 43 - 36066 Sandrigo (Vi) Italy

ENGLISH

• If original TAU spare parts were not used to install the product.

• If the damage was caused by an Act of God, tampering, overvoltage, incorrect power supply,

improper repairs, incorrect installation, or other reasons that do not depend on TAU.

• If a specialised maintenance man does not carry out routine maintenance operations accord-

ing to the instructions provided by the company inside the product pack.

• Wear of components.

The repair or replacement of pieces under guarantee does not extend the guarantee period.

In case of industrial, professional or similar use, this warranty is valid for 12 months.

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) - Italy

Tel +39 0444 750190 - Fax +39 0444 750376

[email protected] - www.tauitalia.com

Foglietto illustrativo

CARTA - Raccolta dierenziata. Segui le indicazioni del tuo comune. (N.B.: togliere i punti metallici)

Instruction leaet

PAPER - Waste separation. Follow the instruction s of your city hall. (Note: remove the staples)

22

PAP

Other manuals for K590M

1

Table of contents

Other tau Control Panel manuals

Popular Control Panel manuals by other brands

REMEHA

REMEHA HMI S-Control Installation and user manual

Panasonic

Panasonic AK-HRP1010G operating instructions

Eaton

Eaton P1RX 240Vac Max instruction manual

ELCOS

ELCOS CEM-256/10 Instruction and user's manual

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren S16 Operation manual

Nakanishi

Nakanishi E4000-PEX4 Operation manual

Vintage Air

Vintage Air 1955-59 manual

Motorline professional

Motorline professional MC50 User& installer's manual

CONSET

CONSET R144120 Mounting instructions

Kaysun

Kaysun KCCHT-06 MODBUS owner's manual

NAPCO

NAPCO Gemini GEM-P3200 installation instructions

Triad

Triad 8900 SH Series Operation and installation manual