Quick start - F610

MR-36200C-U Quick start manual ATEQ F610 Page 1/24

Quick start manual

TABLE OF CONTENTS

TABLE OF CONTENTS..................................................................................................1

PREAMBULE..................................................................................................................2

1. DEFINITION OF THE ATEQ F610 ......................................................................................................2

2. MEASUREMENT CHARACTERISTICS..............................................................................................2

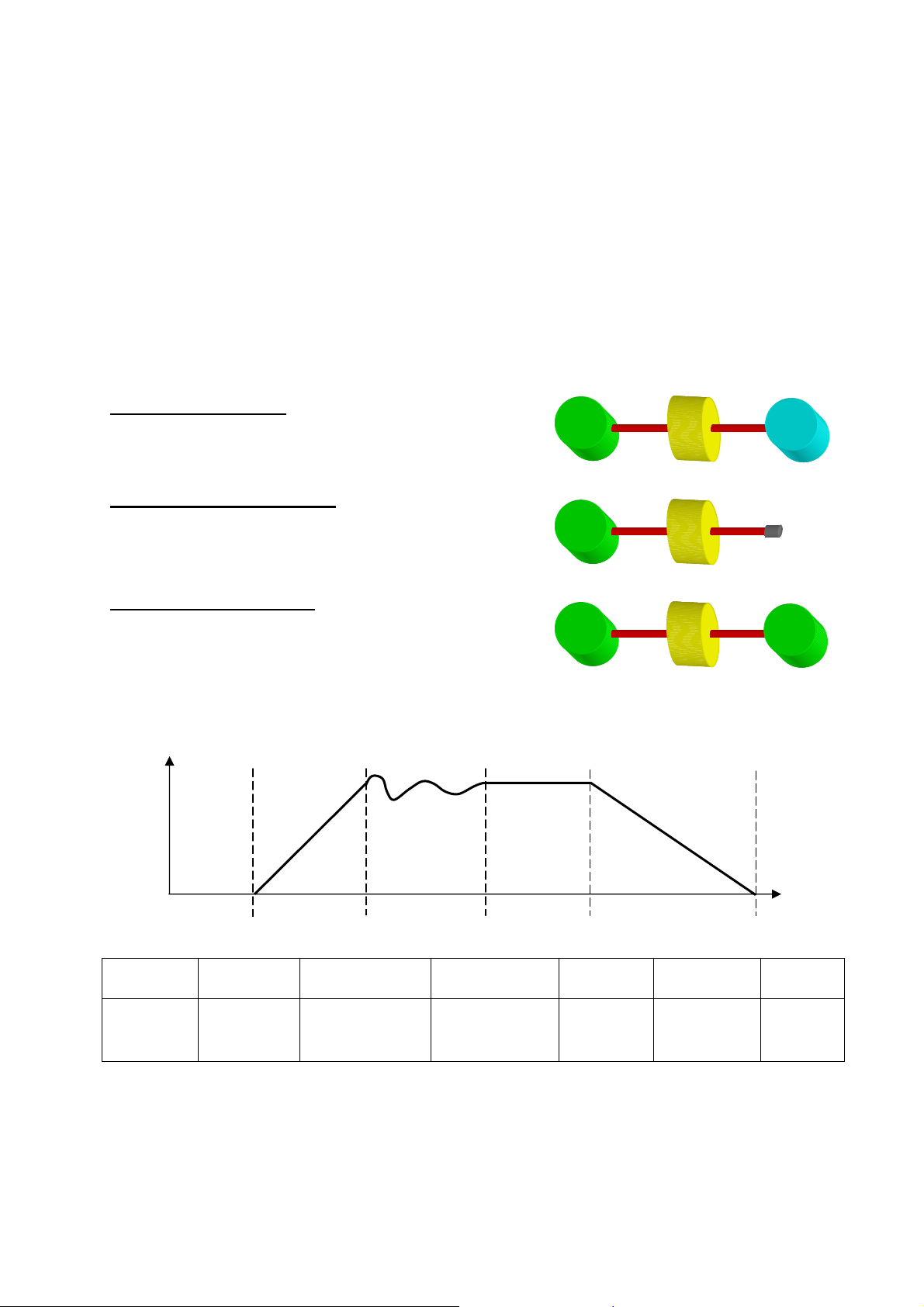

3. THE MAIN TYPES OF MEASUREMENT............................................................................................3

4. THE THREE TYPES OF TEST ............................................................................................................3

5. MEASUREMENT CYCLE ....................................................................................................................3

INSTALLATION ..............................................................................................................4

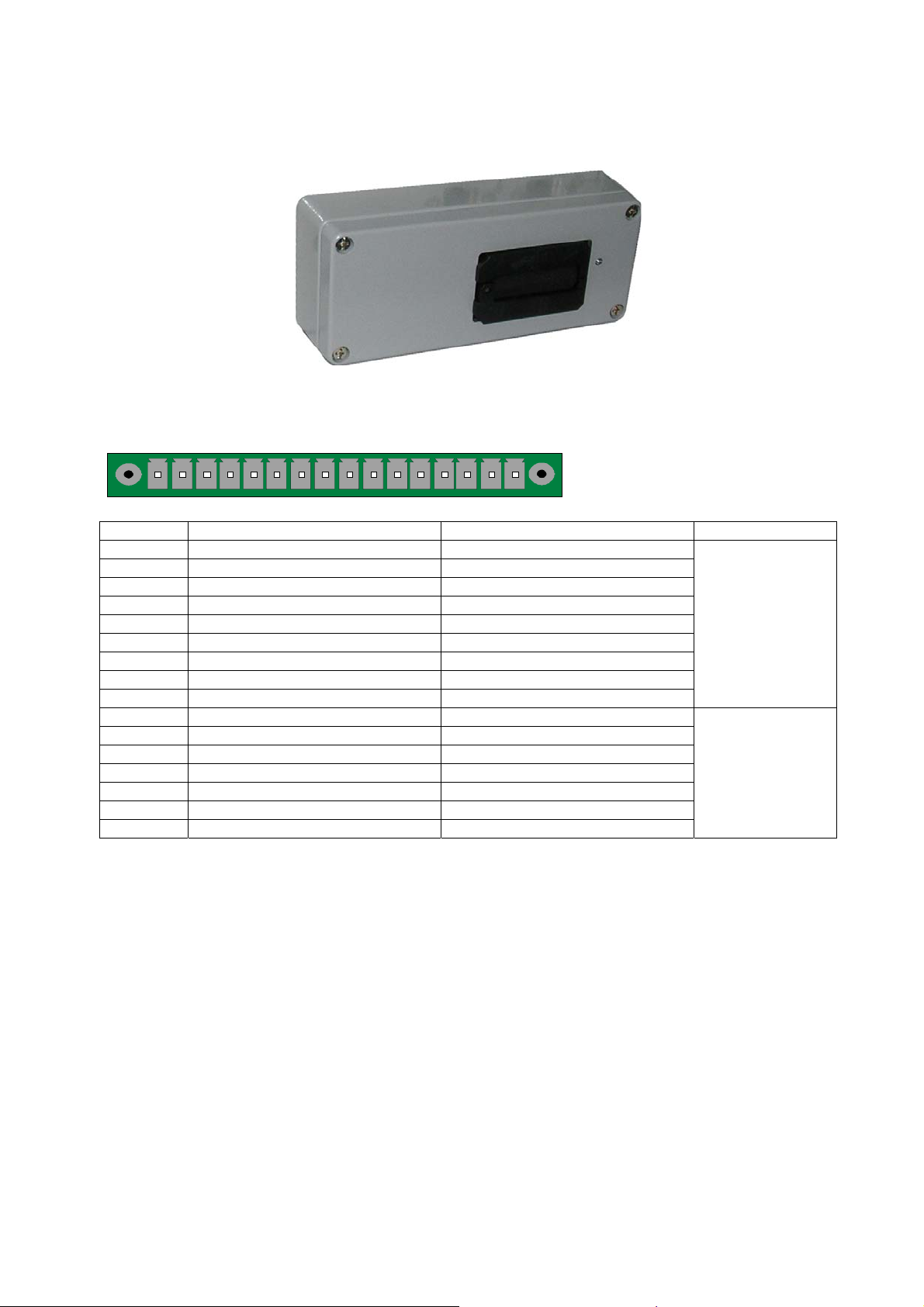

1. APPEARANCE OF THE ATEQ F610..................................................................................................4

2. ELECTRICS CONNECTORS ..............................................................................................................5

3. PNEUMATIC SUPPLY.........................................................................................................................9

4. PNEUMATIC CONNECTORS ...........................................................................................................10

USER INTERFACES.....................................................................................................11

1. CYCLE KEYS ....................................................................................................................................11

2. TOUCHES DE NAVIGATION ............................................................................................................11

STARTING UP AND ADJUSTMENTS..........................................................................13

1. TEST MENU.......................................................................................................................................13

2. MAIN MENU.......................................................................................................................................13

3. LOCK PARAMETERS .......................................................................................................................13

4. PROGRAMS MANAGEMENT...........................................................................................................14

5. PARAMETERS ..................................................................................................................................15

6. START AND STOP MEASUREMENT CYCLE .................................................................................16

7. FUNCTIONS ......................................................................................................................................17

OTHERS MENUS..........................................................................................................18

1. SPECIAL CYCLES ............................................................................................................................18

2. MENU CONFIGURATION .................................................................................................................19

3. SERVICE MENU MAINTENANCE ....................................................................................................20

4. RESULTS MENU ...............................................................................................................................20

5. USB MENU ........................................................................................................................................20

ACCESSORIES AND CHARACTERISTICS.................................................................21

1. ACCESSORIES PROVIDED .............................................................................................................21

2. ACCESSORIES IN OPTION..............................................................................................................21

3. TECHNICAL CHARACTERISTIC OF THE F610 ..............................................................................22

ERRORS AND FAULTS ...............................................................................................23

1. ERROR MESSAGES .........................................................................................................................23

2. IN CASE OF OPERATION DOUBT ..................................................................................................23

INDEX ...........................................................................................................................24

Due to continuing improvements, the information contained in this user manual,

the features and design of this device are subject to be changed without prior

notice.