PAGE 4 OF 4 0412 IH-3070

SAFETY

• Never use oxygen, combustible gases, CO2, steam

or high pressure gas tanks as power sources for the

this tool. The tool could explode and cause serious

injury.

• Use only dry, clean, pressure-regulated compressed

air to drive the tool.

• Connect the tool to the compressed air system

before the fastener unit is loaded.

• The maximum permitted air pressure for the tool is

116 p s i .

• The maximum supply pressure is 127 psi.

• Avoid excessive pressure drop by ensuring that the

minimum internal diameter of the air hose is 3/8"

and that of the nipple is a minimum of 6/32".

• The stapler and its hose are equipped with a

connection nipple that automatically exhausts air

from the tool after it has been disconnected.

• Adjust the air pressure to the lowest level that will

bend the staples correctly. Start at approximately

5.0 bar and raise this by 0.5 bar increments until the

correct pressure is found. Never exceed 8 bar.

• Low air pressure will result in low maintenance costs.

• When working with small cartons, there is a risk of

injury to fingers holding the item.

• Never hold your hand under or close to the stapling

head.

• Keep hands clear of arms carrying the stapling

head when operating the foot valve.

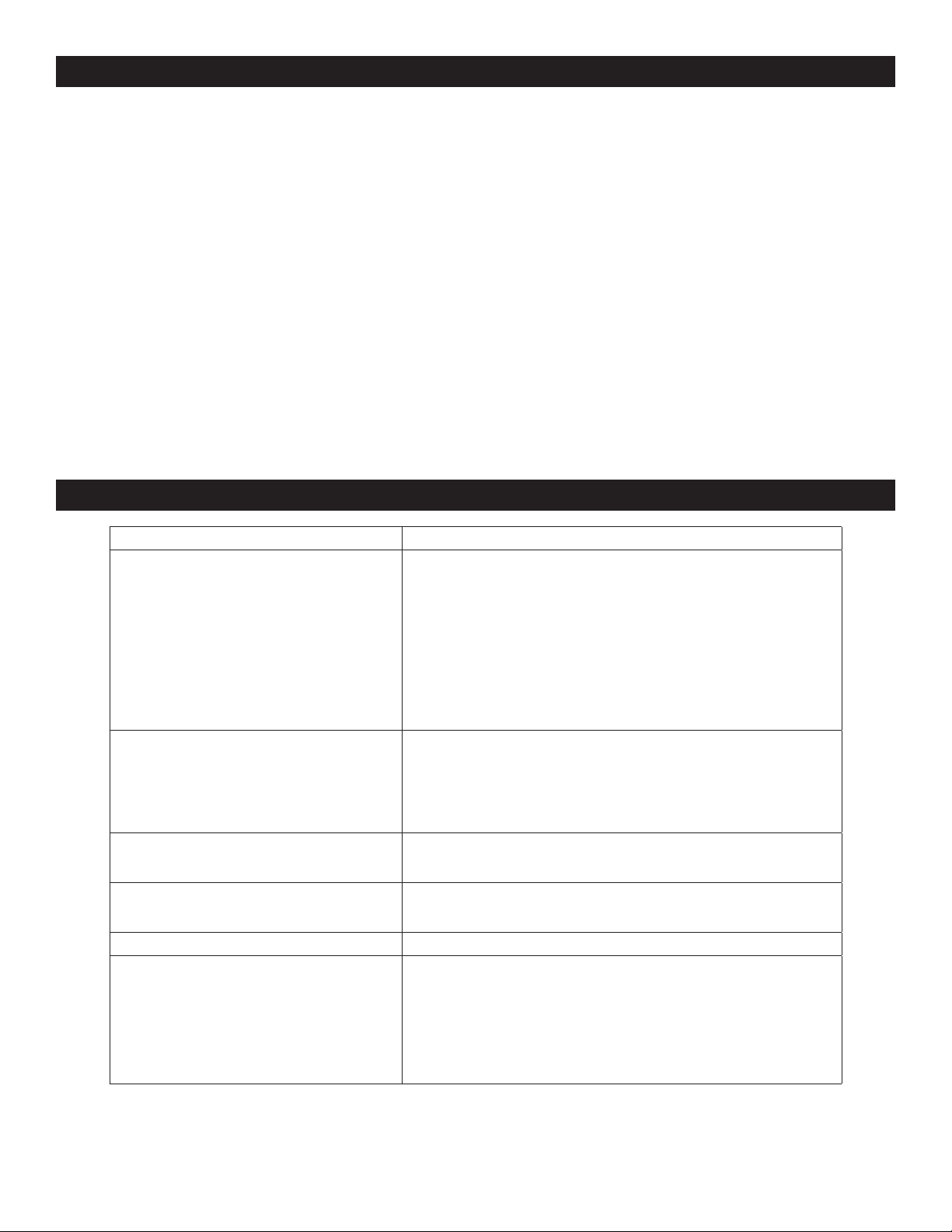

TROUBLESHOOTING

OPERATING ISSUE RECOMMENDATIONS

Staples are not fed properly •Checkthattherighttypeofstaplesarebeingused

•CheckthatthefeederspringisOK

•CheckthatthestaplepusherisOK

•Checkthatthestapletrackiscleanwithnodirtinside

•CheckthatthereturnspringinthestaplingheadisOK

•CheckthatthestaplingheadtripspringsareOKonhead

•CheckthatthesideplatesareOKonhead

Staples are deformed when inserted •Checkthatthestaplingheadbearinghasnoplay

•Checkthattheanvilisproperlycentered

•Checkthatthedriverisnotdamaged

•Checkthatthestaplechannelisclean

Noise level is too high •Checkthattheairpressureisat70psi

•Checkthatthestrokespeedisnotunnecessarilyhigh

The carton is damaged by the stapling head •Checkthattheairpressureisat70psi

•Checkthatthestrokespeedisnotunnecessarilyhigh

The carton is not pressed together properly •Checkthatthelengthofthepistonrodisadjustedproperly

A staple is stuck in the staple head •Removethestaple:

1. Pull the pusher back to take the pressure off the staple strip

2. Loosen the screws that hold the front plate

3. Pull the staple downward to remove

4. Retighten the screws

πCHICAGO•ATLANTA•DALLAS•LOSANGELES•MINNEAPOLIS•NYC/PHILA•SEATTLE•MEXICO•CANADA

1-800-295-5510

uline.com