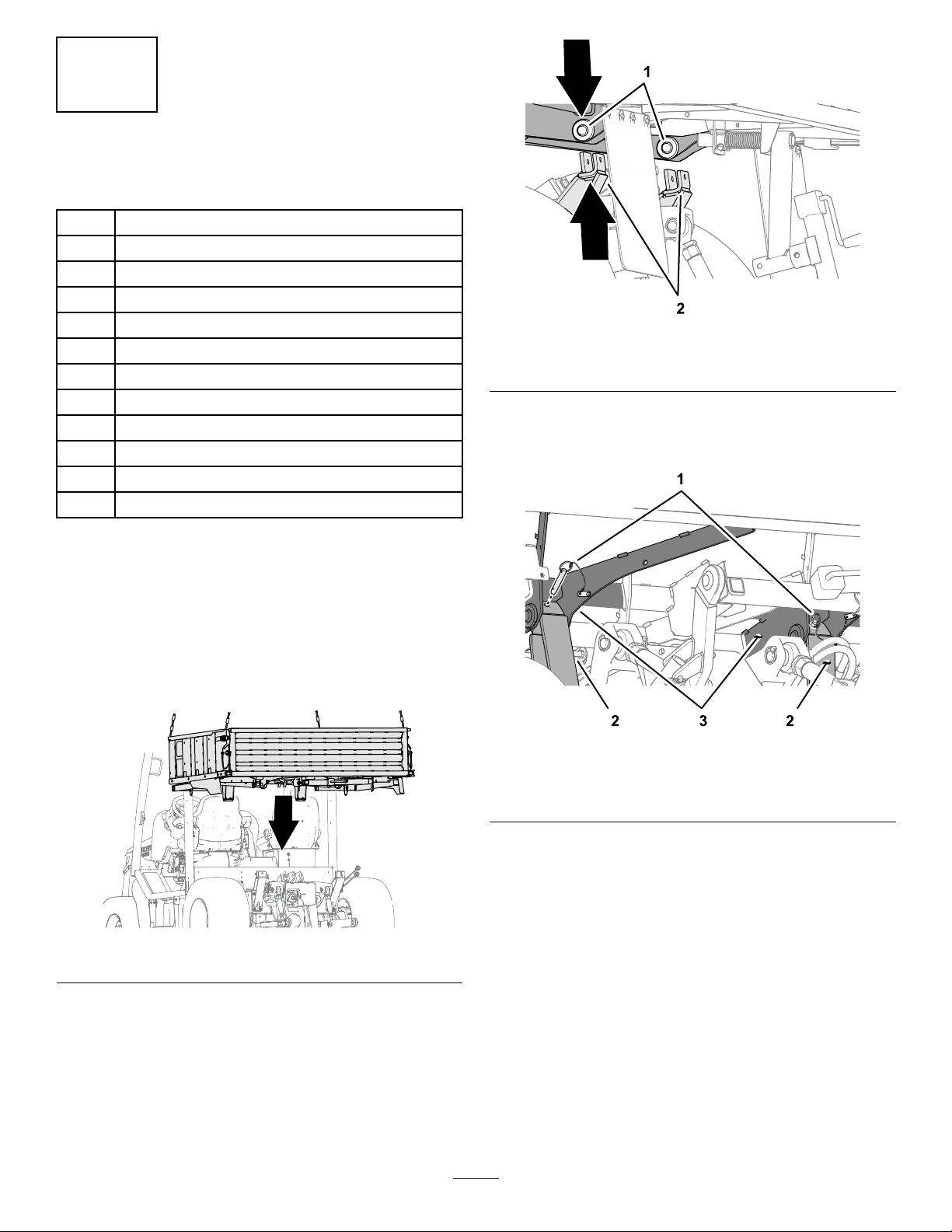

Toro Outcross 9060 Series User manual

Other Toro Farm Equipment manuals

Toro

Toro Road-Ready Pro Force User manual

Toro

Toro Groundsmaster 4500-D User manual

Toro

Toro Sand Pro 5040 User manual

Toro

Toro 22472 User manual

Toro

Toro Reelmaster 33455 User manual

Toro

Toro Trans Pro 100 User manual

Toro

Toro 138-2998 User manual

Toro

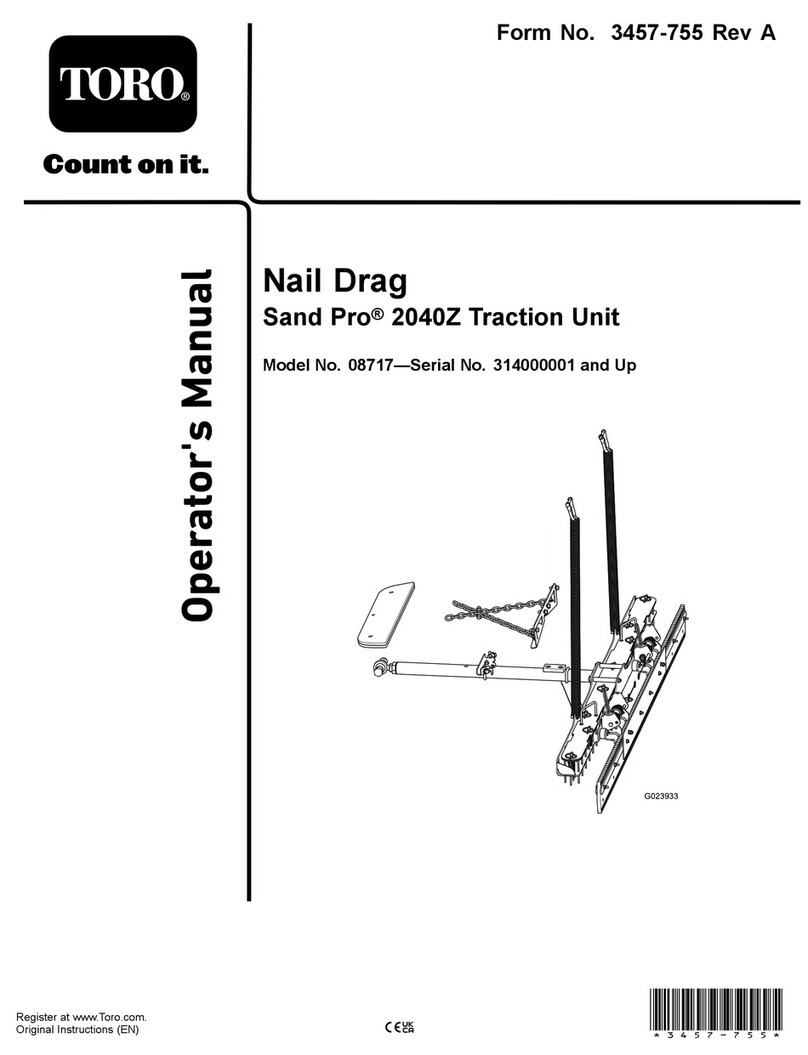

Toro Sand Pro 2040Z User manual

Toro

Toro E-Z Vac Z Master Z400 Series User manual

Toro

Toro Groundsmaster 4500-D User manual

Toro

Toro 133-6314 User manual

Toro

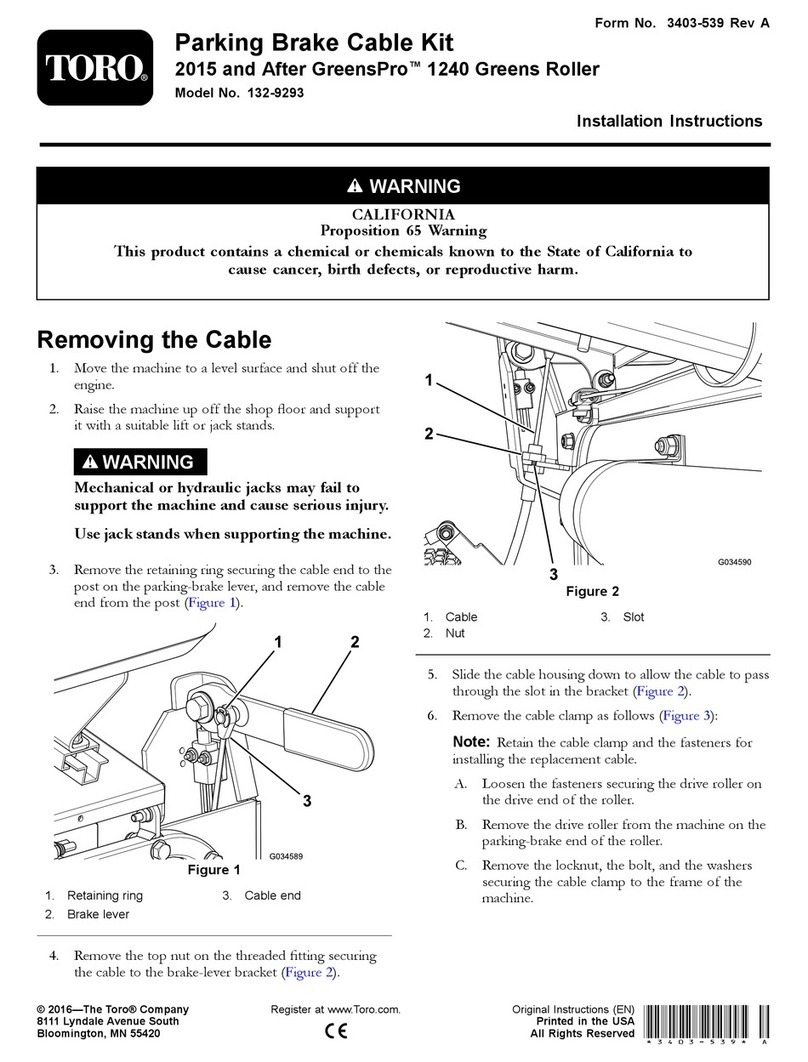

Toro 132-9293 User manual

Toro

Toro 23106 User manual

Toro

Toro Sitework 22447 User manual

Toro

Toro 41355 User manual

Toro

Toro Reelmaster 5510 User manual

Toro

Toro Sand Pro 2040Z User manual

Toro

Toro Groundsmaster 328-D User manual

Toro

Toro 23513 User manual

Toro

Toro 22423 User manual