tau K580M User manual

1

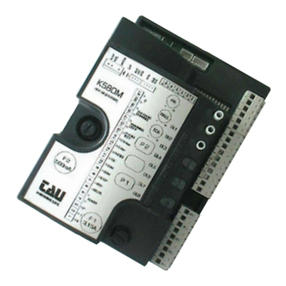

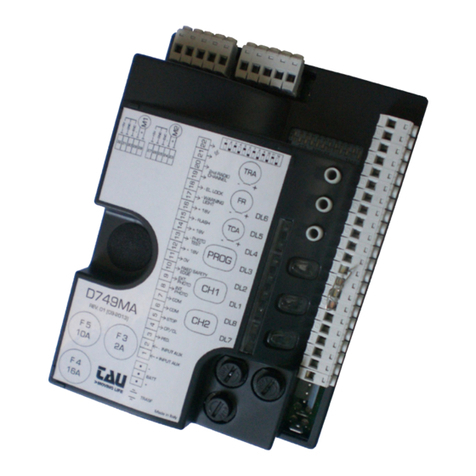

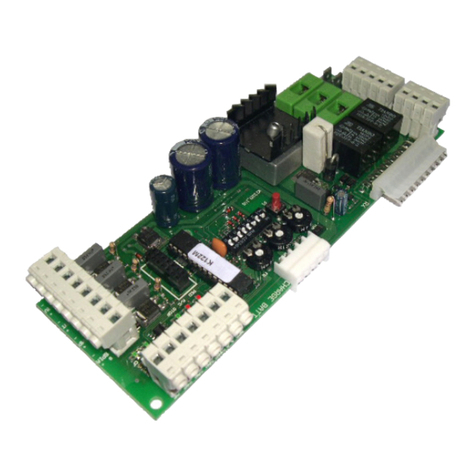

K580M

GUIDA ALL’INSTALLAZIONE

INSTALLATION GUIDE

INSTALLATIONSANLEITUNG

NOTICE D’INSTALLATION

GUÍA PARA LA INSTALACIÓN

GUIA DE INSTALAÇÃO

K580M

Quadro di comando per motoriuttore T-ONE5, T-ONE8, T-ONEXL e MASTER20QR/QM

Control panel for T-ONE5, T-ONE8, T-ONEXL and MASTER20QR/QM gearmotor

Steuerplatine für den getriebemotor T-ONE5, T-ONE8, T-ONEXL und MASTER20QR/QM

Logique de commande pour motoréducteur T-ONE5, T-ONE8, T-ONEXL et MASTER20QR/QM

Panel de mandos para motorreductor T-ONE5 , T-ONE8, T-ONEXL y MASTER20QR/QM

Quadro de comando para motorredutor T-ONE 5, T-ONE8, T-ONEXL e MASTER20QR/QM

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) Italia

Tel +39 0444 750190 - Fax +39 0444 750376

info@tauitalia.com - www.tauitalia.com

IT - Istruzioni originali

D-MNL0K580M 17-11-2015 - Rev.10

2

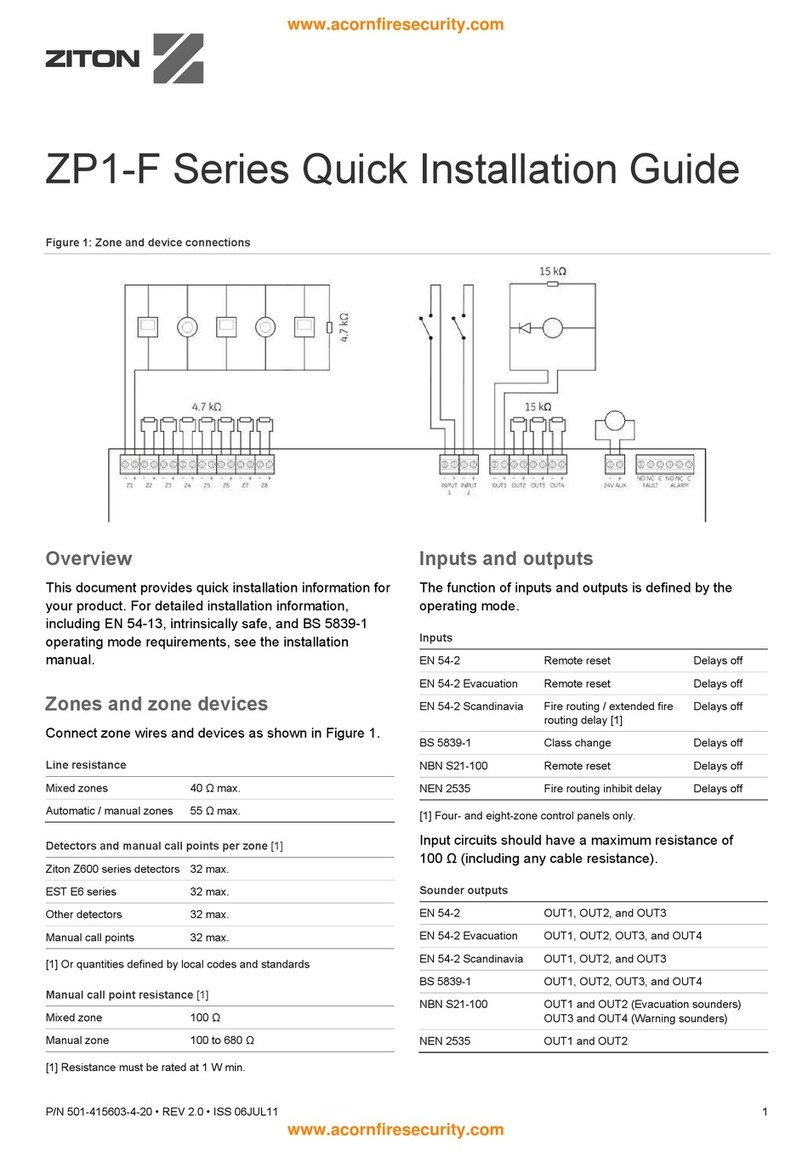

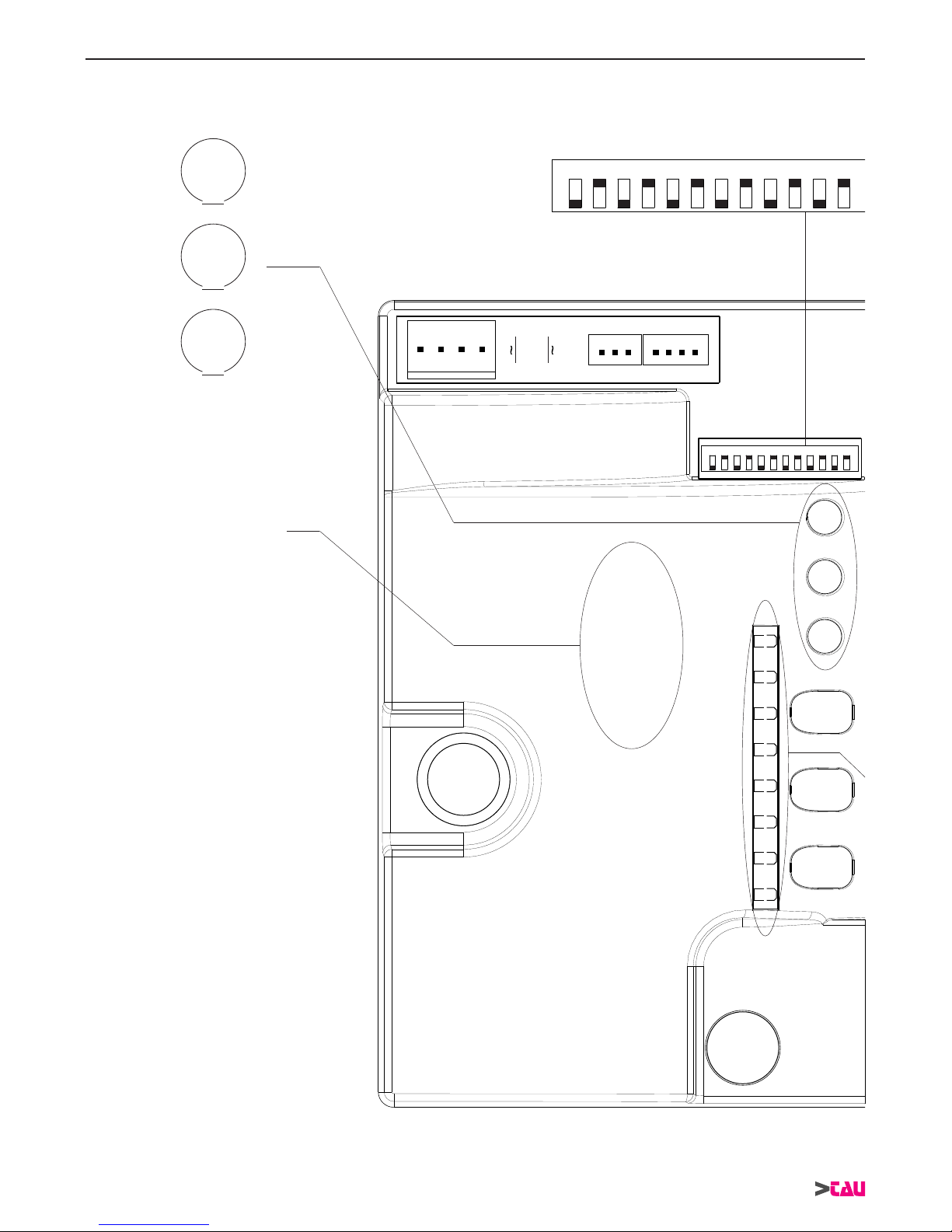

K580M

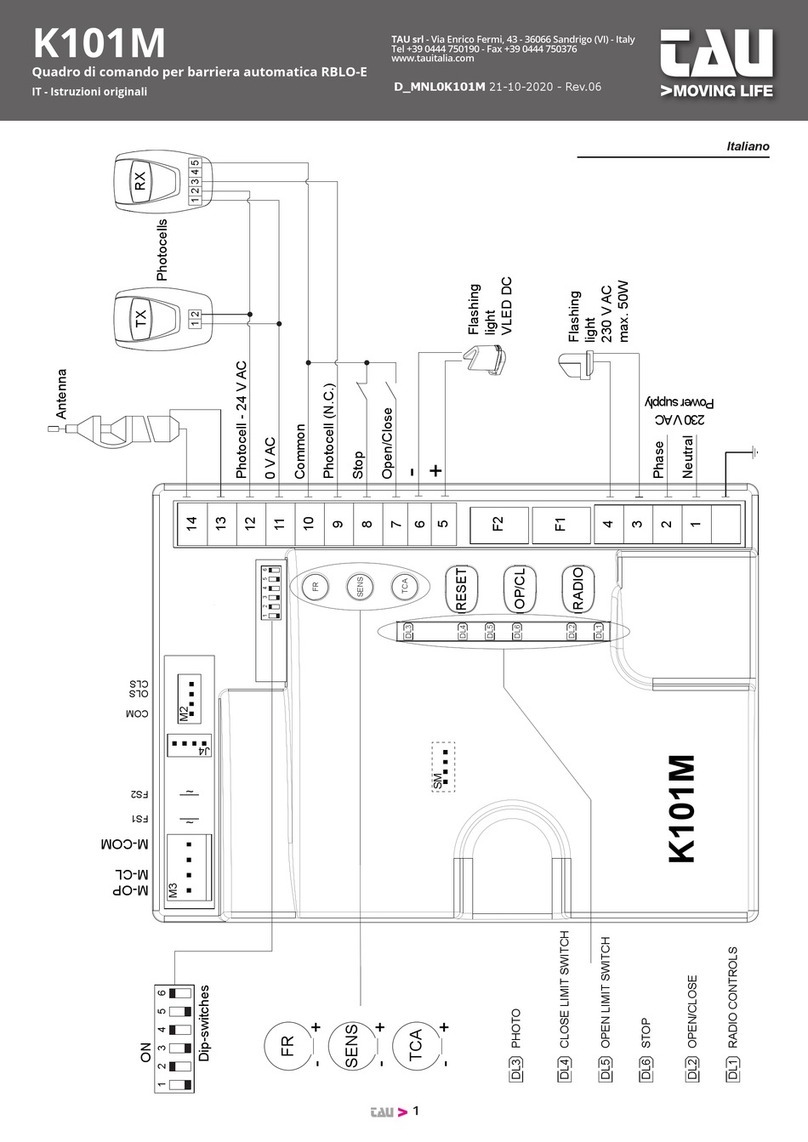

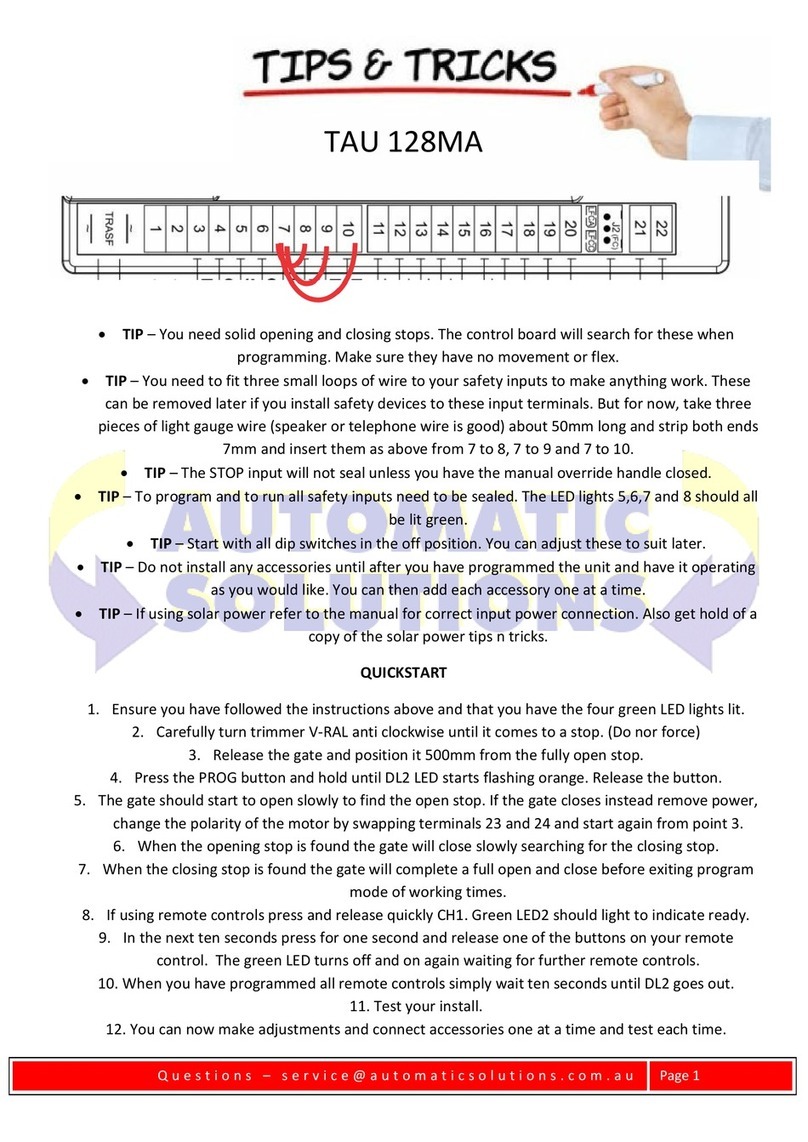

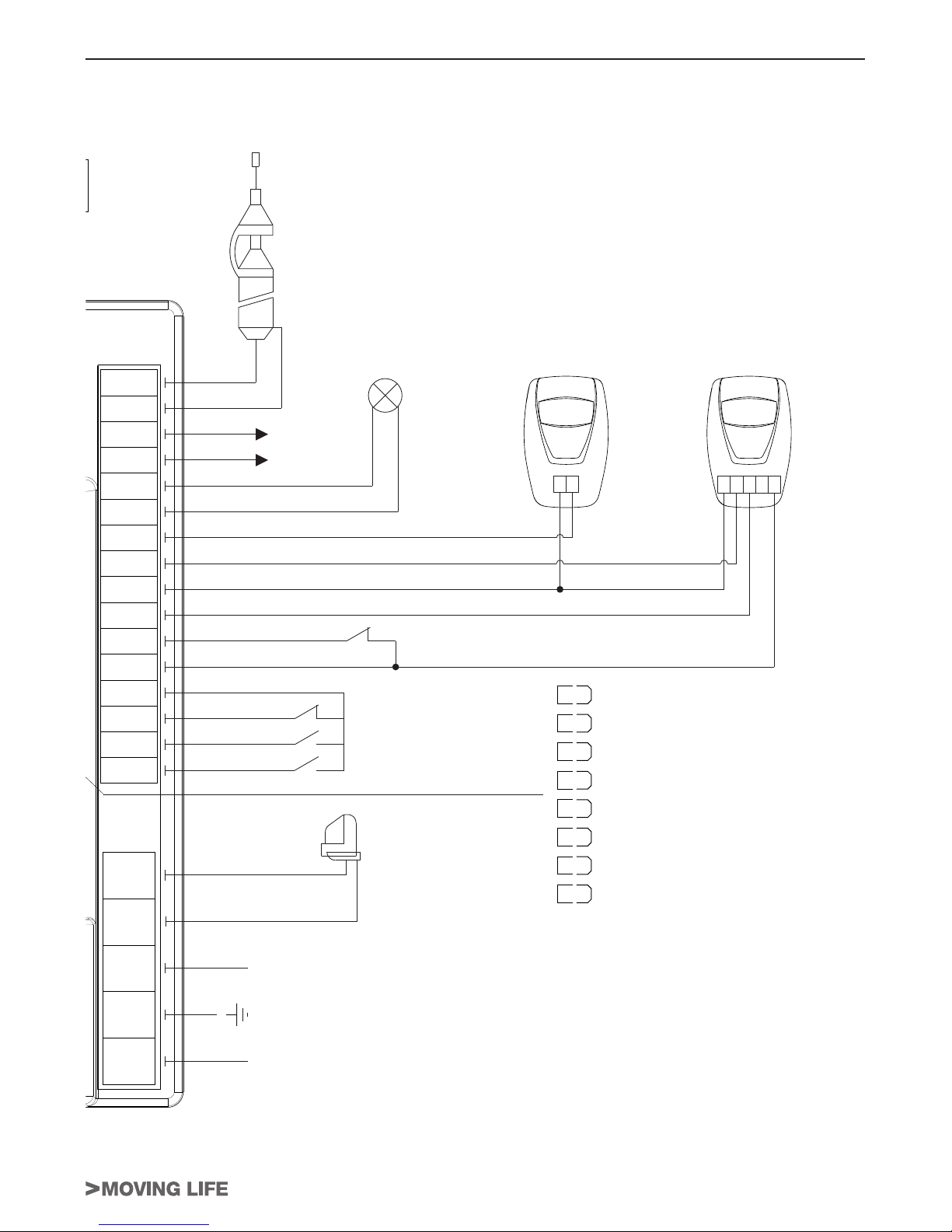

SCHEMA CABLAGGIO K580M / K580M WIRING DIAGRAM / SCHALTPLAN DER K580M

FR

SENS

TCA

M-OP

CLS

OLS

COM

GND

+5V

ENC

FS2

FS1

M-COM

M-CL

P1

P2

F1

3,15A

F2

500mA

DL1

DL2

DL3

DL4

DL5

DL6

DL7

DL8

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

K580M

Dip-switchesON

M1M2

M3

TCA

+-

SENS

+-

FR

+-

3

K580M

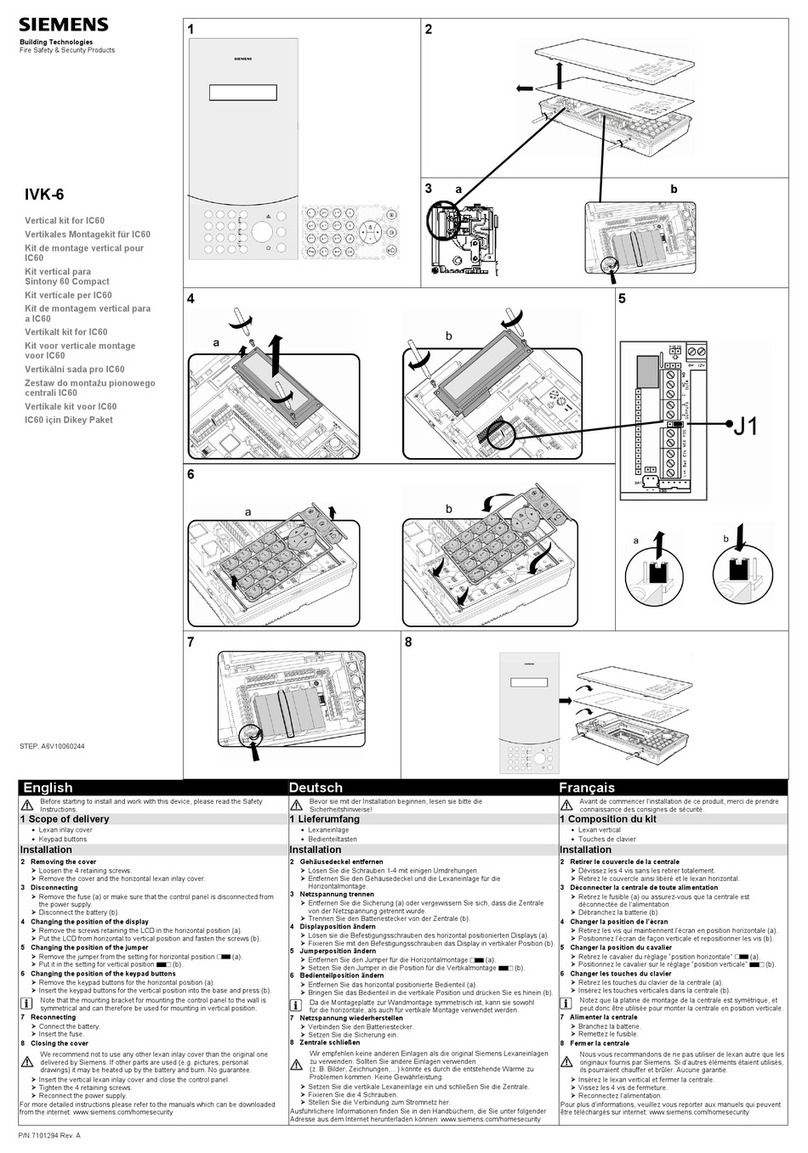

SCHÉMA CÂBLAGE K580M / ESQUEMA DEL CABLEADO K580M / ESQUEMA ELÉCTRICO K580M

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1

2

3

Neutral

230 Vac

Power supply

Phase

4

5

P1

P2

12

12

Flashing

light

230 Vac

max. 50W

Open/Close

Pedestrian

Stop

Common

Gate open

warning light

max. 3W

2nd radio

channel

Antenna

DL1

DL2

DL3

DL4

DL5

DL6

DL7

DL8

PHOTO

SENSITIVE EDGE

CLOSE LIMIT SWITCH

OPEN LIMIT SWITCH

STOP

PEDESTRIAN

OPEN/CLOSE

RADIO CONTROLS

Photocells

Common

Photocell (N.C.)

Photocell TX

Fixed safety edge

RX

1 2 3 4 5

TX

1 2

0 Vac

Photocell RX - 24 Vac

12

K580M

MANUFACTURER’S DECLARATION OF INCORPORATION

(in accordance with European Directive 2006/42/EC App. II.B)

Manufacturer: TAU S.r.l.

Address: Via E. Fermi, 43

36066 Sandrigo (Vi)

ITALY

Declares under its sole responsibility, that the product: Electronic control unit

designed for automatic movement of: Sliding Gates

for use in a: Residential / Communities

complete with: Radioreceiver

Model: K580M

Type: K580M

Serial number: see silver label

Control panel for T-ONE5, T-ONE8, T-ONEXL and

MASTER20QR/QM gearmotor

sliding gate) of for assembly with other devices used

Also declares

- 2006/95/EC Low Voltage Directive

- 2004/108/EC Electromagnetic Compatibility Directive

and, where required, with the Directive:

- 1999/5/CE Radio equipment and telecommunications terminal equipment

Also declares that it is not permitted to start up the machine until the machine in which it is incorporated or of

pertinent to the quasi-machinery.

Legal Representative

_________________________________________

Loris Virgilio Danieli

Name and address of person authorised to draw up all pertinent technical documentation:

Loris Virgilio Danieli - via E. Fermi, 43 - 36066 Sandrigo (Vi) Italy

ENGLISH

13

K580M

WARNINGS

manual can be considered as being of interest to end users. This manual is enclosed with control unit

Important information:

Disconnect the panel from the power supply before opening it.

Any other use is considered improper and is consequently forbidden by current laws.

This directive includes the following prescriptions:

laws, regulations and directives.

When designing its products, TAU observes all applicable standards (please see the attached decla-

ration of conformity) but it is of paramount importance that installers strictly observe the same stand-

ards when installing the system.

and doors” category may not install systems under any circumstances.

Whoever ignores such standards shall be held responsible for any damage caused by the

system!

Do not install the unit before you have read all the instructions.

INSTALLATION

Before proceeding, make sure the mechanical components work correctly. Also check that the

gear motor assembly has been installed according to the instructions. Then make sure that

the power consumption of the gear motor is not greater than 3A (otherwise the control panel

may not work properly).

-

Note: it is compulsory to earth the system and to observe the safety regulations that are in

force in each country.

-

ENGLISH

14

K580M

CONTROL PANEL FOR ONE 230V AC MOTOR

ATTENTION:

- do not use single cables (with one single wire), ex. telephone cables, in order to avoid

breakdowns of the line and false contacts;

- do not re-use old pre-existing cables.

TESTING

When you have completed the connection:

off only when the controls to which they are associated are operated.

be illuminated steadily.

TECHNICAL CHARACTERISTICS

Power input to board

Nominal power 400 W

Input voltage of motor circuits

IP 44

TERMINAL BOARD CONNECTIONS

Terminals Function Description

1 - 2 - 3 POWER

SUPPLY

4 - 5 FLASHING

LIGHT

6 - 9 OPEN/CLOSE

7 - 9 PEDESTRIAN

N.B. by factory setting the automation will open 120 cm.

8 - 9 STOP

10 - 11 SENSITIVE

EDGE

NOTE: if a resistive sensitive edge is connected, set dip-

switch no. 12 to ON;

switch no. 12 to OFF;

ENGLISH

15

K580M

10 - 12 PHOTOCELLS

opening in order to allow the obstacle to be removed (if dip switch

IN SERIES.

Note: the photocell transmitter must always be supplied by

terminals no. 13 - 15, since the safety system test (photo-

test) is carried out on it. To override the testing of the safety

system, or when the photocells are not used, set dip-switch

no. 6 to OFF. If the photo-test is not successful, the control

unit will not operate.

13 - 14 RX

PHOTOCELLS

13 - 15 TX

PHOTOCELL

16 - 17 GATE OPEN

LED

18 - 19 2nd RADIO

CHANNEL

Warning: to connect other devices to the 2nd Radio Channel

(area lighting, pumps, etc.), use an additional auxiliary relay.

20 - 21 AERIAL

M1 LIMIT

SWITCH

(CLS),

(OLS)(COM)

M2 ENCODER (GND),

(+5V)(ENC)

FS1 - FS2 CAPACITOR

M3 230V AC

MOTOR

(M-COM) (M-CL)

(M-OP).

LOGIC ADJUSTMENTS

TRIMMER

FR.

Turning the

trimmer clockwise (+) increases the motor torque, turning it anticlockwise (-) re-

duces it.

SENS Adjustable only with ENCODER enabled (DIP 11 ON).

Note: by rotating the TRIMMER FR. clockwise the sensitivity to obstacles of the

operaor decreases vice-versa, by rotating it

anti-clockwise, the sensitivity to obstacles of the operator increases and therefore

the thrust force decreases.

WARNING: with the trimmer at maximum, the obstacle detection is disabled!!

T.C.A.

Dip switch

1AUTOMATIC

CLOSING

On after opening, the gate automatically closes when the delay set on the

Off automatic closing disabled.

ENGLISH

16

K580M

22 / 4 STROKE

On

switch 4).

Off in the same conditions, the same command sequence causes the

3

OPENING

PHOTOCELLS

OPERATION

On during opening, cutting photocell stops the gate until the obstacle is

Off during opening, the photocell does not cut in.

4NO

REVERSE

On

Off the open-close pushbutton reverses the direction of movement of the

gate even while it is opening.

5PRE-

FLASHING

On

Off

6PHOTOCELL

TEST

On

Off

Note: to be used when the photocells are not used.

7 - 8

Dip 7 Dip 8 Function

Off Off

Gate contact open: The contact activates on opening the gate and remains

once the gate has completed its closure movement.

Off On Bistable function active: the radio control impulse causes the contact to activate

and remain active until the subsequent impulse.

On Off Monostable function active for 2 sec.: the radio control impulse causes the

On On Monostable function active for 180 sec.: the radio control impulse causes the

9GATE

TYPE

On setting for heavy gates

Off setting for standard gates

10

OPENING

DIRECTION

SETUP

On

Off

11

ENCODER On

Off

NOTE: moving DIP 11 from ON to OFF (or vice versa), learning process has to be

initialized again.

12 SENSITIVE

EDGE

On

Off

If the obstacle detection function (which can be set through trimmers FR and SENS) gets activated

-

noeuvre, the gate opens fully.

WARNING: the control panel logics may interpret mechanical friction as an obstacle.

ENGLISH

17

K580M

SETUP PROCEDURE

WARNING: The learning process has to be done even if ENCODER function is disabled

(DIP 11 OFF).

It is recommended to start the learning process with the gate partially opened.

-

cally the learning process:

If the automation opens instead of closing, stop the learning process (by cutting the

photocells or opening the STOP contact), invert DIP 10 and continue the learning pro-

WARNING: - SETTING SLOWDOWN: (skip this procedure to disable slowdown) During

the opening cycle press P1 or close the OPEN/CLOSE contact at the desired position

where to start the slowdown.

WARNING: - SETTING SLOWDOWN: (skip this procedure to disable slowdown) During

the opening cycle press P1 or close the OPEN/CLOSE contact at the desired position

where to start the slowdown.

WARNING: if during the learning process either the STOP, or PHOTOCELLS or SAFE-

TY EDGE contact will be opened the automation stops. By pressing P1 or closing the

OPEN/CLOSE contact the learning process starts again from pont nr. 1

ADVANCED FUNCTIONS

Clock function:

open at certain times during the day, after which it reverts to automatic closing.

Note: the gate remains open as long as the Op/Cl input continues to be activated.

“Open only” function: -

ing command and the gate will close only after the automatic closure time has elapsed.

“Gate contact open” function:

will act as a dry contact which indicates when the gate is open. This function can be used to connect

DIAGNOSTICS LED

DL1 (PHOTO)

DL2 (SENSITIVE EDGE)

DL3 (CLOSE LIMIT SWITCH)

DL4 (OPEN LIMIT SWITCH)

DL5 (STOP) STOP button green LED signal

DL6 (PEDESTRIAN) PEDESTRIAN button red LED signal

DL7 (OPEN/CLOSE)

DL8 (RADIO CONTROLS)

LED - DL8

always on: normal operation;

photo-test error;

Disable photo-test (dip-switch 6 OFF), check the operation of the photocells and

their connection;

no encoder signal (only with dip 11 ON);

Check wiring, check encoder by TEST-ENCODER (optional);

ENGLISH

18

K580M

6 obstacle detected (only with dip 11 ON);

Make sure there are no obstacles across the path of the gate and that it slides

smoothly;

Learning process not completed;

Repeat the Learning process procedure;

Learning procedure in progress;

(duration 30 sec.)

Only when powered up: wrong power supply frequency (50 Hz default set-

ting);

RESTORING AUTOMATIC OPERATION

Should the gate needs to be operated manually, use the release system. After a manual operation:

433.92 MHz BUILT-IN RADIO RECEIVER

4RP) which can be set on both the two channels as desired.

-

-

for about 3 seconds without performing any memorisation.

procedure of remote programming of the new transmitters. Follow the procedure written on the in-

ENGLISH

19

K580M

MALFUNCTIONS: POSSIBLE CAUSES AND SOLUTION

The automation does not start

The radio control has very little range

The gate opens the wrong way

GUARANTEE: GENERAL CONDITIONS

sales document, receipt or invoice).

-

manship or materials.

The guarantee does not cover the following cases:

improper repairs, incorrect installation, or other reasons that do not depend on TAU.

-

ENGLISH

Other manuals for K580M

2

Table of contents

Other tau Control Panel manuals

Popular Control Panel manuals by other brands

Pulsar

Pulsar 17/TRP40/DSPR/S Assembly instruction

Digital Monitoring Products

Digital Monitoring Products XTL Series user guide

INIM

INIM GameOver SmartLiving 505 Installation and programming manual

Texecom

Texecom Premier 8168 Programming steps

Balboa

Balboa ML900 user guide

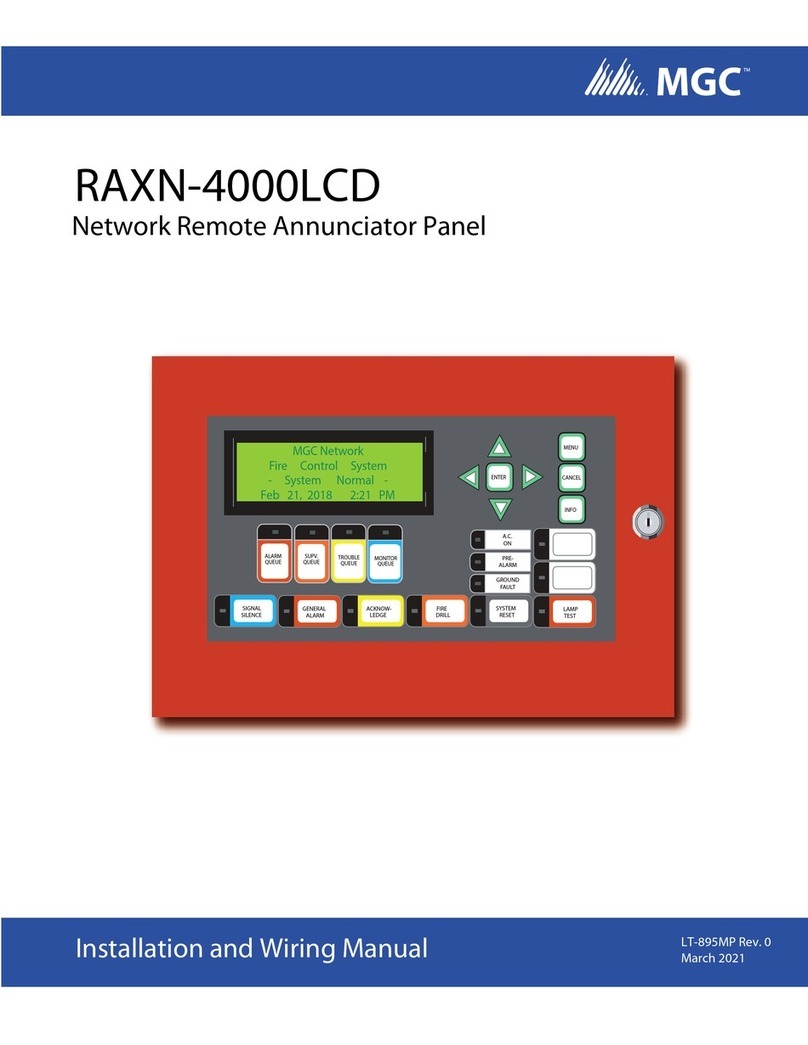

MGC

MGC RAXN-4000LCD Installation and wiring manual