6

•Never drive across a steep hill; always drive straight up

or down or go around the hill.

•If the engine stalls or you begin to lose headway while

climbing a hill, gradually apply the brakes and slowly

back straight down the hill.

•Turning while traveling up or down hills can be

dangerous. If you have to turn while on a hill, do it

slowly and cautiously. Never make sharp or fast turns.

•Heavy loads affect stability. Reduce the weight of the

load and your speed when operating on hills.

•Avoid stopping on hills, especially with a load.

Stopping while going down a hill will take longer than

stopping on level ground. If the sprayer must be

stopped, avoid sudden speed changes, which may

initiate tipping or rolling of the sprayer. Do not slam on

the brakes when rolling backward, as this may cause the

sprayer to overturn.

•The Toro Company strongly recommends installing the

optional ROPS Kit when operating on hilly terrain. If

you install a ROPS, always wear the seat belt when

driving the sprayer.

•Reduce speed and load when operating on rough terrain,

uneven ground, and near curbs, holes, and other sudden

changes in terrain. Loads may shift, causing the sprayer

to become unstable.

Sudden changes in terrain may cause abrupt

steering wheel movement, possibly resulting in

hand and arm injuries.

•Reduce your speed when operating on rough

terrain and near curbs.

•Grip the steering wheel loosely around the

perimeter. Keep your hands clear of the steering

wheel spokes.

Warning

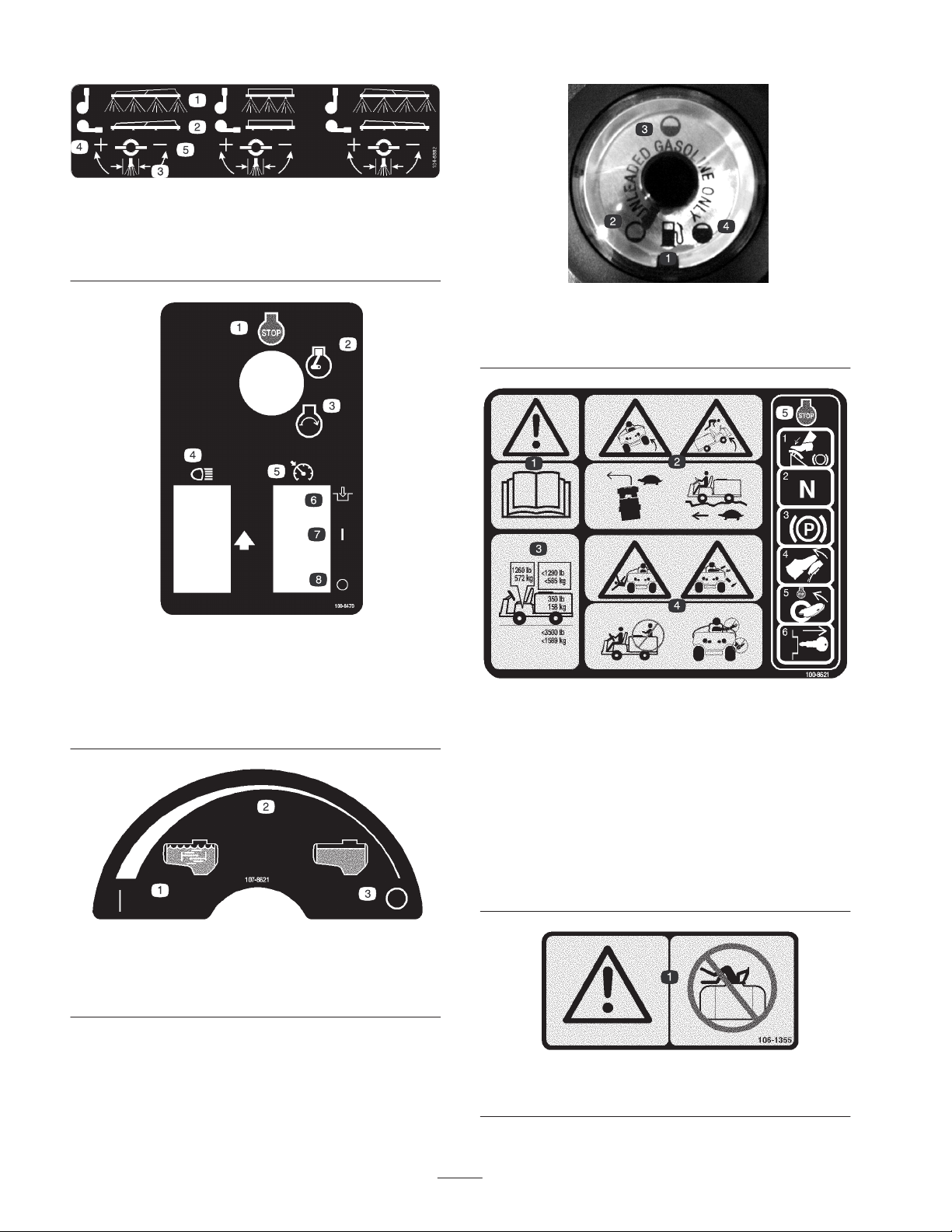

Loading

The weight of the cargo can change the sprayer center of

gravity and sprayer handling. To avoid loss of control and

personal injury, follow these guidelines:

•Reduce the weight of the load when operating on hills

and rough terrain to avoid tipping or overturning of the

sprayer.

•Liquid loads can shift. This shifting happens most often

while turning, going up or down hills, suddenly

changing speeds, or while driving over rough surfaces.

Shifting loads can cause the sprayer to tip over.

•When operating with a heavy load, reduce your speed

and allow for sufficient braking distance. Do not

suddenly apply the brakes. Use extra caution on slopes.

•Be aware that heavy loads increase your stopping

distance and reduce your ability to turn quickly without

tipping over.

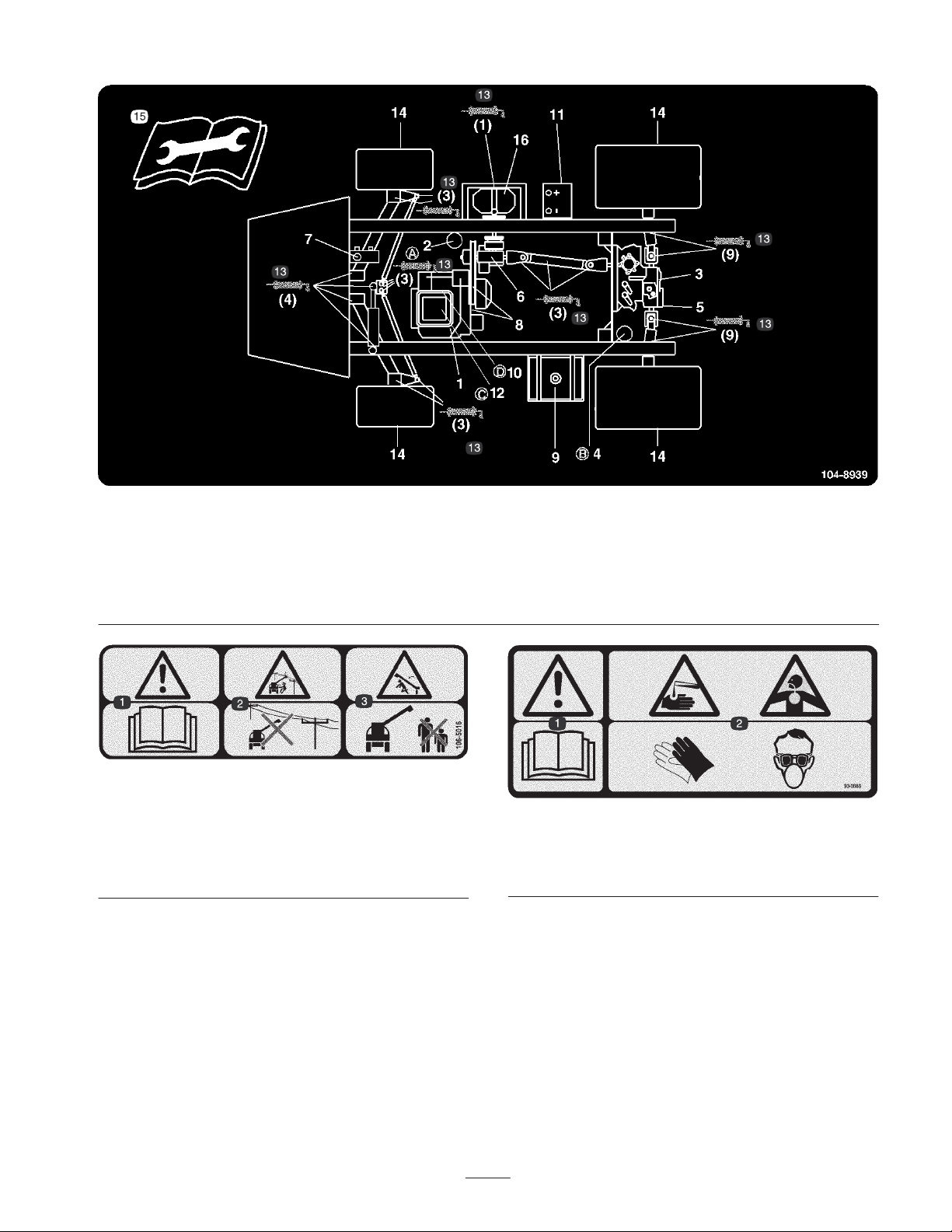

Maintenance

•Only permit qualified and authorized personnel to

maintain, repair, adjust, or inspect the sprayer.

•Before servicing or making adjustments to the machine,

stop the engine, set the parking brake, and remove the

key from the ignition to prevent someone from

accidentally starting the engine.

•To make sure that the entire machine is in good

condition, keep all nuts, bolts, and screws properly

tightened.

•To reduce the potential for fire, keep the engine area

free of excessive grease, grass, leaves, and

accumulation of dirt.

•Never use an open flame to check the level or leakage

of fuel or battery electrolyte.

•If the engine must be running to perform a maintenance

adjustment, keep your hands, feet, clothing, and any

parts of your body away from the engine and any

moving parts. Keep everyone away.

•Do not use open pans of fuel or flammable cleaning

fluids when cleaning parts.

•Do not adjust the ground speed governor. To ensure

safety and accuracy, have an Authorized Toro

Distributor check the ground speed.

•Keep your body and hands away from pin hole leaks or

nozzles that eject high pressure fluid. Use cardboard or

paper to find leaks. Fluid escaping under pressure can

penetrate skin and cause injury requiring surgery within

a few hours by a qualified surgeon or gangrene may

result.

•If major repairs are ever needed or assistance is

required, contact an Authorized Toro Distributor.

•To be sure of optimum performance and safety, always

purchase genuine Toro replacement parts and

accessories. Replacement parts and accessories made by

other manufacturers could be dangerous. Altering this

sprayer in any manner that may affect sprayer

operation, performance, durability, or its use, may result

in injury or death. Such use could void the product

warranty.