Assa Abloy h.e.s. 9200 Series Manual

Other Assa Abloy Door Lock manuals

Assa Abloy

Assa Abloy 8654 User manual

Assa Abloy

Assa Abloy Yale Assure Lock with Wi-Fi User manual

Assa Abloy

Assa Abloy Sargent 10G13 User manual

Assa Abloy

Assa Abloy MSL sFlipLock drive User manual

Assa Abloy

Assa Abloy Hes 5200 Series User manual

Assa Abloy

Assa Abloy Yale Assure Lock YRD620 Technical specifications

Assa Abloy

Assa Abloy Access 3 User manual

Assa Abloy

Assa Abloy Yale Pro SL Technical specifications

Assa Abloy

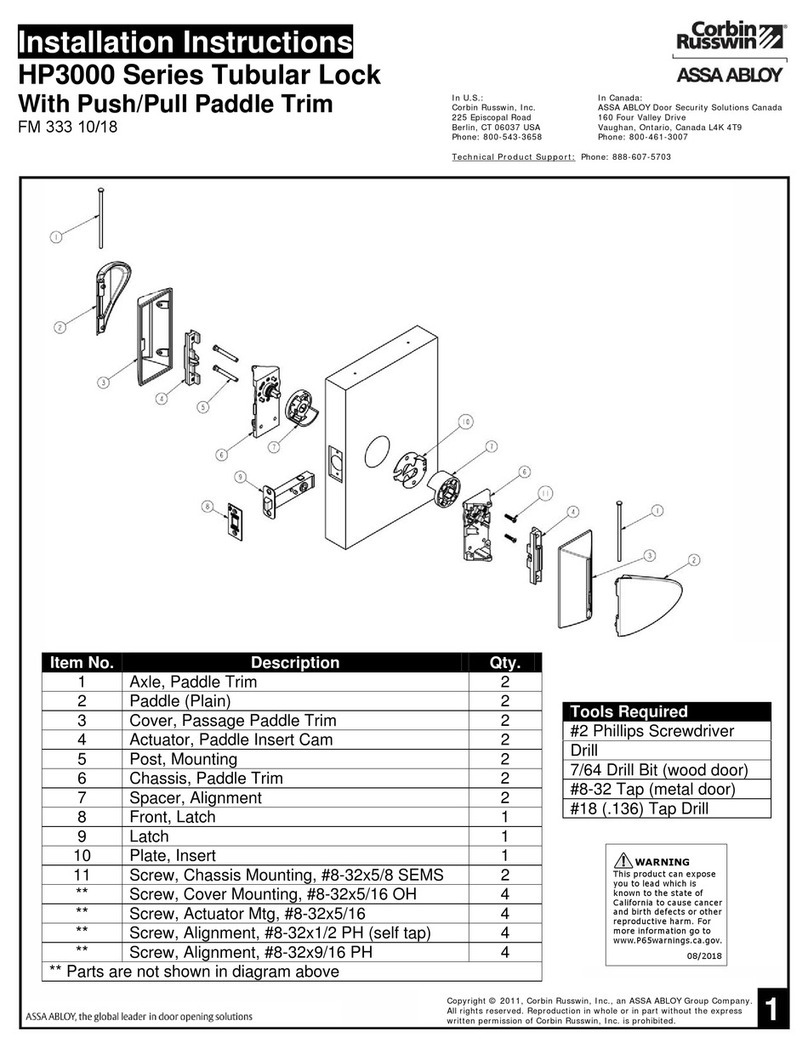

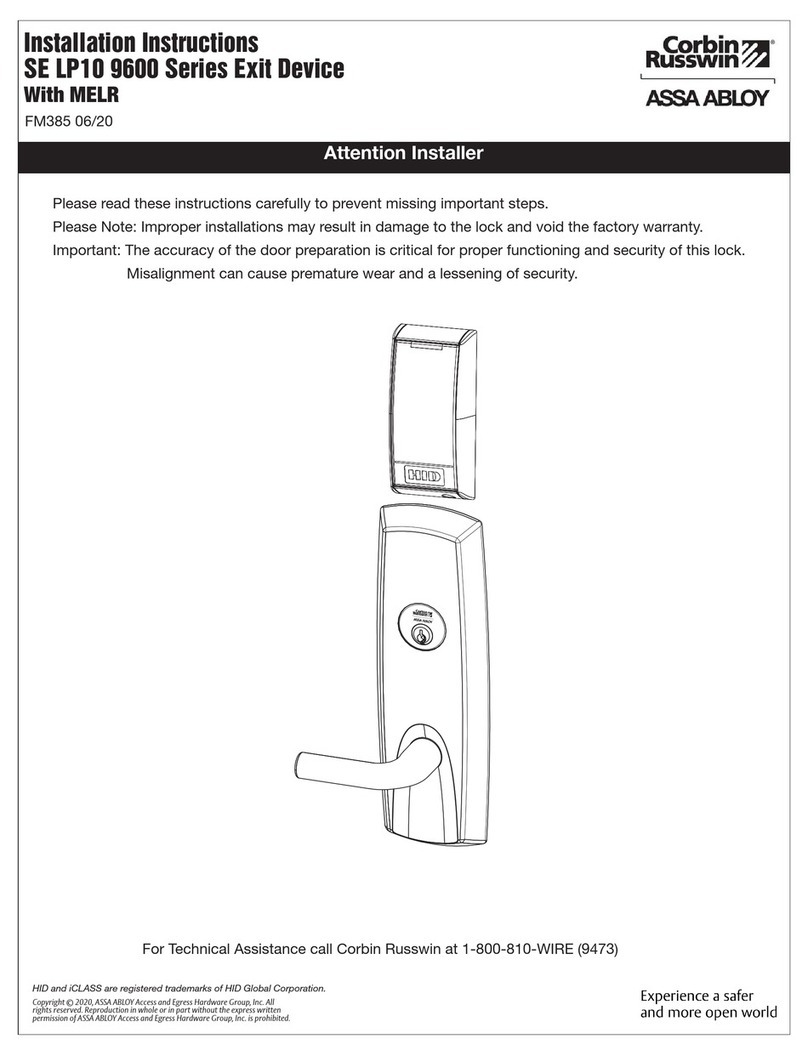

Assa Abloy Corbin Russwin SE LP10 9600 Series User manual

Assa Abloy

Assa Abloy Emtek F20 User manual

Assa Abloy

Assa Abloy v.G1 Sargent User manual

Assa Abloy

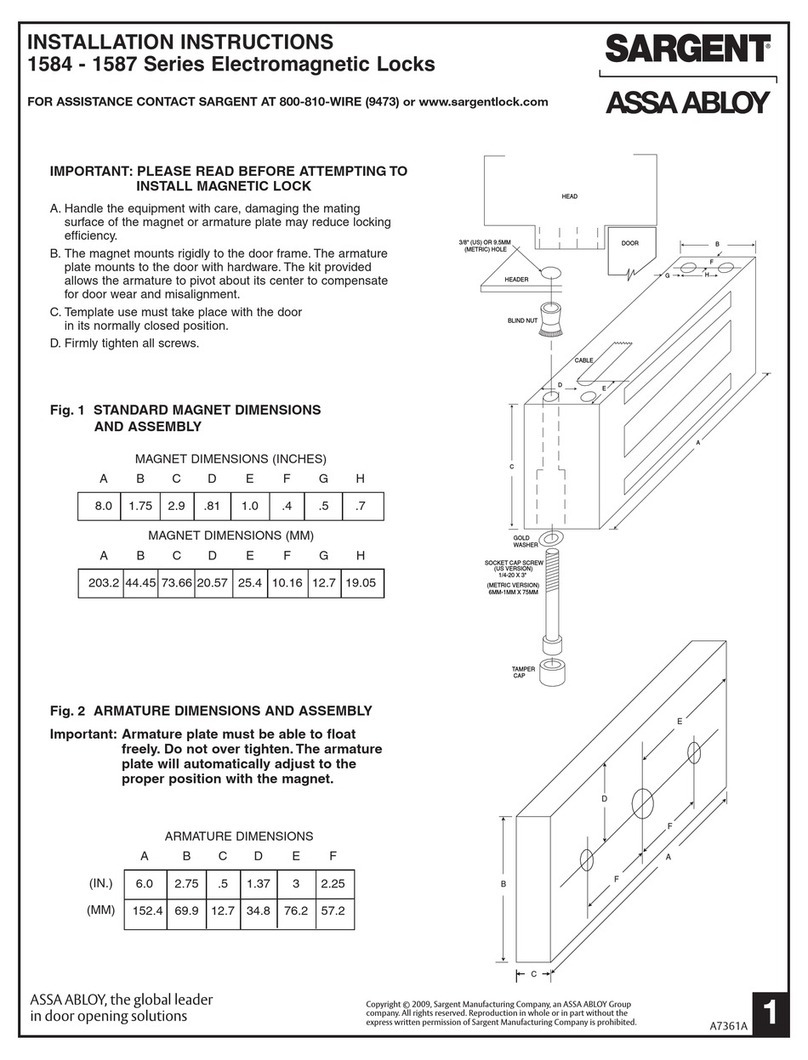

Assa Abloy 1584 Series User manual

Assa Abloy

Assa Abloy Effeff 319 Series User manual

Assa Abloy

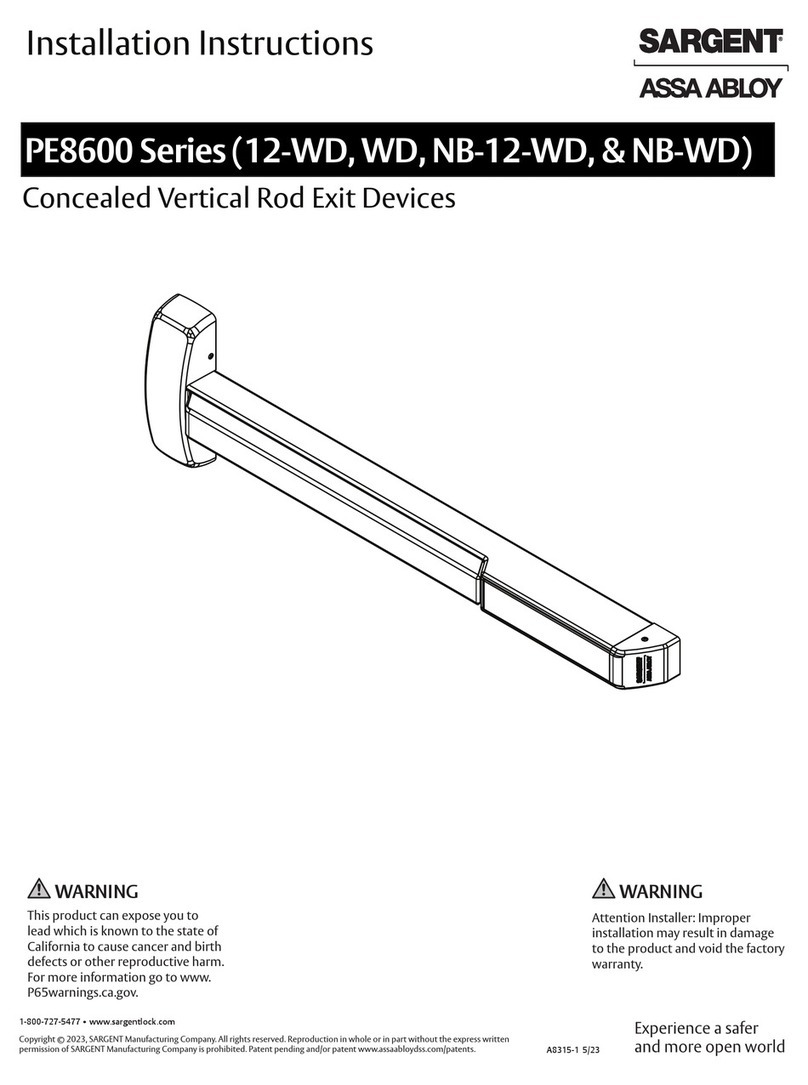

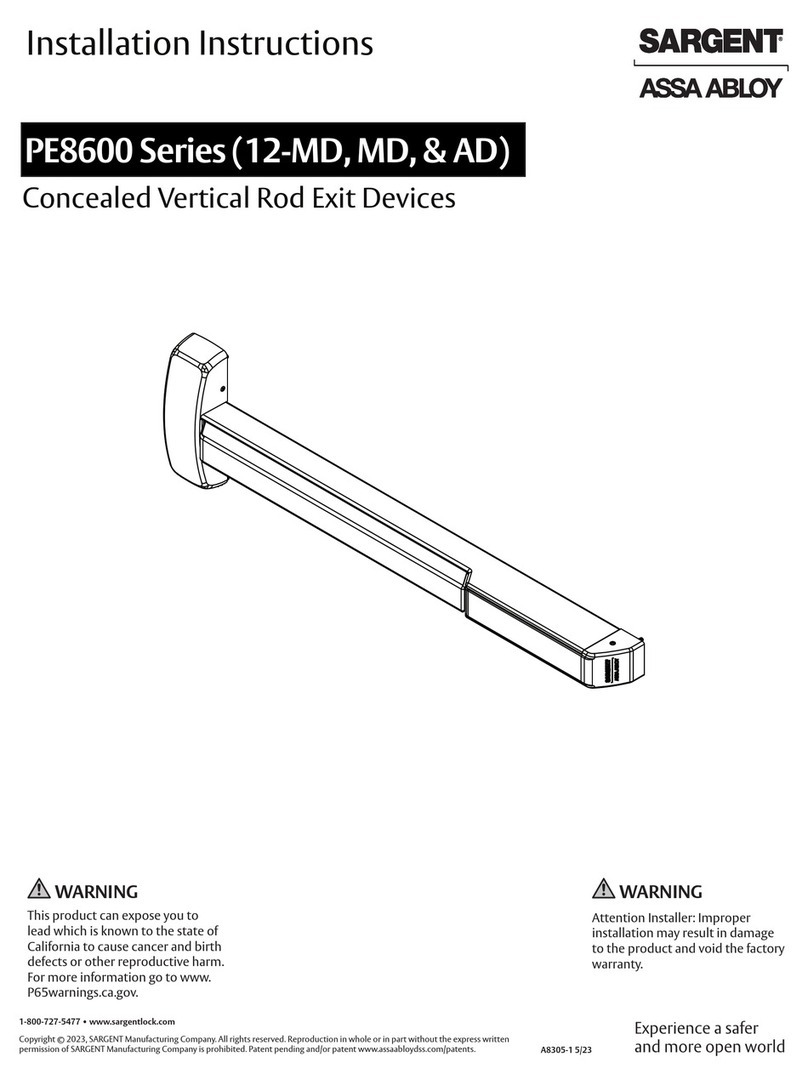

Assa Abloy Sargent AD-PE8600 User manual

Assa Abloy

Assa Abloy OneSystem N1940 User manual

Assa Abloy

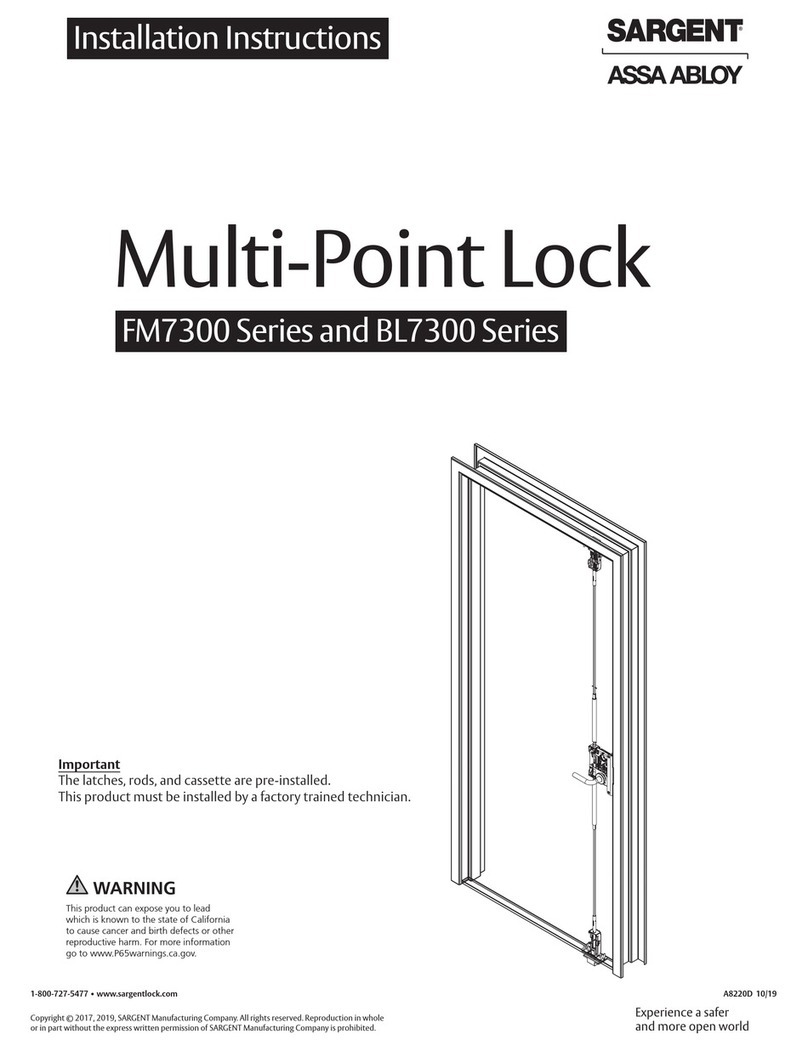

Assa Abloy SARGENT BL7300 Series User manual

Assa Abloy

Assa Abloy Yale AYRD110 User manual

Assa Abloy

Assa Abloy ENTR User manual

Assa Abloy

Assa Abloy Corbin Russwin CLX3300 User manual

Assa Abloy

Assa Abloy effeff ANYKEY User manual

Popular Door Lock manuals by other brands

SCOOP

SCOOP Pullbloc 4.1 FS Panik Assembly instruction

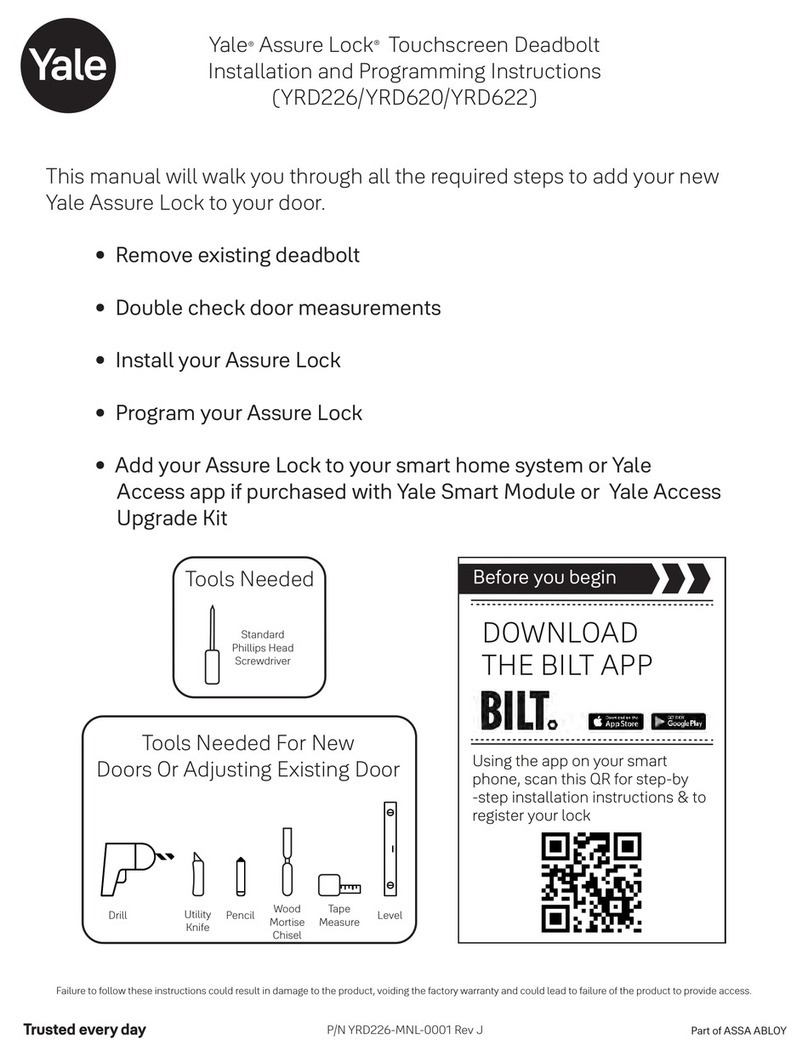

Yale

Yale MORTISE 8800 SERIES installation instructions

Siegenia

Siegenia KFV AS3500 Assembly instructions

Saflok

Saflok Quantum ädesē RFID installation instructions

ArrowVision

ArrowVision Shepherd 210 installation manual

Baldwin

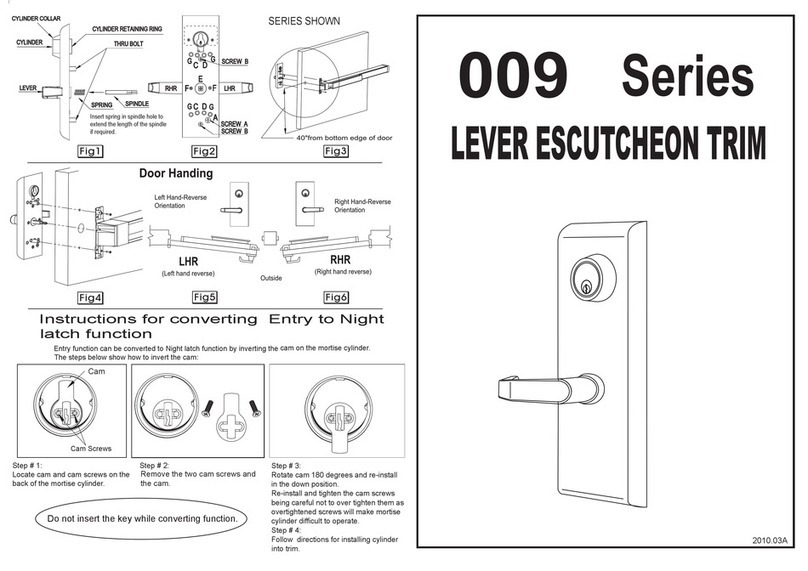

Baldwin 009 Series quick start guide