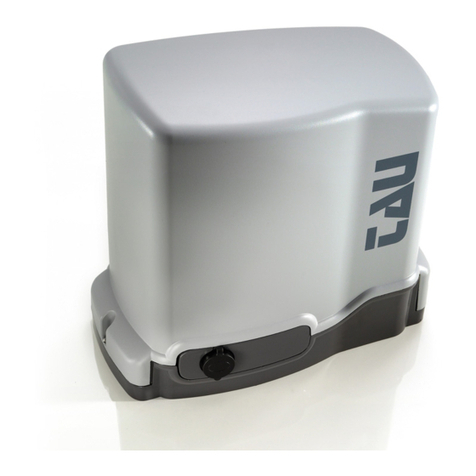

tau BIG Series User manual

1

MANUALE D’USO E MANUTENZIONE

USE AND MAINTENANCE MANUAL

BEDIENUNGS - UND WARTUNGSANLEITUNG

MANUEL D’EMPLOI ET D’ENTRETIEN

MANUAL DE USO Y MANTENIMIENTO

BIG

Series

D_MNL0BIG 11-04-2022 - Rev.24

2

BIG40QI

BIG25QI

2x0,5mm²

4x0,5mm²

4x0,5mm²

2x0,5mm²

4x0,5mm²

2x0,5mm²

2x0,5mm²

2x0,5mm²

3x0,5mm²

3x1,5mm²

4x0,5mm²

Fig.2 Fig.3

BIG25QI

BIG30QI

BIG40Q

76

64

102

317

265.5

314.1

426

141

179

400 354.5

302

370

76

573

141

616

76

179

440

470 424

370

Fig.4

Fig.1

BIG25QI

BIG30QI

BIG40Q

76

64

102

317

265.5

314.1

426

141

179

400 354.5

302

370

76

573

141

616

76

179

440

470 424

370

BIG Series

Fig.5

P-400CP25

3

BIG Series

Fig.6

P-400CP30

Fig.7

65mm

min 15cm

40 mm

10-20mm

Fig.9

65 mm

Fig.8

A B

Fig.10

4

BIG Series

Fig.11 Fig.12

Fig.13

Fig.14 Fig.15

5

AB

C

C

D

3

1

2

1

2

A

B

1

5/8” x 3/8”

BIG Series

Fig.16

Fig.17 Fig.18 Fig.19

Fig.19

13

1. INSTALLATION

The product may only be installed by a qualied tter. The manufacturer, Tau, declines all liability for damage to property and/or injury to

people deriving from the incorrect installation of the system or its noncompliance with current law (see Machinery Directive).

Product installation must NOT be performed on gates that open / close on sloping ground.

FIG. 1 - STANDARD SYSTEM

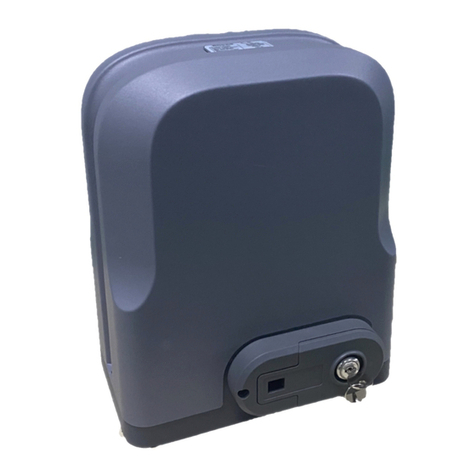

1. Gear motor

2. Release

3. Photocells

4. Posts + Photocells

5. Aerial and Flashing light

6. Key switch

7. Electromechanical edge

8. Gate guide

9. Limit switch shoe

10. Rack

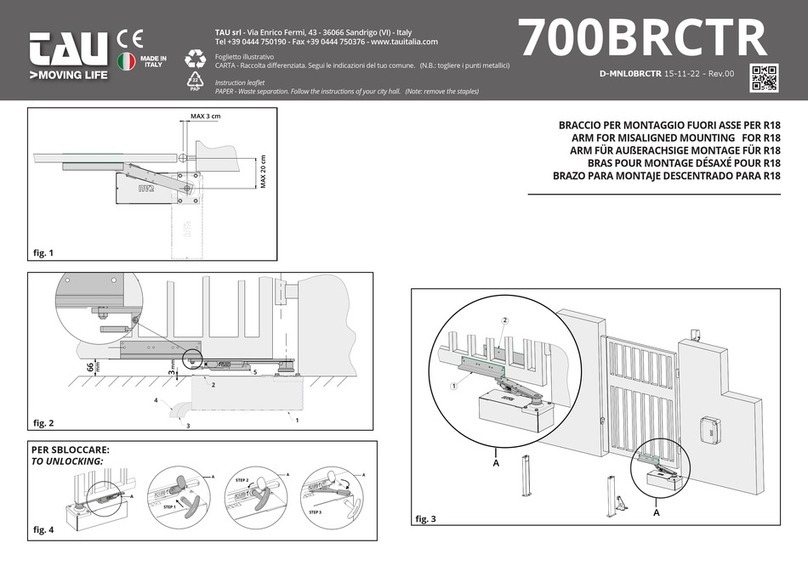

FIG. 2 - INSTALLATION MATERIAL

1. gear motor

2. counterplate

3. rack

4. self-tapping screws

5. limit switch shoes

6. release key

7. rack brackets

8. bent pins for counterplate

Place the control unit (external versions) in the immediate vicinity of the motors.

Be careful not to run cables for auxiliary devices inside raceways housing other cables supplying power to large loads

or lights with electronic starters.

In the event control pushbuttons or indicator lights are installed inside homes or oces several metres from the actual

control unit, it is advisable to decouple the signal by means of a relay in order to avoid induced interference.

OVERALL DIMENSIONS

Figs. 3,4 show the main overall dimensions for the sliding gate; gs.5-6 show the dimensions of the foundation counterplate.

PRELIMINARY OPERATIONS

Carefully read the instructions contained in the handbook before starting work.

Before proceeding with installation, make sure that all the components are present, use suitable work equipment and do not touch live electrical parts.

CONSIDERATIONS PRIOR TO INSTALLATION

Before proceeding with installation check that:

- The wheels of the gate are mounted in such a way as to make it stable and that they are in good condition and perfect working order;

- The whole of the slide rail is unobstructed, straight and clean and a travel stop is tted at either end.

INSTALLATION DISTANCES

To install the gear motor correctly, make sure it is at a distance of 65 mm from the gate.

See g. 7 for xing to a concrete oor, g. 8 for digging and g. 9 for positioning the counterplate.

2. PREPARING THE BASE

Dig foundations at least 15 cm deep and suciently wide. Use protective sheaths for the cables.

FIXING THE FOUNDATION COUNTERPLATE

Fill the hole with concrete and sink the bet pins into it; the counterplate must be perfectly at at 1 or 2 cm from the level of the nished oor and at

a distance of approximately 65 mm from the gate.

NB: it is also possible to install the gear motor without the foundation counterplate by using four foundation bolts on a at concrete base; the

measurements shown in g. 7 must always be respected.

A height-adjustable counterplate may be used for model BIG25QI; in this case, the xed bent pins must be welded to the rail, see g. 10/a.

This makes it possible to adapt the gear motor to a pre-existing system; the measurements shown in g. 10/b must be respected.

3. ANCHORING THE GEAR MOTOR

Tighten the screws (as shown in g. 11) on both sides of the gear motor. Fit all the cables into the sheath, which passes through the hole made

in the base of the foundation counterplate.

4. FIXING THE RACK

Prepare the rack with the relative brackets (g. 12).

Place the rack on the motor pinion (released) respecting the distance between the tooth of the gear and the tooth of the rack as shown in g.

13. Make a hole in the leaf at the centre of the slot and x with the relative screws. Slide the leaf along the pinion and x each bracket in turn.

ENGLISH

14

5. FIXING AND ADJUSTING THE LIMIT SWITCH SHOES

Fix the shoes as shown in g. 14, one near either end of the rack. Move the leaf by hand and position the shoes so that they touch the micro-

switch lever just before the leaf hits the travel stops at both ends of the rail; then tighten the screws.

A single factor or combination of factors (thermal expansion, climate, frequency of use, etc.) may result in the position the

gate stops in changing over the course of the day, both when opening and when closing. Consequently, we cannot guarantee

that the gate will always stop in the same position.

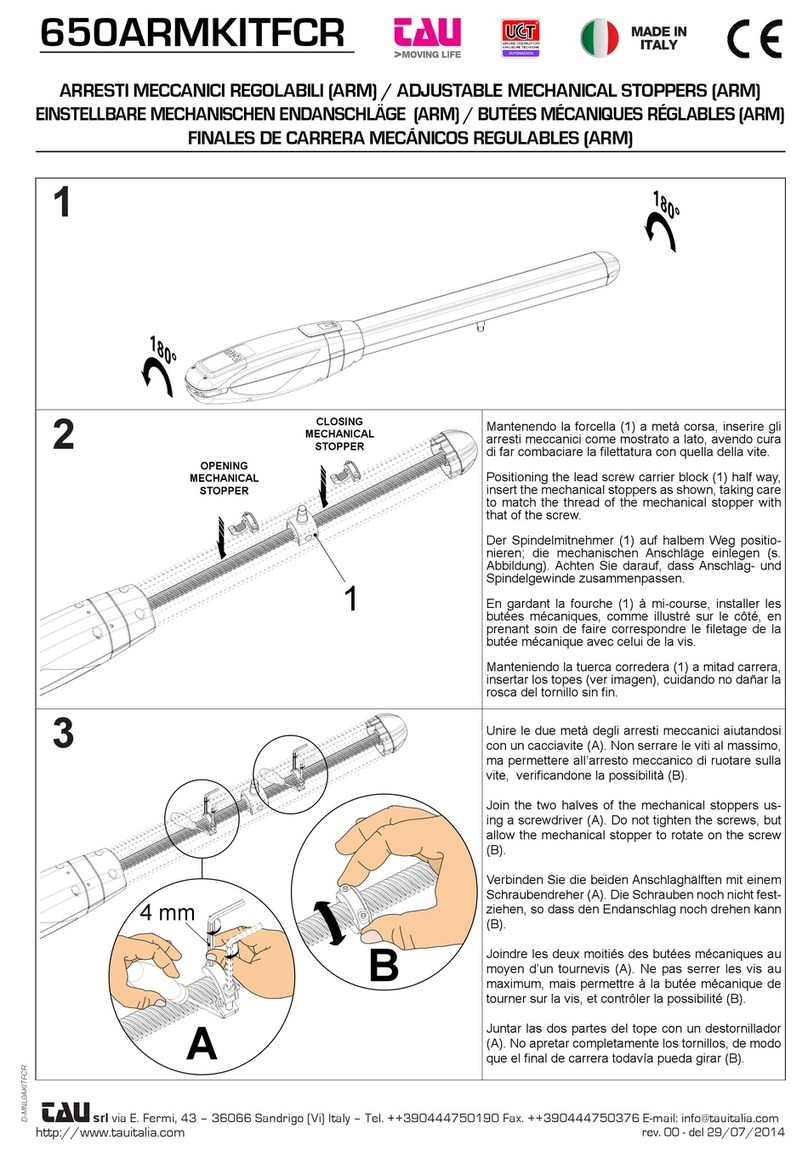

6. ADJUSTING THE MECHANICAL CLUTCH

Before starting, make sure to disconnect the gear motor from the power supply.

BIG25QI: Make a 1/2 or a whole turn at a time using the supplied wrench (g. 15).

BIG40QI: After removing the lock nut (1 g. 16A) and the stop dowel (2 g. 16A), adjust the thrust force using the hex wrench provided

(3 g. 16B) (rotate clockwise to increase the thrust force, rotate counter-clockwise to decrease it). After adjusting as needed,

reassemble the stop dowel (2 g. 16D) until it reaches the mechanical stop, then fasten the lock nut (1 g. 16D).

7. VERSION WITH CHAIN PINION: BIG25QI / BIG40QI

The door can also be power-operated with the version with chain pinion as shown in g. 17.

8. ELECTRICAL CONNECTIONS

For electrical connection, please refer to the specic instructions for each electrical control panel. The following tips apply to all models.

Do not put the power cables in the same sheath as the motor cables. Always choose the shortest routes for the cable lines. Make sure the

equipment is well earthed. A general switch should be tted to the system, out of reach of unauthorised people, allowing power to be discon-

nected from the gear motor for maintenance purposes or if the gear motor remains inactive for a long period.

9. MANUAL RELEASE

In the event of a power failure, use the manual release device to move the gate. Remove the plastic cover over the lock, insert the key and

remove the small safety guard.

BIG25QI: Turn the handle clockwise (g. 18).

BIG40QI: Using the hex wrench provided, rotate the release assembly counter-clockwise at least one complete turn (g. 19B). To restore

normal operation, simply tighten the release assembly (1 g. 19A) by screwing it in until it reaches the mechanical stop.

It is mandatory, at least once a year, to perform the unlocking test. Once the gate has been unlocked, if it is blocked or

particularly heavy to move manually, it is suggested to knock slightly with a hammer on the release screw (g. 19C). This is

in order to detach the clutch plates.

10. LIMIT SWITCH

The gear motors in the BIG series have been designed to work with an electromechanical limit switch featuring a single dual-eect switch.

Cable connections:

1 = common

2 = blue (common)

3 = brown (close L.S. – N.C. contact)

4 = black (open L.S. – N.C. contact)

11. WARNINGS

The tter is responsible for ensuring the system can be used correctly and functionally. He must also provide it with all the safety devices and/

or signals required to ensure it complies with current law. Make sure that each single device is in perfect working order.

As regards vertical tubular gates, the system must be tted with a protective mesh covering the whole surface of the gate.

Put up easy-to-read signs informing people that the gate is powered.

It is forbidden to use the equipment for other purposes or in other circumstances than those mentioned.

In particular:

1 do not touch the equipment with wet hands;

2 disconnect the power supply before opening the control box and/or the gear motor;

3 do not pull the power cable to remove the power plug;

4 do not touch the motor unless you are sure it has cooled down;

5 only move the gate when it is completely visible;

6 do not approach the gate if this is moving: wait until it has stopped;

7 do not allow children or animals to play near the gate;

8 do not allow children or unauthorised people to use the remote control or other control devices;

9 carry out routine maintenance;

10 in the event of a fault, disconnect the power supply and only move the gate if it is possible and safe to do so.

12. MAINTENANCE

Attention: only the maintenance man, who must be a specialised technician, is allowed to operate the automatic system during maintenance.

The power supply should therefore be disconnected. If the power supply must be left on for certain operations, each control device should be

checked or disabled (remote controls, push button strips, etc.) except for the one used by the maintenance man.

ROUTINE MAINTENANCE

ENGLISH

15

Each of the following operations must be carried out when necessary and always every 6 months.

Gate: check the general condition of the gate.

Automation system:

1 check the safety devices.

2 regularly grease the release device

EXTRAORDINARY MAINTENANCE OR BREAKAGE

If major work on electromechanical parts must be carried out, the faulty part should be removed and repaired in the workshop by the manu-

facturer’s or other authorised technicians.

13. GUARANTEE: GENERAL CONDITIONS

TAU guarantees this product for a period of 24 months from the date of purchase (as proved by the sales document, receipt or invoice).

This guarantee covers the repair or replacement at TAU’s expense (ex-works TAU: packing and transport at the customer’s expense) of parts

that TAU recognises as being faulty as regards workmanship or materials.

For visits to the customer’s facilities, also during the guarantee period, a “Call-out fee” will be charged for travelling expenses and labour costs.

The guarantee does not cover the following cases:

• If the fault was caused by an installation that was not performed according to the instructions provided by the company inside the

product pack.

• If original TAU spare parts were not used to install the product.

• If the damage was caused by an Act of God, tampering, overvoltage, incorrect power supply, improper repairs, incorrect installation,

or other reasons that do not depend on TAU.

• If a specialised maintenance man does not carry out routine maintenance operations according to the instructions provided by the

company inside the product pack.

• Wear of components.

The repair or replacement of pieces under guarantee does not extend the guarantee period.

In case of industrial, professional or similar use, this warranty is valid for 12 months.

MANUFACTURER’S DECLARATION OF INCORPORATION

(in accordance with European Directive 2006/42/EC App. II.B)

Manufacturer: TAU S.r.l.

Address: Via E. Fermi, 43 - 36066 Sandrigo (Vi) - ITALY

Declares under its sole responsibility, that the product: Electromechanical actuator designed for automatic movement of: Sliding Gates

for use in a: Industrial complete with: Electronic control unit

Model: BIG Type:BIG25QIQI / BIG40QI

Serial number: SEE SILVER LABEL Commercial name: AUTOMATION FOR SLIDING GATES

Has been produced for incorporation on an access point (sliding gate) of for assembly with other devices used to move such an access point, to

constitute a machine in accordance with the Machinery Directive 2006/42/EC.

Also declares that this product complies with the essential safety requirements of the following EEC directives:

- 2014/35/EU Low Voltage Directive - 2014/30/EU Electromagnetic Compatibility Directive

and, where required, with the Directive: - 2014/53/EU Radio equipment and telecommunications terminal equipment

Also declares that it is not permitted to start up the machine until the machine in which it is incorporated or of which it will be a component has

been identied with the relative declaration of conformity with the provisions of Directive 2006/42/EC.

The following standards and technical specications are applied:

EN 61000-6-2; EN 61000-6-3; EN 60335-1; ETSI EN 301 489-1 V1.9.2; ETSI EN 301 489-3 V1.6.1; EN 300 220-2 V2.4.1;

EN 12453:2000; EN 12445:2000; EN 60335-2-103

The manufacturer undertakes to provide, on suciently motivated request by national authorities, all information pertinent to the quasi-machinery.

Sandrigo, 29/11/2017 Legal Representative

_________________________________________

Loris Virgilio Danieli

Name and address of person authorised to draw up all pertinent technical documentation:

Loris Virgilio Danieli - via E. Fermi, 43 - 36066 Sandrigo (Vi) Italy

ENGLISH

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) - Italy

Tel +39 0444 750190 - Fax +39 0444 750376

[email protected] - www.tauitalia.com

Foglietto illustrativo

CARTA - Raccolta dierenziata. Segui le indicazioni del tuo comune. (N.B.: togliere i punti metallici)

Instruction leaet

PAPER - Waste separation. Follow the instructions of your city hall. (Note: remove the staples)

22

PAP

Other manuals for BIG Series

2

This manual suits for next models

1

Table of contents

Other tau Gate Opener manuals

Popular Gate Opener manuals by other brands

Chamberlain

Chamberlain ATSW manual

Novoferm tormatic

Novoferm tormatic Novomatic 200 Installation, operating and maintenance instructions

Aprimatic

Aprimatic XT2500 INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER

CAME

CAME FROG installation manual

SOMFY

SOMFY IXENGO J S 230V installation instructions

Hiland

Hiland SLG5150 Series user manual